ASTM C1617-15

(Practice)Standard Practice for Quantitative Accelerated Laboratory Evaluation of Extraction Solutions Containing Ions Leached from Thermal Insulation on Aqueous Corrosion of Metals

Standard Practice for Quantitative Accelerated Laboratory Evaluation of Extraction Solutions Containing Ions Leached from Thermal Insulation on Aqueous Corrosion of Metals

SIGNIFICANCE AND USE

5.1 Corrosion associated with insulation is an important concern for insulation manufacturers, specification writers, designers, contractors, users and operators of the equipment. Some material specifications contain test methods (or reference test methods contained in other material specifications), for use in evaluating the insulation with regard to the corrosion of steel, copper, and aluminum. In some cases these tests are not applicable or effective and have not been evaluated for precision and bias.

5.2 A properly selected, installed, and maintained insulation system will reduce the corrosion that often occurs on an un-insulated structure. However, when the protective weather-resistant covering of an insulation system fails, the conditions for the aqueous environment necessary for corrosion under insulation (CUI) often develop. It is possible the insulation contains, collects, or concentrates corrosive agents, or a combination thereof, often found in industrial and coastal environments. If water is not present, these electrolytes cannot migrate to the metal surface. The electrochemical reaction resulting in the aqueous corrosion of metal surfaces cannot take place in the absence of water and electrolytes. Additional environmental factors contributing to increased corrosion rates are oxygen, and elevated-temperature (near boiling point).

5.3 Chlorides and other corrosive ions are common to many environments. The primary corrosion preventative is to protect insulation and metal from contamination and moisture. Insulation covers, jackets, and metal coating of various kinds are often used to prevent water infiltration and contact with the metal.

5.4 This procedure can be used to evaluate all types of thermal insulation and fireproofing materials (industrial, commercial, residential, cryogenic, fire-resistive, insulating cement) manufactured using inorganic or organic materials, faced or unfaced, for which a filtered extraction solution can be obtained.

...

SCOPE

1.1 This practice covers procedures for a quantitative accelerated laboratory evaluation of the influence of extraction solutions containing ions leached from thermal insulation on the aqueous corrosion of metals. The primary intent of the practice is for use with thermal insulation and associated materials that contribute to, or alternatively inhibit, the aqueous corrosion of different types and grades of metals due to soluble ions that are leached by water from within the insulation. The quantitative evaluation criteria are Mass Loss Corrosion Rate (MLCR) expressed in mils per year determined from the weight loss due to corrosion of exposed metal coupons after they are cleaned.

1.2 The insulation extraction solutions prepared for use in the test can be altered by the addition of corrosive ions to the solutions to simulate contamination from an external source. Ions expected to provide corrosion inhibition can be added to investigate their inhibitory effect.

