ASTM E1508-12a

(Guide)Standard Guide for Quantitative Analysis by Energy-Dispersive Spectroscopy

Standard Guide for Quantitative Analysis by Energy-Dispersive Spectroscopy

SIGNIFICANCE AND USE

5.1 This guide covers procedures for quantifying the elemental composition of phases in a microstructure. It includes both methods that use standards as well as standardless methods, and it discusses the precision and accuracy that one can expect from the technique. The guide applies to EDS with a solid-state X-ray detector used on an SEM or EPMA.

5.2 EDS is a suitable technique for routine quantitative analysis of elements that are 1) heavier than or equal to sodium in atomic weight, 2) present in tenths of a percent or greater by weight, and 3) occupying a few cubic micrometres, or more, of the specimen. Elements of lower atomic number than sodium can be analyzed with either ultra-thin-window or windowless spectrometers, generally with less precision than is possible for heavier elements. Trace elements, defined as 2 can be analyzed but with lower precision compared with analyses of elements present in greater concentration.

SCOPE

1.1 This guide is intended to assist those using energy-dispersive spectroscopy (EDS) for quantitative analysis of materials with a scanning electron microscope (SEM) or electron probe microanalyzer (EPMA). It is not intended to substitute for a formal course of instruction, but rather to provide a guide to the capabilities and limitations of the technique and to its use. For a more detailed treatment of the subject, see Goldstein, et al.(1) This guide does not cover EDS with a transmission electron microscope (TEM).

1.2 Units—The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E1508 − 12a

Standard Guide for

1

Quantitative Analysis by Energy-Dispersive Spectroscopy

This standard is issued under the fixed designation E1508; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.2 Definitions of Terms Specific to This Standard:

3.2.1 accelerating voltage—the high voltage between the

1.1 This guide is intended to assist those using energy-

cathode and the anode in the electron gun of an electron beam

dispersive spectroscopy (EDS) for quantitative analysis of

instrument, such as an SEM or EPMA.

materials with a scanning electron microscope (SEM) or

electron probe microanalyzer (EPMA). It is not intended to 3.2.2 beam current—the current of the electron beam mea-

substitute for a formal course of instruction, but rather to sured with a Faraday cup positioned near the specimen.

provide a guide to the capabilities and limitations of the

3.2.3 Bremsstrahlung—background X rays produced by in-

technique and to its use. For a more detailed treatment of the

elastic scattering (loss of energy) of the primary electron beam

subject,seeGoldstein,etal. (1)ThisguidedoesnotcoverEDS

in the specimen. It covers a range of energies up to the energy

with a transmission electron microscope (TEM).

of the electron beam.

1.2 Units—The values stated in SI units are to be regarded

3.2.4 critical excitation voltage—the minimum voltage re-

as standard. No other units of measurement are included in this

quired to ionize an atom by ejecting an electron from a specific

standard.

electron shell.

1.3 This standard does not purport to address all of the

3.2.5 dead time—the time during which the system will not

safety concerns, if any, associated with its use. It is the

process incoming X rays (real time less live time).

responsibility of the user of this standard to establish appro-

3.2.6 k-ratio—the ratio of background-subtracted X-ray in-

priate safety and health practices and determine the applica-

tensity in the unknown specimen to that of the standard.

bility of regulatory limitations prior to use.

3.2.7 live time—the time that the system is available to

detect incoming X rays.

2. Referenced Documents

2

3.2.8 overvoltage—the ratio of accelerating voltage to the

2.1 ASTM Standards:

critical excitation voltage for a particular X-ray line.

E3 Guide for Preparation of Metallographic Specimens

E7 Terminology Relating to Metallography

3.2.9 SDD (silicon drift detector)—An x-ray detector char-

E673 Terminology Relating to SurfaceAnalysis (Withdrawn

acterized by a pattern in the biasing electrodes which induces

3

2012)

generated electrons to move laterally (drift) to a small-area

E691 Practice for Conducting an Interlaboratory Study to

anode for collection, resulting in greatly reduced capacitance

Determine the Precision of a Test Method

which to a first approximation does not depend on the active

area, in contrast to conventional detectors using flat-plate

3. Terminology

electrodes. (2)

3.1 Definitions—For definitions of terms used in this guide, 3.2.10 shaping time—a measure of the time it takes the

see Terminologies E7 and E673.

amplifier to integrate the incoming charge; it depends on the

time constant of the circuitry.

3.2.11 spectrum—the energy range of electromagnetic ra-

1

ThisguideisunderthejurisdictionofASTMCommitteeE04onMetallography

diation produced by the method and, when graphically

and is the direct responsibility of Subcommittee E04.11 on X-Ray and Electron

displayed, is the relationship of X-ray counts detected to X-ray

Metallography.

energy.

Current edition approved Dec. 1, 2012. Published February 2013. Originally

approved in 1993. Last previous edition approved in 2012 as E1508 – 12. DOI:

10.1520/E1508-12A.

