ASTM D2270-10(2016)

(Practice)Standard Practice for Calculating Viscosity Index from Kinematic Viscosity at 40 °C and 100 °C

Standard Practice for Calculating Viscosity Index from Kinematic Viscosity at 40 °C and 100 °C

SIGNIFICANCE AND USE

4.1 The viscosity index is a widely used and accepted measure of the variation in kinematic viscosity due to changes in the temperature of a petroleum product between 40 °C and 100 °C.

4.2 A higher viscosity index indicates a smaller decrease in kinematic viscosity with increasing temperature of the lubricant.

4.3 The viscosity index is used in practice as a single number indicating temperature dependence of kinematic viscosity.

4.4 Viscosity Index is sometimes used to characterize base oils for purposes of establishing engine testing requirements for engine oil performance categories.6

SCOPE

1.1 This practice2 covers the procedures for calculating the viscosity index of petroleum products, such as lubricating oils, and related materials from their kinematic viscosities at 40 °C and 100 °C.

Note 1: The results obtained from the calculation of VI from kinematic viscosities determined at 40 °C and 100 °C are virtually the same as those obtained from the former VI system using kinematic viscosities determined at 37.78 °C and 98.89 °C.

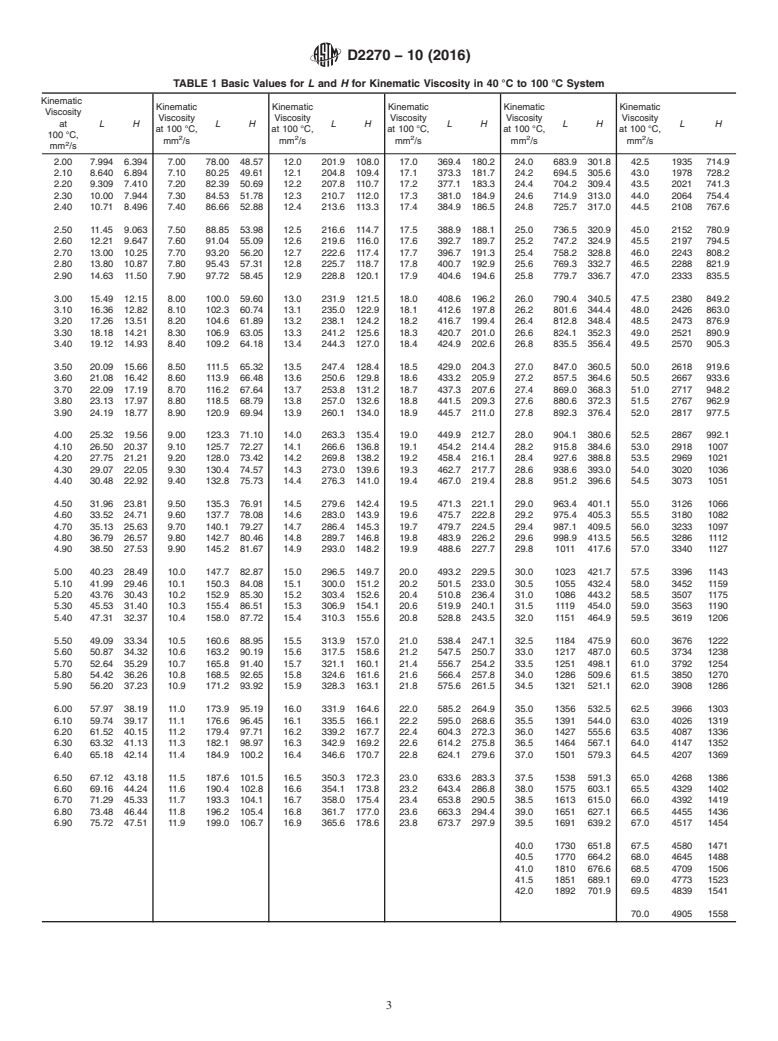

1.2 This practice does not apply to petroleum products with kinematic viscosities less than 2.0 mm2/s at 100 °C. Table 1 given in this practice applies to petroleum products with kinematic viscosities between 2 mm2/s and 70 mm2/s at 100 °C. Equations are provided for calculating viscosity index for petroleum products having kinematic viscosities above 70 mm2/s at 100 °C.

