ASTM D4688-99(2005)

(Test Method)Standard Test Method for Evaluating Structural Adhesives for Finger Jointing Lumber

Standard Test Method for Evaluating Structural Adhesives for Finger Jointing Lumber

SIGNIFICANCE AND USE

This test method is specifically designed to measure the performance of adhesives in finger joints manufactured under production line conditions.

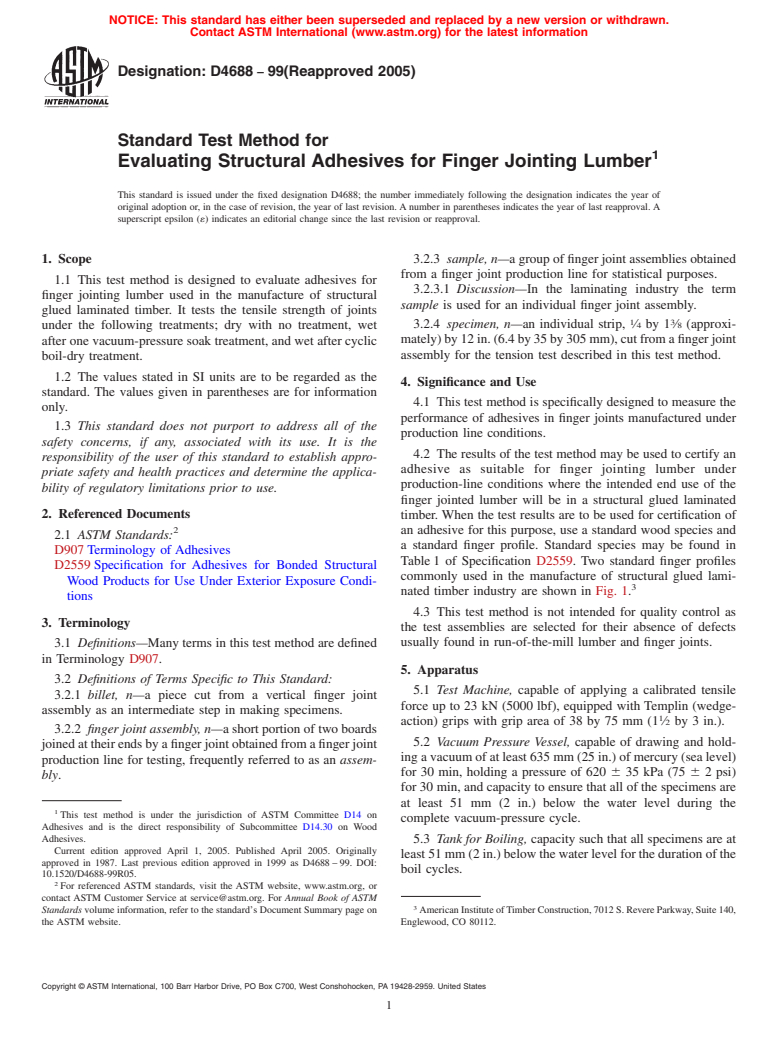

The results of the test method may be used to certify an adhesive as suitable for finger jointing lumber under production-line conditions where the intended end use of the finger jointed lumber will be in a structural glued laminated timber. When the test results are to be used for certification of an adhesive for this purpose, use a standard wood species and a standard finger profile. Standard species may be found in Table 1 of Specification D 2559. Two standard finger profiles commonly used in the manufacture of structural glued laminated timber industry are shown in Fig. 1.3

This test method is not intended for quality control as the test assemblies are selected for their absence of defects usually found in run-of-the-mill lumber and finger joints.

Note—Recommended by American Institute of Timber Construction.3 FIG. 1 Standard Joint Profiles for Certification Tests

SCOPE

1.1 This test method is designed to evaluate adhesives for finger jointing lumber used in the manufacture of structural glued laminated timber. It tests the tensile strength of joints under the following treatments; dry with no treatment, wet after one vacuum-pressure soak treatment, and wet after cyclic boil-dry treatment.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D4688 −99(Reapproved 2005)

Standard Test Method for

1

Evaluating Structural Adhesives for Finger Jointing Lumber

This standard is issued under the fixed designation D4688; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

