ASTM E1966-15

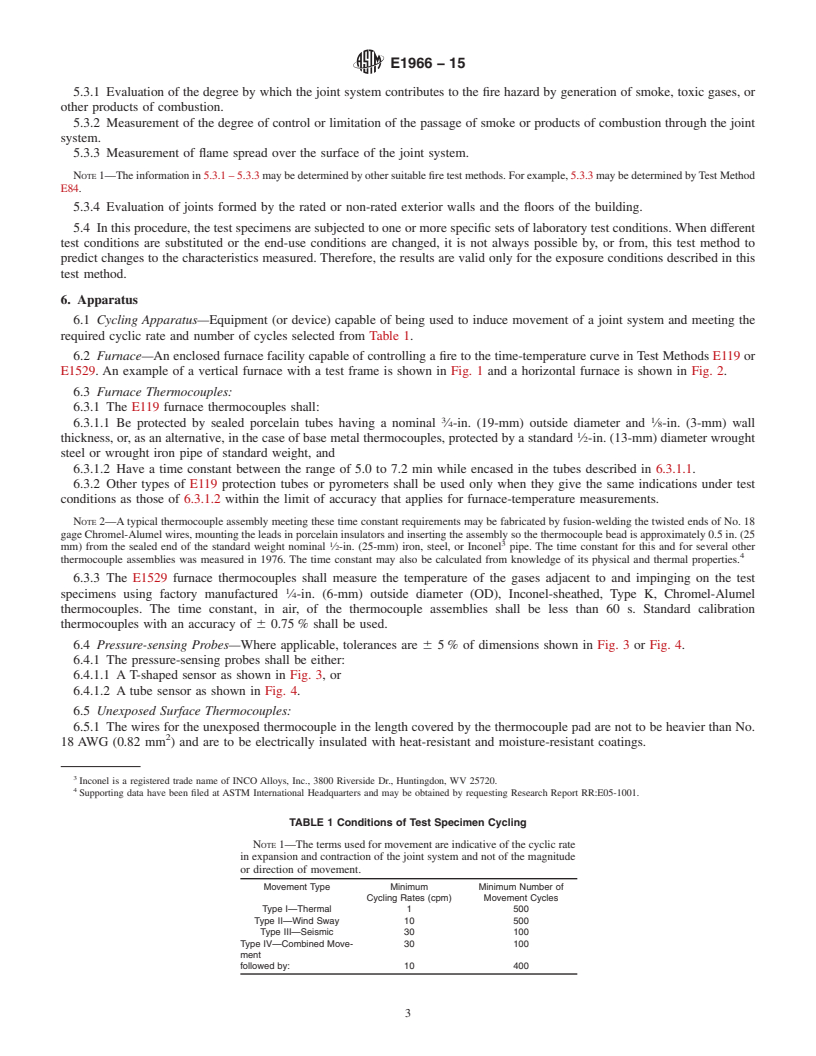

(Test Method)Standard Test Method for Fire-Resistive Joint Systems

Standard Test Method for Fire-Resistive Joint Systems

SIGNIFICANCE AND USE

5.1 This test method evaluates, under the specified test conditions: (1) the ability of a fire resistive joint system to undergo movement without reducing the fire rating of the adjacent fire separating elements and (2) the duration for which test specimens will contain a fire and retain their integrity during a predetermined test exposure.

5.2 This test method provides for the following measurements and evaluations where applicable:

5.2.1 Capability of the joint system to movement cycle.

5.2.2 Loadbearing capacity of the joint system.

5.2.3 Ability of the joint system to prohibit the passage of flames and hot gases.

5.2.4 Transmission of heat through the joint system.

5.2.5 Ability of the joint system, that is an extension of a wall, to resist the passage of water during a hose stream test.

5.3 This test method does not provide the following:

5.3.1 Evaluation of the degree by which the joint system contributes to the fire hazard by generation of smoke, toxic gases, or other products of combustion.

5.3.2 Measurement of the degree of control or limitation of the passage of smoke or products of combustion through the joint system.

5.3.3 Measurement of flame spread over the surface of the joint system.

Note 1: The information in 5.3.1 – 5.3.3 may be determined by other suitable fire test methods. For example, 5.3.3 may be determined by Test Method E84.

5.3.4 Evaluation of joints formed by the rated or non-rated exterior walls and the floors of the building.

5.4 In this procedure, the test specimens are subjected to one or more specific sets of laboratory test conditions. When different test conditions are substituted or the end-use conditions are changed, it is not always possible by, or from, this test method to predict changes to the characteristics measured. Therefore, the results are valid only for the exposure conditions described in this test method.