1.2.1 In cases where kinematic viscosity data are not available at temperatures of 40 °C and 100 °C, an estimate may be made of the viscosity index by calculating the kinematic viscosity at temperatures of 40 °C and 100 °C from data obtained at other temperatures. Such viscosity index data may be considered as suitable for information only and not for specification purposes. See Test Method D341, Annex A1.

1.3 The kinematic viscosity values are determined with reference to a value of 1.0034 mm2/s at 20.00 °C for distilled water. The determination of the kinematic viscosity of a petroleum product shall be carried out in accordance with Test Methods D445, D7042, IP 71, or ISO 3104.

1.3.1 If Viscosity Index calculated for a given sample using kinematic viscosity measurements from different test methods are in disagreement, the values calculated from Test Method D445 measurements shall be accepted.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4.1 The values stated in SI units are to be regarded as the standard. For user reference, 1 mm2/s = 10-6m 2/s = 1 cSt.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D2270 − 10 (Reapproved 2016) British Standard 4459

Designation: 226/91 (95)

Standard Practice for

Calculating Viscosity Index from Kinematic Viscosity at

40 °C and 100 °C

This standard is issued under the fixed designation D2270; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 1.3.1 If Viscosity Index calculated for a given sample using

2 kinematic viscosity measurements from different test methods

1.1 This practice covers the procedures for calculating the

are in disagreement, the values calculated from Test Method

viscosity index of petroleum products, such as lubricating oils,

D445 measurements shall be accepted.

and related materials from their kinematic viscosities at 40 °C

and 100 °C. 1.4 The values stated in SI units are to be regarded as

standard. No other units of measurement are included in this

NOTE 1—The results obtained from the calculation of VI from kine-

standard.

matic viscosities determined at 40 °C and 100 °C are virtually the same as

1.4.1 The values stated in SI units are to be regarded as the

those obtained from the former VI system using kinematic viscosities

2 -6 2

determined at 37.78 °C and 98.89 °C.

standard. For user reference, 1 mm/s=10 m /s = 1 cSt.

1.2 This practice does not apply to petroleum products with

1.5 This standard does not purport to address all of the

kinematic viscosities less than 2.0 mm /s at 100 °C. Table 1

safety concerns, if any, associated with its use. It is the

given in this practice applies to petroleum products with

responsibility of the user of this standard to establish appro-

2 2

kinematic viscosities between 2 mm /s and 70 mm /s at

priate safety and health practices and determine the applica-

100 °C. Equations are provided for calculating viscosity index

bility of regulatory limitations prior to use.

for petroleum products having kinematic viscosities above

70 mm /s at 100 °C. 2. Referenced Documents

1.2.1 In cases where kinematic viscosity data are not avail-

2.1 ASTM Standards:

able at temperatures of 40 °C and 100 °C, an estimate may be

D341 Practice for Viscosity-Temperature Charts for Liquid

made of the viscosity index by calculating the kinematic

Petroleum Products

viscosity at temperatures of 40 °C and 100 °C from data

D445 Test Method for Kinematic Viscosity of Transparent

obtained at other temperatures. Such viscosity index data may

and Opaque Liquids (and Calculation of Dynamic Viscos-

be considered as suitable for information only and not for

ity)

specification purposes. See Test Method D341, Annex A1.

