ASTM E1966-07(2011)

(Test Method)Standard Test Method for Fire-Resistive Joint Systems

Standard Test Method for Fire-Resistive Joint Systems

SIGNIFICANCE AND USE

This test method evaluates, under the specified test conditions: (1) the ability of a fire resistive joint system to undergo movement without reducing the fire rating of the adjacent fire separating elements and (2) the duration for which test specimens will contain a fire and retain their integrity during a predetermined test exposure.

This test method provides for the following measurements and evaluations where applicable:

Capability of the joint system to movement cycle.

Loadbearing capacity of the joint system.

Ability of the joint system to prohibit the passage of flames and hot gases.

Transmission of heat through the joint system.

Ability of the joint system, that is an extension of a wall, to resist the passage of water during a hose stream test.

This test method does not provide the following:

Evaluation of the degree by which the joint system contributes to the fire hazard by generation of smoke, toxic gases, or other products of combustion.

Measurement of the degree of control or limitation of the passage of smoke or products of combustion through the joint system.

Measurement of flame spread over the surface of the joint system.

Note 1—The information in 5.3.1-5.3.3 may be determined by other suitable fire test methods. For example, 5.3.3 may be determined by Test Method E84.

Evaluation of joints formed by the rated or non-rated exterior walls and the floors of the building.

In this procedure, the test specimens are subjected to one or more specific sets of laboratory test conditions. When different test conditions are substituted or the end-use conditions are changed, it is not always possible by, or from, this test method to predict changes to the characteristics measured. Therefore, the results are valid only for the exposure conditions described in this test method.

SCOPE

1.1 This fire-test-response test method measures the performance of joint systems designed to be used with fire rated floors and walls during a fire endurance test exposure. The fire endurance test end point is the period of time elapsing before the first performance criteria is reached when the joint system is subjected to one of two time-temperature fire exposures.

1.2 The fire exposure conditions used are either those specified by Test Method E119 for testing assemblies to standard time-temperature exposures or Test Method E1529 for testing assemblies to rapid-temperature rise fires.

1.3 This test method specifies the heating conditions, methods of test, and criteria for the evaluation of the ability of a joint system to maintain the fire resistance where hourly rated fire-separating elements meet.

1.4 Test results establish the performance of joint systems during the fire-exposure period and shall not be construed as having determined the joint systems suitability for use after that exposure.

1.5 This test method does not provide quantitative information about the joint system relative to the rate of leakage of smoke or gases or both. However, it requires that such phenomena be noted and reported when describing the general behavior of joint systems during the fire endurance test but is not part of the conditions of compliance.

1.6 Potentially important factors and fire characteristics not addressed by this test method include, but are not limited to:

1.6.1 The performance of the fire-resistive joint system constructed with components other than those tested.

1.6.2 The cyclic movement capabilities of joint systems other than the cycling conditions tested.

1.7 The values stated in inch-pound units are to be regarded as the standard. The SI values given in parentheses are for information only.

1.8 The text of this standard references notes and footnotes which provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of the standard.

1.9 This standard is used to measure and describe...

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E1966 − 07(Reapproved 2011) An American National Standard

Standard Test Method for

Fire-Resistive Joint Systems

This standard is issued under the fixed designation E1966; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

Joint systems are positioned in joints, voids, gaps, or other discontinuities between or bounded by

two or more supporting elements. Normally such openings are denoted as “linear” because the length

is greater than their width—defined by a typical ratio of at least 10:1 as in practice. Joints are present

in buildings as a result of:

(i) Design to accommodate various movements induced by thermal differentials, seismicity, and

wind loads and exist as a clearance separation.

(ii) Acceptable dimensional tolerances between two or more building elements, for example,

between non-loadbearing walls and floors.

(iii) Inadequate design, inaccurate assembly, repairs or damage to the building.

1. Scope behavior of joint systems during the fire endurance test but is

not part of the conditions of compliance.

1.1 This fire-test-response test method measures the perfor-

mance of joint systems designed to be used with fire rated

1.6 Potentially important factors and fire characteristics not

floors and walls during a fire endurance test exposure. The fire

addressed by this test method include, but are not limited to:

endurance test end point is the period of time elapsing before

1.6.1 The performance of the fire-resistive joint system

the first performance criteria is reached when the joint system

constructed with components other than those tested.

is subjected to one of two time-temperature fire exposures.

1.6.2 The cyclic movement capabilities of joint systems

1.2 The fire exposure conditions used are either those

other than the cycling conditions tested.

specified by Test Method E119 for testing assemblies to

1.7 The values stated in inch-pound units are to be regarded

standardtime-temperatureexposuresorTestMethodE1529for

as the standard. The SI values given in parentheses are for

testing assemblies to rapid-temperature rise fires.

information only.

