ASTM D6330-98(2014)

(Practice)Standard Practice for Determination of Volatile Organic Compounds (Excluding Formaldehyde) Emissions from Wood-Based Panels Using Small Environmental Chambers Under Defined Test Conditions

Standard Practice for Determination of Volatile Organic Compounds (Excluding Formaldehyde) Emissions from Wood-Based Panels Using Small Environmental Chambers Under Defined Test Conditions

SIGNIFICANCE AND USE

4.1 The effects of VOC sources on the indoor air quality in buildings have not been well established. One basic requirement that has emerged from indoor air quality studies is the need for well-characterized test data on the emission factors of VOCs from building materials. Standard test method and procedure are a requirement for the comparison of emission factor data from different products.

4.2 This practice describes a procedure for using a small environmental test chamber to determine the emission factors of VOCs from wood-based panels over a specified period of time. A pre-screening analysis procedure is also provided to identify the VOCs emitted from the products, to determine the appropriate GC/MS or GC/FID analytical procedure, and to estimate required sampling volume for the subsequent environmental chamber testing.

4.3 Test results obtained using this practice provide a basis for comparing the VOC emission characteristics of different wood-based panel products. The emission data can be used to inform manufacturers of the VOC emissions from their products. The data can also be used to identify building materials with reduced VOC emissions over the time interval of the test.

4.4 While emission factors determined by using this practice can be used to compare different products, the concentrations measured in the chamber shall not be considered as the resultant concentrations in an actual indoor environment.

SCOPE

1.1 The practice measures the volatile organic compounds (VOC), excluding formaldehyde, emitted from manufactured wood-based panels. A pre-screening analysis is used to identify the VOCs emitted from the panel. Emission factors (that is, emission rates per unit surface area) for the VOCs of interest are then determined by measuring the concentrations in a small environmental test chamber containing a specimen. The test chamber is ventilated at a constant air change rate under the standard environmental conditions. For formaldehyde determination, see Test Method D6007.

1.2 This practice describes a test method that is specific to the measurement of VOC emissions from newly manufactured individual wood-based panels, such as particleboard, plywood, and oriented strand board (OSB), for the purpose of comparing the emission characteristics of different products under the standard test condition. For general guidance on conducting small environmental chamber tests, see Guide D5116.

1.3 VOC concentrations in the environmental test chamber are determined by adsorption on an appropriate single adsorbent tube or multi-adsorbent tube, followed by thermal desorption and combined gas chromatograph/mass spectrometry (GC/MS) or gas chromatograph/flame ionization detection (GC/FID). The air sampling procedure and the analytical method recommended in this practice are generally valid for the identification and quantification of VOCs with saturation vapor pressure between 500 and 0.01 kPa at 25°C, depending on the selection of adsorbent(s).

Note 1: VOCs being captured by an adsorbent tube depend on the adsorbent(s) and sampling procedure selected (see Practice D6196). The user should have a thorough understanding of the limitations of each adsorbent used.

1.4 The emission factors determined using the above procedure describe the emission characteristics of the specimen under the standard test condition. These data can be used directly to compare the emission characteristics of different products and to estimate the emission rates up to one month after the production. They shall not be used to predict the emission rates over longer periods of time (that is, more than one month) or under different environmental conditions.

1.5 Emission data from chamber tests can be used for predicting the impact of wood-based panels on the VOC concentrations in buildings by using an appropriate indoor air quality model, which is beyond the scope of this practice.

1.6 The values stated ...

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D6330 −98 (Reapproved 2014)

Standard Practice for

Determination of Volatile Organic Compounds (Excluding

Formaldehyde) Emissions from Wood-Based Panels Using

Small Environmental Chambers Under Defined Test

Conditions

This standard is issued under the fixed designation D6330; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.4 The emission factors determined using the above pro-

cedure describe the emission characteristics of the specimen

1.1 The practice measures the volatile organic compounds

under the standard test condition. These data can be used

(VOC), excluding formaldehyde, emitted from manufactured

directly to compare the emission characteristics of different

wood-basedpanels.Apre-screeninganalysisisusedtoidentify

products and to estimate the emission rates up to one month

the VOCs emitted from the panel. Emission factors (that is,

after the production. They shall not be used to predict the

emission rates per unit surface area) for the VOCs of interest

emission rates over longer periods of time (that is, more than

arethendeterminedbymeasuringtheconcentrationsinasmall

one month) or under different environmental conditions.

environmental test chamber containing a specimen. The test

1.5 Emission data from chamber tests can be used for

chamber is ventilated at a constant air change rate under the

predicting the impact of wood-based panels on the VOC

standard environmental conditions. For formaldehyde

concentrations in buildings by using an appropriate indoor air

determination, see Test Method D6007.

quality model, which is beyond the scope of this practice.

