ASTM E2912-17

(Test Method)Standard Test Method for Fire Test of Non-Mechanical Fire Dampers Used in Vented Construction

Standard Test Method for Fire Test of Non-Mechanical Fire Dampers Used in Vented Construction

SIGNIFICANCE AND USE

5.1 This test method provides for the following observations, measurements and evaluations of an open state during the test fire.

5.1.1 Ability of the test specimen to resist the passage of flames, radiation, and hot gases caused by sudden direct flame impingement.

5.1.2 Transmission of heat through the test specimen.

5.2 This test method does not provide the following:

5.2.1 Evaluation of the degree to which the test assembly contributes to the fire hazard by generation of smoke, toxic gases, or other products of combustion.

5.2.2 Measurement of the degree of control or limitation of the passage of smoke or products of combustion through the test specimen or the test assembly.

5.2.3 Measurement of flame spread over the surface of the test specimen or the test assembly.

5.2.4 Durability of the test specimen or test assembly under actual service conditions, including the effects of cycled temperature.

5.2.5 Effects of a load on the test specimen or test assembly.

5.2.6 Any other attributes of the test specimen or the test assembly, such as wear resistance, chemical resistance, air infiltration, water-tightness, and so forth.

5.3 The results of this test method shall not be used as an alternative to, or a substitute for, requirements for a required fire resistance rating of building construction.

SCOPE

1.1 This fire-test-response standard assesses the ability of non-mechanical fire dampers used in vented construction in its open state to limit passage of hot gases, radiation, and flames during a prescribed fire test exposure. The fire exposure condition in this test method is sudden direct flame impingement, which produces these hot gases, radiation, and flames.

Note 1: Non-mechanical fire dampers can be used in vented construction. Vented constructions may be parts of buildings including walls, floors, ceilings and concealed spaces and cavities used for air transfer and to allow ventilation in structures without ductwork. Non-mechanical fire dampers can be located adjacent to combustible construction or materials and situated in exposed or concealed locations, or both. Unlike typical fire resistive assemblies, vented construction uses non-mechanical fire dampers to allow air transfer without the use of ducts. Resistance to flame, radiation, and hot gases may be requirements when direct flame impingement is a credible risk, or when no penetration of flames is required by the authority having jurisdiction, or both. The proposed test method provides procedures that enable an assessment of this direct flame impingement on non-mechanical fire dampers. This test method does not alter any requirements for non-mechanical fire dampers used in fire resistance rated construction and assemblies.

1.2 This fire-test-response standard is intended to provide a means to assess the reaction of a non-mechanical fire damper used in vented construction to sudden direct flame impingement, or as a supplement to existing fire-resistive test methods, or both.

1.3 This test method does not circumvent or eliminate the fire resistance rating requirements for construction. The fire resistance rating of construction shall be tested in accordance with published fire-resistance test standards as appropriate for the relevant application of the construction, or as required by the authority having jurisdiction (regulatory authority), or both. Non-mechanical fire dampers shall be tested to the appropriate fire-resistive test standards required for their application in order to determine a fire resistance rating in those constructions.

Note 2: Some of the major international standards development organizations (SDO) include, but are not limited to, ASTM International, CEN, ISO, UL, and ULC. Some examples of standards employing standard time-temperature curves for fire exposure used to determine a construction’s fire resistance rating include, but are not limited to, the following: Test Met...

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: E2912 − 17 An American National Standard

Standard Test Method for

Fire Test of Non-Mechanical Fire Dampers Used in Vented

1

Construction

This standard is issued under the fixed designation E2912; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

NOTE 2—Some of the major international standards development

1. Scope*

organizations (SDO) include, but are not limited to, ASTM International,

1.1 This fire-test-response standard assesses the ability of

CEN, ISO, UL, and ULC. Some examples of standards employing

non-mechanical fire dampers used in vented construction in its standard time-temperature curves for fire exposure used to determine a

construction’s fire resistance rating include, but are not limited to, the

open state to limit passage of hot gases, radiation, and flames

following: Test Methods E119, E814, E1966, E2307, UL 10B, UL 10C,

during a prescribed fire test exposure. The fire exposure

UL 555, UL 555C etc. The term “authority having jurisdiction” is defined

condition in this test method is sudden direct flame

in Practice E2174.

