ASTM G86-98a

(Test Method)Standard Test Method for Determining Ignition Sensitivity of Materials to Mechanical Impact in Ambient Liquid Oxygen and Pressurized Liquid and Gaseous Oxygen Environments

Standard Test Method for Determining Ignition Sensitivity of Materials to Mechanical Impact in Ambient Liquid Oxygen and Pressurized Liquid and Gaseous Oxygen Environments

SCOPE

1.1 This test method describes test apparatus and a technique to determine the relative sensitivity of materials to mechanical impact in liquid or gaseous oxygen at pressures from 0 to 10 000 psig (0 to 68.9 MPa). The test method described herein addresses testing with pure oxygen environments; however, oxygen-enriched fluids may be substituted throughout this document. This test method utilizes an Army Ballistic Missile Agency (ABMA)-type impact tester of the type depicted in Test Method D2512 modified for pressurized testing.

1.2 This test method provides a means for ranking nonmetallic materials as defined in Guide G63 for use in liquid and gaseous oxygen systems, and is not directly applicable to the determination of the sensitivity of the material in an end-use configuration. This test method can be employed to provide batch-to-batch acceptance data.

1.3 The criteria used for the acceptance, retest or rejection of materials shall be determined by the user and are not fixed by this test method.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. See also Section 7.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: G 86 – 98a

Standard Test Method for

Determining Ignition Sensitivity of Materials to Mechanical

Impact in Ambient Liquid Oxygen and Pressurized Liquid

and Gaseous Oxygen Environments

ThisstandardisissuedunderthefixeddesignationG 86;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope Liquid Oxygen (Impact Sensitivity Threshold and Pass-

2 Fail Techniques)

1.1 This test method describes test equipment and tech-

D 1193 Specification for Reagent Water

niques to determine the impact sensitivity of materials in

D 4080 Specification for Trichloroethylene, Technical and

oxygen under two different conditions: (1) in ambient pressure

Vapor Degreasing

liquid oxygen (LOX) or (2) under pressure-controlled condi-

G 63 Guide for Evaluating Nonmetallic Materials for Oxy-

tions in LOX or gaseous oxygen (GOX). It is applicable to

gen Service

materials for use in LOX or GOX systems at pressures from

G 88 Guide for Designing Systems for Oxygen Service

ambient to 68.9 MPa (0 to 10 000 psig). The test method

G 93 Practice for Cleaning Methods for Materials and

described herein addresses testing with pure oxygen environ-

Equipment Used in Oxygen-Enriched Environments

ments; however, other oxygen-enriched fluids may be substi-

G 94 Guide for Evaluating Metals for Oxygen Service

tuted throughout this document.

2.2 Military Document:

1.2 This test method provides a means for ranking nonme-

MIL-D-16791 Detergent, General Purpose (Liquid, Non-

tallic materials as defined in Guide G 63 for use in liquid and

ionic), Type One

gaseous oxygen systems and may not be directly applicable to

2.3 American Chemical Society:

the determination of the sensitivity of the materials in an

Trichloroethylene, Reagent Grade

end-useconfiguration.Thistestmethodmaybeusedtoprovide

2.4 Compressed Gas Association:

batch-to batch acceptance data. This test method may provide

G-4 Oxygen

a means for evaluating metallic materials in oxygen-enriched

G-4.1 Cleaning Equipment for Oxygen Service

atmospheres also; however, Guide 94 should be consulted for

G-4.3 Oxygen, Gaseous, Type I B

preferred testing methods.

G-4.3 Oxygen, Liquid, Type II B

1.3 Values stated in SI units are to be regarded as the

G-10.1 Nitrogen, Gaseous, Type I B

standard. The values given in parentheses are for information

G-10.1 Nitrogen, Liquid, Type II B

only.

2.5 NASA Standard:

1.4 This standard does not purport to address all of the

NSS 1740.15 Safety Standard for Oxygen and Oxygen

safety concerns, if any, associated with its use. It is the

Systems

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

3. Terminology

bility of regulatory limitations prior to use. See also Section 9.

3.1 Definitions of Terms Specific to This Standard:

2. Referenced Documents 3.1.1 GOX, n—gaseous oxygen.

2.1 ASTM Standards:

D 2512 Test Method for Compatibility of Materials with

Annual Book of ASTM Standards, Vol. 15.03.