4. Summary of Practice

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

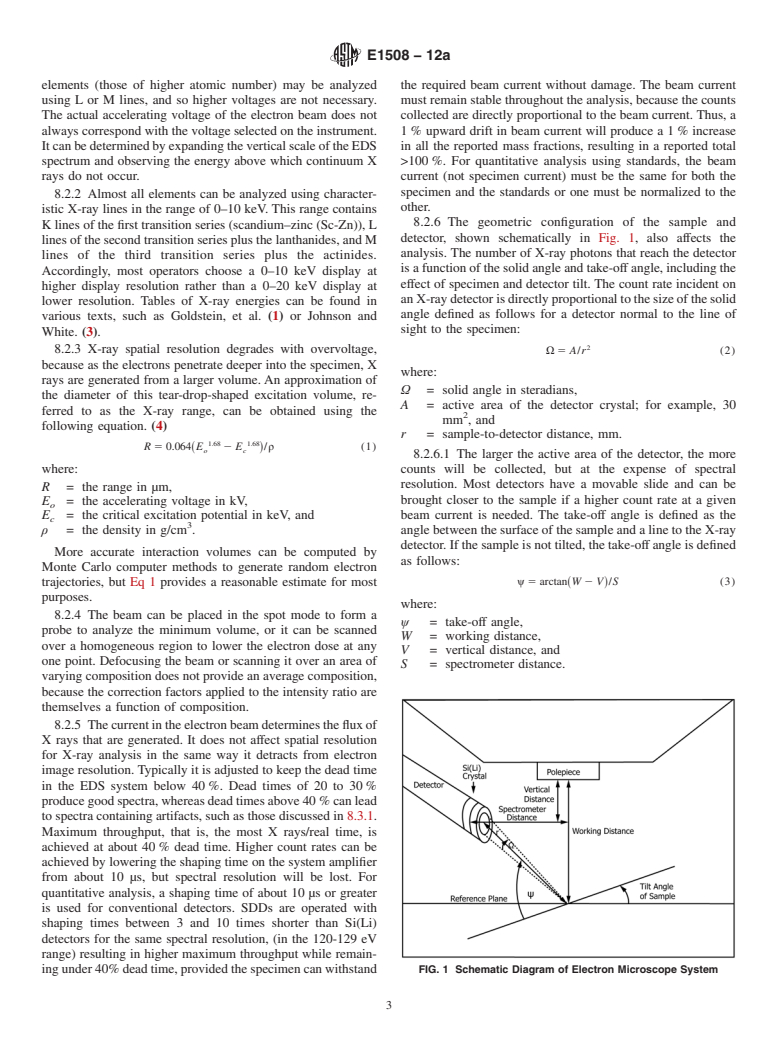

4.1 As high-energy electrons produced with an SEM or

Standards volume information, refer to the standard’s Document Summary page on

EPMAinteract with the atoms within the top few micrometres

the ASTM website.

3

of a specimen surface, X rays are generated with an energy

The last approved version of this historical standard is referenced on

www.astm.org. characteristic of the atom that produced them. The intensity of

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E1508 − 12a

such X rays is proportional to the mass fraction of that element fracture surfaces and particles.Although data can

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: E1508 − 12 E1508 − 12a

Standard Guide for

1

Quantitative Analysis by Energy-Dispersive Spectroscopy

This standard is issued under the fixed designation E1508; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This guide is intended to assist those using energy-dispersive spectroscopy (EDS) for quantitative analysis of materials with

a scanning electron microscope (SEM) or electron probe microanalyzer (EPMA). It is not intended to substitute for a formal course

of instruction, but rather to provide a guide to the capabilities and limitations of the technique and to its use. For a more detailed

treatment of the subject, see Goldstein, et al. (1) This guide does not cover EDS with a transmission electron microscope (TEM).

1.2 Units—The values stated in SI units are to be regarded as standard. No other units of measurement are included in this

standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

E3 Guide for Preparation of Metallographic Specimens

E7 Terminology Relating to Metallography

3

E673 Terminology Relating to Surface Analysis (Withdrawn 2012)

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

3. Terminology

3.1 Definitions—For definitions of terms used in this guide, see Terminologies E7 and E673.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 accelerating voltage—the high voltage between the cathode and the anode in the electron gun of an electron beam

instrument, such as an SEM or EPMA.

3.2.2 beam current—the current of the electron beam measured with a Faraday cup positioned near the specimen.

3.2.3 Bremsstrahlung—background X rays produced by inelastic scattering (loss of energy) of the primary electron beam in the

specimen. It covers a range of energies up to the energy of the electron beam.

3.2.4 critical excitation voltage—the minimum voltage required to ionize an atom by ejecting an electron from a specific

electron shell.

3.2.5 dead time—the time during which the system will not process incoming X rays (real time less live time).

3.2.6 k-ratio—the ratio of background-subtracted X-ray intensity in the unknown specimen to that of the standard.

3.2.7 live time—the time that the system is available to detect incoming X rays.

3.2.8 overvoltage—the ratio of accelerating voltage to the critical excitation voltage for a particular X-ray line.

3.2.9 SDD (silicon drift detector)—An x-ray detector characterized by a pattern in the biasing electrodes which induces

generated electrons to move laterally (drift) to a small-area anode for collection, resulting in greatly reduced capacitance which

to a first approximation does not depend on the active area, in contrast to conventional detectors using flat-plate electrodes. (2)

1

This guide is under the jurisdiction of ASTM Committee E04 on Metallography and is the direct responsibility of Subcommittee E04.11 on X-Ray and Electron

Metallography.

Current edition approved May 1, 2012Dec. 1, 2012. Published November 2012February 2013. Originally approved in 1993. Last previous edition approved in 20082012

as E1508 – 98E1508 – 12.(2008). DOI: 10.1520/E1508-12.10.1520/E1508-12A.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

The last approved version of this historical standard is referenced on www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E1508 − 12a

3.2.10 shaping time—a measure of the time it takes the amplifier to integrate the incoming charge; it depends on the time

constant of the circuitry.

3.2.11 spectrum—the energy range of electromagnetic radiation produced by the method and, when graphically displayed, is the

relationship of X-ray counts detected to X-ray energy.

4. Summary of P

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.