ASTM D3636-06

(Practice)Standard Practice for Sampling and Judging Quality of Solid Electrical Insulating Materials

Standard Practice for Sampling and Judging Quality of Solid Electrical Insulating Materials

ABSTRACT

This practice covers procedures for obtaining data on the quality of solid electrical insulating materials and for judging whether the materials meet the requirements specified. This practice, however, is not intended to define internal quality control procedures of the producer; rather, it is designed to determine the acceptability of all, or some portion, of a quantity of electrical insulating materials available for inspection by the user of the material. In addition, this practice is intended for use in conjunction with existing material specifications including property characteristic limits, acceptable quality level, standard test methods, and sampling instructions. Data shall be obtained by taking lot samples randomly. Sampling plans are available in single, double, and multiple types. Acceptable quality levels for each critical, major, and minor property as well as inspection levels shall conform to the requirements specified. Acceptance of lot quality shall be determined based on the comparison of test results and other information obtained using the sampling plans with the requirements set forth in the material specification (nonconformity) and on whether the lot meets the requirements specified.

SCOPE

1.1 This practice covers procedures for obtaining data pertaining to the quality of a lot of electrical insulating material and for making a judgement whether the lot meets the requirements of a material specification.

1.2 This practice is not intended to define a producer's internal quality control procedures but is designed to determine the acceptability of all, or some portion, of a quantity of electrical insulating material that is available for inspection by the user of the material.

1.3 This practice is intended to be used in conjunction with an existing material specification that specifies property characteristic limits, acceptable quality level (AQL), standard test methods, and specific sampling instructions.

1.4 In the absence of a specification as described in , use this practice as a guide, after establishment of agreed-upon property characteristics, limits, AQL, standard test methods, and specific sampling instructions.

1.5 It is intended that this be a practice for inspection by attributes.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation:D3636–06

Standard Practice for

Sampling and Judging Quality of Solid Electrical Insulating

1

Materials

This standard is issued under the fixed designation D3636; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