Annual Book of ASTM Standards, Vol. 11.01.

Annual Book of ASTM Standards, Vol. 15.05.

1 6

This test method is under the jurisdiction of ASTM Committee G 4 on Annual Book of ASTM Standards, Vol. 14.02.

Compatibility and Sensitivity of Materials in Oxygen EnrichedAtmospheres and is Available from Naval Publications and Forms Center, 5801 Tabor Ave.,

the direct responsibility of G 4.01 on Test Methods. Philadelphia, PA 19120.

8 th

Current edition approved Sept. 10, 1998. Published March 1999. Originally American Chemical Society, 1155 16 St., N.W., Washington, DC 20036.

published as G 86-84. Last previous edition G 86-98. Compressed Gas Association, 1725 Jefferson Davis Highway, Arlington, VA

NASA Handbook 8060.1B, Pressurized Liquid and Gaseous Oxygen Mechani- 22202-4100.

cal Impact Test, Sept. 1981, pp. 4-72. National Aeronautics and Space Adminstration, Washington, DC 20546.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

G86

3.1.2 LOX, n—liquid oxygen.

3.1.3 mechanical impact, n—a blow delivered by a plum-

met that has been dropped from a preestablished height onto a

striker pin in contact with a sample.

3.1.4 reaction, n—a chemical change or transformation in

the sample initiated by a mechanical impact.

3.1.4.1 Discussion—A reaction from ambient pressure,

LOX mechanical impact may be determined by an audible

report, an electronically or visually detected flash, obvious

charring of the sample, cup, or striker pin.

3.1.4.2 Discussion—Reactions in pressurized LOX or GOX

are typically indicated by an abrupt increase in test sample

temperature, chamber pressure, and light levels and may be

supplemented by obvious changes in odor, color, or material

appearance as a result of thermal decompositions observed

during examination after the test.

3.1.5 pressure threshold, n—the highest pressure at a given

impact energy level for which the passing criteria have been

met.

3.1.6 energy threshold, n—the highest impact energy level

at a given pressure for which the passing criteria have been

met.