1.3 This test method specifies the heating conditions, meth-

1.8 The text of this standard references notes and footnotes

ods of test, and criteria for the evaluation of the ability of a

which provide explanatory material. These notes and footnotes

joint system to maintain the fire resistance where hourly rated

(excluding those in tables and figures) shall not be considered

fire-separating elements meet.

as requirements of the standard.

1.4 Test results establish the performance of joint systems

1.9 This standard is used to measure and describe the

during the fire-exposure period and shall not be construed as

response of materials, products, or assemblies to heat and

having determined the joint systems suitability for use after

flame under controlled conditions, but does not by itself

that exposure.

incorporate all factors required for fire hazard or fire risk

1.5 This test method does not provide quantitative informa-

assessment of the materials, products, or assemblies under

tion about the joint system relative to the rate of leakage of

actual fire conditions.

smoke or gases or both. However, it requires that such

1.10 Fire testing is inherently hazardous. Adequate safe-

phenomena be noted and reported when describing the general

guards for personnel and property shall be employed in

conducting these tests.

1.11 This standard does not purport to address all of the

This test method is under the jurisdiction of ASTM Committee E05 on Fire

Standards and is the direct responsibility of Subcommittee E05.11 on Fire

safety concerns, if any, associated with its use. It is the

Resistance.

responsibility of the user of this standard to establish appro-

Current edition approved July 1, 2011. Published September 2011. Originally

priate safety and health practices and determine the applica-

approved in 1998. Last previous edition approved in 2007 as E1966–07. DOI:

10.1520/E1966-07R11. bility of regulatory limitations prior to use.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E1966 − 07 (2011)

2. Referenced Documents 4.1.1 When the maximum joint width does not equal the

2 minimum joint width, joint systems shall be movement cycled

2.1 ASTM Standards:

before being fire tested.

E84 Test Method for Surface Burning Characteristics of

4.1.2 Joint systems and their supporting construction shall

Building Materials

be conditioned and fire tested.

E119 Test Methods for Fire Tests of Building Construction

4.1.3 A duplicate test specimen, that is an extension of a

and Materials

wall, is subject to a fire of lesser duration than the fire

E176 Terminology of Fire Standards

resistance rating. After which, the duplicate test specimen is

E631 Terminology of Building Constructions

subject to the hose stream test.

E1529 Test Methods for Determining Effects of Large Hy-

drocarbon Pool Fires on Structural Members and Assem-

5. Significance and Use

blies

E2226 Practice for Application of Hose Stream

5.1 This test method evaluates, under the specified test

E2307 Test Method for Determining Fire Resistance of

conditions: (1) the ability of a fire resistive joint system to

Perimeter Fire Barriers Using Intermediate-Scale, Multi-

undergo movement without reducing the fire rating of the

story Test Apparatus

adjacentfireseparatingelementsand(2)thedurationforwhich

test specimens will contain a fire and retain their integrity

3. Terminology

during a predetermined test exposure.

3.1 Definitions:

5.2 This test method provides for the following measure-

3.1.1 For the purpose of this standard, the definitions given

ments and evaluations where applicable:

in Terminologies E176 and E631, together with the following,

5.2.1 Capability of the joint system to movement cycle.

apply:

5.2.2 Loadbearing capacity of the joint system.

3.1.2 fire-separating element, n—floors, walls, and parti-

5.2.3 Ability of the joint system to prohibit the passage of

tions having a period of fire resistance determined in accor-

flames and hot gases.

dance with Test Methods E119 or E1529.

5.2.4 Transmission of heat through the joint system.

3.1.3 fire resistive joint system, n—a device or designed

5.2.5 Ability of the joint system, that is an extension of a

feature that provides a fire separating function along continu-

wall, to resist the passage of water during a hose stream test.

ous linear openings, including changes in direction, between or

bounded by fire separating elements.

5.3 This test method does not provide the following:

3.1.4 joint, n—the linear void located between juxtaposed 5.3.1 Evaluation of the degree by which the joint system

contributes to the fire hazard by generation of smoke, toxic

fire-separating elements.

gases, or other products of combustion.

3.1.5 maximum joint width, n—the widest opening of an

5.3.2 Measurement of the degree of control or limitation of

installed joint system.

the passage of smoke or products of combustion through the

3.1.6 minimum joint width, n—the narrowest opening of an

joint system.

installed joint system.

5.3.3 Measurement of flame spread over the surface of the

3.1.7 movement cycle, n—the change between the minimum

joint system.

and the maximum joint widths of a joint system.

NOTE 1—The information in 5.3.1 – 5.3.3 may be determined by other

3.1.8 nominal joint width, n—the specified opening of a

suitable fire test methods. For example, 5.3.3 may be determined by Test

joint in practice that is selected for test purposes.

Method E84.

3.1.9 splice, n—the connection or junction within the length

5.3.4 Evaluation of joints formed by the rated or non-rated

of a joint system.

exterior walls and the floors of the building.

