ASTM D648-18

(Test Method)Standard Test Method for Deflection Temperature of Plastics Under Flexural Load in the Edgewise Position

Standard Test Method for Deflection Temperature of Plastics Under Flexural Load in the Edgewise Position

SIGNIFICANCE AND USE

5.1 This test is particularly suited to control and development work. Data obtained by this test method shall not be used to predict the behavior of plastic materials at elevated temperatures except in applications in which the factors of time, temperature, method of loading, and fiber stress are similar to those specified in this test method. The data are not intended for use in design or predicting endurance at elevated temperatures.

5.2 For many materials, there may be a specification that requires the use of this test method, but with some procedural modifications that take precedence when adhering to the specification. Therefore, it is advisable to refer to that material specification before using this test method. Refer to Table 1 in Classification D4000, which lists the ASTM material standards that currently exist.

SCOPE

1.1 This test method covers the determination of the temperature at which an arbitrary deformation occurs when specimens are subjected to an arbitrary set of testing conditions.

1.2 This test method applies to molded and sheet materials available in thicknesses of 3 mm (1/8 in.) or greater and which are rigid or semirigid at normal temperature.

Note 1: Sheet stock less than 3 mm (0.125 in.) but more than 1 mm (0.040 in.) in thickness may be tested by use of a composite sample having a minimum thickness of 3 mm. The laminae must be of uniform stress distribution. One type of composite specimen has been prepared by cementing the ends of the laminae together and then smoothing the edges with sandpaper. The direction of loading shall be perpendicular to the edges of the individual laminae.

1.3 The values stated in SI units are to be regarded as standard. The values given in parentheses are for information only.

1.4 Some older machines still use mercury-in-glass thermometers. (Warning—Mercury has been designated by many regulatory agencies as a hazardous material that can cause serious medical issues. Mercury, or its vapor, has been demonstrated to be hazardous to health and corrosive to materials. Caution should be taken when handling mercury and mercury containing products. See the applicable product Safety Data Sheet (SDS) for additional information. Users should be aware that selling mercury and/or mercury containing products into your state or country may be prohibited by law.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

Note 2: The text of this standard references notes and footnotes that provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of the standard.

Note 3: This standard and ISO 75-1 and ISO 75-2 address the same subject matter, but differ in technical content, and results shall not be compared between the two test methods.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:D648 −18

Standard Test Method for

Deflection Temperature of Plastics Under Flexural Load in

1

the Edgewise Position

This standard is issued under the fixed designation D648; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

provide explanatory material. These notes and footnotes (excluding those

1. Scope*

in tables and figures) shall not be considered as requirements of the

1.1 This test method covers the determination of the tem-

standard.

perature at which an arbitrary deformation occurs when speci- NOTE 3—This standard and ISO 75-1 and ISO 75-2 address the same

subject matter, but differ in technical content, and results shall not be

mens are subjected to an arbitrary set of testing conditions.

compared between the two test methods.

1.2 This test method applies to molded and sheet materials

1.6 This international standard was developed in accor-

1

available in thicknesses of 3 mm ( ⁄8 in.) or greater and which

dance with internationally recognized principles on standard-

are rigid or semirigid at normal temperature.

ization established in the Decision on Principles for the

NOTE 1—Sheet stock less than 3 mm (0.125 in.) but more than 1 mm

Development of International Standards, Guides and Recom-

(0.040in.)inthicknessmaybetestedbyuseofacompositesamplehaving

mendations issued by the World Trade Organization Technical

a minimum thickness of 3 mm. The laminae must be of uniform stress

Barriers to Trade (TBT) Committee.

distribution. One type of composite specimen has been prepared by

cementing the ends of the laminae together and then smoothing the edges

2. Referenced Documents

with sandpaper. The direction of loading shall be perpendicular to the

edges of the individual laminae. 2

2.1 ASTM Standards:

1.3 The values stated in SI units are to be regarded as

D618 Practice for Conditioning Plastics for Testing

standard. The values given in parentheses are for information

D883 Terminology Relating to Plastics

only.

D4000 Classification System for Specifying Plastic Materi-

als

1.4 Some older machines still use mercury-in-glass ther-

D5947 Test Methods for Physical Dimensions of Solid

mometers. (Warning—Mercury has been designated by many

Plastics Specimens

regulatory agencies as a hazardous material that can cause

E1 Specification for ASTM Liquid-in-Glass Thermometers

serious medical issues. Mercury, or its vapor, has been

E77 Test Method for Inspection and Verification of Ther-

demonstrated to be hazardous to health and corrosive to

mometers

materials. Caution should be taken when handling mercury

E608/E608M Specification for Mineral-Insulated, Metal-

and mercury containing products. See the applicable product

Sheathed Base Metal Thermocouples

Safety Data Sheet (SDS) for additional information. Users

E691 Practice for Conducting an Interlaboratory Study to

should be aware that selling mercury and/or mercury contain-

Determine the Precision of a Test Method

ing products into your state or country may be prohibited by

E1137/E1137M Specification for Industrial Platinum Resis-

law.