SCOPE

1.1 This fire-test-response test method measures the performance of joint systems designed to be used with fire rated floors and walls during a fire endurance test exposure. The fire endurance test end point is the period of time elapsing before the first performance criteria is reached when the joint system is subjected to one of two time-temperature fire exposures.

1.2 The fire exposure conditions used are either those specified by Test Method E119 for testing assemblies to standard time-temperature exposures or Test Method E1529 for testing assemblies to rapid-temperature rise fires.

1.3 This test method specifies the heating conditions, methods of test, and criteria for the evaluation of the ability of a joint system to maintain the fire resistance where hourly rated fire-separating elements meet.

1.4 Test results establish the performance of joint systems during the fire-exposure period and shall not be construed as having determined the joint systems suitability for use after that exposure.

1.5 This test method does not provide quantitative information about the joint system relative to the rate of leakage of smoke or gases or both. However, it requires that such phenomena be noted and reported when describing the general behavior of joint systems during the fire endurance test but is not part of the conditions of compliance.

1.6 Potentially important factors and fire characteristics not addressed by this test method include, but are not limited to:

1.6.1 The performance of the fire-resistive joint system constructed with components other than those tested.

1.6.2 The cyclic movement capabilities of joint systems other than the cycling conditions tested.

1.7 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.8 The text of this standard references notes and footnotes which provide explanatory material. Th...

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E1966 − 15 An American National Standard

Standard Test Method for

1

Fire-Resistive Joint Systems

This standard is issued under the fixed designation E1966; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

Joint systems are positioned in joints, voids, gaps, or other discontinuities between or bounded by

two or more supporting elements. Normally such openings are denoted as “linear” because the length

is greater than their width—defined by a typical ratio of at least 10:1 as in practice. Joints are present

in buildings as a result of:

(i) Design to accommodate various movements induced by thermal differentials, seismicity, and

wind loads and exist as a clearance separation.

(ii) Acceptable dimensional tolerances between two or more building elements, for example,

between non-loadbearing walls and floors.

(iii) Inadequate design, inaccurate assembly, repairs or damage to the building.

1. Scope behavior of joint systems during the fire endurance test but is

not part of the conditions of compliance.

1.1 This fire-test-response test method measures the perfor-

mance of joint systems designed to be used with fire rated 1.6 Potentially important factors and fire characteristics not

floors and walls during a fire endurance test exposure. The fire addressed by this test method include, but are not limited to:

endurance test end point is the period of time elapsing before 1.6.1 The performance of the fire-resistive joint system

the first performance criteria is reached when the joint system

constructed with components other than those tested.

is subjected to one of two time-temperature fire exposures.

1.6.2 The cyclic movement capabilities of joint systems

other than the cycling conditions tested.

1.2 The fire exposure conditions used are either those

specified by Test Method E119 for testing assemblies to 1.7 The values stated in inch-pound units are to be regarded

standardtime-temperatureexposuresorTestMethodE1529for

as standard. The values given in parentheses are mathematical

testing assemblies to rapid-temperature rise fires. conversions to SI units that are provided for information only

and are not considered standard.

1.3 This test method specifies the heating conditions, meth-

ods of test, and criteria for the evaluation of the ability of a 1.8 The text of this standard references notes and footnotes

joint system to maintain the fire resistance where hourly rated

which provide explanatory material. These notes and footnotes

fire-separating elements meet. (excluding those in tables and figures) shall not be considered

as requirements of the standard.

1.4 Test results establish the performance of joint systems

during the fire-exposure period and shall not be construed as 1.9 This standard is used to measure and describe the

having determined the joint systems suitability for use after response of materials, products, or assemblies to heat and

that exposure.

flame under controlled conditions, but does not by itself

incorporate all factors required for fire hazard or fire risk

1.5 This test method does not provide quantitative informa-

assessment of the materials, products, or assemblies under

tion about the joint system relative to the rate of leakage of

actual fire conditions.

smoke or gases or both. However, it requires that such

phenomena be noted and reported when describing the general 1.10 Fire testing is inherently hazardous. Adequate safe-

guards for personnel and property shall be employed in

conducting these tests.

