ASTM A1049/A1049M-06

(Specification)Standard Specification for Stainless Steel Forgings, Ferritic/Austenitic (Duplex), for Pressure Vessels and Related Components

Standard Specification for Stainless Steel Forgings, Ferritic/Austenitic (Duplex), for Pressure Vessels and Related Components

ABSTRACT

This specification covers ferritic/austenitic (duplex) stainless steel forgings for boilers, pressure vessels, and associated equipment. The steels shall be manufactured using melting and forging processes. Forgings may be machined before solution annealing. The forgings shall undergo tension and hardness tests. Also, they shall be subjected to a non-destructive examination by ultrasonic inspection.

SCOPE

1.1 This specification covers ferritic/austenitic (duplex) stainless steel forgings for boilers, pressure vessels, and associated equipment in grades that are also found in Specification A 182/A 182M.

1.2 The purchaser may specify in the order or contract any appropriate supplementary requirements that are provided in Specification A 788/A 788M.

1.3 Unless the order specifies the applicable "M" specification designation the material shall be furnished to the inch-pound units.

1.4 The values stated in either inch-pound or SI (metric) units are to be regarded separately as standard. Within the text and tables, the SI units are shown in brackets. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the specification.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A1049/A1049M – 06

Standard Specification for

Stainless Steel Forgings, Ferritic/Austenitic (Duplex), for

Pressure Vessels and Related Components

This standard is issued under the fixed designation A1049/A1049M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E165 PracticeforLiquidPenetrantExaminationforGeneral

Industry

1.1 This specification covers ferritic/austenitic (duplex)

G48 Test Methods for Pitting and Crevice Corrosion Resis-

stainless steel forgings for boilers, pressure vessels, and asso-

tance of Stainless Steels and Related Alloys by Use of

ciated equipment in grades that are also found in Specification

Ferric Chloride Solution

A182/A182M.

2.2 Other Standards:

1.2 The purchaser may specify in the order or contract any

ASME Boiler and Pressure Vessel Code

appropriate supplementary requirements that are provided in

NACE MR0175/ISO15156 Petroleum and Natural Gas

Specification A788/A788M.

Industries—Materials for Use in H S—Containing Envi-

1.3 Unless the order specifies the applicable “M” specifica-

ronments in Oil and Gas Production

tion designation the material shall be furnished to the inch-

pound units.

3. Ordering Information and General Requirements

1.4 The values stated in either inch-pound or SI (metric)

3.1 Material supplied to this specification shall conform to

units are to be regarded separately as standard. Within the text

the requirements of Specification A788/A788M, which out-

andtables,theSIunitsareshowninbrackets.Thevaluesstated

lines additional ordering information, manufacturing require-

in each system may not be exact equivalents; therefore, each

ments, testing and retesting methods and procedures, marking,

system shall be used independently of the other. Combining

certification,productanalysisvariations,andadditionalsupple-

values from the two systems may result in nonconformance

mentary requirements.

with the specification.

3.1.1 If the requirements of this specification are in conflict

2. Referenced Documents with the requirements of Specification A788/A788M, the

requirements of this specification shall prevail.

2.1 ASTM Standards:

3.1.2 The purchaser may require that the forging be ma-

A182/A182M Specification for Forged or RolledAlloy and

chined to an approved heat treatment drawing indicating the

Stainless Steel Pipe Flanges, Forged Fittings, and Valves

proposed configuration of the forging at the time of the

and Parts for High-Temperature Service

specified solution heat treatment.

A370 Test Methods and Definitions for Mechanical Testing

3.1.3 The purchaser may approve the use of an alternate

of Steel Products

liquid quenching medium for cooling from the solution treat-

A388/A388M Practice for Ultrasonic Examination of Steel

ment temperature.

Forgings

3.2 The purchaser shall specify the acceptance criteria for

A745/A745M Practice for Ultrasonic Examination of Aus-

eitherMethodsBorCofTestMethodsA923,ifsupplementary

tenitic Steel Forgings

requirement S1 is selected.

A788/A788M Specification for Steel Forgings, General Re-

3.3 The purchaser shall specify the required minimum

quirements

pitting resistance equivalent number (PREN) value determined

A923 Test Methods for Detecting Detrimental Intermetallic

according to the applicable equation in Table 1.

