ASTM F936-85(1991)

(Specification)Specification for Chocks, Panama, Mooring Cast Steel (Withdrawn 1997)

Specification for Chocks, Panama, Mooring Cast Steel (Withdrawn 1997)

General Information

Standards Content (Sample)

ASTM F93b 85 0759530 0503924 2 =

4CTB Designation: F 936 - 85 (Reapproved 1991)

Standard Specification for

Chocks, Panama, Mooring Cast Steel’

This standard is issued under the fixed designation F 936; the number immediately following the designation indicates the year of

original adoption or, in the case of revision. the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

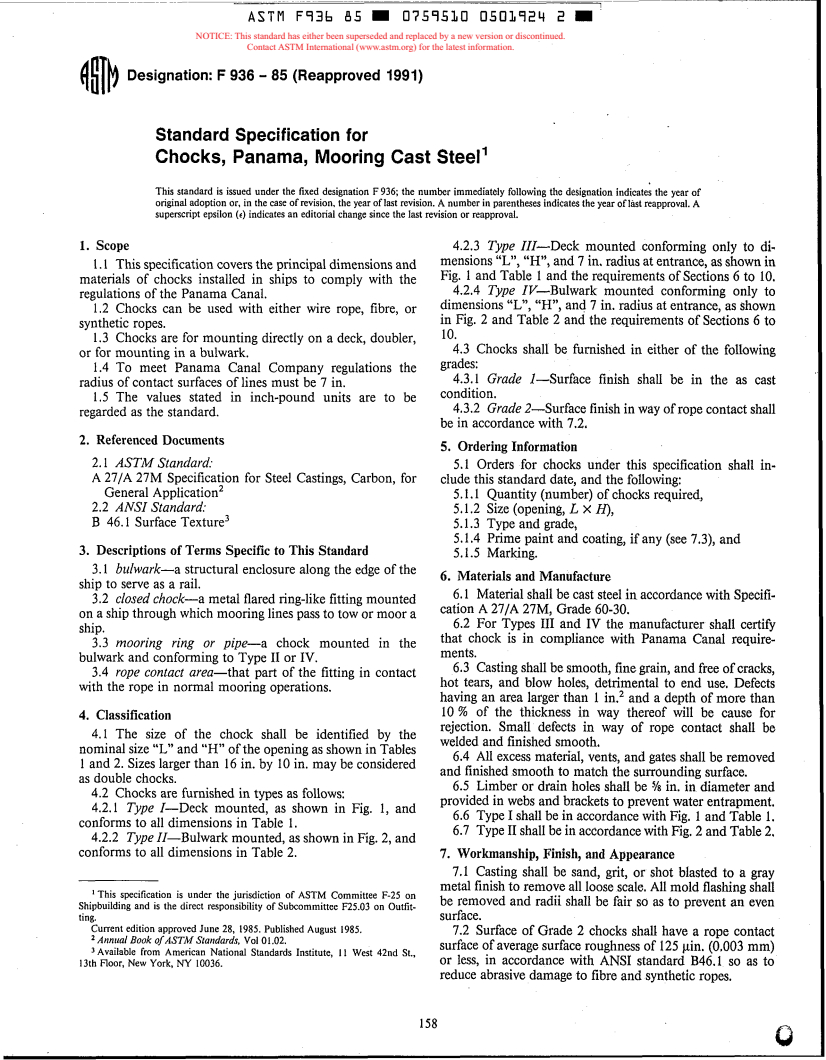

1. Scope 4.2.3 Type III-Deck mounted conforming only to di-

mensions “L”, “”, and 7 in. radius at entrance, as shown in

I. 1 This specification covers the principal dimensions and

Fig. 1 and Table 1 and the requirements of Sections 6 to 10.