tance Thermometers

1.5 This standard does not purport to address all of the

E2251 Specification for Liquid-in-Glass ASTM Thermom-

safety concerns, if any, associated with its use. It is the

eters with Low-Hazard Precision Liquids

responsibility of the user of this standard to establish appro-

3

2.2 ISO Standards:

priate safety, health, and environmental practices and deter-

ISO 75-1 Plastics—Determination of Temperature of De-

mine the applicability of regulatory limitations prior to use.

flection Under Load—Part 1: General Test Method

NOTE 2—The text of this standard references notes and footnotes that

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

1

This test method is under the jurisdiction ofASTM Committee D20 on Plastics contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

and is the direct responsibility of Subcommittee D20.30 on Thermal Properties. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved April 1, 2018. Published April 2018. Originally the ASTM website.

3

approved in 1941. Last previous edition approved in 2016 as D648 - 16. DOI: Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

10.1520/D0648-18. 4th Floor, New York, NY 10036, http://www.ansi.org.

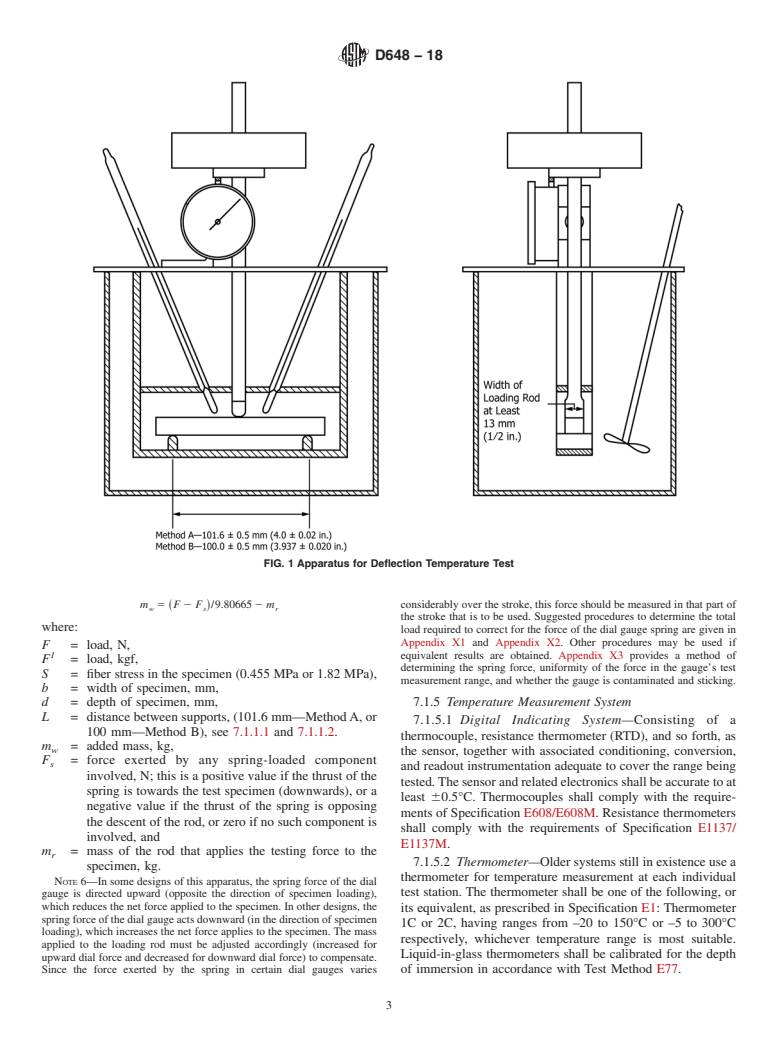

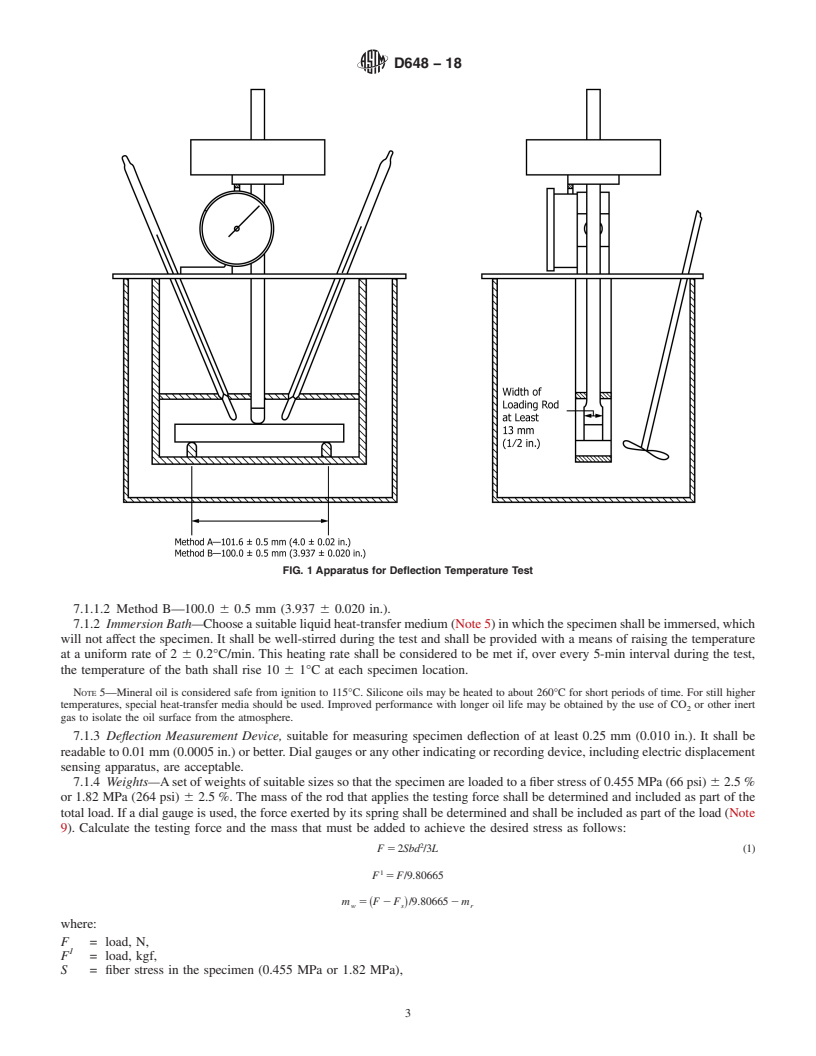

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D648 − 16 D648 − 18

Standard Test Method for

Deflection Temperature of Plastics Under Flexural Load in

1

the Edgewise Position

This standard is issued under the fixed designation D648; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope*

1.1 This test method covers the determination of the temperature at which an arbitrary deformation occurs when specimens are

subjected to an arbitrary set of testing conditions.

1

1.2 This test method applies to molded and sheet materials available in thicknesses of 3 mm ( ⁄8 in.) or greater and which are

rigid or semirigid at normal temperature.

NOTE 1—Sheet stock less than 3 mm (0.125 in.) but more than 1 mm (0.040 in.) in thickness may be tested by use of a composite sample having a

minimum thickness of 3 mm. The laminae must be of uniform stress distribution. One type of composite specimen has been prepared by cementing the

ends of the laminae together and then smoothing the edges with sandpaper. The direction of loading shall be perpendicular to the edges of the individual

laminae.

