ASTM D3588-98(2003)

(Practice)Standard Practice for Calculating Heat Value, Compressibility Factor, and Relative Density of Gaseous Fuels

Standard Practice for Calculating Heat Value, Compressibility Factor, and Relative Density of Gaseous Fuels

SIGNIFICANCE AND USE

The heating value is a measure of the suitability of a pure gas or a gas mixture for use as a fuel; it indicates the amount of energy that can be obtained as heat by burning a unit of gas. For use as heating agents, the relative merits of gases from different sources and having different compositions can be compared readily on the basis of their heating values. Therefore, the heating value is used as a parameter for determining the price of gas in custody transfer. It is also an essential factor in calculating the efficiencies of energy conversion devices such as gas-fired turbines. The heating values of a gas depend not only upon the temperature and pressure, but also upon the degree of saturation with water vapor. However, some calorimetric methods for measuring heating values are based upon the gas being saturated with water at the specified conditions.

The relative density (specific gravity) of a gas quantifies the density of the gas as compared with that of air under the same conditions.

SCOPE

1.1 This practice covers procedures for calculating heating value, relative density, and compressibility factor at base conditions (14.696 psia and 60°F (15.6°C)) for natural gas mixtures from compositional analysis. It applies to all common types of utility gaseous fuels, for example, dry natural gas, reformed gas, oil gas (both high and low Btu), propane-air, carbureted water gas, coke oven gas, and retort coal gas, for which suitable methods of analysis as described in Section 6 are available. Calculation procedures for other base conditions are given.

1.2 The values stated in inch-pound units are to be regarded as the standard. The SI units given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D3588–98 (Reapproved 2003)

Standard Practice for

Calculating Heat Value, Compressibility Factor, and Relative

Density of Gaseous Fuels

This standard is issued under the fixed designation D3588; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope (LP) Gases and Propene Concentrates by Gas Chromatog-

raphy

1.1 This practice covers procedures for calculating heating

D2650 Test Method for Chemical Composition of Gases by

value, relative density, and compressibility factor at base

Mass Spectrometry

conditions (14.696 psia and 60°F (15.6°C)) for natural gas

2.2 GPA Standards:

mixtures from compositional analysis. It applies to all com-

GPA2145 PhysicalConstantsfortheParaffinHydrocarbons

montypesofutilitygaseousfuels,forexample,drynaturalgas,

and Other Components in Natural Gas

reformed gas, oil gas (both high and low Btu), propane-air,

GPA Standard 2166 Methods of Obtaining Natural Gas

carbureted water gas, coke oven gas, and retort coal gas, for

Samples for Analysis by Gas Chromatography

which suitable methods of analysis as described in Section 6

GPA 2172 Calculation of Gross Heating Value, Relative

are available. Calculation procedures for other base conditions

Density, and Compressibility Factor for Natural Gas

are given.

,

4 5

Mixtures from Compositional Analysis

1.2 The values stated in inch-pound units are to be regarded

GPAStandard2261 MethodofAnalysisforNaturalGasand

as the standard. The SI units given in parentheses are for

Similar Gaseous Mixtures by Gas Chromatography

information only.

GPA Technical Publication TP-17 Table of Physical Prop-

1.3 This standard does not purport to address all of the

erties of Hydrocarbons for Extended Analysis of Natural

safety concerns, if any, associated with its use. It is the

Gases

responsibility of the user of this standard to establish appro-

GPSA Data Book, Fig. 23-2, Physical Constants

priate safety and health practices and determine the applica-

2.3 TRC Document:

bility of regulatory limitations prior to use.

TRC Thermodynamic Tables—Hydrocarbons

2. Referenced Documents

2.4 ANSI Standard:

ANSI Z 132.1-1969: Base Conditions of Pressure and

2.1 ASTM Standards:

Temperature for the Volumetric Measurement of Natural

D1717 Method for Analysis of Commercial Butane-Butene

7,8

Gas

Mixtures and Isobutylene by Gas Chromatography

D1945 Test Method for Analysis of Natural Gas by Gas

3. Terminology

Chromatography

3.1 Definitions:

D1946 Practice for Analysis of Reformed Gas by Gas

3.1.1 British thermal unit—the defined International Tables

Chromatography

British thermal unit (Btu).

