ASTM E1324-00

(Guide)Standard Guide for Measuring Some Electronic Characteristics of Ultrasonic Examination Instruments

Standard Guide for Measuring Some Electronic Characteristics of Ultrasonic Examination Instruments

SCOPE

1.1 This guide describes procedures for electronically measuring the following performance-related characteristics of some sections of ultrasonic instruments:

1.1.1 Power Supply Section: line regulation, battery discharge time, and battery charge time.

1.1.2 Pulser Section: pulse shape, pulse amplitude, pulse rise time, pulse length, and pulse frequency spectrum.

1.1.3 Receiver Section: vertical linearity, frequency response, noise and sensitivity, and dB controls.

1.1.4 Time Base Section: horizontal linearity, and clock (pulse repetition rate).

1.1.5 Gate/Alarm Section: delay and width, resolution, alarm level, gain uniformity, analog output, and back echo gate.

1.2 This guide complements Practice E317, and is not intended for evaluating the performance characteristics of ultrasonic examination instruments on the inspection/production line. Note 1-No access to internal circuity is required.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E1324–00

Standard Guide for

Measuring Some Electronic Characteristics of Ultrasonic

Examination Instruments

This standard is issued under the fixed designation E 1324; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

NOTE 1—No access to internal circuity is required.

1. Scope

1.1 This guide describes procedures for electronically mea-

2. Referenced Documents

suring the following performance-related characteristics of

2.1 ASTM Standards:

some sections of ultrasonic instruments:

E 317 Practice for Evaluating Performance Characteristics

1.1.1 Power Supply Section:

of Ultrasonic Pulse-EchoTesting SystemsWithout the Use

line regulation,

of Electronic Measurement Instruments

battery discharge time, and

E 1316 Terminology for Nondestructive Examinations

battery charge time.

2.2 Military Standard:

1.1.2 Pulser Section:

MIL-STD-45662A Calibration System Requirements

2.3 Other Standard:

pulse shape,

IEEE Std. 100, IEEE Standard Dictionary of Electrical and

pulse amplitude,

Electronic Terms

pulse rise time, pulse length, and

pulse frequency spectrum.

3. Summary of Guide

1.1.3 Receiver Section:

3.1 The electronic performance of each section is measured

by identifying that portion of the electrical circuit of the

vertical linearity,

instrument which comprises the section, applying the recom-

frequency response,

mended stimulus or load, or both, and performing the required

noise and sensitivity, and

measurements using commercially available electronic test

dB controls.

equipment. These data are then summarized in tabular or

1.1.4 Time Base Section:

graphical form as performance-related values which can be

comparedwithcorrespondingvaluesofotherultrasonicexami-

horizontal linearity, and

nation instruments or of values for the same instrument

clock (pulse repetition rate).

obtained earlier (see Section 12 for a suggested reporting

1.1.5 Gate/Alarm Section:

format).

3.2 The following describes the sections of the ultrasonic

delay and width,

instrument and their interrelations during measurement:

resolution,

3.2.1 Power Supply Section—The power supply section is

alarm level,

that portion of the total instrument circuitry which supplies the

gain uniformity,

regulated DC voltages required to power all other sections of

analog output, and

the ultrasonic instrument, including the high voltage (that is,

back echo gate.

pulser and CRT voltage) circuitry.

1.2 This guide complements Practice E 317, and is not

3.2.2 Pulser Section—The pulser section is that portion of

intended for evaluating the performance characteristics of

the total instrument circuitry which generates the electrical

ultrasonic examination instruments on the inspection/

pulse used to energize the ultrasonic search unit. The pulser

production line.

1 2

ThisguideisunderthejurisdictionofASTMCommitteeE-7onNondestructive Annual Book of ASTM Standards, Vol 03.03.