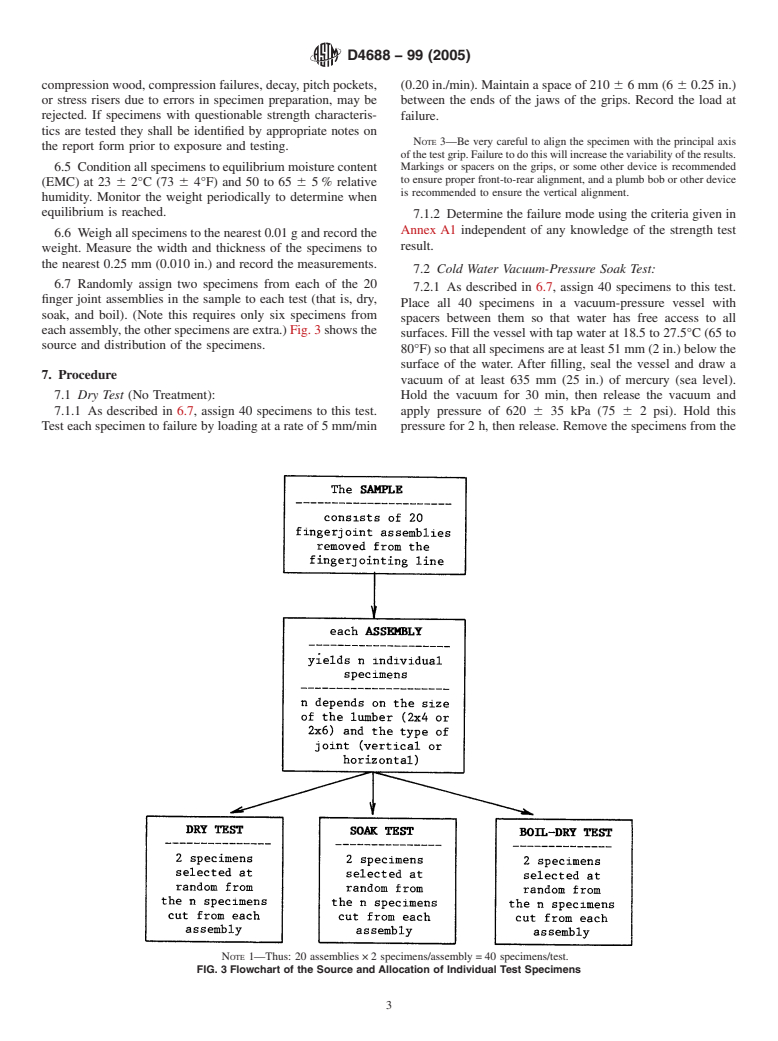

1. Scope 3.2.3 sample, n—agroupoffingerjointassembliesobtained

from a finger joint production line for statistical purposes.

1.1 This test method is designed to evaluate adhesives for

3.2.3.1 Discussion—In the laminating industry the term

finger jointing lumber used in the manufacture of structural

sample is used for an individual finger joint assembly.

glued laminated timber. It tests the tensile strength of joints

1 3

3.2.4 specimen, n—an individual strip, ⁄4 by 1 ⁄8 (approxi-

under the following treatments; dry with no treatment, wet

mately)by12in.(6.4by35by305mm),cutfromafingerjoint

after one vacuum-pressure soak treatment, and wet after cyclic

assembly for the tension test described in this test method.

boil-dry treatment.

1.2 The values stated in SI units are to be regarded as the

4. Significance and Use

standard. The values given in parentheses are for information

4.1 This test method is specifically designed to measure the

only.

performance of adhesives in finger joints manufactured under

1.3 This standard does not purport to address all of the

production line conditions.

safety concerns, if any, associated with its use. It is the

4.2 The results of the test method may be used to certify an

responsibility of the user of this standard to establish appro-

adhesive as suitable for finger jointing lumber under

priate safety and health practices and determine the applica-

production-line conditions where the intended end use of the

bility of regulatory limitations prior to use.

finger jointed lumber will be in a structural glued laminated

2. Referenced Documents timber. When the test results are to be used for certification of

2

an adhesive for this purpose, use a standard wood species and

2.1 ASTM Standards:

a standard finger profile. Standard species may be found in

D907Terminology of Adhesives

Table1 of Specification D2559. Two standard finger profiles

D2559Specification for Adhesives for Bonded Structural

commonly used in the manufacture of structural glued lami-

Wood Products for Use Under Exterior Exposure Condi-

3

nated timber industry are shown in Fig. 1.

tions

4.3 This test method is not intended for quality control as

3. Terminology

the test assemblies are selected for their absence of defects

usually found in run-of-the-mill lumber and finger joints.

3.1 Definitions—Many terms in this test method are defined

in Terminology D907.

5. Apparatus

3.2 Definitions of Terms Specific to This Standard:

5.1 Test Machine, capable of applying a calibrated tensile

3.2.1 billet, n—a piece cut from a vertical finger joint

force up to 23 kN (5000 lbf), equipped with Templin (wedge-

assembly as an intermediate step in making specimens.

1

action) grips with grip area of 38 by 75 mm (1 ⁄2 by 3 in.).

3.2.2 finger joint assembly, n—ashortportionoftwoboards

5.2 Vacuum Pressure Vessel, capable of drawing and hold-

joinedattheirendsbyafingerjointobtainedfromafingerjoint

ingavacuumofatleast635mm(25in.)ofmercury(sealevel)

production line for testing, frequently referred to as an assem-

for 30 min, holding a pressure of 620 6 35 kPa (75 6 2 psi)

bly.

for 30 min, and capacity to ensure that all of the specimens are

at least 51 mm (2 in.) below the water level during the

1

This test method is under the jurisdiction of ASTM Committee D14 on

complete vacuum-pressure cycle.

Adhesives and is the direct responsibility of Subcommittee D14.30 on Wood

Adhesives.

5.3 Tank for Boiling, capacity such that all specimens are at

Current edition approved April 1, 2005. Published April 2005. Originally

least51mm(2in.)belowthewaterlevelforthedurationofthe

approved in 1987. Last previous edition approved in 1999 as D4688–99. DOI:

boil cycles.

10.1520/D4688-99R05.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on AmericanInstituteofTimberConstruction,7012S.RevereParkway,Suite140,

the ASTM website. Englewood, CO 80112.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D4688−99 (2005)

FIG. 2 Finger Joint Assembly and Specimen Descriptions

6.2.3 Plane the second face of the assembly until the finger

3

on the surface is feathered maintain

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.