D2163 Test Method for Analysis of Liquefied Petroleum

3.1.1.1 Discussion—The defining relationships are:

–1 –1

1 Btu•lb = 2.326 J•g (exact)

This practice is under the jurisdiction of ASTM Committee D03 on Gaseous

Fuels and is the direct responsibility of Subcommittee D03.03 on Determination of

Available from Gas ProcessorsAssociation (GPA), 6526 E. 60th St.,Tulsa, OK

Heating Value and Relative Density of Gaseous Fuels. 74145, http://www.gasprocessors.com.

Current edition approved May 10, 2003. Published May 2003. Originally The sole source of supply of the program in either BASIC or FORTRAN

approved in 1998. Last previous edition approved in 1998 as D3588 – 98. DOI: suitable for running on computers known to the committee at this time is the Gas

10.1520/D3588-98R03. ProcessorsAssociation. If you are aware of alternative suppliers, please provide this

A more rigorous calculation of Z(T,P) at both base conditions and higher information to ASTM International Headquarters. Your comments will receive

pressures can be made using the calculation procedures in “Compressibility and careful consideration at a meeting of the responsible technical committee , which

Super Compressibility for Natural Gas and Other Hydrocarbon Gases,” American you may attend.

Gas Association Transmission Measurement Committee Report 8, AGA Cat. No. AvailablefromThermodynamicsResearchCenter,TheTexasA&MUniversity,

XQ1285, 1985, AGA, 1515 Wilson Blvd., Arlington, VA 22209. College Station, TX 77843-3111.

3 7

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM 4th Floor, New York, NY 10036, http://www.ansi.org.

Standards volume information, refer to the standard’s Document Summary page on Supporting data have been filed at ASTM International Headquarters and may

the ASTM website. be obtained by requesting Research Report RR:D03-1007.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D3588–98 (2003)

1 lb = 453.592 37 g (exact) 3.2.1.17 M—molar mass

By these relationships, 1 Btu = 1 055.055 852 62 J (exact). For 3.2.1.18 m—mass flow rate

most purposes, the value (rounded) 1 Btu = 1055.056 J is 3.2.1.19 n—number of components

adequate. 3.2.1.20 P—pressure in absolute units (psia)

id

3.1.2 compressibility factor (z)—the ratio of the actual 3.2.1.21 Q —ideal energy per unit time released as heat

volume of a given mass of gas at a specified temperature and upon combustion

pressure to its volume calculated from the ideal gas law under 3.2.1.22 R—gasconstant,10.7316psia.ft /(lbmol•R)inthis

the same conditions. practice (based upon R = 8.314 48 J/(mol•K))

3.2.1.23 (sat)—denotes saturation value

3.1.3 grossheatingvalue—theamountofenergytransferred

asheatfromthecomplete,idealcombustionofthegaswithair, 3.2.1.24 T—absolute temperature, °R = °F + 459.67 or K =

at standard temperature, in which all the water formed by the °C + 273.15

reaction condenses to liquid. The values for the pure gases 3.2.1.25 (T, P)—value dependent upon temperature and

appear in GPAStandard 2145, which is revised annually. If the pressure

gross heating value has a volumetric rather than a mass or 3.2.1.26 V—gas volumetric flow rate

molar basis, a base pressure must also be specified. 3.2.1.27 x—mole fraction

3.2.1.28 Z—gascompressibilityfactorrepeatabilityofprop-

3.1.4 net heating value—the amount of energy transferred

erty

as heat from the total, ideal combustion of the gas at standard

3.2.1.29 d—repeatability of property

temperature in which all the water formed by the reaction

remains in the vapor state. Condensation of any “spectator” 3.2.1.30 r—density in mass per unit volume

n

water does not contribute to the net heating value. If the net 3.2.1.31 —property summed for Components 1

(j51

heating value has a volumetric rather than a mass or molar

through n, where n represents the total number of components

basis, a base pressure must also be specified. in the mixture

3.1.5 relative density—the ratio of the density of the gas- 3.2.2 Superscripts:

eous fuel, under observed conditions of temperature and 3.2.2.1 id—ideal gas value