1

1.11 This standard does not purport to address all of the

This test method is under the jurisdiction of ASTM Committee E05 on Fire

Standards and is the direct responsibility of Subcommittee E05.11 on Fire

safety concerns, if any, associated with its use. It is the

Resistance.

responsibility of the user of this standard to establish appro-

CurrenteditionapprovedJune1,2015.PublishedJuly2015.Originallyapproved

priate safety and health practices and determine the applica-

in 1998. Last previous edition approved in 2011 as E1966–07(2011). DOI:

10.1520/E1966-15. bility of regulatory limitations prior to use.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

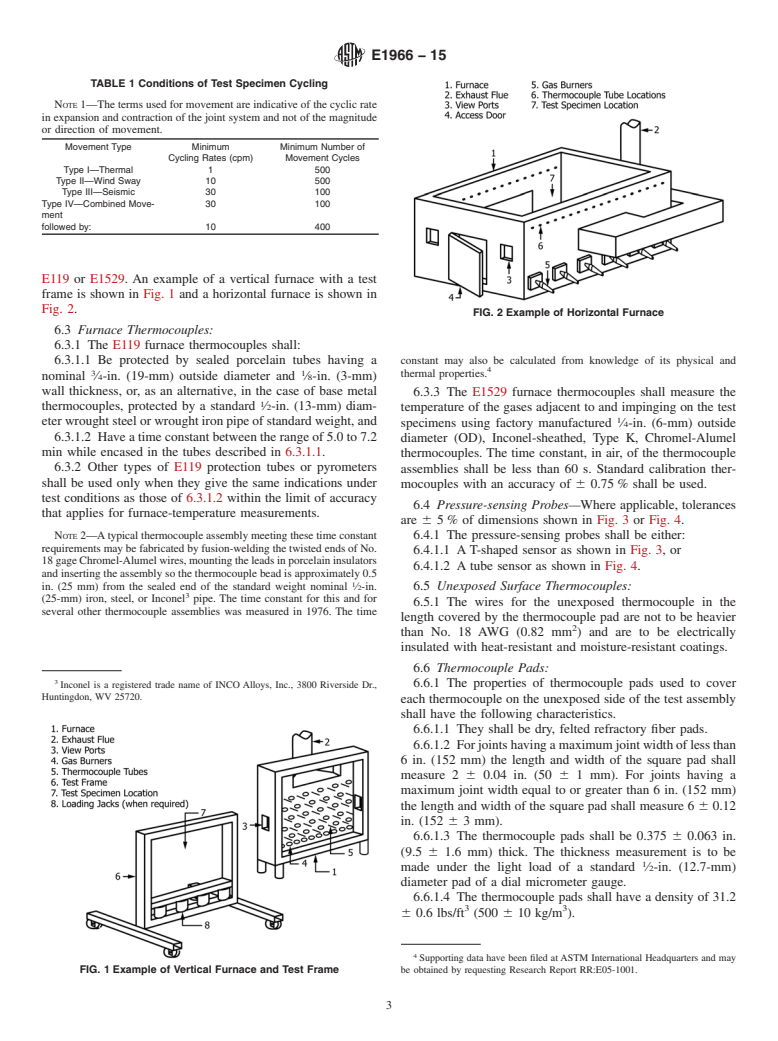

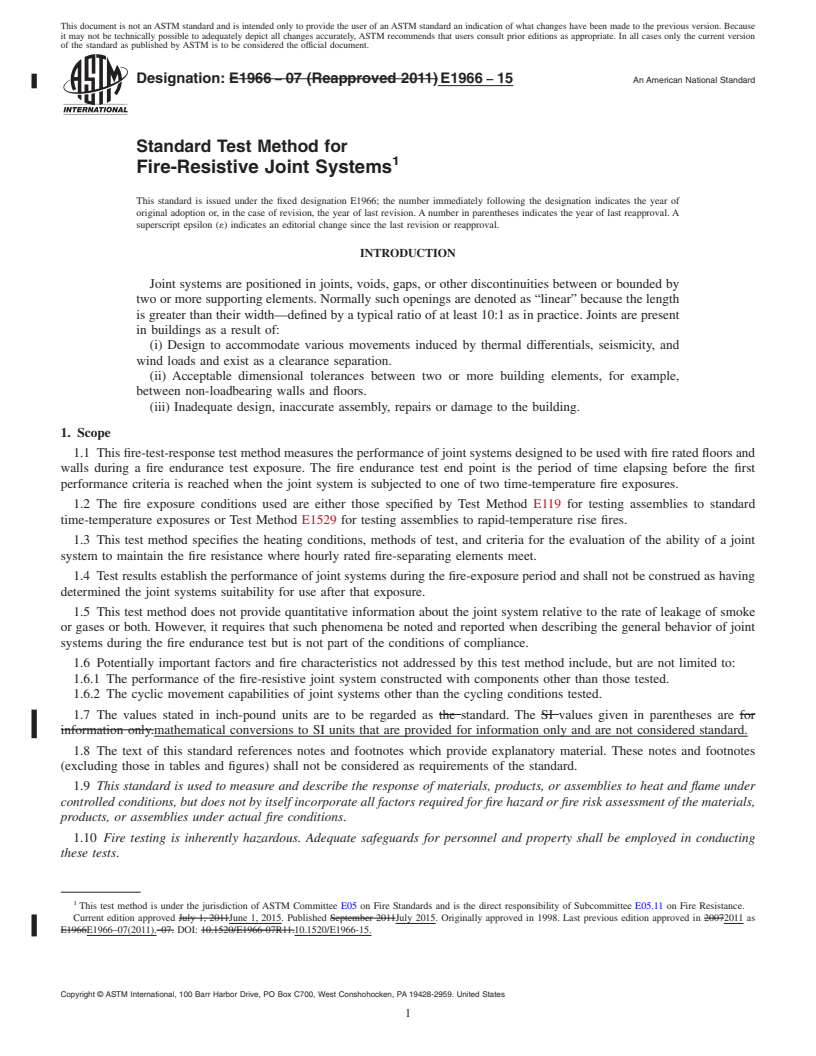

E1966 − 15

2. Referenced Documents 4.1.1 When the maximum joint width does not equal the

2 minimum joint width, joint systems shall be movement cycled

2.1 ASTM Standards:

before being fire tested.

E84 Test Method for Surface Burning Characteristics of

4.1.2 Joint systems and their supporting construction shall

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: E1966 − 07 (Reapproved 2011) E1966 − 15 An American National Standard

Standard Test Method for

1

Fire-Resistive Joint Systems

This standard is issued under the fixed designation E1966; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

Joint systems are positioned in joints, voids, gaps, or other discontinuities between or bounded by

two or more supporting elements. Normally such openings are denoted as “linear” because the length

is greater than their width—defined by a typical ratio of at least 10:1 as in practice. Joints are present

in buildings as a result of:

(i) Design to accommodate various movements induced by thermal differentials, seismicity, and

wind loads and exist as a clearance separation.

(ii) Acceptable dimensional tolerances between two or more building elements, for example,

between non-loadbearing walls and floors.

(iii) Inadequate design, inaccurate assembly, repairs or damage to the building.

1. Scope

1.1 This fire-test-response test method measures the performance of joint systems designed to be used with fire rated floors and

walls during a fire endurance test exposure. The fire endurance test end point is the period of time elapsing before the first

performance criteria is reached when the joint system is subjected to one of two time-temperature fire exposures.

1.2 The fire exposure conditions used are either those specified by Test Method E119 for testing assemblies to standard