1.2 This practice describes a test method that is specific to

1.6 The values stated in SI units shall be regarded as the

the measurement ofVOC emissions from newly manufactured

standard (see IEEE/ASTM SI-10).

individualwood-basedpanels,suchasparticleboard,plywood,

andorientedstrandboard(OSB),forthepurposeofcomparing 1.7 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

the emission characteristics of different products under the

standard test condition. For general guidance on conducting responsibility of the user of this standard to establish appro-

priate safety, health, and environmental practices and deter-

small environmental chamber tests, see Guide D5116.

mine the applicability of regulatory limitations prior to use.

1.3 VOC concentrations in the environmental test chamber

For specified hazard statements see Section 6.

are determined by adsorption on an appropriate single adsor-

1.8 This international standard was developed in accor-

benttubeormulti-adsorbenttube,followedbythermaldesorp-

dance with internationally recognized principles on standard-

tionandcombinedgaschromatograph/massspectrometry(GC/

ization established in the Decision on Principles for the

MS) or gas chromatograph/flame ionization detection (GC/

Development of International Standards, Guides and Recom-

FID). The air sampling procedure and the analytical method

mendations issued by the World Trade Organization Technical

recommended in this practice are generally valid for the

Barriers to Trade (TBT) Committee.

identificationandquantificationofVOCswithsaturationvapor

pressure between 500 and 0.01 kPa at 25°C, depending on the

2. Referenced Documents

selection of adsorbent(s).

2.1 ASTM Standards:

NOTE 1—VOCs being captured by an adsorbent tube depend on the

D1356Terminology Relating to Sampling and Analysis of

adsorbent(s) and sampling procedure selected (see Practice D6196). The

Atmospheres

user should have a thorough understanding of the limitations of each

D1914PracticeforConversionUnitsandFactorsRelatingto

adsorbent used.

Sampling and Analysis of Atmospheres

ThispracticeisunderthejurisdictionofASTMCommitteeD22onAirQuality

and is the direct responsibility of Subcommittee D22.05 on Indoor Air. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Nov. 1, 2014. Published November 2014. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1998. Last previous edition approved in 2008 as D6330–98 (2008). Standards volume information, refer to the standard’s Document Summary page on

DOI: 10.1520/D6330-98R14. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D6330−98 (2014)

D5116Guide for Small-Scale Environmental Chamber De- 3.2.7 TVOC—total concentration of all the individual vola-

terminationsofOrganicEmissionsfromIndoorMaterials/ tile organic compounds (VOC) captured from air by a given

Products sorbent, or a given combination of several sorbents, thermally

D6007TestMethodforDeterminingFormaldehydeConcen- desorbed into and eluted from a given gas chromatographic

trations in Air from Wood Products Using a Small-Scale system and measured by a given detector. ForVOC definition,

Chamber see Terminology D1356.

D6196Practice for Choosing Sorbents, Sampling Param- 3.2.7.1 Discussion—The measured value of TVOC will

eters and Thermal Desorption Analytical Conditions for depend on the collection and desorption efficiency of the

Monitoring Volatile Organic Chemicals in Air sorbent trap, the efficiency of transfer to the GC column, the

E355PracticeforGasChromatographyTermsandRelation- type and size of the GC column, the GC temperature program

ships and other chromatographic parameters, and the type of GC

E741Test Method for Determining Air Change in a Single detector. One way to report TVOC values is recommended in

Zone by Means of a Tracer Gas Dilution 8.2.7.6.

IEEE/ASTM SI-10Standard for Use of the International

3.2.8 wood-based panel test specimen—a specimen of a

System of Units (SI): The Modern Metric System

panel cut from an original wood-based panel sample, such as

2.2 Other Standard:

particleboard, oriented strand board (OSB), or plywood.