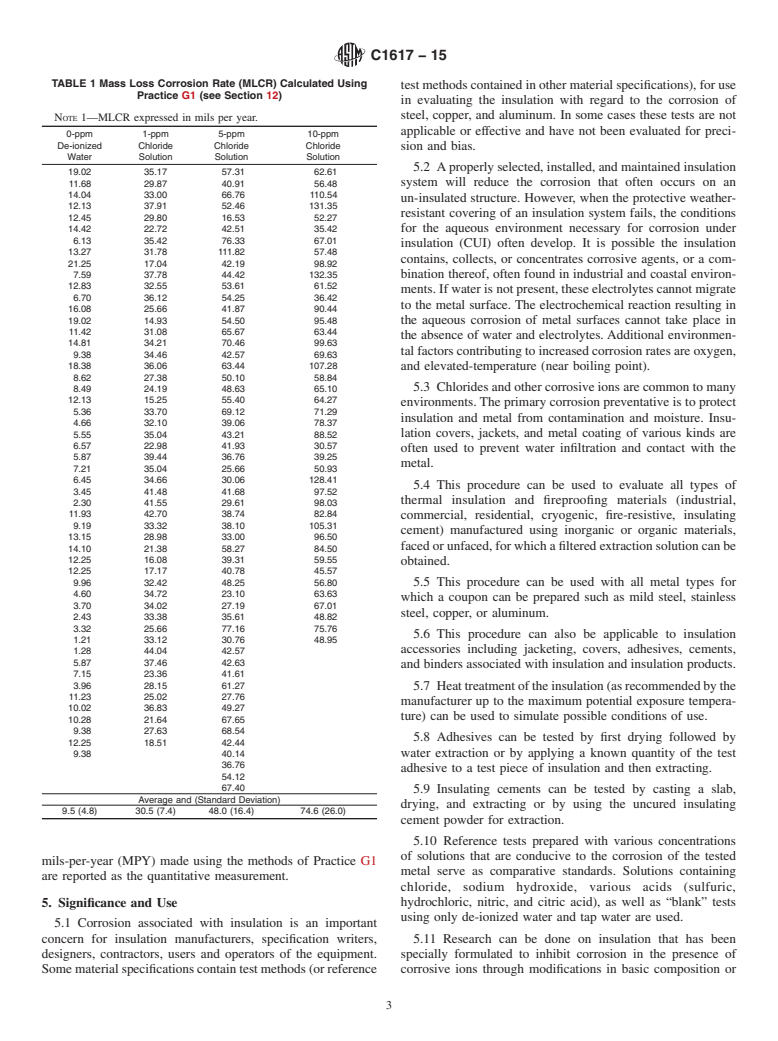

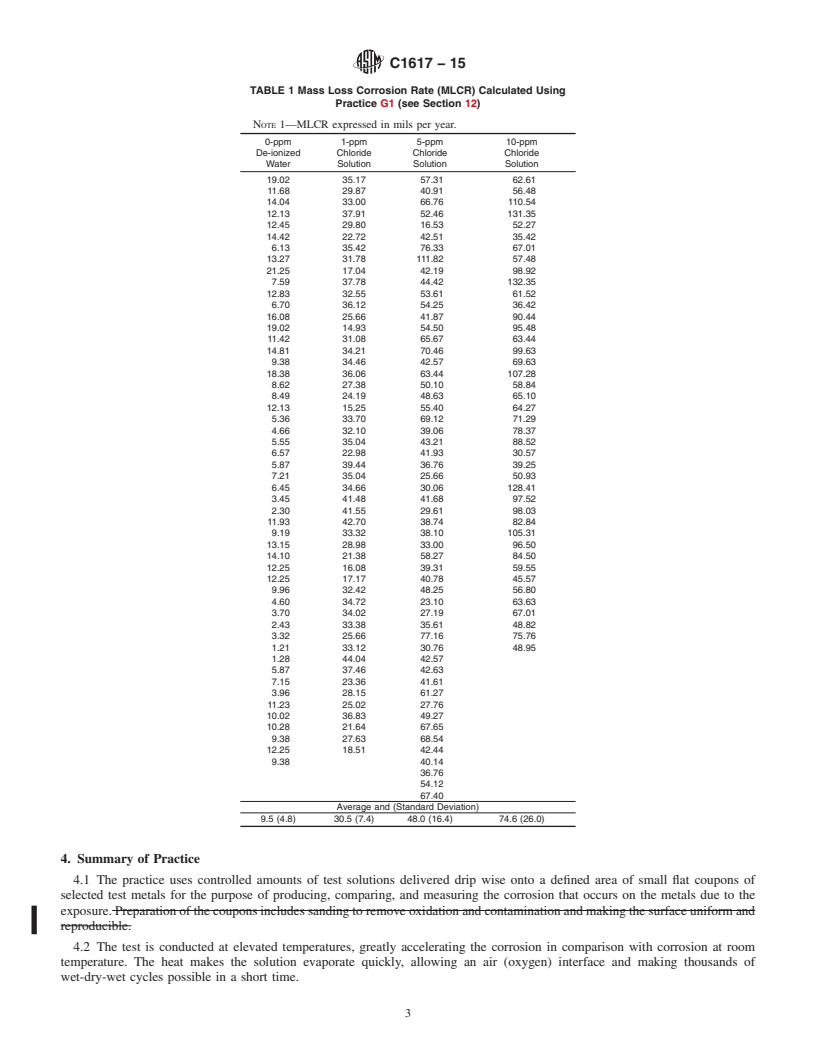

1.3 Prepared laboratory standard solutions are used as reference solutions and controls, to provide a means of calibration and comparison. See Fig. 1 and Table 1.Solution