Testing and is the direct responsibility of Subcommittee E07.06 on Ultrasonic AvailablefromStandardizationDocumentsOrderDesk,Bldg.4SectionD,700

Method. Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

Current edition approved May 10, 2000. Published July 2000. Originally Available from Institute of Electrical and Electronic Engineers, 345 E47th St.,

published as E 1324 – 90. Last previous edition E 1324 – 95. New York, NY 10017.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E1324–00

section may also include the pulse-shape modification controls 4.4 Thisguideismeanttobeusedbyelectronicpersonnelto

such as pulse length, damping, or tuning controls. evaluate the electronic system components and not the ultra-

3.2.3 Receiver Section—The receiver section is that portion sonic system characteristics.

ofthetotalinstrumentcircuitrywhichamplifies,ormodifies,or

5. Apparatus

both, the radio frequency (RF) pulses received from the

5.1 UltrasonicInstrument—Anyelectronicinstrumentcom-

ultrasonic search unit. This includes the RF amplifiers, detec-

prised of a power supply, pulser, clock, receiver, and a sweep

tors, video amplifiers, suppression and filtering, and the CRT

and display section to generate, receive, and display electrical

vertical deflection circuits. Some instruments may not contain

signals related to ultrasonic waves for examination purposes.

all of these circuits.

3.2.3.1 Time Variable Gain (TVG), (alternatively referred to

NOTE 3—Someultrasonicinstrumentsdonotincludeacathoderaytube

as Distance Amplitude Correction (DAC), Time Controlled

display. Some sections of this guide may not apply to these instruments,

Gain (TCG), etc.) and reject or threshold, while part of the or may be applicable only with modifications. Such modifications should

be made only by personnel competent in electronics.

receiver section, should be turned off while making measure-

ments unless otherwise specified by the user.

5.2 Voltmeter—Any instrument(s) capable of measuring the

3.2.4 Gate/Alarm Section—This section monitors the sig-

AC line and DC battery voltages required for 7.1 or 7.2.

nals in the receiver section to detect the presence or absence of

5.3 Variable Transformer—An autotransformer or other

significant indications. The gate may include attenuation or

device capable of supplying variable AC power to the ultra-

gain controls. This section is considered separate from the

sonicinstrumentoverthefullrangeofvoltagesandwaveforms

receiversectionforthepurposesofthisguide.Thealarmsignal

specified by the manufacturer.

may be audible, a voltage proportional to the indication

5.4 Pulser Load—Unless otherwise requested by the using

amplitude, or a mark on voltage or current sensitive paper or

parties, the pulser load should be a 50-ohm noninductive

some combination of these.

resistor, preferably mounted in a shielded coaxial assembly.

3.2.5 Time Base Section—The time base section provides

The resistor must be able to withstand the maximum peak

the linear horizontal sweep, or baseline. It includes the hori-

pulser voltage. The impedance of the resistor should be

zontal deflection circuits and the clock and delay circuits that

checked at the anticipated operating frequency to ensure that it

control repetition rate and positioning of signals on the

is noninductive. Other impedances may be used if specified.

baseline.

5.5 Spectrum Analyzer—Any spectrum analyzer (and probe

assembly if required) that is capable of analyzing the electrical

4. Significance and Use

pulse from the pulser module and displaying the frequency

components of the pulse as described in 8.3.Arecording of the

4.1 The recommended measurement procedures described

display (photograph or chart recorder) is desirable.

in this guide are intended to provide performance-related

5.6 Probe—A wide band high input impedance ($10 kV)

measurements that can be reproduced under the specified test

attenuating(100Xor50X)probetoreducethepulseamplitude,

conditions using commercially available test instrumentation.

These measurements indicate capabilities of sections of the as delivered to the oscilloscope and the spectrum analyzer, to a

level that (a) will not harm the equipment and ( b) will allow

ultrasonic examination instrument independent of specific

transducers or examination conditions. Measurements are for frequency and time analysis without significantly altering

the pulse shape.The probe output impedance should match the

made from normally available connectors or test points so that

no access to internal circuitry is required. Further, this guide is input impedance of the measurement instrument. (If the im-

pedanceishigh,aterminatingresistancemayberequiredatthe

not intended for service, calibration, or maintenance of cir-

cuitry for which the manufacturer’s instructions are available. input to match the output impedance of the probe.) The

frequency bandwidth should be at least as wide as that of the

It is intended primarily for pulse echo flaw detection instru-

ments operating in the nominal frequency range of 100 kHz to measuring instruments. The probe must be able to withstand

the pulser output voltage.

25 MHz, but the procedures are applicable to measurements on

instruments utilizing significantly higher frequency compo-

NOTE 4—More than one probe may be needed to match the various test

nents.

instruments used.