EPA TO-17Determination of Volatile Organic Compounds

in Ambient Air Using Active Sampling Onto Sorbent 4. Significance and Use

Tubes, Compendium of Methods for the Determination of

4.1 The effects of VOC sources on the indoor air quality in

Toxic Organic Compounds in Ambient Air

buildings have not been well established. One basic require-

ment that has emerged from indoor air quality studies is the

3. Terminology

need for well-characterized test data on the emission factors of

3.1 Definitions—For definitions and terms that are com-

VOCs from building materials. Standard test method and

monly used, refer to Terminology D1356 and Practice E355.

procedure are a requirement for the comparison of emission

For definitions and terms related to test methods using small-

factor data from different products.

scale environmental chamber, refer to Guide D5116. For an

4.2 This practice describes a procedure for using a small

explanation of units, symbols, and conversion factors, refer to

environmental test chamber to determine the emission factors

Practice D1914.

of VOCs from wood-based panels over a specified period of

3.2 Definitions of Terms Specific to This Standard:

time. A pre-screening analysis procedure is also provided to

3.2.1 environmental enclosure—a container or space in

identify the VOCs emitted from the products, to determine the

which the environmental test chamber(s) is placed. The enclo-

appropriate GC/MS or GC/FID analytical procedure, and to

sure has controlled temperature and relative humidity.

estimate required sampling volume for the subsequent envi-

2 3

ronmental chamber testing.

3.2.2 loading ratio (m /m )—the total exposed surface area

of each test specimen divided by the net air volume of the

4.3 Test results obtained using this practice provide a basis

environmental test chamber.

for comparing the VOC emission characteristics of different

3.2.3 nominaltimeconstant(t )—thetimerequiredtoobtain wood-based panel products. The emission data can be used to

n

inform manufacturers of the VOC emissions from their prod-

one air change in the environmental test chamber, which is

equal to the inverse of the air change rate. ucts. The data can also be used to identify building materials

with reducedVOC emissions over the time interval of the test.

3.2.4 pre-screening analysis—a procedure for identifying

theVOCsemittedfromatestspecimen.Theresultsareusedto

4.4 While emission factors determined by using this prac-

determine the appropriate GC/MS or GC/FID analytical

tice can be used to compare different products, the concentra-

method for subsequent dynamic chamber tests.

tions measured in the chamber shall not be considered as the

resultant concentrations in an actual indoor environment.

3.2.5 standardenvironmentaltestchambercondition—atest

conditionoftemperatureat23 60.5°C,relativehumidity(RH)

5. Apparatus

at 50 6 5%, air change rate per hour in the chamber at 1 6

2 3

5.1 This practice requires the use of an environmental

0.03 ACH, and chamber loading ratio at 0.40 6 0.01 m /m .

chamber test system, an air sample collection system, and a

3.2.5.1 Discussion—The VOC emission rates for wood-

chemicalanalysissystem.Ageneralguideforconductingsmall

based panel products are generally controlled by VOC diffu-

environmental chamber tests is provided in Guide D5116. The

sions within the material. The airflow condition (air velocity

following paragraphs describe the requirements that are spe-

and turbulence) over the test specimen has minimal effect on

cific to this practice:

the emission rates; therefore, it is not specified in the standard

test condition.