4. Summary of Test Method

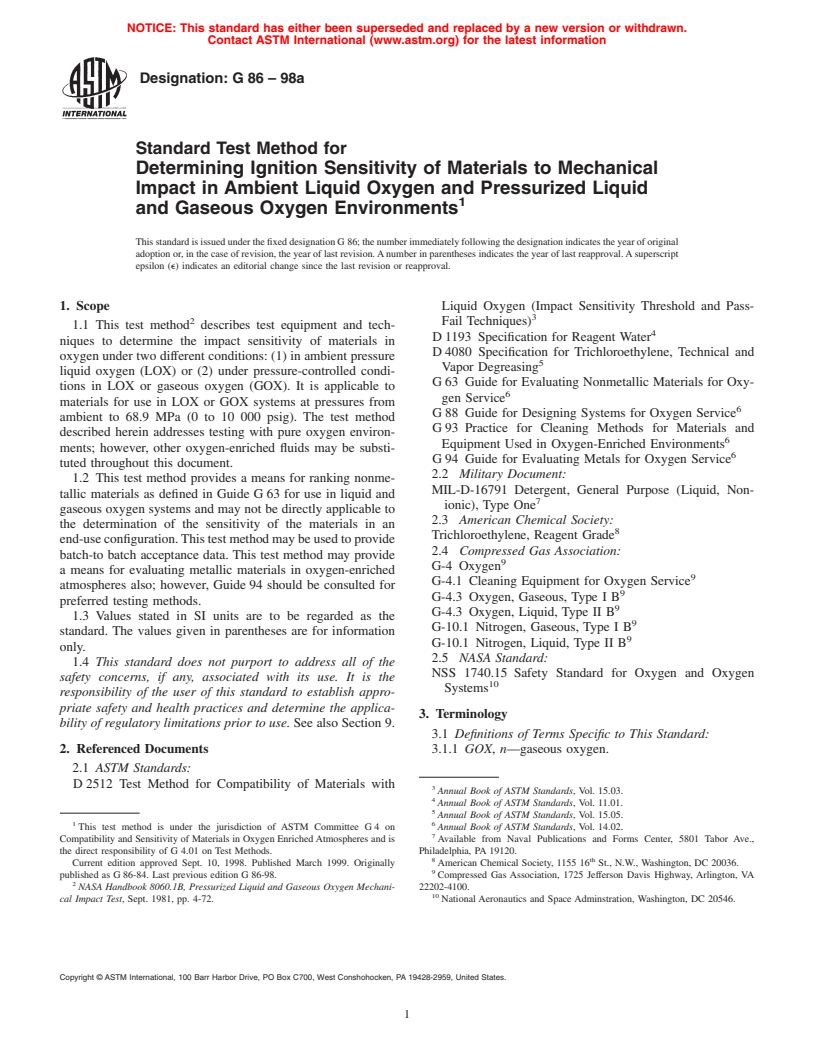

4.1 The mechanical impact test system is designed to

expose material samples to mechanical impact in the presence

of liquid or gaseous oxygen at pressures from ambient to 68.9

MPa (0 to 10 000 psig). The basic drop tower configuration

consists of: an electromagnet, a plummet, plummet guide

tracks, plummet hold/release mechanism, base plate, anvil

FIG. 1 Oxygen Impact Test Frame

plate, a specimen cup holder, sample cup, and striker pin (see

Fig. 1). For tests conducted under pressure-controlled condi-

tions,theanvilplateandspecimencupholderarereplacedwith removed from the chamber, and the sample is inspected for

a test chamber equipped with a striker pin or striker pin

other evidence of reaction such as odor or charring. Drop tests

counterloader (see Fig. 2), test chamber purge, pressurization are continued using a fresh sample, sample holder, and striker

and vent systems (see Fig. 3), and a plummet catcher (see Fig. pin or striker pin counterloader for each drop, until the

4). The general procedure is to prepare the test sample and threshold level is determined or the test series is completed.

record significant pretest data. Additional modifications to the above procedure are required

4.2 Ambient LOX Impact Test—The test conditions (pres- when testing is performed at temperatures above ambient.

sure and temperature) are the ambient pressure of the test 4.4 This test method may be used to determine the impact

facility and the boiling point of LOX at that pressure. Each sensitivity of a material, batch-to-batch acceptance, or to

sample is placed into a specimen cup (see Fig. 5), precooled in satisfy other prescribed pass-fail criteria.

a sample freezing box (Fig. 6), covered with LOX, and placed

5. Significance and Use

in the cup holder seater in the anvil assembly of the impact

5.1 This test method evaluates the relative sensitivity of

tester. The plummet is dropped from a selected height onto the

striker pin, which transmits the energy to the test sample. materials to mechanical impact in ambient pressure liquid

Observation for any reaction is made and noted. Drop tests are oxygen, pressurized liquid oxygen, and pressurized gaseous

continued using a fresh sample, sample cup, and striker pin for oxygen.

each drop until the threshold level is determined or the test 5.2 Any change or variation in test sample configuration,

series is completed. thickness, preparation, or cleanliness may cause a significant

4.3 For materials tested in pressurized LOX or GOX, each change in impact sensitivity/reaction threshold.

sample is placed in the test chamber. The test chamber is filled 5.3 Suggested criteria for discontinuing the tests are: (1)

with liquid or gaseous oxygen, pressurized to the required test occurrence of two reactions in a maximum of 60 samples or

pressure, and the striker pin or striker pin counterloader is less tested at the maximum energy level of 98 J (72 ft•lbf) or

pressed down against the top of the test sample. The plummet one reaction in a maximum of 20 samples tested at any other

is dropped from a selected height onto the striker pin or striker energy level for a material that fails; (2) no reactions for 20

pincounterloader.Instrumentationdevicesthatmonitorthetest samples tested at the 98-J (72-ft•lbf) energy level; or (3) a

chamber interior for pressure, temperature, and light emission maximumofonereactionin60samplestestedatthemaximum

provide evidence of test sample reaction. The sample is energy level.