3.1.10 supporting construction, n—the arrangement of

5.4 Inthisprocedure,thetestspecimensaresubjectedtoone

building sections forming the fire-separating elements into

or more specific sets of laboratory test conditions. When

which the joint systems are installed.

different test conditions are substituted or the end-use condi-

3.1.11 test assembly, n—the complete assembly of test

tions are changed, it is not always possible by, or from, this test

specimens together with their supporting construction.

method to predict changes to the characteristics measured.

3.1.12 test specimen, n—a joint system of a specific Therefore,theresultsarevalidonlyfortheexposureconditions

described in this test method.

material(s), design, and width.

4. Summary of Test Method

6. Apparatus

4.1 This test method describes the following test sequence

6.1 Cycling Apparatus—Equipment (or device) capable of

and procedure:

being used to induce movement of a joint system and meeting

the required cyclic rate and number of cycles selected from

Table 1.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

6.2 Furnace—An enclosed furnace facility capable of con-

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. trolling a fire to the time-temperature curve in Test Methods

E1966 − 07 (2011)

TABLE 1 Conditions of Test Specimen Cycling

NOTE 1—The terms used for movement are indicative of the cyclic rate

in expansion and contraction of the joint system and not of the magnitude

or direction of movement.

Movement Type Minimum Minimum Number of

Cycling Rates (cpm) Movement Cycles

Type I—Thermal 1 500

Type II—Wind Sway 10 500

Type III—Seismic 30 100

Type IV—Combined Move- 30 100

ment

followed by: 10 400

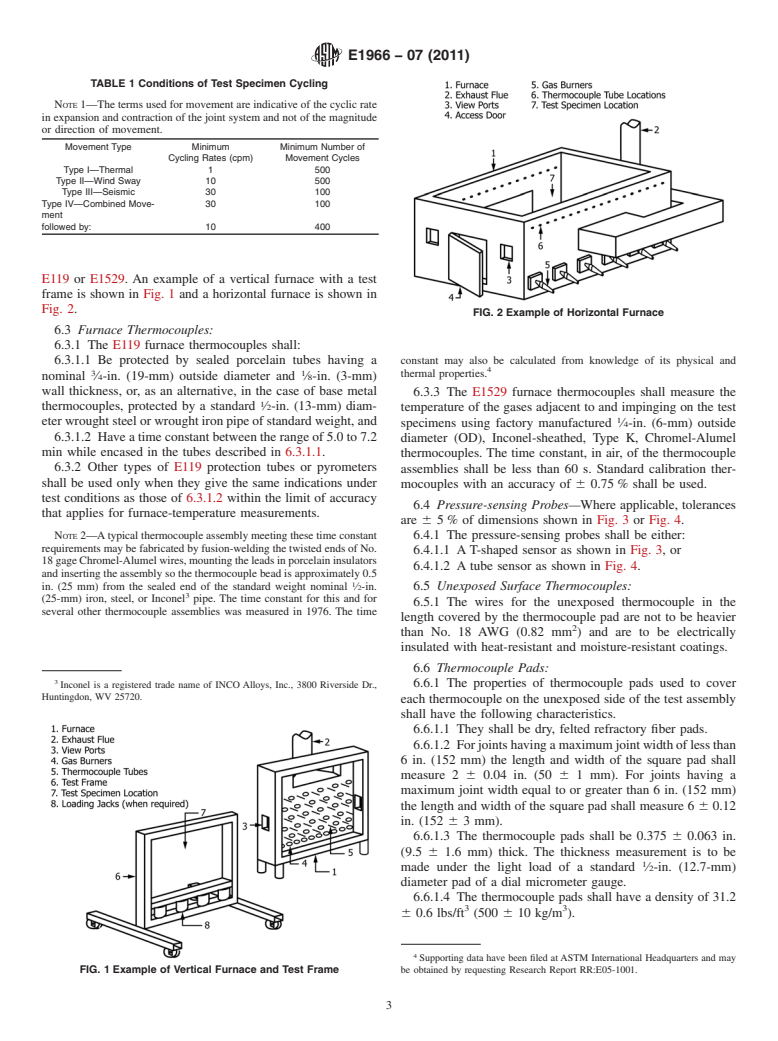

E119 or E1529. An example of a vertical furnace with a test

frame is shown in Fig. 1 and a horizontal furnace is shown in

Fig. 2.