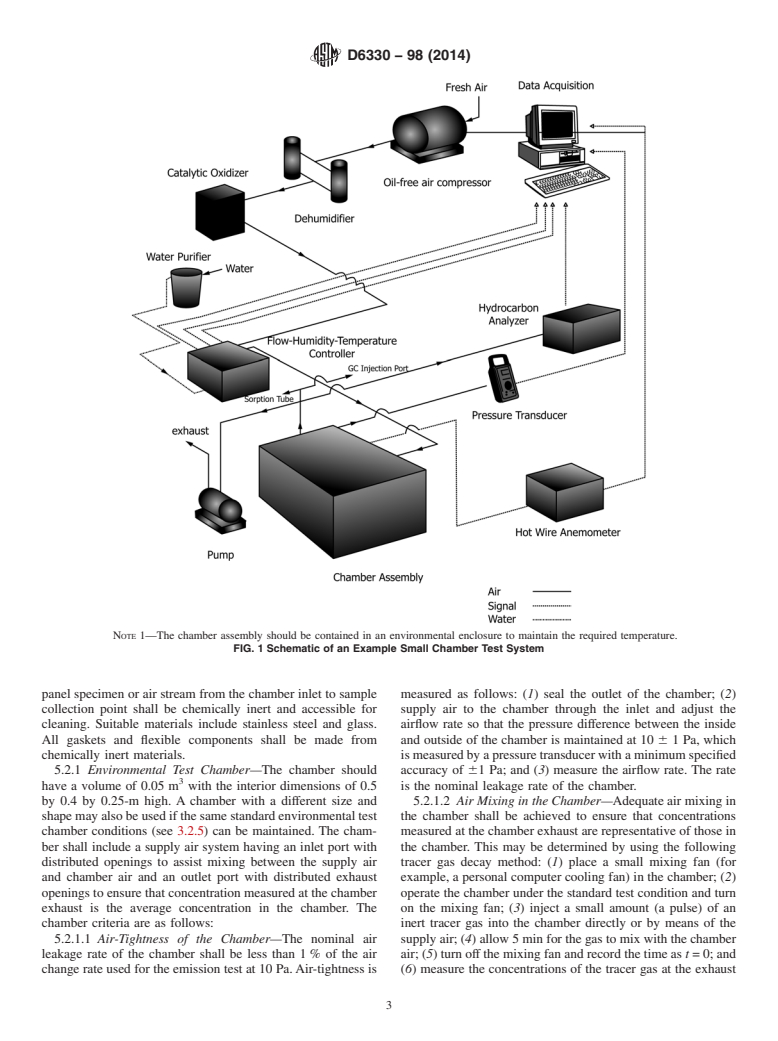

5.2 Environmental Chamber Testing System—The system

3.2.6 tracer gas—a gaseous compound that is neither emit- shall include an environmental test chamber, an environmental

tedbythewood-basedpanelnorpresentinthesupplyairtothe enclosure, equipment for supplying clean and conditioned air

chamber.Itcanbeusedtodeterminethemixingcharacteristics to the chamber, and outlet fittings for sampling the air

of the environmental test chamber, and it provides a cross- exhausted from the chamber. Fig. 1 illustrates an example of

check of the air change rate measurements. such systems. All materials and components in contact with

D6330−98 (2014)

NOTE 1—The chamber assembly should be contained in an environmental enclosure to maintain the required temperature.

FIG. 1Schematic of an Example Small Chamber Test System

panel specimen or air stream from the chamber inlet to sample measured as follows: (1) seal the outlet of the chamber; (2)

collection point shall be chemically inert and accessible for supply air to the chamber through the inlet and adjust the

cleaning. Suitable materials include stainless steel and glass. airflow rate so that the pressure difference between the inside

All gaskets and flexible components shall be made from and outside of the chamber is maintained at 10 6 1 Pa, which

chemically inert materials. ismeasuredbyapressuretransducerwithaminimumspecified

5.2.1 Environmental Test Chamber—The chamber should accuracy of 61 Pa; and (3) measure the airflow rate. The rate

have a volume of 0.05 m with the interior dimensions of 0.5 is the nominal leakage rate of the chamber.

by 0.4 by 0.25-m high. A chamber with a different size and 5.2.1.2 Air Mixing in the Chamber—Adequateairmixingin

shapemayalsobeusedifthesamestandardenvironmentaltest the chamber shall be achieved to ensure that concentrations

chamber conditions (see 3.2.5) can be maintained. The cham- measured at the chamber exhaust are representative of those in

ber shall include a supply air system having an inlet port with the chamber. This may be determined by using the following

distributed openings to assist mixing between the supply air tracer gas decay method: (1) place a small mixing fan (for

and chamber air and an outlet port with distributed exhaust example, a personal computer cooling fan) in the chamber; (2)

openingstoensurethatconcentrationmeasuredatthechamber operate the chamber under the standard test condition and turn

exhaust is the average concentration in the chamber. The on the mixing fan; (3) inject a small amount (a pulse) of an

chamber criteria are as follows: inert tracer gas into the chamber directly or by means of the