impingement, which produces these hot gases, radiation, and

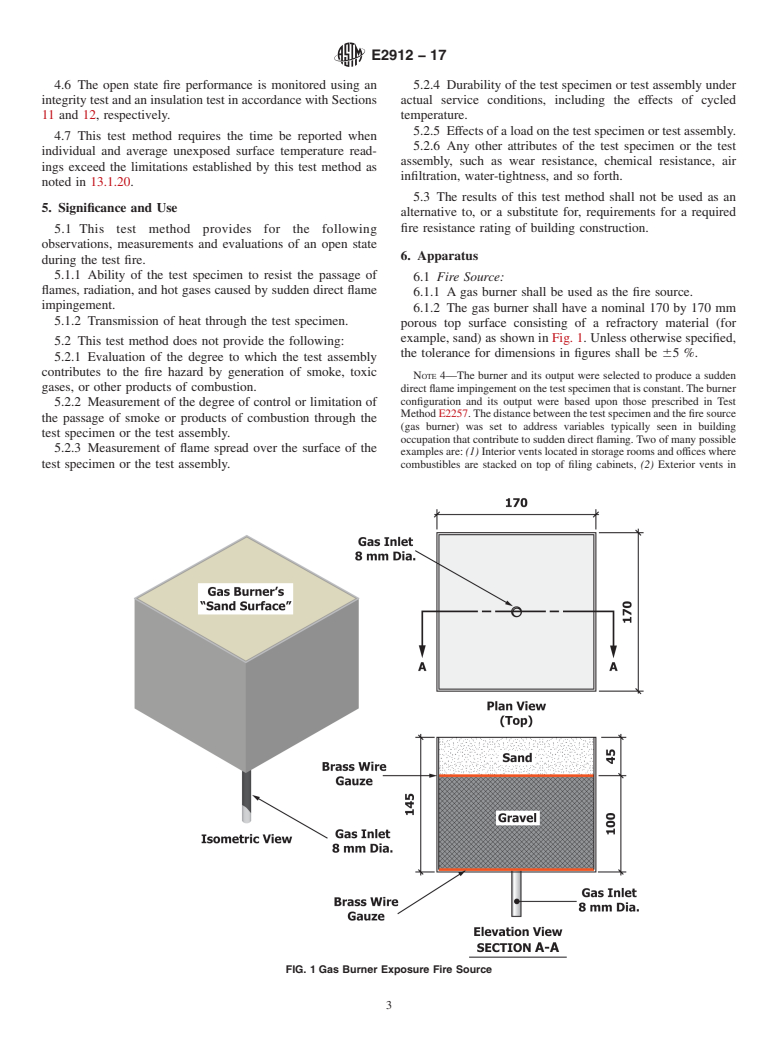

1.4 This test method specifies the fire exposure conditions,

flames.

fire test protocol, and criteria to evaluate an open state.

NOTE 1—Non-mechanical fire dampers can be used in vented construc-

NOTE 3—There are currently no published test methods (nationally or

tion. Vented constructions may be parts of buildings including walls,

internationally) that address the application of sudden direct flame

floors, ceilings and concealed spaces and cavities used for air transfer and

impingement on non-mechanical fire dampers used in vented construction.

to allow ventilation in structures without ductwork. Non-mechanical fire

In the European Union (EU), CEN (European Committee for Standard-

dampers can be located adjacent to combustible construction or materials

ization) has very recently started a work item to address reaction to sudden

and situated in exposed or concealed locations, or both. Unlike typical fire

direct flame impingement on non-mechanical fire dampers. Also, in the

resistive assemblies, vented construction uses non-mechanical fire damp-

EU, some countries have used large scale tests with 5MW fire exposures

ers to allow air transfer without the use of ducts. Resistance to flame,

to assess test specimens’ reactions to sudden direct flame impingement as

radiation, and hot gases may be requirements when direct flame impinge-

part of the entire building construction. Standard time-temperature curves

ment is a credible risk, or when no penetration of flames is required by the

used to control gas-fired furnaces do not ensure a sudden direct flame

authority having jurisdiction, or both. The proposed test method provides

impingement on the test specimen, which this test method is designed to

procedures that enable an assessment of this direct flame impingement on

do. A post flashover condition, the spontaneous combustion of materials,

non-mechanical fire dampers. This test method does not alter any

ignition of a highly combustible material acting as the source of the fire

requirements for non-mechanical fire dampers used in fire resistance rated

(for example, stored cleaning solutions or fuels) or the location of

construction and assemblies.