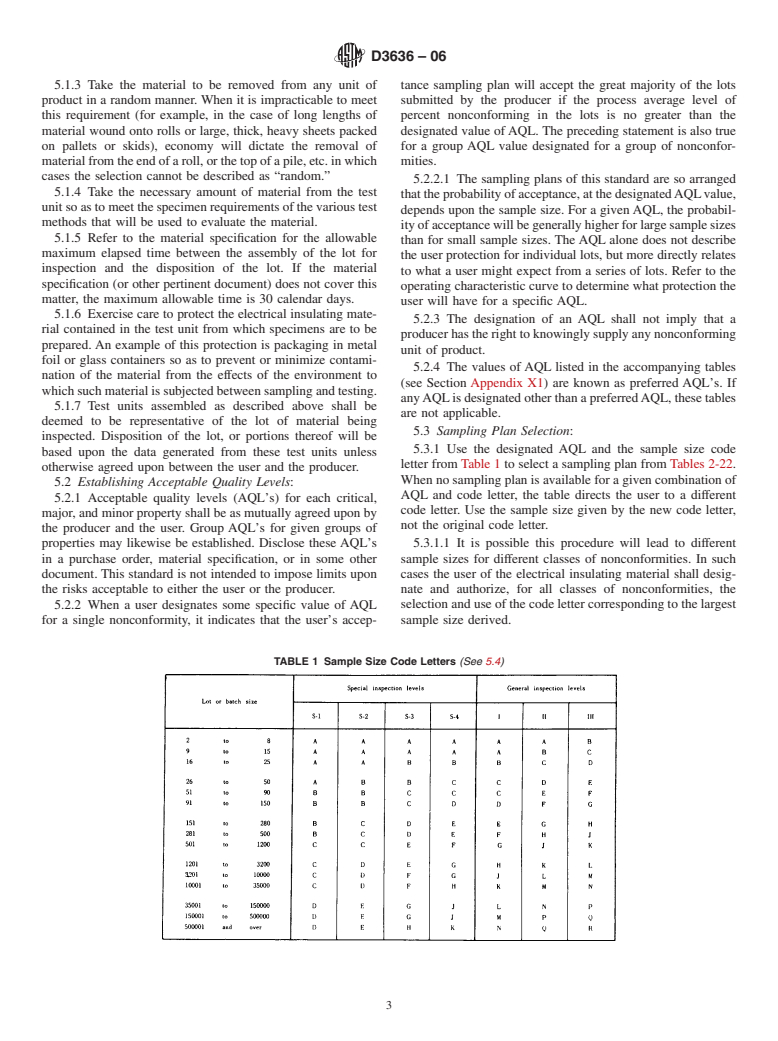

1. Scope* 2.3 Other Document:

4

ANSI/ASQC A2 -1987

1.1 This practice covers procedures for obtaining data

pertainingtothequalityofalotofelectricalinsulatingmaterial

3. Terminology

and for making a judgement whether the lot meets the

3.1 Definitions:

requirements of a material specification.

3.1.1 acceptance number, n—themaximumallowablenum-

1.2 This practice is not intended to define a producer’s

ber of nonconformities for a given AQL and sample size

internalqualitycontrolproceduresbutisdesignedtodetermine

(lot-sample size).

the acceptability of all, or some portion, of a quantity of

3.1.2 acceptable quality level (AQL), n— the maximum

electrical insulating material that is available for inspection by

percent nonconforming which, for purposes of sampling in-

the user of the material.

spection, is considered satisfactory as a process average.

1.3 This practice is intended to be used in conjunction with

3.1.3 critical property, n—aquantitativelymeasurablechar-

an existing material specification that specifies property char-

acteristic which is absolutely necessary to be met if a material

acteristic limits, acceptable quality level (AQL), standard test

or product is to provide satisfactory performance for the

methods, and specific sampling instructions.

intended use.

1.4 In the absence of a specification as described in 1.3, use

3.1.3.1 Discussion—In some situations, specification re-

this practice as a guide, after establishment of agreed-upon

quirements coincide with customer usage requirements. In

property characteristics, limits, AQL, standard test methods,

other situations, they may not coincide, being either more or

and specific sampling instructions.

less stringent. More stringent sampling (for example, smaller

1.5 It is intended that this be a practice for inspection by

AQLvalues)isusuallyusedformeasurementofcharacteristics

attributes.

which are considered critical. The selection of sampling plans

1.6 This standard does not purport to address all of the

is independent of whether the term defect or nonconformity is

safety concerns, if any, associated with its use. It is the

appropriate.

responsibility of the user of this standard to establish appro-

3.1.4 defect, n—a departure of a quality characteristic from

priate safety and health practices and determine the applica-

its intended level, or state, that occurs with a severity sufficient

bility of regulatory limitations prior to use.

tocauseanassociatedproductorservicenottosatisfyintended

2. Referenced Documents normal, or reasonably foreseeable, usage requirements.

2 3.1.4.1 Discussion—The terms defect and nonconformity

2.1 ASTM Standards:

and their derivatives are used somewhat interchangeably in the

E300 Practice for Sampling Industrial Chemicals

historical and current literature. Nonconformity objectively

2.2 Military Standard:

describesthecomparisonoftestresultstospecificationrequire-

MIL-STD-105D Sampling Procedures and Tables for In-

3 ments,whiletheterm defecthasaconnotationofpredictingthe

spection by Attributes

failure of a product or service to perform its intended function

in use. Since this latter connotation is often unintended, the

1

This practice is under the jurisdiction of ASTM Committee D09 on Electrical term nonconformity is preferred in full consensus standards.

and Electronic Insulating Materials and is the direct responsibility of Subcommittee

The selection of any sample plan is independent of whether the

D09.94 on Editorial.

term defect or nonconformity is appropriate.

Current edition approved June 1, 2006. Published August 2006. Originally

approved in 1977. Last previous edition approved in 2000 as D3636 – 00. DOI:

The term defect may be appropriate for specifications mutually

10.1520/D3636-06.

agreed upon by a producer and a user where specific use conditions are

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

clearly understood. Even in these cases however, use the term defect

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

3 4

AvailablefromU.S.GovernmentPrintingOfficeSuperintendentofDocuments, Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

732 N. Capitol St., NW, Mail Stop: SDE, Washington, DC 20401. 4th Fl

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.