materials of chocks installed in ships to comply with the

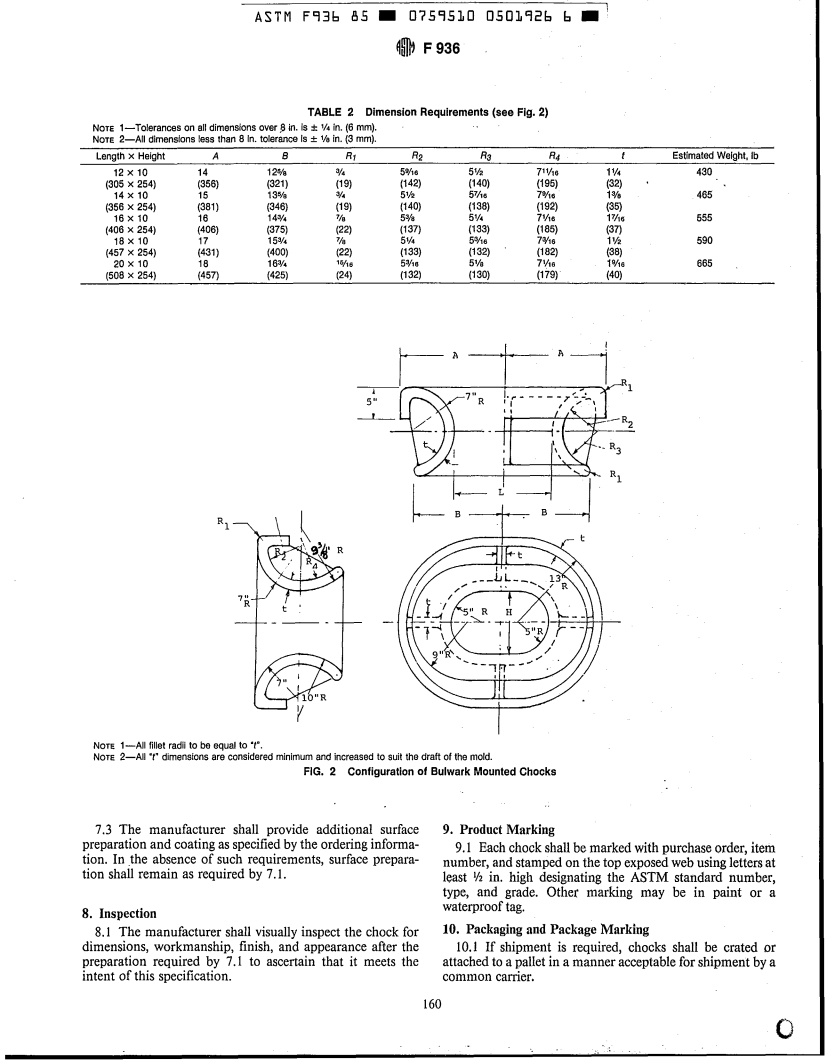

4.2.4 Type ZV-Bulwark mounted conforming only to

regulations of the Panama Canal.

dimensions “L”, “H”, and 7 in. radius at entrance, as shown

1.2 Chocks can be used with either wire rope, fibre, or

in Fig. 2 and Table 2 and the requirements of Sections 6 to

synthetic ropes.

10.

1.3 Chocks are for mounting directly on a deck, doubler,

4.3 Chocks shall be furnished in either of the following

or for mounting in a bulwark.

grades:

1.4 To meet Panama Canal Company regulations the

4.3.1 Grade 1-Surface finish shali be in the as cast

radius of contact surfaces of lines must be 7 in.

condition.

1.5 The values stated in inch-pound units are to be

4.3.2 Grade 2-Surface finish in way of rope contact shall

regarded as the standard.

be in accordance with 7.2.

2. Referenced Documents

5. Ordering Information

2.1 ASTiW Standard:

5.1 Orders for chocks under this specification shall in-

A 27/A 27M Specification for Steel Castings, Carbon, for

clude this standard date, and the following:

General Application2

5. I. 1 Quantity (number) of chocks required,

2.2 ANSI Standard:

5.1.2 Size (opening, L X H),

B 46.1 Surface Texture3 5.1.3 Type and grade,

5.1.4 Prime paint and coating, if any (see 7.3), and

3. Descriptions of Terms Specific to This Standard

5.1.5 Marking.

3.1 biilwark-a structural enclosure along the edge of the

6. Materials and Manufacture

ship to serve as a rail.

6.1 Material shall be cast steel in accordance with Specifi-

3.2 closed chock-a metal flared ring-like fitting mounted

cation A 27/A 27M, Grade 60-30.

on a ship through which mooring lines pass to tow or moor a

6.2 For Types III and IV the manufacturer shall certiSr

ship.

that chock is in compliance with Panama Canal require-

3.3 mooring ring or pipe-a chock mounted in the

ments.

bulwark and conforming to Type II or IV.

6.3 Casting shall be smooth, fine grain, and free of cracks,

3.4 rope contact area-that part of the fitting in contact

hot tears, and blow holes, detrimental to end use. Defects

with the rope in normal mooring operations.

having an area larger than 1 in2 and a depth of more than

10 % of the thickness in way thereof will be cause for

4. Classification

rejection. Small defects in way of rope contact shail be

4.1 The size of the chock shall be identified by the

welded and finished smooth.

nominal size “L” and “H” of the opening as shown in Tables

6.4 All excess maferial, vents, and gates shall be removed

1 and 2. Sizes larger than 16 in. by 10 in. may be considered

and finished smooth to match the surrounding surface.

as double chocks.

6.5 Limber or drain holes shall be Ya in. in diameter and

4.2 Chocks are furnished in types as follows:

provided in webs and brackets to prevent water entrapment.

4.2.1 Type Z-Deck mounted, as shown in Fig. 1, and

6.6 Type I shail be in accordance with Fig. 1 and Table 1.

conforms to all dimensions in Table 1.

6.7 Type II shall be in accordance with Fig. 2 and Table 2.

4.2.2 Type ZZ-Bulwark mounted, as shown in Fig. 2, and

conforms to all dimensions in Table 2. 7. Workmanship, Finish, and Appearance

7.1 Casting shall be sand, grit, or shot blasted to a gray

metal finish to remove all loose scale. All mold flashing shall

‘This specification is under the jurisdiction of ASTM Committee F-25 on

be removed and radii shall be fair so as to prevent an even

Shipbuilding and is the direct responsibility of Subcommittee F25.03 on Outfit-

surface.

ting.

Current edition approved June 28, 1985. Published August 1985.

7.2 Surface of Grade 2 chocks shall have a rope contact

Amiral Book ofASTM Standards, Vol 01.02.

surface of average surface roughness of 125 pin. (0,003 mm)

3 Available from American National Standards Institute, I1 West 42nd St.,

or less, in accordance with ANSI standard B46.1 so as to

13th Floor, New York, NY 10036.

reduce abrasive damage to fibre and synthetic ropes.

158

e3

---------------------- Page: 1 ----------------------

-

~ ~~

~ ~~

ASTI Fî3b 85 0759530 0503925 4

. TABLE 1 Dimension Requirements (see Fig. 1)

NOTE l-Tolerances on all dimensions over 8 in.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.