materials can create a fire scenario resulting in a sudden direct flame

1.2 This fire-test-response standard is intended to provide a

impingement.

means to assess the reaction of a non-mechanical fire damper

1.5 Results generated by this test method provide the

used in vented construction to sudden direct flame

following information:

impingement, or as a supplement to existing fire-resistive test

1.5.1 the open state fire performance of vented construction,

methods, or both.

and

1.3 This test method does not circumvent or eliminate the

1.5.2 the non-mechanical fire damper’s fire-test-response

fire resistance rating requirements for construction. The fire

characteristic when exposed to sudden direct flame impinge-

resistance rating of construction shall be tested in accordance

ment.

with published fire-resistance test standards as appropriate for

1.6 This test method does not provide quantitative informa-

the relevant application of the construction, or as required by

tion about the test assembly related to the leakage of smoke, or

the authority having jurisdiction (regulatory authority), or both.

gases, or both.

Non-mechanical fire dampers shall be teste

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: E2912 − 13 E2912 − 17 An American National Standard

Standard Test Method for

Fire Test of Non-Mechanical Fire Dampers Used in Vented

1

Construction

This standard is issued under the fixed designation E2912; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Scope*

1.1 This fire-test-response standard assesses the ability of non-mechanical fire dampers used in vented construction in its open

state to limit passage of hot gases, radiation, and flames during a prescribed fire test exposure. The fire exposure condition in this

test method is sudden direct flame impingement, which produces these hot gases, radiation, and flames.

NOTE 1—Non-mechanical fire dampers can be used in vented construction. Vented constructions may be parts of buildings including walls, floors,

ceilings and concealed spaces and cavities used for air transfer and to allow ventilation in structures without ductwork. Non-mechanical fire dampers can

be located adjacent to combustible construction or materials and situated in exposed or concealed locations, or both. Unlike typical fire resistive

assemblies, vented construction uses non-mechanical fire dampers to allow air transfer without the use of ducts. Resistance to flame, radiation, and hot

gases may be requirements when direct flame impingement is a credible risk, or when no penetration of flames is required by the authority having

jurisdiction, or both. The proposed test method provides procedures that enable an assessment of this direct flame impingement on non-mechanical fire

dampers. This test method does not alter any requirements for non-mechanical fire dampers used in fire resistance rated construction and assemblies.

1.2 This fire-test-response standard is intended to provide a means to assess the reaction of a non-mechanical fire damper used

in vented construction to sudden direct flame impingement, or as a supplement to existing fire-resistive test methods, or both.

1.3 This test method does not circumvent or eliminate the fire resistance rating requirements for construction. The fire resistance

rating of construction shall be tested in accordance with published fire-resistance test standards as appropriate for the relevant

application of the construction, or as required by the authority having jurisdiction (regulatory authority), or both. Non-mechanical

fire dampers shall be tested to the appropriate fire-resistive test standards required for their application in order to determine a fire

resistance rating in those constructions.

NOTE 2—Some of the major international standards development organizations (SDO) include, but are not limited to, ASTM International, CEN, ISO,

UL, and ULC. Some examples of standards employing standard time-temperature curves for fire exposure used to determine a construction’s fire

resistance rating include, but are not limited to, the following: Test Methods E119, E814, E1966, E2307, UL 10B, UL 10C, UL 555, UL 555C etc. The

term “authority having jurisdiction” is defined in Practice E2174.

1.4 This test method specifies the fire exposure conditions, fire test protocol, and criteria to evaluate an open state.

NOTE 3—There are currently no published test methods (nationally or internationally) that address the application of sudden direct flame impingement

on non-mechanical fire dampers used in vented construction. In the European Union (EU), CEN (European Committee for Standardization) has very

recently started a work item to address reaction to sudden direct flame impingement on non-mechanical fire dampers. Also, in the EU, some countries

have used large scale tests with 5MW fire exposures to assess test specimens’ reactions to sudden direct flame impingement as part of the entire building

construction. Standard time-temperature curves used to control gas-fired furnaces do not ensure a sudden direct flame impingement on the test specimen,

which this test method is designed to do. A post flashover condition, the spontaneous combustion of materials, ignition of a highly combustible material

acting as the source of the fire (for example, stored cleaning solutions or fuels) or the location of materials can create a fire scenario resulting in a sudden

direct flame impingement.

1.5 Results generated by this test method provide the following information:

1.5.1 the open state fire performance of vente

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.