5.2.1.1 Air-Tightness of the Chamber—The nominal air supplyair;(4)allow5minforthegastomixwiththechamber

leakage rate of the chamber shall be less than 1% of the air air;(5)turnoffthemixingfanandrecordthetimeas t=0;and

change rate used for the emission test at 10 Pa.Air-tightness is (6) measure the concentrations of the tracer gas at the exhaust

D6330−98 (2014)

of the chamber at the following time points:t=0, 0.25 t , 0.5 value. The above mixing test shall be conducted with a

n

t ,1.0t ,1.5t ,and2.0t ,wheret isthenominaltimeconstant simulated test specimen placed in the chamber.

n n n n n

and is equal to 1.0 h for the standard test condition. The

NOTE 2—The above test method is a simplified version of the decay

measured concentrations are compared to the values given by

methoddescribedinGuideD5116.Alternatively,themethodofdetermin-

the following theoretical equation under the perfect mixing

ing adequate air mixing described in Guide D5116 may also be used to

check the mixing condition in the chamber.

condition(inwhichtheconcentrationsmeasuredattheexhaust

are the same as those in the chamber):

5.2.1.3 Sample Specimen Holder—A sample specimen

2Nt

holder shall be used to hold the test specimen so that only the

C 5 C e (1)

~t! 0

test surface of the specimen is exposed to the chamber air.The

where:

holdershallbedesignedtominimizetheemissionsfromedges

C = initial concentration at t=0, µg/m ,

and non-testing surface of the specimen. A design example is

C = concentration at time t, µg/m ,

(t) shown in Fig. 2.

–1

N = air change rate, h , and

5.2.1.4 Sink Effect—Thechamberandspecimenholdershall

t = time from the start of the air purging, h.

have minimum sink effect. The recovery factor determined by

The maximum difference between the measured and calcu- the following procedure shall be higher than 95% for decane:

latedtheoreticalvaluesshallbewithin 65%ofthetheoretical (1) seal the supply inlet and exhaust of the chamber; (2) inject

NOTE 1—All materials for the sample holder should be made of electropolished stainless steel.

FIG. 2Schematic of an Example Sample Holder

D6330−98 (2014)

5 µg of vaporized decane into the chamber; (3) take an air purpos

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D6330 − 98 (Reapproved 2008) D6330 − 98 (Reapproved 2014)

Standard Practice for

Determination of Volatile Organic Compounds (Excluding

Formaldehyde) Emissions from Wood-Based Panels Using

Small Environmental Chambers Under Defined Test

Conditions

This standard is issued under the fixed designation D6330; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 The practice measures the volatile organic compounds (VOC), excluding formaldehyde, emitted from manufactured

wood-based panels. A pre-screening analysis is used to identify the VOCs emitted from the panel. Emission factors (that is,

emission rates per unit surface area) for the VOCs of interest are then determined by measuring the concentrations in a small

environmental test chamber containing a specimen. The test chamber is ventilated at a constant air change rate under the standard

environmental conditions. For formaldehyde determination, see Test Method D6007.

1.2 This practice describes a test method that is specific to the measurement of VOC emissions from newly manufactured

individual wood-based panels, such as particleboard, plywood, and oriented strand board (OSB), for the purpose of comparing the

emission characteristics of different products under the standard test condition. For general guidance on conducting small

environmental chamber tests, see Guide D5116.

1.3 VOC concentrations in the environmental test chamber are determined by adsorption on an appropriate single adsorbent tube

or multi-adsorbent tube, followed by thermal desorption and combined gas chromatograph/mass spectrometry (GC/MS) or gas

chromatograph/flame ionization detection (GC/FID). The air sampling procedure and the analytical method recommended in this

practice are generally valid for the identification and quantification of VOCs with saturation vapor pressure between 500 and 0.01

kPa at 25°C, depending on the selection of adsorbent(s).

NOTE 1—VOCs being captured by an adsorbent tube depend on the adsorbent(s) and sampling procedure selected (see Practice D6196). The user should

have a thorough understanding of the limitations of each adsorbent used.

1.4 The emission factors determined using the above procedure describe the emission characteristics of the specimen under the

standard test condition. These data can be used directly to compare the emission characteristics of different products and to estimate

the emission rates up to one month after the production. They shall not be used to predict the emission rates over longer periods

of time (that is, more than one month) or under different environmental conditions.