D1695 Terminology of Cellulose and Cellulose Derivatives

1.3 The kinematic viscosity values are determined with D7042 Test Method for Dynamic Viscosity and Density of

reference to a value of 1.0034 mm /s at 20.00 °C for distilled Liquids by Stabinger Viscometer (and the Calculation of

water. The determination of the kinematic viscosity of a Kinematic Viscosity)

petroleum product shall be carried out in accordance with Test E29 Practice for Using Significant Digits in Test Data to

Methods D445, D7042, IP 71, or ISO 3104. Determine Conformance with Specifications

2.2 ISO Standards:

ISO 3104 Petroleum Products—Transparent and Opaque

This practice is under the jurisdiction ofASTM Committee D02 on Petroleum

Liquids—Determination of Kinematic Viscosity and Cal-

Products, Liquid Fuels, and Lubricants and is the direct responsibility of Subcom-

mittee D02.07 on Flow Properties.

culation of Dynamic Viscosity

In the IP, this practice is under the jurisdiction of the Standardization Committee

and issued under the fixed designation IP 226. The final number indicates the year

of last revision.

Current edition approved Jan. 1, 2016. Published February 2016. Originally For referenced ASTM standards, visit the ASTM website, www.astm.org, or

ɛ1

approved in 1964. Last previous edition approved in 2010 as D2270 – 10 . DOI: contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

10.1520/D2270-10R16. Standards volume information, refer to the standard’s Document Summary page on

Supporting data (Metrication of Viscosity Index System Method D2270) have the ASTM website.

been filed at ASTM International Headquarters and may be obtained by requesting Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

Research Report RR:D02-1009. 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D2270 − 10 (2016)

2.3 Energy Institute Standard:

L = kinematicviscosityat40 °Cofanoilof0viscosityindex

IP71 Determination of Kinematic Viscosity and Calculation

having the same kinematic viscosity at 100 °C as the oil

of Dynamic Viscosity

whose viscosity index is to be calculated, mm /s,

Y = kinematic viscosity at 100 °C of the oil whose viscosity

3. Terminology index is to be calculated, mm /s, and

H = kinematic viscosity at 40 °C of an oil of 100 viscosity

3.1 Definitions:

index having the same kinematic viscosity at 100 °C as

3.1.1 viscosity index, n—an arbitrary number used to char- 2

the oil whose viscosity index is to be calculated, mm /s.

acterize the variation of the kinematic viscosity of a petroleum

5.2.3 If U> H,calculatetheviscosityindex, VI,oftheoilas

product with temperature.

follows:

3.1.1.1 Discussion—For oils of similar kinematic viscosity,

VI 5 @~L 2 U!/~L 2 H!# 3100 (3)

the higher the viscosity index the smaller the effect of tem-

perature on its kinematic viscosity.

where:

3.1.1.2 Discussion—Viscosity index is also used in Termi-

U = kinematic viscosity at 40 °C of the oil whose viscosity

nology D1695 in a definition unrelated to this one.

index is to be calculated, mm /s.

5.2.3.1 Calculation Example—Measured kinematic viscos-

4. Significance and Use

ity at 40 °C of the oil whose viscosity index is to be

4.1 The viscosity index is a widely used and accepted

calculated = 73.30 mm /s; kinematic viscosity at 100 °C of the

measure of the variation in kinematic viscosity due to changes

oil whose viscosity index is to be calculated = 8.86 mm /s.

in the temperature of a petroleum product between 40 °C and

From Table 1 (by interpolation) L = 119.94

100 °C. From Table 1 (by interpolation) H = 69.48

Substituting in Eq 3 and rounding to the nearest whole

4.2 Ahigher viscosity index indicates a smaller decrease in

number:

kinematic viscosity with increasing temperature of the lubri-

VI 5 @~119.94 2 73.30!/~119.94 2 69.48!# 3100 5 92.43 (4)

cant.

VI 592 (5)

4.3 The viscosity index is used in practice as a single

number indicating temperature dependence of kinematic vis-

5.2.4 If U < H, calculate the viscosity index, VI , of the oil

cosity.

as follows:

VI 5 antilogN 2 1 /0.00715 1100 (6)

@~~ ! ! #

4.4 Viscosity Index is sometimes used to characterize base

oils for purposes of establishing engine testing requirements

where:

for engine oil performance categories.

