ASTM C1895-20

(Test Method)Standard Test Method for Determination of Mohs Scratch Hardness

Standard Test Method for Determination of Mohs Scratch Hardness

SIGNIFICANCE AND USE

2.1 Mohs scratch hardness is a useful tool for determining a ceramic tile’s resistance to scratching. The resistance to scratching is determined based on a visual observation of the ceramic tile surface after an attempt to scratch the surface using a pick of known hardness.

SCOPE

1.1 This test method covers the procedures to determine the Mohs scratch hardness of ceramic tile, glass tile, and other hard surfaces.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: C1895 − 20

Standard Test Method for

1

Determination of Mohs Scratch Hardness

This standard is issued under the fixed designation C1895; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 0.2 kg) where the hardness point contacts the test specimen

(see Fig. 2). This may be accomplished by adding an auxiliary

1.1 This test method covers the procedures to determine the

weight to the top of the sled. The sled shall be equipped with

Mohsscratchhardnessofceramictile,glasstile,andotherhard

a handle to aid in pulling the hardness pick across the test

surfaces.

specimen.

1.2 The values stated in inch-pound units are to be regarded

NOTE 1—The total weight necessary to apply the required force will

as standard. The values given in parentheses are mathematical

vary based on the overall weight of the sled and location of the weight on

conversions to SI units that are provided for information only

the sled, if an auxiliary weight is used.

and are not considered standard.

3.3 Jeweler’s Loupe or Other Suitable Magnification De-

1.3 This standard does not purport to address all of the

vice.

safety concerns, if any, associated with its use. It is the

3.4 Sharpening Stone or Whetstone—A surface constructed

responsibility of the user of this standard to establish appro-

of suitable material to sharpen the hardness picks. Diamond

priate safety, health, and environmental practices and deter-

coated sharpening stones and sharpening stones constructed of

mine the applicability of regulatory limitations prior to use.

aluminum oxide or corundum have been known to work.

1.4 This international standard was developed in accor-

dance with internationally recognized principles on standard-

4. Reagents and Materials

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom-

4.1 Optional staining solution, such as methylene blue

mendations issued by the World Trade Organization Technical

solution, 1%.

Barriers to Trade (TBT) Committee.

5. Test Specimens

2. Significance and Use

5.1 Number of Test Specimens—The test sample shall con-

2.1 Mohs scratch hardness is a useful tool for determining a

sist of at least one tile.

ceramic tile’s resistance to scratching. The resistance to

5.2 Size of Test Specimens—Test specimens up to6×6in.

scratching is determined based on a visual observation of the

(15 × 15 cm) shall remain uncut for testing. Specimens with

ceramictilesurfaceafteranattempttoscratchthesurfaceusing

edges greater than 6in. may be reduced in size to no smaller

a pick of known hardness.

than 6 in. (15 cm) for ease of handling.