1.5 Emission data from chamber tests can be used for predicting the impact of wood-based panels on the VOC concentrations

in buildings by using an appropriate indoor air quality model, which is beyond the scope of this practice.

1.6 The values stated in SI units shall be regarded as the standard (see IEEE/ASTM SI-10).

1.7 This practice does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of the standard to consult and establish appropriate safety and health practices and determine the applicability of

regulatory limitations prior to use. For specified hazard statements see Section 6.

2. Referenced Documents

2.1 ASTM Standards:

D1356 Terminology Relating to Sampling and Analysis of Atmospheres

D1914 Practice for Conversion Units and Factors Relating to Sampling and Analysis of Atmospheres

D5116 Guide for Small-Scale Environmental Chamber Determinations of Organic Emissions from Indoor Materials/Products

This practice is under the jurisdiction of ASTM Committee D22 on Air Quality and is the direct responsibility of Subcommittee D22.05 on Indoor Air.

Current edition approved Aug. 1, 2008Nov. 1, 2014. Published September 2008November 2014. Originally approved in 1998. Last previous edition approved in 20032008

as D6330 - 98 (2003).D6330 – 98 (2008). DOI: 10.1520/D6330-98R08.10.1520/D6330-98R14.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D6330 − 98 (2014)

D6007 Test Method for Determining Formaldehyde Concentrations in Air from Wood Products Using a Small-Scale Chamber

D6196 Practice for Selection of Sorbents, Sampling, and Thermal Desorption Analysis Procedures for Volatile Organic

Compounds in Air

E355 Practice for Gas Chromatography Terms and Relationships

E741 Test Method for Determining Air Change in a Single Zone by Means of a Tracer Gas Dilution

IEEE/ASTM SI-10 Standard for Use of the International System of Units (SI): The Modern Metric System

2.2 Other Standard:

EPA TO-17 Determination of Volatile Organic Compounds in Ambient Air Using Active Sampling Onto Sorbent Tubes,

Compendium of Methods for the Determination of Toxic Organic Compounds in Ambient Air

3. Terminology

3.1 Definitions—For definitions and terms that are commonly used, refer to Terminology D1356 and Practice E355. For

definitions and terms related to test methods using small-scale environmental chamber, refer to Guide D5116. For an explanation

of units, symbols, and conversion factors, refer to Practice D1914.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 environmental enclosure—a container or space in which the environmental test chamber(s) is placed. The enclosure has

controlled temperature and relative humidity.

2 3

3.2.2 loading ratio (m /m )—the total exposed surface area of each test specimen divided by the net air volume of the

environmental test chamber.

3.2.3 nominal time constant (t )—the time required to obtain one air change in the environmental test chamber, which is equal

n

to the inverse of the air change rate.

3.2.4 pre-screening analysis—a procedure for identifying the VOCs emitted from a test specimen. The results are used to

determine the appropriate GC/MS or GC/FID analytical method for subsequent dynamic chamber tests.

3.2.5 standard environmental test chamber condition—a test condition of temperature at 23 6 0.5°C, relative humidity (RH)

2 3

at 50 6 5 %, air change rate per hour in the chamber at 1 6 0.03 ACH, and chamber loading ratio at 0.40 6 0.01 m /m .

3.2.5.1 Discussion—

The VOC emission rates for wood-based panel products are generally controlled by VOC diffusions within the material. The

airflow condition (air velocity and turbulence) over the test specimen has minimal effect on the emission rates; therefore, it is not

specified in the standard test condition.

3.2.6 tracer gas—a gaseous compound that is neither emitted by the wood-based panel nor present in the supply air to the

chamber. It can be used to determine the mixing characteristics of the environmental test chamber, and it provides a cross-check

of the air change rate measurements.

3.2.7 TVOC—total concentration of all the individual volatile organic compounds (VOC) captured from air by a given sorbent,

or a given combination of several sorbents, thermally desorbed into and eluted from a given gas chromatographic system and

measured by a given detector. For VOC definition, see Terminology D1356.

3.2.7.1 Discussion—

The measured value of TVOC will depend on the collection and desorption efficiency of the sorbent trap, the efficiency of transfer

to the GC column, the type and size of the GC column, the GC temperature program and other chromatographic parameters, and

the type of GC detector. One way to report TVOC values is recommended in 8.2.7.6.