N 5 logH 2 logU /logY (7)

~ !

5. Procedure

or

N

Y 5 H/U (8)

5.1 Determine the kinematic viscosity of the sample at

40 °C and 100 °C in accordance with Test Method D445, Test

5.2.4.1 Calculation Example—Measured kinematic viscos-

Method D7042, ISO 3104, or IP 71.

ity at 40 °C of the oil whose viscosity index is to be

calculated = 22.83 mm /s; kinematic viscosity at 100 °C of the

5.2 Calculation:

oil whose viscosity index is to be calculated = 5.05 mm /s:

5.2.1 If the kinematic viscosity of the sample at 100 °C is

From Table 1 (by interpolation) H = 28.975

less than or equal to 70 mm /s, extract from Table 1 the

Substituting by Eq 7 (by logarithms):

correspondingvaluesfor Land H.Measuredvaluesthatarenot

listed, but are within the range of Table 1, may be obtained by log 28.975 2 log 22.83

~ ! ~ !

N 5 5 0.14719 (9)

F G

linearinterpolation.Theviscosityindexisnotdefinedandshall log 5.05

~ !

Substituting in Eq 6 and rounding to the nearest whole num-

not be reported for oils with kinematic viscosity of less than

ber:

2.0 mm /s at 100 °C.

antilog~0.14719! 2 1 1.40343 2 1

5.2.2 If the kinematic viscosity is greater than 70 mm /s at

VI 5 1100 5 1100

F G F G

0.00715 0.00715

100 °C, calculate the values of L and H as follows:

2 0.40343

L 5 0.8353 Y 114.67 Y 2 216 (1)

5 1100 5 156.4235 (10)

F G

0.00715

H 5 0.1684 Y 111.85 Y 297 (2)

VI 5 156

where:

5.2.4.2 Calculation Example—Measured kinematic viscos-

ity at 40 °C of the oil whose viscosity index is to be

calculated = 53.47 mm /s; kinematic viscosity at 100 °C of the

Available from Energy Institute, 61 New Cavendish St., London, W1G 7AR, 2

oil whose viscosity index is to be calculated = 7.80 mm /s:

U.K., http://www.energyinst.org.

From Table 1, H = 57.31

API 1509, “Engine Oil Licensing and Certification System, “ 16e, American

Petroleum Institute, April 2007. Substituting in Eq 7 (by logarithms):

D2270 − 10 (2016)

TABLE 1 Basic Values for L andH for Kinematic Viscosity in 40 °C to 100 °C System

Kinematic

Kinematic Kinematic Kinematic Kinematic Kinematic

Viscosity

Viscosity Viscosity Viscosity Viscosity Viscosity

at LH LH LH LH LH LH

at 100 °C, at 100 °C, at 100 °C, at 100 °C, at 100 °C,

100 °C,

2 2 2 2 2

mm /s mm /s mm /s mm /s mm /s

mm /s

2.00 7.994 6.394 7.00 78.00 48.57 12.0 201.9 108.0 17.0 369.4 180.2 24.0 683.9 301.8 42.5 1935 714.9

2.10 8.640 6.894 7.10 80.25 49.61 12.1 204.8 109.4 17.1 373.3 181.7 24.2 694.5 305.6 43.0 1978 728.2

2.20 9.309 7.410 7.20 82.39 50.69 12.2 207.8 110.7 17.2 377.1 183.3 24.4 704.2 309.4 43.5 2021 741.3

2.30 10.00 7.944 7.30 84.53 51.78 12.3 210.7 112.0 17.3 381.0 184.9 24.6 714.9 313.0 44.0 2064 754.4

2.40 10.71 8.496 7.40 86.66 52.88 12.4 213.6 113.3 17.4 384.9 186.5 24.8 725.7 317.0 44.5 2108 767.6

2.50 11.45 9.063 7.50 88.85 53.98 12.5 216.6 114.7 17.5 388.9 188.1 25.0 736.5 320.9 45.0 2152 780.9