3. Apparatus

6. Preparation of Apparatus

2

3.1 Hardness Picks:

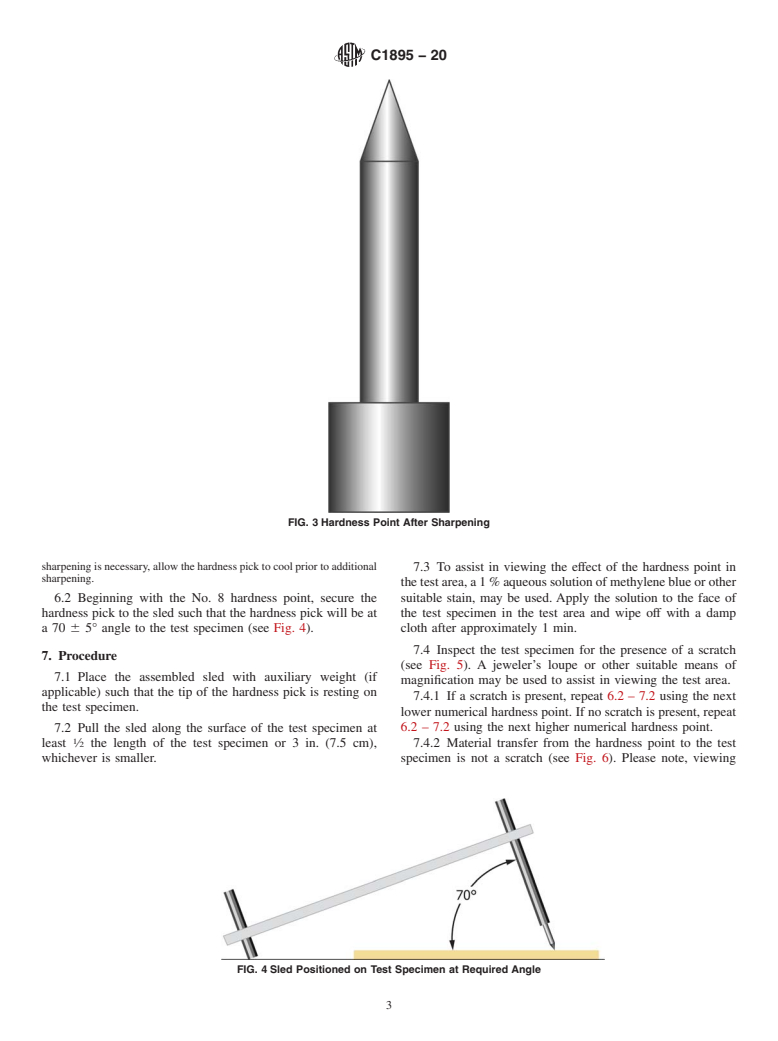

6.1 Sharpening Hardness Points—The hardness points may

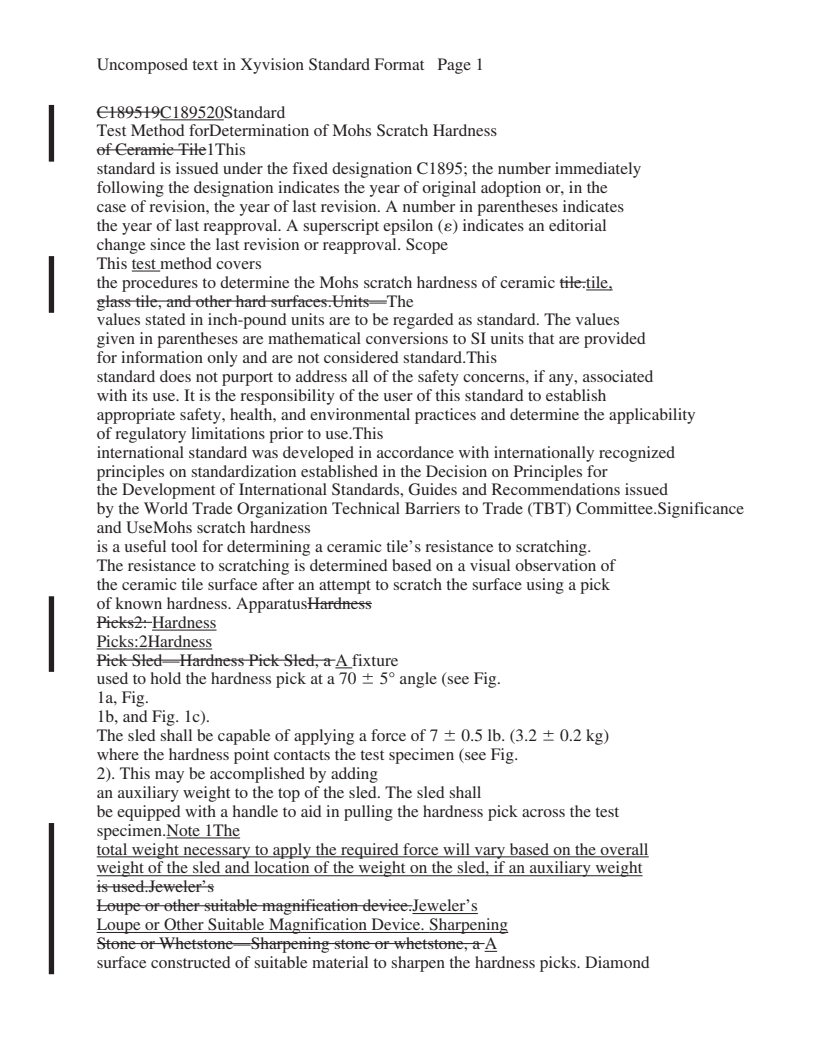

3.2 Hardness Pick Sled—Afixtureusedtoholdthehardness

wear with use. Prior to testing, inspect the point of the pick

pick at a 70 6 5° angle (see Fig. 1a, Fig. 1b, and Fig. 1c). The

under magnification to assure that a sharp point exists with an

sled shall be capable of applying a force of 7 6 0.5 lb. (3.2 6

even taper (see Fig. 3). Sharpening of the hardness points may

be necessary to remove any flat spots or imperfections.