4.2 Theseprocedurescanbeappliedtotheevaluationofany

5.7 Function Generator—The function generator should be

pulse-echo ultrasonic examination instrument which can be

capable of producing a single-cycle sine wave or a five-cycle

described as a combination of the electronic sections discussed

sine wave burst (as required in 9.1.3, 9.2.3, 9.3.1, 10.1.1, and

in this guide.

11.1), the frequency of which is variable over the range of the

NOTE 2—These procedures are not intended to preclude the use or

frequency capabilities of the ultrasonic instrument. The fre-

application of equipment for which some or all of the measurement

quency read-out should be accurate to 1.0 %. It must be

techniques of this document are not applicable.

capable of being triggered from a signal derived from the

4.3 An ultrasonic examination instrument that cannot be instrument clock to provide wave trains coherent with the

completely described as a combination of the electronic display. An adjustable delay of at least 10 µs is required.

sections discussed in this practice can be partially evaluated. 5.7.1 A free-running (that is, non-triggered) single-cycle

Each portion of the ultrasonic examination instrument that is sine wave may not be used for receiver evaluation.

evaluated must fit the description for the corresponding sec- 5.8 Calibrated Oscilloscope—The oscilloscope should be

tion. capable of displaying all portions of the pulser output with

E1324–00

sufficient timebase expansion, triggering capability, and fre- instruments (which should be described in the specifications

quency response to enable measurement of the pulse rise time, and calibrations for these instruments), and the precisions

amplitude, and duration, as well as fulfilling the requirements associated with reading the values of each part of the measure-

of other measurements. ment system. It is assumed that the precision of measuring the

5.9 CalibratedAttenuator—Theattenuatorshouldprovidea vertical and horizontal values from the ultrasonic instrument

measuring range of 60 dB in 1 dB steps with an accuracy screen is 60.04 in. (61 mm).

within6 0.5 dB and have a frequency bandwidth at least as 6.7 All measuring instrumentation should have current cali-

wide as the highest frequency of interest. Most attenuators bration certificates. A calibration control system, such as that

have a nominal input and output impedance of 50 V, but other described in MIL-STD-45662A, is suggested.

impedancesmaybespecified.Properterminationrulesmustbe

observed. An impedance matching probe should be used to 7. Power-Supply Section Measurements

protect the attenuator if it is to be used to reduce pulse output.