3.2.2.2 l—liquid

pressure, to the density of dry air (of normal carbon dioxide

content) at the same temperature and pressure. 3.2.2.3 s—value at saturation (vapor pressure)

3.2.2.4 8—reproducibility

3.1.6 standard cubic foot of gas—the amount of gas that

3 3

occupies 1 ft (0.028 m ) at a temperature of 60°F (15.6°C) 3.2.3 Subscripts:

3.2.3.1 a—value for air

under a given base pressure and either saturated with water

vapor (wet) or free of water vapor (dry) as specified (seeANSI 3.2.3.2 a—relative number of atoms of carbon in Eq 1

3.2.3.3 b—relative number of atoms of hydrogen in Eq 1

Z 132.1). In this practice, calculations have been made at

14.696 psia and 60°F (15.6°C), because the yearly update of 3.2.3.4 c—relative number of atoms of sulfur in Eq 1

3.2.3.5 j—property for component j

GPA 2145 by the Thermodynamics Research Center, on which

these calculations are based, are given for this base pressure. 3.2.3.6 ii—non-ideal gas property for component i

Conversionstootherbaseconditionsshouldbemadeattheend 3.2.3.7 ij—non-ideal gas property for mixture of i and j

of the calculation to reduce roundoff errors. 3.2.3.8 jj—non-ideal gas property for component j

3.2.3.9 w—value for water

3.1.7 standard temperature (USA)—60°F (15.6°C).

3.2 Symbols: 3.2.3.10 1—property for Component 1

3.2.3.11 2—property for Component 2

3.2.1 Nomenclature:

3.2.1.1 B—second virial coefficient for gas mixture

4. Summary of Practice

3.2.1.2 b —summation factor for calculating real gas

=

ij

4.1 The ideal gas heating value and ideal gas relative

correction (alternate method)

density at base conditions (14.696 psia and 60°F (5.6°C)) are

3.2.1.3 (cor)—corrected for water content

calculated from the molar composition and the respective ideal

3.2.1.4 (dry)—value on water-free basis

gas values for the components; these values are then adjusted

3.2.1.5 d—density for gas relative to the density of air.

id

by means of a calculated compressibility factor.

3.2.1.6 d —ideal relative density or relative molar mass,

that is, molar mass of gas relative to molar mass of air

5. Significance and Use

id

3.2.1.7 G —molar mass ratio

5.1 The heating value is a measure of the suitability of a

id

3.2.1.8 H —gross heating value per unit mass

m

pure gas or a gas mixture for use as a fuel; it indicates the

id

3.2.1.9 H —gross heating value per unit volume

v

amountofenergythatcanbeobtainedasheatbyburningaunit

id

3.2.1.10 H —gross heating value per unit mole

n

of gas. For use as heating agents, the relative merits of gases

id

3.2.1.11 h —net heating value per unit mass

m from different sources and having different compositions can

id

3.2.1.12 h —net heating value per unit volume

v be compared readily on the basis of their heating values.

id

3.2.1.13 h —net heating value per unit mole

Therefore, the heating value is used as a parameter for

n

3.2.1.14 a, b, c—in Eq 1, integers required to balance the

determining the price of gas in custody transfer. It is also an

equation: C, carbon; H, hydrogen; S, sulfur; O, oxygen essential factor in calculating the efficiencies of energy con-

3.2.1.15 (id)—ideal gas state

version devices such as gas-fired turbines. The heating values

3.2.1.16 (l)—liquid phase of a gas depend not only upon the temperature and pressure,

D3588–98 (2003)

but also upon the degree of saturation with water vapor. components such as butanes, pentanes, hexanes, butenes, and

However, some calorimetric methods for measuring heating so forth).Any group used must be one of those listed in Table

values are based upon the gas being saturated with water at the 1 for which average values appear. The following test methods

specified conditions. are applicable to this practice when appropriate for the sample

5.2 The relative density (specific gravity) of a gas quantifies under test: Test Methods D1717, D1945, D2163, and D2650.

the density of the gas as compared with that of air under the

same conditions.