19.02

35.17

57.31

62.61

11.68

29.87

40.91

56.48

14.04

33.00

66.76

110.54

12.13

37.91

52.46

131.35

12.45

29.80

16.53

52.27

14.42

22.72

42.51

35.42

6.13

35.42

76.33

67.01

13.27

31.78

111.82

57.48

21.25

17.04

42.19

98.92

7.59

37.78

44.42

132.35

12.83

32.55

53.61

61.52

6.70

36.12

54.25

36.42

16.08

25.66

41.87

90.44

19.02

14.93

54.50

95.48

11.42

31.08

65.67

63.44

14.81

34.21

70.46

99.63

9.38

34.46

42.57

69.63

18.38

36.06

63.44

107.28

8.62

27.38

50.10

58.84

8.49

24.19

48.63

65.10

12.13

15.25

55.40

64.27

5.36

33.70

69.12 ...

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C1617 − 15

Standard Practice for

Quantitative Accelerated Laboratory Evaluation of

Extraction Solutions Containing Ions Leached from Thermal

1

Insulation on Aqueous Corrosion of Metals

This standard is issued under the fixed designation C1617; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope is based on general corrosion spread equally over the test

durationandtheexposedareaoftheexperimentalcellscreated

1.1 This practice covers procedures for a quantitative accel-

for the test. Corrosion found in field situations and this

erated laboratory evaluation of the influence of extraction

accelerated test also involves pitting and edge effects and the

solutions containing ions leached from thermal insulation on

rate changes over time.

the aqueous corrosion of metals. The primary intent of the

practice is for use with thermal insulation and associated

1.6 Thevaluesstatedininch-poundunitsaretoberegarded

materialsthatcontributeto,oralternativelyinhibit,theaqueous

as standard. The values given in parentheses are mathematical

corrosionofdifferenttypesandgradesofmetalsduetosoluble

conversions to SI units that are provided for information only

ions that are leached by water from within the insulation. The

and are not considered standard.

quantitative evaluation criteria are Mass Loss Corrosion Rate

1.7 This standard does not purport to address all of the

(MLCR) expressed in mils per year determined from the

safety concerns, if any, associated with its use. It is the

weight loss due to corrosion of exposed metal coupons after

responsibility of the user of this standard to establish appro-

they are cleaned.

priate safety and health practices and determine the applica-

1.2 The insulation extraction solutions prepared for use in

bility of regulatory limitations prior to use.

the test can be altered by the addition of corrosive ions to the

solutions to simulate contamination from an external source.

2. Referenced Documents

Ions expected to provide corrosion inhibition can be added to

2

investigate their inhibitory effect. 2.1 ASTM Standards:

A53/A53MSpecification for Pipe, Steel, Black and Hot-

1.3 Prepared laboratory standard solutions are used as

Dipped, Zinc-Coated, Welded and Seamless

reference solutions and controls, to provide a means of

A105/A105MSpecification for Carbon Steel Forgings for

calibration and comparison. See Fig. 1 and Table 1.

Piping Applications

1.4 Other liquids can be tested for their potential corrosive-

C168Terminology Relating to Thermal Insulation

ness including cooling tower water, boiler feed, and chemical

C518Test Method for Steady-State Thermal Transmission

stocks. Added chemical inhibitors or protective coatings ap-

Properties by Means of the Heat Flow Meter Apparatus

plied to the metal can also be evaluated using the general

C665SpecificationforMineral-FiberBlanketThermalInsu-

guidelines of the practice.