7.1 AC-Powered Instrument Line Regulation:

5.10 Terminators—Terminators are used to match the im-

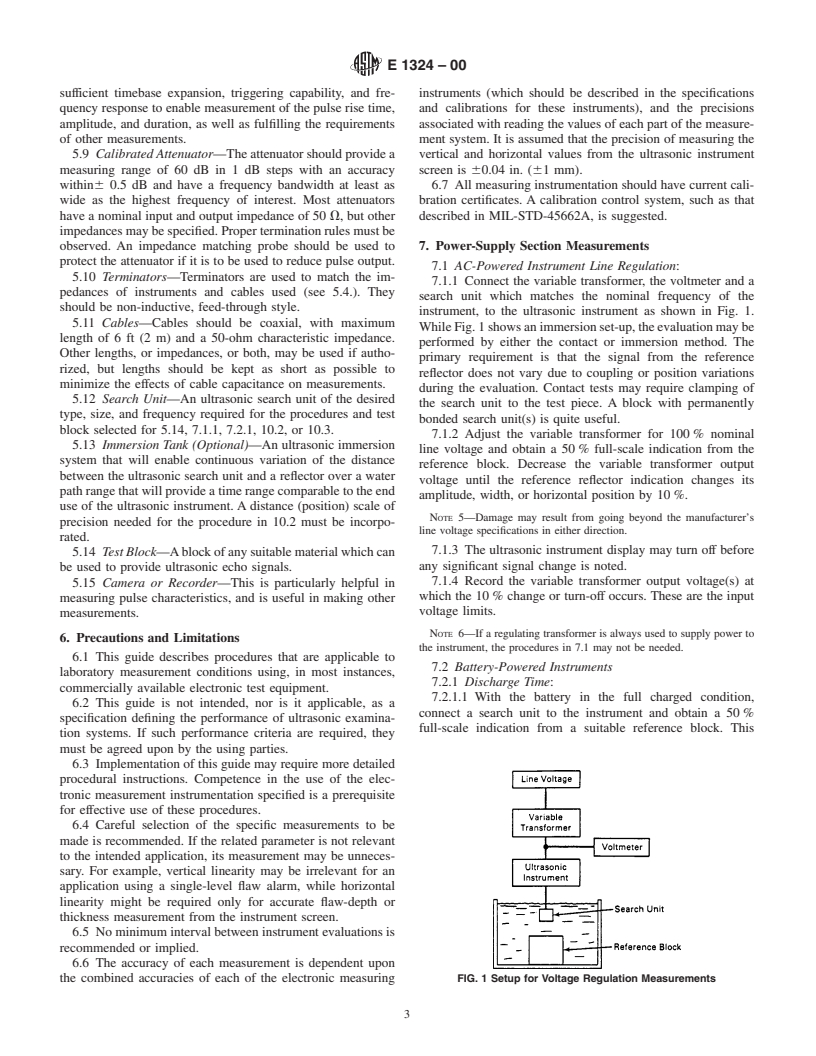

7.1.1 Connect the variable transformer, the voltmeter and a

pedances of instruments and cables used (see 5.4.). They

search unit which matches the nominal frequency of the

should be non-inductive, feed-through style.

instrument, to the ultrasonic instrument as shown in Fig. 1.

5.11 Cables—Cables should be coaxial, with maximum

WhileFig.1showsanimmersionset-up,theevaluationmaybe

length of 6 ft (2 m) and a 50-ohm characteristic impedance.

performed by either the contact or immersion method. The

Other lengths, or impedances, or both, may be used if autho-

primary requirement is that the signal from the reference

rized, but lengths should be kept as short as possible to

reflector does not vary due to coupling or position variations

minimize the effects of cable capacitance on measurements.

during the evaluation. Contact tests may require clamping of

5.12 Search Unit—An ultrasonic search unit of the desired

the search unit to the test piece. A block with permanently

type, size, and frequency required for the procedures and test

bonded search unit(s) is quite useful.

block selected for 5.14, 7.1.1, 7.2.1, 10.2, or 10.3.

7.1.2 Adjust the variable transformer for 100 % nominal

5.13 Immersion Tank (Optional)—An ultrasonic immersion

line voltage and obtain a 50 % full-scale indication from the

system that will enable continuous variation of the distance

reference block. Decrease the variable transformer output

between the ultrasonic search unit and a reflector over a water

voltage until the reference reflector indication changes its

pathrangethatwillprovideatimerangecomparabletotheend

amplitude, width, or horizontal position by 10 %.

use of the ultrasonic instrument. A distance (position) scale of

NOTE 5—Damage may result from going beyond the manufacturer’s

precision needed for the procedure in 10.2 must be incorpo-

line voltage specifications in either direction.

rated.

7.1.3 The ultrasonic instrument display may turn off before

5.14 TestBlock—Ablockofanysuitablematerialwhichcan

any significant signal change is noted.

be used to provide ultrasonic echo signals.

7.1.4 Record the variable transformer output voltage(s) at

5.15 Camera or Recorder—This is particularly helpful in

which the 10 % change or turn-off occurs. These are the input

measuring pulse characteristics, and is useful in making other

voltage limits.

measurements.

NOTE 6—If a regulating transformer is always used to supply power to

6. Precautions and Limitations

the instrument, the procedures in 7.1 may not be needed.

6.1 This guide describes procedures that are applicable to

7.2 Battery-Powered Instruments

laboratory measurement conditions using, in most instances,

7.2.1 Discharge Time:

commercially available electronic test equipment.

7.2.1.1 With the battery in the full charged condition,

6.2 This guide is not intended, nor is it applicable, as a

connect a search unit to the instrument and obtain a 50 %

specification defining the performance of ultrasonic examina-

full-scale indication from a suitable reference block. This

tion systems. If such performance criteria are required, they

must be agreed upon by the using parties.

6.3 Implementation of this guide may require more detailed

procedural instructions. Competence in the use of the elec-

tronic measurement instrumentation specified is a prerequisite

for effective use of these procedures.

6.4 Careful selection of the specific measurements to be

made is recomme

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.