G86

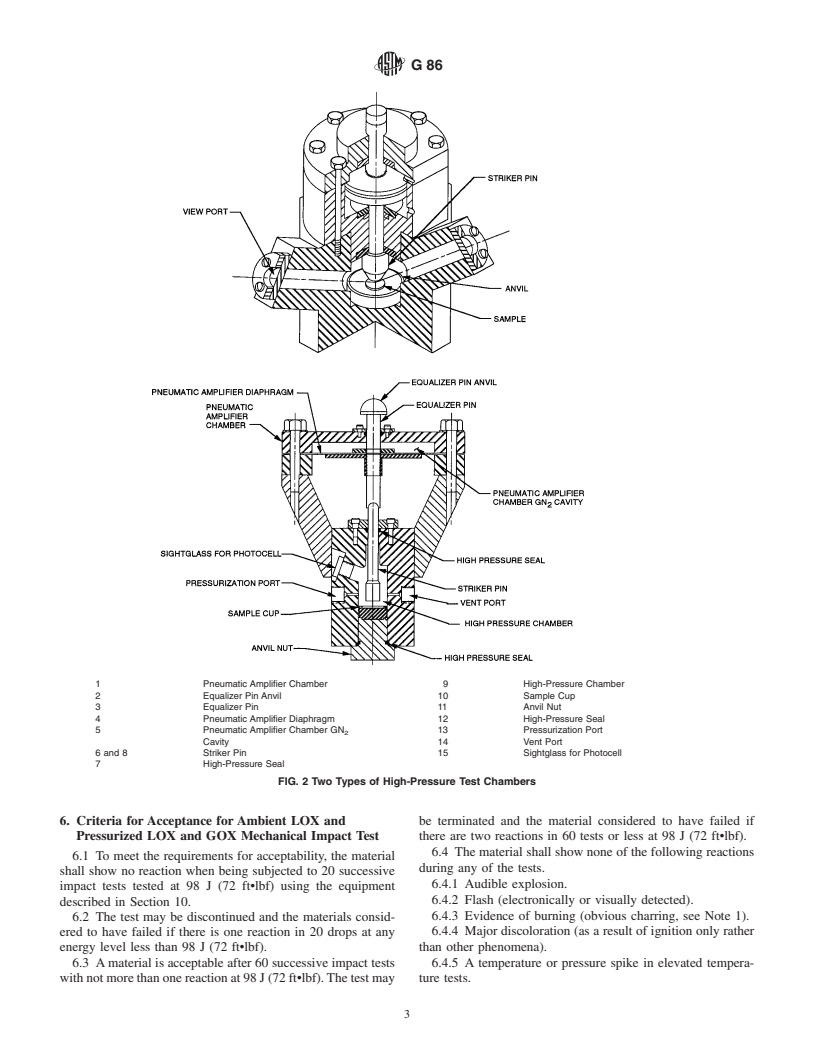

1 Pneumatic Amplifier Chamber 9 High-Pressure Chamber

2 Equalizer Pin Anvil 10 Sample Cup

3 Equalizer Pin 11 Anvil Nut

4 Pneumatic Amplifier Diaphragm 12 High-Pressure Seal

5 Pneumatic Amplifier Chamber GN 13 Pressurization Port

Cavity 14 Vent Port

6 and 8 Striker Pin 15 Sightglass for Photocell

7 High-Pressure Seal

FIG. 2 Two Types of High-Pressure Test Chambers

6. Criteria for Acceptance for Ambient LOX and be terminated and the material considered to have failed if

Pressurized LOX and GOX Mechanical Impact Test there are two reactions in 60 tests or less at 98 J (72 ft•lbf).

6.4 The material shall show none of the following reactions

6.1 To meet the requirements for acceptability, the material

during any of the tests.

shall show no reaction when being subjected to 20 successive

6.4.1 Audible explosion.

impact tests tested at 98 J (72 ft•lbf) using the equipment

6.4.2 Flash (electronically or visually detected).

described in Section 10.

6.4.3 Evidence of burning (obvious charring, see Note 1).

6.2 The test may be discontinued and the materials consid-

6.4.4 Major discoloration (as a result of ignition only rather

ered to have failed if there is one reaction in 20 drops at any

energy level less than 98 J (72 ft•lbf). than other phenomena).

6.3 Amaterial is acceptable after 60 successive impact tests 6.4.5 A temperature or pressure spike in elevated tempera-

withnotmorethanonereactionat98J(72ft•lbf).Thetestmay ture tests.