3.2.8 wood-based panel test specimen—a specimen of a panel cut from an original wood-based panel sample, such as

particleboard, oriented strand board (OSB), or plywood.

4. Significance and Use

4.1 The effects of VOC sources on the indoor air quality in buildings have not been well established. One basic requirement

that has emerged from indoor air quality studies is the need for well-characterized test data on the emission factors of VOCs from

building materials. Standard test method and procedure are a requirement for the comparison of emission factor data from different

products.

4.2 This practice describes a procedure for using a small environmental test chamber to determine the emission factors of VOCs

from wood-based panels over a specified period of time. A pre-screening analysis procedure is also provided to identify the VOCs

emitted from the products, to determine the appropriate GC/MS or GC/FID analytical procedure, and to estimate required sampling

volume for the subsequent environmental chamber testing.

D6330 − 98 (2014)

4.3 Test results obtained using this practice provide a basis for comparing the VOC emission characteristics of different

wood-based panel products. The emission data can be used to inform manufacturers of the VOC emissions from their products.

The data can also be used to identify building materials with reduced VOC emissions over the time interval of the test.

4.4 While emission factors determined by using this practice can be used to compare different products, the concentrations

measured in the chamber shall not be considered as the resultant concentrations in an actual indoor environment.

5. Apparatus

5.1 This practice requires the use of an environmental chamber test system, an air sample collection system, and a chemical

analysis system. A general guide for conducting small environmental chamber tests is provided in Guide D5116. The following

paragraphs describe the requirements that are specific to this practice:

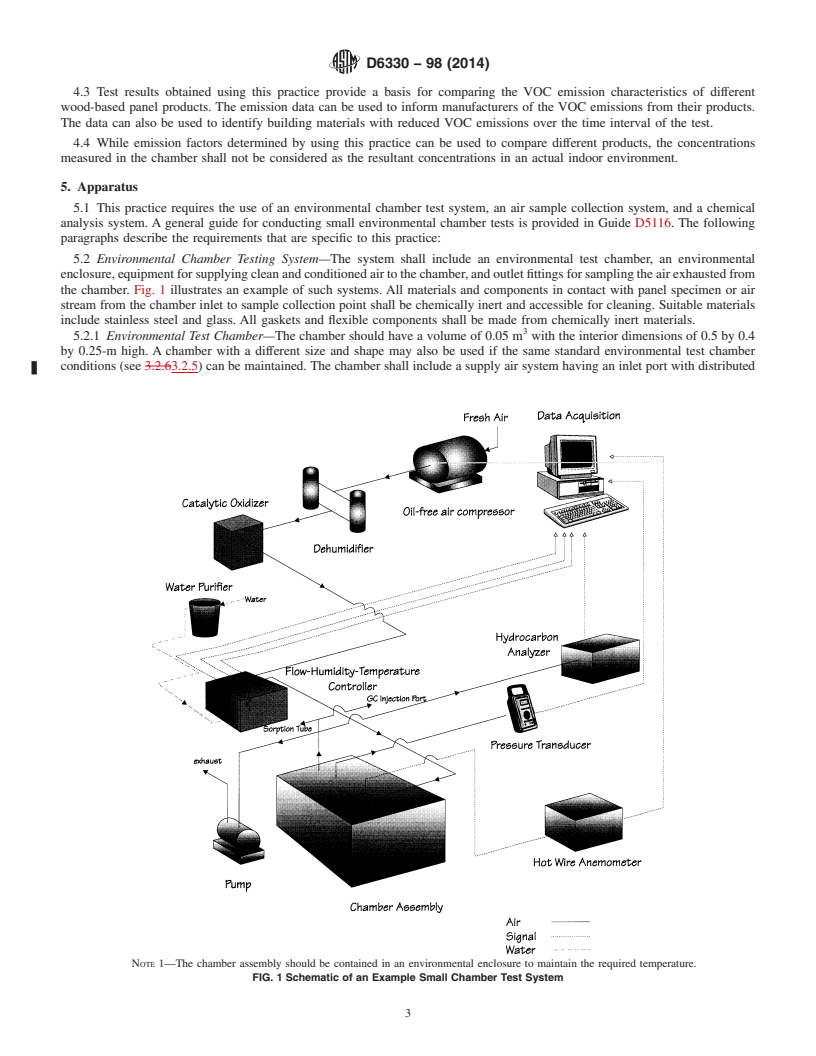

5.2 Environmental Chamber Testing System—The system shall include an environmental test chamber, an environmental

enclosure, equipment for supplying clean and conditioned air to the chamber, and outlet fittings for sampling the air exhausted from