2.60 12.21 9.647 7.60 91.04 55.09 12.6 219.6 116.0 17.6 392.7 189.7 25.2 747.2 324.9 45.5 2197 794.5

2.70 13.00 10.25 7.70 93.20 56.20 12.7 222.6 117.4 17.7 396.7 191.3 25.4 758.2 328.8 46.0 2243 808.2

2.80 13.80 10.87 7.80 95.43 57.31 12.8 225.7 118.7 17.8 400.7 192.9 25.6 769.3 332.7 46.5 2288 821.9

2.90 14.63 11.50 7.90 97.72 58.45 12.9 228.8 120.1 17.9 404.6 194.6 25.8 779.7 336.7 47.0 2333 835.5

3.00 15.49 12.15 8.00 100.0 59.60 13.0 231.9 121.5 18.0 408.6 196.2 26.0 790.4 340.5 47.5 2380 849.2

3.10 16.36 12.82 8.10 102.3 60.74 13.1 235.0 122.9 18.1 412.6 197.8 26.2 801.6 344.4 48.0 2426 863.0

3.20 17.26 13.51 8.20 104.6 61.89 13.2 238.1 124.2 18.2 416.7 199.4 26.4 812.8 348.4 48.5 2473 876.9

3.30 18.18 14.21 8.30 106.9 63.05 13.3 241.2 125.6 18.3 420.7 201.0 26.6 824.1 352.3 49.0 2521 890.9

3.40 19.12 14.93 8.40 109.2 64.18 13.4 244.3 127.0 18.4 424.9 202.6 26.8 835.5 356.4 49.5 2570 905.3

3.50 20.09 15.66 8.50 111.5 65.32 13.5 247.4 128.4 18.5 429.0 204.3 27.0 847.0 360.5 50.0 2618 919.6

3.60 21.08 16.42 8.60 113.9 66.48 13.6 250.6 129.8 18.6 433.2 205.9 27.2 857.5 364.6 50.5 2667 933.6

3.70 22.09 17.19 8.70 116.2 67.64 13.7 253.8 131.2 18.7 437.3 207.6 27.4 869.0 368.3 51.0 2717 948.2

3.80 23.13 17.97 8.80 118.5 68.79 13.8 257.0 132.6 18.8 441.5 209.3 27.6 880.6 372.3 51.5 2767 962.9

3.90 24.19 18.77 8.90 120.9 69.94 13.9 260.1 134.0 18.9 445.7 211.0 27.8 892.3 376.4 52.0 2817 977.5

4.00 25.32 19.56 9.00 123.3 71.10 14.0 263.3 135.4 19.0 449.9 212.7 28.0 904.1 380.6 52.5 2867 992.1

4.10 26.50 20.37 9.10 125.7 72.27 14.1 266.6 136.8 19.1 454.2 214.4 28.2 915.8 384.6 53.0 2918 1007

4.20 27.75 21.21 9.20 128.0 73.42 14.2 269.8 138.2 19.2 458.4 216.1 28.4 927.6 388.8 53.5 2969 1021

4.30 29.07 22.05 9.30 130.4 74.57 14.3 273.0 139.6 19.3 462.7 217.7 28.6 938.6 393.0 54.0 3020 1036

4.40 30.48 22.92 9.40 132.8 75.73 14.4 276.3 141.0 19.4 467.0 219.4 28.8 951.2 396.6 54.5 3073 1051

4.50 31.96 23.81 9.50 135.3 76.91 14.5 279.6 142.4 19.5 471.3 221.1 29.0 963.4 401.1 55.0 3126 1066

4.60 33.52 24.71 9.60 137.7 78.08 14.6 283.0 143.9 19.6 475.7 222.8 29.2 975.4 405.3 55.5 3180 1082

4.70 35.13 25.63 9.70 140.1 79.27 14.7 286.4 145.3 19.7 479.7 224.5 29.4 987.1 409.5 56.0 3233 1097