G86

FIG. 3 Typical Pressurization Piping system for a LOX/GOX Pressurized Test System

NOTE 1—Break sharp edges 0.4 mm.

NOTE 2—The cup is formed by deep drawing.

NOTE 3—The thickness and parallelness of the cup bottom shall be

FIG. 4 Typical Plummet Rebound Limiter Assembly

controlled to 2.0 mm by coining.

NOTE 4—Material: any 3000 or 5000 series aluminum alloy.

NOTE 1—A burnt odor alone is not considered sufficient proof that a

FIG. 5 LOX Impact Tester One-Piece Sample Cup

reaction has occurred. If a reaction occurs (including those during bounce

of plummet), it shall be reported as evidence of sensitivity. Inclusion of

bounce reactions applies to ambient LOX mechanical impact tests only.

6.7 The thickness of the sample shall be the worst-case

6.5 All materials that fail 6.1 criteria and remain candidates thickness. While the worst-case thickness has been found to

for use must be subjected to LOX or GOX mechanical impact vary from material to material, the general trend has been that

energy threshold determinations in the thickness of use. thinner samples of materials are generally more reactive.

6.6 The material to be tested must be traceable back to the 6.8 For the ambient LOX impact test, test conditions (pres-

original manufacturer and to a specific batch or lot numbers, or sure and temperature) are the ambient pressure of the test

both. facility and the boiling point of LOX at that pressure. For the

G86

7.1.2 Materials normally used in thicknesses greater than

6.35 mm ( ⁄4 in.) shall be sized and tested as 17.5-mm diameter

disks of 6.35- 6 0.13-mm (0.250- 6 0.006-in.) thickness.

Failure of samples to meet the requirements of this test method

shall be cause for the rejection of the material. Greases, fluids,

and other materials, whose thicknesses are directed by condi-

tions of use, shall be tested as 1.27- 6 0.13-mm (0.050- 6

0.005-in.) layers in special test cups. Materials not readily

available in sheet form shall be tested in the available configu-

ration. Specimens shall be free of ragged edges, fins, or other

irregularities.

7.2 Liquid Samples—Prepare a homogeneous sample. A

microburette may be used to transfer the sample into special

sample cups 1.27 6 0.13 mm (0.050 6 0.005 in.) deep (see

Fig. 7). For highly viscous materials, a microsyringe may be

used. Determine the volume of the sample required to obtain a

sample thickness of 1.27 6 0.13 mm (0.050 6 0.005 in.) in the

FIG. 6 Typical Sample Freezing Box

sample cup. This determination is required due to variations in

such physical properties as density, surface tension, and

pressurized test, test conditions (pressure and temperature)

volatility from liquid to liquid. A micrometre depth gage with

shall be determined for each test according to the requirements

leveling blocks is suggested for measurement. The work table

specified by the requester.

must be level. Test material should be loaded into the sample

6.9 Preparation of the samples for testing involve the

cup just before loading the cup into the test chamber (or

following tasks.

freezing box, if testing in liquid oxygen).

6.9.1 Receiving the visually inspecting the material.

7.3 Leak Check Compounds, Dye, Dye Penetrant, and

6.9.2 Preparing the sample to the specified dimensions.

Emulsifier, Method 1—Clean, unsealed, sulfuric acid-anodized

6.9.3 Cleaning the samples.

6061-T6aluminumalloydisks(oranyothersubstratespecified

6.9.4 Inspecting the samples.

by the manufacturer or requester), 17.5 mm ( ⁄16 in.) in

diameter by 1.60 mm (0.063 in.) thick are used as a carrier.

7. Sample Preparation

Clean the disks before use (see 11.2.2.1). To ascertain the

7.1 The material to be tested must be traceable back to the

effectiveness of the cleaning procedure, test a minimum of 20

original manufacturer and to specific batch or lot numbers, or

blankdisks.Aftercleaningandblanktesting,dipnewanodized

to both. When received, the test material must be accompanied

disks in the test materials for 15 min and drain for 15 min with

by proper identification, for example, product data sheets,

the disks oriented vertically. Cure the sample as specified, then

batch or lot numbers identifying the sample, material manu-

store the prepared disks in a clean container until required for

facturer, and appropriate material safety data sheets. The

testing.

material must be

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.