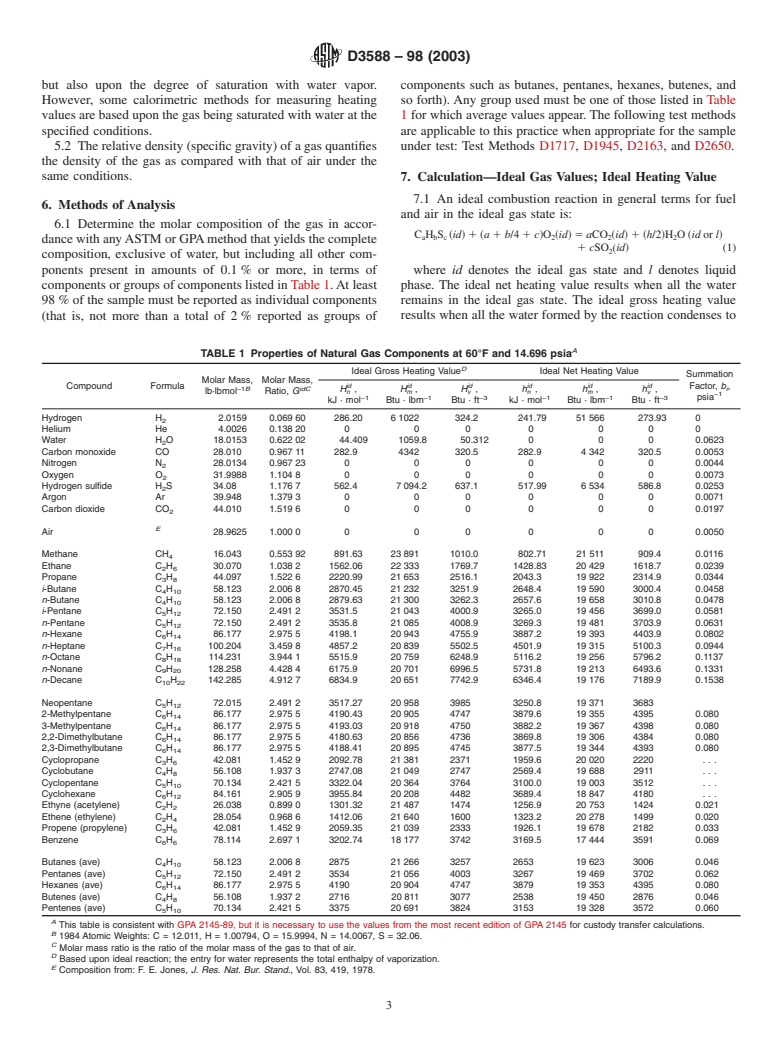

7. Calculation—Ideal Gas Values; Ideal Heating Value

7.1 An ideal combustion reaction in general terms for fuel

6. Methods of Analysis

and air in the ideal gas state is:

6.1 Determine the molar composition of the gas in accor-

C H S ~id! 1 ~a 1 b/4 1 c!O ~id! 5 aCO ~id! 1 ~h/2!H O ~id or l!

a b c 2 2 2

dance with anyASTM or GPAmethod that yields the complete

1 cSO id! (1)

~

composition, exclusive of water, but including all other com-

ponents present in amounts of 0.1 % or more, in terms of where id denotes the ideal gas state and l denotes liquid

components or groups of components listed inTable 1.At least phase. The ideal net heating value results when all the water