1.3 The values stated in SI units are to be regarded as standard. The values given in parentheses are for information only.

1.4 Some older machines still use mercury-in-glass thermometers. (Warning—Mercury has been designated by many

regulatory agencies as a hazardous material that can cause serious medical issues. Mercury, or its vapor, has been demonstrated

to be hazardous to health and corrosive to materials. Caution should be taken when handling mercury and mercury containing

products. See the applicable product Safety Data Sheet (SDS) for additional information. Users should be aware that selling

mercury and/or mercury containing products into your state or country may be prohibited by law.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

NOTE 2—The text of this standard references notes and footnotes that provide explanatory material. These notes and footnotes (excluding those in tables

and figures) shall not be considered as requirements of the standard.

NOTE 3—This standard and ISO 75-1 and ISO 75-2 address the same subject matter, but differ in technical content, and results shall not be compared

between the two test methods.

NOTE 2—The text of this standard references notes and footnotes that provide explanatory material. These notes and footnotes (excluding those in tables

and figures) shall not be considered as requirements of the standard.

NOTE 3—This standard and ISO 75-1 and ISO 75-2 address the same subject matter, but differ in technical content, and results shall not be compared

between the two test methods.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D618 Practice for Conditioning Plastics for Testing

D883 Terminology Relating to Plastics

D4000 Classification System for Specifying Plastic Materials

D5947 Test Methods for Physical Dimensions of Solid Plastics Specimens

1

This test method is under the jurisdiction of ASTM Committee D20 on Plastics and is the direct responsibility of Subcommittee D20.30 on Thermal Properties.

Current edition approved April 1, 2016April 1, 2018. Published April 2016April 2018. Originally approved in 1941. Last previous edition approved in 20072016 as

D648 - 07D648 - 16., which was withdrawn January 2016 and reinstated in April 2016. DOI: 10.1520/D0648-16. DOI: 10.1520/D0648-18.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standar

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.