6.1.1 To sharpen the hardness point, remove the hardness

1

ThistestmethodisunderthejurisdictionofASTMCommitteeC21onCeramic

Whitewares and Related Products and is the direct responsibility of Subcommittee point from the hardness pick and place it into the chuck of an

C21.06 on Ceramic Tile.

electric drill.

Current edition approved April 1, 2020. Published April 2020. Originally

6.1.2 Hold the hardness point against a sharpening stone at

approved in 2019. Last previous edition approved in 2019 as C1895–19. DOI:

approximately a 20° angle to the sharpening stone and use the

10.1520/C1895-20.

2

The sole source of supply of the apparatus known to the committee at this time

electric drill to rotate the hardness point (see Note 2).

is Mineralab, LLC, 2860 W. Live Oak Drive, Prescott,AZ 86305. If you are aware

NOTE 2—Excessive heat caused by friction may change the hardness of

of alternative suppliers, please provide this information to ASTM International

Headquarters.Your comments will receive careful consideration at a meeting of the the pick.To prevent excessive heating, keep the sharpening stone wet and

1

responsible technical committee, which you may attend. do not attempt to sharpen for intervals greater than 10s. If additional

Copyright © ASTM Interna

...

Uncomposed text in Xyvision Standard Format Page 1

C189519C189520Standard

Test Method forDetermination of Mohs Scratch Hardness

of Ceramic Tile1This

standard is issued under the fixed designation C1895; the number immediately

following the designation indicates the year of original adoption or, in the

case of revision, the year of last revision. A number in parentheses indicates

the year of last reapproval. A superscript epsilon (´) indicates an editorial

change since the last revision or reapproval. Scope

This test method covers

the procedures to determine the Mohs scratch hardness of ceramic tile.tile,

glass tile, and other hard surfaces.Units—The

values stated in inch-pound units are to be regarded as standard. The values

given in parentheses are mathematical conversions to SI units that are provided

for information only and are not considered standard.This

standard does not purport to address all of the safety concerns, if any, associated

with its use. It is the responsibility of the user of this standard to establish

appropriate safety, health, and environmental practices and determine the applicability

of regulatory limitations prior to use.This

international standard was developed in accordance with internationally recognized

principles on standardization established in the Decision on Principles for

the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.Significance

and UseMohs scratch hardness

is a useful tool for determining a ceramic tile’s resistance to scratching.

The resistance to scratching is determined based on a visual observation of

the ceramic tile surface after an attempt to scratch the surface using a pick

of known hardness. ApparatusHardness

Picks2: Hardness

Picks:2Hardness

Pick Sled—Hardness Pick Sled, a A fixture

used to hold the hardness pick at a 70 6 5° angle (see Fig.

1a, Fig.

1b, and Fig. 1c).

The sled shall be capable of applying a force of 7 6 0.5 lb. (3.2 6 0.2 kg)

where the hardness point contacts the test specimen (see Fig.

2). This may be accomplished by adding

an auxiliary weight to the top of the sled. The sled shall

be equipped with a handle to aid in pulling the hardness pick across the test

specimen.Note 1The

total weight necessary to apply the required force will vary based on the overall

weight of the sled and location of the weight on the sled, if an auxiliary weight

is used.Jeweler’s

Loupe or other suitable magnification device.Jeweler’s

Loupe or Other Suitable Magnification Device. Sharpening

Stone or Whetstone—Sharpening stone or whetstone, a A

surface constructed of suitable material to sharpen the hardness picks. Diamond

---------------------- Page: 1 ----------------------

Uncomposed text in Xyvision Standard Format Page 2

co

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.