98 % of the sample must be reported as individual components remains in the ideal gas state. The ideal gross heating value

results when all the water formed by the reaction condenses to

(that is, not more than a total of 2 % reported as groups of

A

TABLE 1 Properties of Natural Gas Components at 60°F and 14.696 psia

D

Ideal Gross Heating Value Ideal Net Heating Value

Summation

Molar Mass, Molar Mass,

id id id id id id

Compound Formula Factor, b ,

–1B idC i

H , H , H , h , h , h ,

n m v n m v

lb·lbmol Ratio, G

−1

–1 –1 –3 –1 –1 –3 psia

kJ · mol Btu · lbm Btu · ft kJ · mol Btu · lbm Btu · ft

Hydrogen H 2.0159 0.069 60 286.20 6 1022 324.2 241.79 51 566 273.93 0

Helium He 4.0026 0.138 20 0 0 0 0 0 0 0

Water H O 18.0153 0.622 02 44.409 1059.8 50.312 0 0 0 0.0623

Carbon monoxide CO 28.010 0.967 11 282.9 4342 320.5 282.9 4 342 320.5 0.0053

Nitrogen N 28.0134 0.967 23 0 0 0 0 0 0 0.0044

Oxygen O 31.9988 1.104 8 0 0 0 0 0 0 0.0073

Hydrogen sulfide H S 34.08 1.176 7 562.4 7 094.2 637.1 517.99 6 534 586.8 0.0253

Argon Ar 39.948 1.379 3 0 0 0 0 0 0 0.0071

Carbon dioxide CO 44.010 1.519 6 0 0 0 0 0 0 0.0197

E

Air 28.9625 1.000 0 0 0 0 0 0 0 0.0050

Methane CH 16.043 0.553 92 891.63 23 891 1010.0 802.71 21 511 909.4 0.0116

Ethane C H 30.070 1.038 2 1562.06 22 333 1769.7 1428.83 20 429 1618.7 0.0239

2 6

Propane C H 44.097 1.522 6 2220.99 21 653 2516.1 2043.3 19 922 2314.9 0.0344

3 8

i-Butane C H 58.123 2.006 8 2870.45 21 232 3251.9 2648.4 19 590 3000.4 0.0458

4 10

n-Butane C H 58.123 2.006 8 2879.63 21 300 3262.3 2657.6 19 658 3010.8 0.0478

4 10

i-Pentane C H 72.150 2.491 2 3531.5 21 043 4000.9 3265.0 19 456 3699.0 0.0581

5 12

n-Pentane C H 72.150 2.491 2 3535.8 21 085 4008.9 3269.3 19 481 3703.9 0.0631

5 12

n-Hexane C H 86.177 2.975 5 4198.1 20 943 4755.9 3887.2 19 393 4403.9 0.0802

6 14

n-Heptane C H 100.204 3.459 8 4857.2 20 839 5502.5 4501.9 19 315 5100.3 0.0944

7 16

n-Octane C H 114.231 3.944 1 5515.9 20 759 6248.9 5116.2 19 256 5796.2 0.1137

8 18

n-Nonane C H 128.258 4.428 4 6175.9 20 701 6996.5 5731.8 19 213 6493.6 0.1331

9 20

n-Decane C H 142.285 4.912 7 6834.9 20 651 7742.9 6346.4 19 176 7189.9 0.1538

10 22

Neopentane C H 72.015 2.491 2 3517.27 20 958 3985 3250.8 19 371 3683

5 12

2-Methylpentane C H 86.177 2.975 5 4190.43 20 905 4747 3879.6 19 355 4395 0.080

6 14

3-Methylpentane C H 86.177 2.975 5 4193.03 20 918 4750 3882.2 19 367 4398 0.080

6 14

2,2-Dimethylbutane C H 86.177 2.975 5 4180.63 20 856 4736 3869.8 19 306 4384 0.080

6 14

2,3-Dimethylbutane C H 86.177 2.975 5 4188.41 20 895 4745 3877.5 19 344 4393 0.080

6 14

Cyclopropane C H 42.081 1.452 9 2092.78 21 381 2371 1959.6 20 020 2220 . . .

3 6

Cyclobutane C H 56.108 1.937 3 2747.08 21 049 2747 2569.4 19 688 2911 . . .

4 8

Cyclopentane C H 70.134 2.421 5 3322.04 20 364 3764 3100.0 19 003 3512 . . .

5 10

Cyclohexane C H 84.161 2.905 9 3955.84 20 208 4482 3689.4 18 847 4180 . . .

6 12

Ethyne (acetylene) C H 26.038 0.899 0 1301.32 21 487 1474 1256.9 20 753 1424 0.021

2 2

Ethene (ethylene) C H

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.