lation for Light Frame Construction and Manufactured

1.5 This practice cannot cover all possible field conditions Housing

thatcontributetoaqueouscorrosion.Theintentistoprovidean C692Test Method for Evaluating the Influence of Thermal

acceleratedmeanstoobtainanon-subjectivenumericvaluefor Insulations on External Stress Corrosion Cracking Ten-

judging the potential contribution to the corrosion of metals dency of Austenitic Stainless Steel

that can come from ions contained in thermal insulation

C739Specification for Cellulosic Fiber Loose-Fill Thermal

materials or other experimental solutions. The calculated Insulation

numeric value is the mass loss corrosion rate. This calculation

C795Specification for Thermal Insulation for Use in Con-

tact with Austenitic Stainless Steel

1

This practice is under the jurisdiction of ASTM Committee C16 on Thermal

InsulationandisthedirectresponsibilityofSubcommitteeC16.31onChemicaland

2

Physical Properties. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved March 1, 2015. Published April 2015. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 2005. Last previous edition approved in 2009 as C1617–09. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/C1617-15. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C1617 − 15

NOTE 1—The Fig. 1 bar graph was created using the MLCR data shown in Table 1. Standard reference tests using de-ionized water, 1 ppm, 5 ppm,

and 10 ppm ch

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: C1617 − 09 C1617 − 15

Standard Practice for

Quantitative Accelerated Laboratory Evaluation of

Extraction Solutions Containing Ions Leached from Thermal

1

Insulation on Aqueous Corrosion of Metals

This standard is issued under the fixed designation C1617; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This practice covers procedures for a quantitative accelerated laboratory evaluation of the influence of extraction solutions

containing ions leached from thermal insulation on the aqueous corrosion of metals. The primary intent of the practice is for use

with thermal insulation and associated materials that contribute to, or alternatively inhibit, the aqueous corrosion of different types

and grades of metals due to soluble ions that are leached by water from within the insulation. The quantitative evaluation criteria

are Mass Loss Corrosion Rate (MLCR) expressed in mils per year determined from the weight loss due to corrosion of exposed

metal coupons after they are cleaned.

1.2 The insulation extraction solutions prepared for use in the test can be altered by the addition of corrosive ions to the solutions

to simulate contamination from an external source. Ions expected to provide corrosion inhibition can be added to investigate their

inhibitory effect.

1.3 Prepared laboratory standard solutions are used as reference solutions and controls, to provide a means of calibration and

comparison. See Fig. 1 and Table 1.

1.4 Other liquids can be tested for their potential corrosiveness including cooling tower water, boiler feed, and chemical stocks.

Added chemical inhibitors or protective coatings applied to the metal can also be evaluated using the general guidelines of the

practice.

1.5 This practice cannot cover all possible field conditions that contribute to aqueous corrosion. The intent is to provide an

accelerated means to obtain a non-subjective numeric value for judging the potential contribution to the corrosion of metals that

can come from ions contained in thermal insulation materials or other experimental solutions. The calculated numeric value is the

mass loss corrosion rate. This calculation is based on general corrosion spread equally over the test duration and the exposed area

of the experimental cells created for the test. Corrosion found in field situations and this accelerated test also involves pitting and

edge effects and the rate changes over time.

1.6 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

A53/A53M Specification for Pipe, Steel, Black and Hot-Dipped, Zinc-Coated, Welded and Seamless

A105/A105M Specification for Carbon Steel Forgings for Piping Applications

C168 Terminology Relating to Thermal Insulation

C518 Test Method for Steady-State Thermal Transmission Properties by Means of the Heat Flow Meter Apparatus

1

This practice is under the jurisdiction of ASTM Committee C16 on Thermal Insulation and is the direct responsibility of Subcommittee C16.31 on Chemical and Physical

Properties.

Current edition approved Nov. 1, 2009March 1, 2015. Published November 2009.April 2015.Originally . Originally approved in 2005. Last previous edition approved in

20052009 as C1617C1617–05.–09. DOI: 10.1520/C1617-09.10.1520/C1617-15.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C1617 − 15

NOTE 1—The Fig. 1 bar graph was created using the MLCR data shown in Table 1. Standard reference tests using de-ionized water, 1 ppm, 5 ppm,

and 10 ppm chl

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.