Phase in Duplex Austenitic/Ferritic Stainless Steels

3.4 When Practice A745/A745M is the basis for ultrasonic

examinationinaccordancewith7.1,thepurchasershallspecify

whether Quality levels 1 or 2 form the basis for acceptance.

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

Supplementary requirement S4 permits the purchaser to

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

A01.06 on Steel Forgings and Billets.

Current edition approved Sept. 1, 2006. Published September 2006. DOI:

10.1520/A1049_A1049M-06.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available from American Society of Mechanical Engineers (ASME), ASME

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM International Headquarters, Three Park Ave., New York, NY 10016-5990.

Standards volume information, refer to the standard’s Document Summary page on Available from National Association of Corrosion Engineers (NACE), 1440

the ASTM website. South Creek Dr., Houston, TX 77084-4906.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

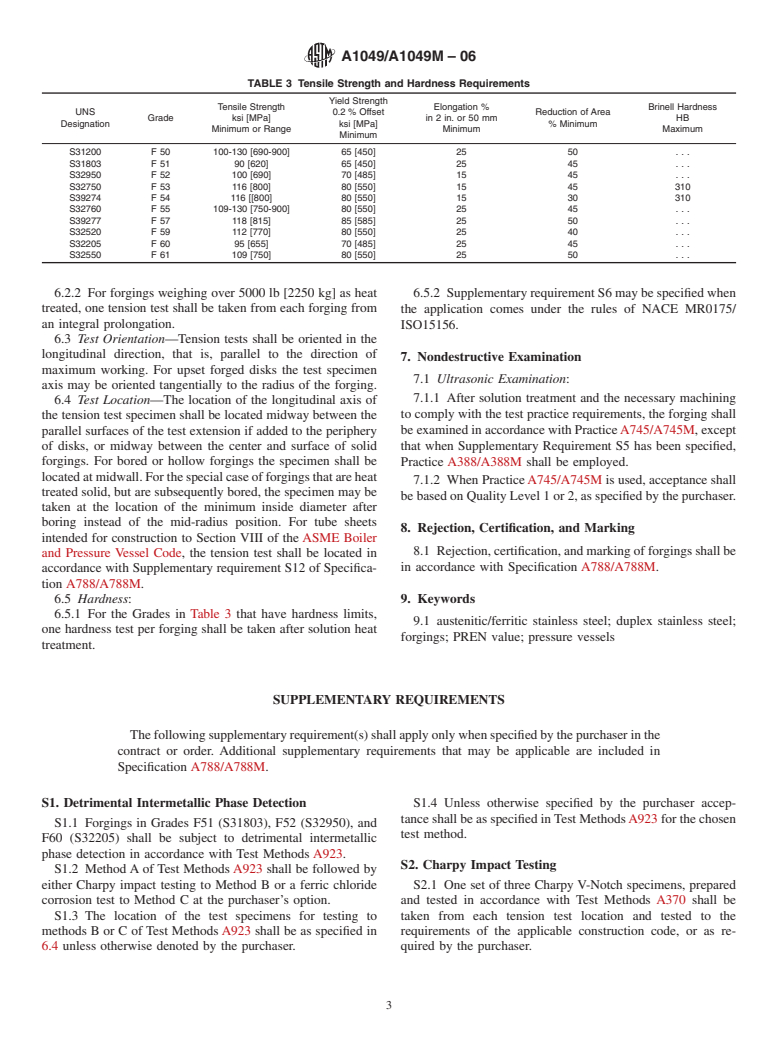

A1049/A1049M – 06

TABLE 1 Chemical Requirements

A A A A B B B A A A

Grade F50 F51 F52 F53 F54 F55 F57 F59 F60 F61

A A A A B B B A A A

UNS No. S31200 S31803 S32950 S32750 S39274 S32760 S39277 S32520 S32205 S32550

Carbon, max 0.030 0.030 0.030 0.030 0.030 0.030 0.025 0.030 0.030 0.04

Manganese, max 2.00 2.00 2.00 1.20 1.00 1.00 0.80 1.50 2.00 1.50

Phosphorous, max 0.045 0.030 0.035 0.035 0.030 0.030 0.025 0.035 0.030 0.040

Sulfur, max 0.030 0.020 0.010 0.020 0.020 0.010 0.002 0.020 0.020 0.030

Silicon, max 1.00 1.00 0.60 0.80 0.80 1.00 0.80 0.80 1.00 1.00

Nickel 5.5-6.5 4.5-6.5 3.5-5.2 6.0-8.0 6.0-8.0 6.0-8.0 6.5-8.0 5.5-8.0 4.5-6.5 4.5-6.5