4.80 36.79 26.57 9.80 142.7 80.46 14.8 289.7 146.8 19.8 483.9 226.2 29.6 998.9 413.5 56.5 3286 1112

4.90 38.50 27.53 9.90 145.2 81.67 14.9 293.0 148.2 19.9 488.6 227.7 29.8 1011 417.6 57.0 3340 1127

5.00 40.23 28.49 10.0 147.7 82.87 15.0 296.5 149.7 20.0 493.2 229.5 30.0 1023 421.7 57.5 3396 1143

5.10 41.99 29.46 10.1 150.3 84.08 15.1 300.0 151.2 20.2 501.5 233.0 30.5 1055 432.4 58.0 3452 1159

5.20 43.76 30.43 10.2 152.9 85.30 15.2 303.4 152.6 20.4 510.8 236.4 31.0 1086 443.2 58.5 3507 1175

5.30 45.53 31.40 10.3 155.4 86.51 15.3 306.9 154.1 20.6 519.9 240.1 31.5 1119 454.0 59.0 3563 1190

5.40 47.31 32.37 10.4 158.0 87.72 15.4 310.3 155.6 20.8 528.8 243.5 32.0 1151 464.9 59.5 3619 1206

5.50 49.09 33.34 10.5 160.6 88.95 15.5 313.9 157.0 21.0 538.4 247.1 32.5 1184 475.9 60.0 3676 1222

5.60 50.87 34.32 10.6 163.2 90.19 15.6 317.5 158.6 21.2 547.5 250.7 33.0 1217 487.0 60.5 3734 1238

5.70 52.64 35.29 10.7 165.8 91.40 15.7 321.1 160.1 21.4 556.7 254.2 33.5 1251 498.1 61.0 3792 1254

5.80 54.42 36.26 10.8 168.5 92.65 15.8 324.6 161.6 21.6 566.4 257.8 34.0 1286 509.6 61.5 3850 1270

5.90 56.20 37.23 10.9 171.2 93.92 15.9 328.3 163.1 21.8 575.6 261.5 34.5 1321 521.1 62.0 3908 1286

6.00 57.97 38.19 11.0 173.9 95.19 16.0 331.9 164.6 22.0 585.2 264.9 35.0 1356 532.5 62.5 3966 1303

6.10 59.74 39.17 11.1 176.6 96.45 16.1 335.5 166.1 22.2 595.0 268.6 35.5 1391 544.0 63.0 4026 1319

6.20 61.52 40.15 11.2 179.4 97.71 16.2 339.2 167.7 22.4 604.3 272.3 36.0 1427 555.6 63.5 4087 1336

6.30 63.32 41.13 11.3 182.1 98.97 16.3 342.9 169.2 22.6 614.2 275.8 36.5 1464 567.1 64.0 4147 1352

6.40 65.18 42.14 11.4 184.9 100.2 16.4 346.6 170.7 22.8 624.1 279.6 37.0 1501 579.3 64.5 4207 1369

6.50 67.12 43.18 11.5 187.6 101.5 16.5 350.3 172.3 23.0 633.6 283.3 37.5 1538 591.3 65.0 4268 1386

6.60 69.16 44.24 11.6 190.4 102.8 16.6 354.1 173.8 23.2 643.4 286.8 38.0 1575 603.1 65.5 4329 1402

6.70 71.29 45.33 11.7 193.3 104.1 16.7 358.0 175.4 23.4 653.8 290.5 38.5 1613 615.0 66.0 4392 1419

6.80 73.48 46.44 11.8 196.2 105.4 16.8 361.7 177.0 23.6 663.3 294.4 39.0 1651 627.1 66.5 4455 1436

6.90 75.72 47.51 11.9 199.0 106.7 16.9 365.6 178.6 23.8 673.7 297.9 39.5 1691 639.2 67.0 4517 1454

40.0 1730 651.8 67.5 4580 1471

40.5 1770 664.2 68.0 4645 1488

41.0

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.