the chamber. Fig. 1 illustrates an example of such systems. All materials and components in contact with panel specimen or air

stream from the chamber inlet to sample collection point shall be chemically inert and accessible for cleaning. Suitable materials

include stainless steel and glass. All gaskets and flexible components shall be made from chemically inert materials.

5.2.1 Environmental Test Chamber—The chamber should have a volume of 0.05 m with the interior dimensions of 0.5 by 0.4

by 0.25-m high. A chamber with a different size and shape may also be used if the same standard environmental test chamber

conditions (see 3.2.63.2.5) can be maintained. The chamber shall include a supply air system having an inlet port with distributed

NOTE 1—The chamber assembly should be contained in an environmental enclosure to maintain the required temperature.

FIG. 1 Schematic of an Example Small Chamber Test System

D6330 − 98 (2014)

openings to assist mixing between the supply air and chamber air and an outlet port with distributed exhaust openings to ensure

that concentration measured at the chamber exhaust is the average concentration in the chamber. The chamber criteria are as

follows:

5.2.1.1 Air-Tightness of the Chamber—The nominal air leakage rate of the chamber shall be less than 1 % of the air change rate

used for the emission test at 10 Pa. Air-tightness is measured as follows: (1) seal the outlet of the chamber; (2) supply air to the

chamber through the inlet and adjust the airflow rate so that the pressure difference between the inside and outside of the chamber

is maintained at 10 6 1 Pa, which is measured by a pressure transducer with a minimum specified accuracy of 61 Pa; and (3)

measure the airflow rate. The rate is the nominal leakage rate of the chamber.

5.2.1.2 Air Mixing in the Chamber—Adequate air mixing in the chamber shall be achieved to ensure that concentrations

measured at the chamber exhaust are representative of those in the chamber. This may be determined by using the following tracer

gas decay method: (1) place a small mixing fan (for example, a personal computer cooling fan) in the chamber; (2) operate the

chamber under the standard test condition and turn on the mixing fan; (3) inject a small amount (a pulse) of an inert tracer gas

(for example, SF ) into the chamber directly or by means of the supply air; (4) allow 5 min for the gas to mix with the chamber

air; (5) turn off the mixing fan and record the time as t = 0; and (6) measure the concentrations of the tracer gas at the exhaust

of the chamber at the following time points: t = 0, 0.25 t , 0.5 t , 1.0 t , 1.5 t , and 2.0 t , where t is the nominal time constant

n n n n n n

and is equal to 1.0 h for the standard test condition. The measured concentrations are compared to the values given by the following

theoretical equation under the perfect mixing condition (in which the concentrations measured at the exhaust are the same as those

in the chamber):

2Nt

C 5 C e (1)

t 0

~ !

where:

C = initial concentration at t=0, μg/m ,

C = concentration at time t, μg/m ,

(t)

–1

N = air change rate, h , and

t = time from the start of the air purging, h.

The maximum difference between the measured and calculated theoretical values shall be within 6 5 % of the theoretical value.

The above mixing test shall be conducted with a simulated test specimen placed in the chamber.

NOTE 2—The above test method is a simplified version of the decay method described in Guide D5116. Alternatively, the method of determining

adequate air mixing described in Guide D5116 may also be used to check the mixing condition in the chamber.

5.2.1.3 Sample Specimen Holder—A sample specimen holder shall be used to hold the test specimen so that only the test surface

of the specimen is exposed to the chamber air. The holder shall be designed to minimize the emissions from edges and non-testing

surface of the specimen. A design example is shown in Fig. 2.

5.2.1.4 Sink Effect—The chamber and specimen holder shall have minimum sink effect. The recovery factor determined by the

following procedure shall be higher than 95 % for decane: (1) seal the supply inlet and exhaust of the cham

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.