Chromium 24.0-26.0 21.0-23.0 26.0-29.0 24.0-26.0 24.0-26.0 24.0-26.0 24.0-26.0 24.0-26.0 22.0-23.0 24.0-27.0

Molybdenum 1.20-2.00 2.5-3.5 1.00-2.50 3.0-5.0 2.5-3.5 3.0-4.0 3.0-4.0 3.0-5.0 3.0-3.5 2.9-3.9

Nitrogen 0.14-0.20 0.08-0.20 0.15-0.35 0.240.32 0.24-0.32 0.20-0.30 0.23-0.33 0.20-0.35 0.14-0.20 0.10-0.25

Copper . . . . . . . . . 0.50 max 0.20-0.80 0.50-1.00 1.20-2.00 0.50-3.00 . . . 1.50-2.50

Tungsten . . . . . . . . . . . . 1.50-2.50 0.50-1.00 0.80-1.20 . . . . . . . . .

A

PREN = Cr + 3.3(Mo) + 16(N)

B

PREN = Cr + 3.3(Mo + ⁄2 W) + 16(N)

NOTE—The required PREN value for both the tungsten bearing forging Grades with the superscript B and the non-tungsten bearing Grades with the

superscript A frequently lies between 33 and 40 depending on service experience, so that the Purchaser shall specify the required minimum PREN value

(see 3.3).

TABLE 2 Solution Heat Treatment

specify Practice A388/A388M in lieu of Practice A745/

A

UNS Solution Temperature Water Quench

A745M, in which case the purchaser must also specify the

Grade

Designation °F [°C] to Below °F [°C]

acceptance criteria.

S31200 F 50 1925 [1050] min 200 [95]

3.5 When Supplementary requirement S3, for pitting corro-

S31803 F 51 1870 [1020] min 200 [95]

sion testing, of Test Methods G48 is specified, the purchaser

S32950 F 52 1825-1875 [1000-1025] 200 [95]

S32750 F 53 1880 [1025] min 200 [95]

shall identify the method and test temperature to be used.

S39274 F 54 1920-2060 [1050-1125] 200 [95]

3.6 When Supplementary requirement S5 for the liquid

S32760 F 55 2010-2085 [1100-1140] 200 [95]

penetrant examination of forgings in the final machined con-

S39277 F 57 1940 [1060] min 200 [95]

S32520 F 59 1975-2050 [1080-1120] 200 [95]

figurationisspecified,thepurchasershallspecifythenecessary

S32205 F 60 1870 [1020] min 200 [95]

acceptance criteria, if the requirements of S19 in Specification

S32550 F 61 1920-2060 [1050-1125] 200 [95]

A788/A788M are not sufficient.

A

Water quenching is required unless the use of another liquid quenching

medium is approved by the purchaser (see 3.1.3).

4. Materials and Manufacture

4.1 Steel melting and forging shall be in accordance with

5.4 Dual marking is permitted when the actual values of the

Specification A788/A788M.

listed elements match two or more of the Grades in Table 1;

4.2 Heat Treatment:

however, grade substitution such as combining a tungsten

4.2.1 Forgings may be machined before solution annealing

bearing Grade with one that has no requirement for tungsten is

at the manufacturer’s option, unless the purchaser requires that

not permitted.

machining to a prescribed configuration be done before heat

treatment (see 3.2).

6. Mechanical Properties

4.2.2 All forgings shall be reheated to the required tempera-

ture for solution treatment followed, unless otherwise agreed 6.1 Requirements—The material shall conform to the re-

with the purchaser, by water quenching. With the purchaser’s

quirements for mechanical properties prescribed in Table 3.

consent (see 3.1.3) some other liquid quenching medium may The mechanical testing requirements of Test Methods A370

be used to rapidly cool the forging.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.