time-temperature exposures or Test Method E1529 for testing assemblies to rapid-temperature rise fires.

1.3 This test method specifies the heating conditions, methods of test, and criteria for the evaluation of the ability of a joint

system to maintain the fire resistance where hourly rated fire-separating elements meet.

1.4 Test results establish the performance of joint systems during the fire-exposure period and shall not be construed as having

determined the joint systems suitability for use after that exposure.

1.5 This test method does not provide quantitative information about the joint system relative to the rate of leakage of smoke

or gases or both. However, it requires that such phenomena be noted and reported when describing the general behavior of joint

systems during the fire endurance test but is not part of the conditions of compliance.

1.6 Potentially important factors and fire characteristics not addressed by this test method include, but are not limited to:

1.6.1 The performance of the fire-resistive joint system constructed with components other than those tested.

1.6.2 The cyclic movement capabilities of joint systems other than the cycling conditions tested.

1.7 The values stated in inch-pound units are to be regarded as the standard. The SI values given in parentheses are for

information only.mathematical conversions to SI units that are provided for information only and are not considered standard.

1.8 The text of this standard references notes and footnotes which provide explanatory material. These notes and footnotes

(excluding those in tables and figures) shall not be considered as requirements of the standard.

1.9 This standard is used to measure and describe the response of materials, products, or assemblies to heat and flame under

controlled conditions, but does not by itself incorporate all factors required for fire hazard or fire risk assessment of the materials,

products, or assemblies under actual fire conditions.

1.10 Fire testing is inherently hazardous. Adequate safeguards for personnel and property shall be employed in conducting

these tests.

1

This test method is under the jurisdiction of ASTM Committee E05 on Fire Standards and is the direct responsibility of Subcommittee E05.11 on Fire Resistance.

Current edition approved July 1, 2011June 1, 2015. Published September 2011July 2015. Originally approved in 1998. Last previous edition approved in 20072011 as

E1966E1966–07(2011).–07. DOI: 10.1520/E1966-07R11.10.1520/E1966-15.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E1966 − 15

1.11 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.