FIG. 2 Example of Horizontal Furnace

6.3 Furnace Thermocouples:

6.3.1 The E119 furnace thermocouples shall:

6.3.1.1 Be protected by sealed porcelain tubes having a constant may also be calculated from knowledge of its physical and

3 1

thermal properties.

nominal ⁄4-in. (19-mm) outside diameter and ⁄8-in. (3-mm)

wall thickness, or, as an alternative, in the case of base metal

6.3.3 The E1529 furnace thermocouples shall measure the

thermocouples, protected by a standard ⁄2-in. (13-mm) diam-

temperature of the gases adjacent to and impinging on the test

eter wrought steel or wrought iron pipe of standard weight, and

specimens using factory manufactured ⁄4-in. (6-mm) outside

6.3.1.2 Have a time constant between the range of 5.0 to 7.2 diameter (OD), Inconel-sheathed, Type K, Chromel-Alumel

min while encased in the tubes described in 6.3.1.1.

thermocouples. The time constant, in air, of the thermocouple

6.3.2 Other types of E119 protection tubes or pyrometers

assemblies shall be less than 60 s. Standard calibration ther-

shall be used only when they give the same indications under

mocouples with an accuracy of 6 0.75 % shall be used.

test conditions as those of 6.3.1.2 within the limit of accuracy

6.4 Pressure-sensing Probes—Where applicable, tolerances

that applies for furnace-temperature measurements.

are 6 5 % of dimensions shown in Fig. 3 or Fig. 4.

NOTE 2—Atypical thermocouple assembly meeting these time constant 6.4.1 The pressure-sensing probes shall be either:

requirements may be fabricated by fusion-welding the twisted ends of No.

6.4.1.1 A T-shaped sensor as shown in Fig. 3,or

18gageChromel-Alumelwires,mountingtheleadsinporcelaininsulators

6.4.1.2 A tube sensor as shown in Fig. 4.

and inserting the assembly so the thermocouple bead is approximately 0.5

in. (25 mm) from the sealed end of the standard weight nominal ⁄2-in.

6.5 Unexposed Surface Thermocouples:

(25-mm) iron, steel, or Inconel pipe. The time constant for this and for

6.5.1 The wires for the unexposed thermocouple in the

several other thermocouple assemblies was measured in 1976. The time

length covered by the thermocouple pad are not to be heavier

than No. 18 AWG (0.82 mm ) and are to be electrically

insulated with heat-resistant and moisture-resistant coatings.

6.6 Thermocouple Pads:

Inconel is a registered trade name of INCO Alloys, Inc., 3800 Riverside Dr., 6.6.1 The properties of thermocouple pads used to cover

Huntingdon, WV 25720.

each thermocouple on the unexposed side of the test assembly

shall have the following characteristics.

6.6.1.1 They shall be dry, felted refractory fiber pads.

6.6.1.2 Forjointshavingamaximumjointwidthoflessthan

6 in. (152 mm) the length and width of the square pad shall

measure 2 6 0.04 in. (50 6 1 mm). For joints having a

maximum joint width equal to or greater than 6 in. (152 mm)

the length and width of the square pad shall measure 6 6 0.12

in. (152 6 3 mm).

6.6.1.3 The thermocouple pads shall be 0.375 6 0.063 in.

(9.5 6 1.6 mm) thick. The thickness measurement is to be

made under the light load of a standard ⁄2-in. (12.7-mm)

diameter pad of a dial micrometer gauge.

6.6.1.4 The thermocouple pads shall have a density of 31.2

3 3

6 0.6 lbs/ft (500 6 10 kg/m ).

Supporting data have been filed at ASTM International Headquarters and may

FIG. 1 Example of Vertical Furnace and Test Frame be obtained by requesting Research Report RR:E05-1001.

E1966 − 07 (2011)

FIG. 3 “T” Shaped Pressure Sensing Probe

FIG. 4 Tube Type Pressure Sensing Probe

6.6.1.5 The thermal conductivity of the thermocouple pads pounds-mass (0.91 kg) and an additional major load of 10

at 150°F (66°C) shall be 0.37 6 0.03 Btu -in./h -ft -°F [0.053 pounds-mass (4.5 kg) [12 pounds-mass (5.4 kg) total load].

6 0.004 W/(m -K)]. The hardness is obtained by the relationship:

6.6.1.6 The thermocouple pads shall have a hardness (on Hardness = 2.24/y

soft face) of 2.25 to 4.5 (modified Brinnell). The hardness

where:

measurement is to be made by pressing a standard 1-in.

y = the difference in indentation [in. (mm)].

(25-mm) diameter steel ball against the specimen and measur-

ing the indentation obtained between a minor load of 2 6.7 Differential Pressure Measurement Instruments:

E1966 − 07 (2011)

6.7.1 The differential pressure measurement instrument nipple, shall be centered in its length, and shall not protrude

shall be: into the water stream.

6.7.1.1 A manometer or equivalent transducer. 6.10.1.5 A suitable pressure gage capable of reading a

6.7.1.2 Capable of reading in graduated increments of no minimum of 0-50 psi (0-344.8 kPa) and graduated into no

greater than 0.01 in H O (2.5 Pa) w

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.