ASTM D8203-18(2023)

(Test Method)Standard Test Method for Determination of the Horizontal Water Flow Rate of a Geosynthetic Screening Material, Product, or Device

Standard Test Method for Determination of the Horizontal Water Flow Rate of a Geosynthetic Screening Material, Product, or Device

SIGNIFICANCE AND USE

5.1 The test method simulates the flow conditions (without sediment) applicable to sediment retention devices exposed to sheet-flow runoff. Horizontal flow rate is an inherent (index) property of sediment retention devices (SRDs), and can be used to control quality and to assess the effects of product changes.

SCOPE

1.1 This test method covers test procedures for determining the horizontal water flow rate through a geosynthetic or geosynthetic-enhanced screening device, such as a sediment retention device (SRD), under a constant-head pressure. The test is conducted with potable water.

1.2 This test is intended to be used for quality control and product development efforts, but should not be considered a performance test.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are provided for information purposes only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D8203 − 18 (Reapproved 2023)

Standard Test Method for

Determination of the Horizontal Water Flow Rate of a

Geosynthetic Screening Material, Product, or Device

This standard is issued under the fixed designation D8203; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

1.1 This test method covers test procedures for determining 3.1 Definitions:

the horizontal water flow rate through a geosynthetic or 3.1.1 For definitions of common technical terms used in this

geosynthetic-enhanced screening device, such as a sediment standard, refer to Terminology D4439.

retention device (SRD), under a constant-head pressure. The 3.2 Definitions of Terms Specific to This Standard:

test is conducted with potable water. 3.2.1 geosynthetic screening device, n—geosynthetic or

geosynthetic-enhanced materials, products, or devices that

1.2 This test is intended to be used for quality control and

primarily provide the screening function, such as a sediment

product development efforts, but should not be considered a

retention device (SRD).

performance test.

3.2.2 screening—a geosynthetic, placed across the path of a

1.3 The values stated in SI units are to be regarded as the

flowing fluid (ground water, surface water, wind), carrying

standard. The values given in parentheses are provided for

particles in suspension, provides screening when it retains

information purposes only.

some or all fine soil particles while allowing the fluid to pass

1.4 This standard does not purport to address all of the

through. After some period of time, particles accumulate

safety concerns, if any, associated with its use. It is the

against the screen, which requires that the screen be able to

responsibility of the user of this standard to establish appro-

withstand pressures generated by the accumulated particles and

priate safety, health, and environmental practices and deter-

the increasing pressure from accumulated fluid. (See Guide

mine the applicability of regulatory limitations prior to use.

D5819.)

1.5 This international standard was developed in accor-

3.2.3 sediment retention device (SRD), n—a material,

dance with internationally recognized principles on standard-

product, or device designed to intercept sediment-laden flow,

ization established in the Decision on Principles for the

screening out suspended solids and reducing the velocity of the

Development of International Standards, Guides and Recom-

flow, causing transported sediments to settle out. Typical SRDs

mendations issued by the World Trade Organization Technical

include silt fences, as well as natural or manmade materials

Barriers to Trade (TBT) Committee.

encapsulated in geosynthetic fabrics, meshes, or nettings such

as wattles, filter logs, fiber filtration tubes, fiber rolls, and

2. Referenced Documents

compost socks.

2.1 ASTM Standards:

4. Summary of Test Method

D4354 Practice for Sampling of Geosynthetics and Rolled

Erosion Control Products (RECPs) for Testing

4.1 A test specimen is positioned vertically across the mouth

D4439 Terminology for Geosynthetics

of a “box” reservoir, and potable water is introduced upstream

D5819 Guide for Selecting Test Methods for Experimental

and maintained at a predetermined constant head as the water

Evaluation of Geosynthetic Durability

is allowed to seep through the specimen. Once a steady-state

flow condition is established, a discharge volume and the

associated time are measured.

This test method is under the jurisdiction of ASTM Committee D35 on

5. Significance and Use

Geosynthetics and is the direct responsibility of Subcommittee D35.05 on Geosyn-

thetic Erosion Control.

5.1 The test method simulates the flow conditions (without

Current edition approved May 1, 2023. Published May 2023. Originally

sediment) applicable to sediment retention devices exposed to

approved in 2018. Last previous edition approved in 2018 as D8203 – 18. DOI:

10.1520/D8203-18R23.

sheet-flow runoff. Horizontal flow rate is an inherent (index)

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

property of sediment retention devices (SRDs), and can be

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

used to control quality and to assess the effects of product

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. changes.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D8203 − 18 (2023)

6. Apparatus 8. Procedure

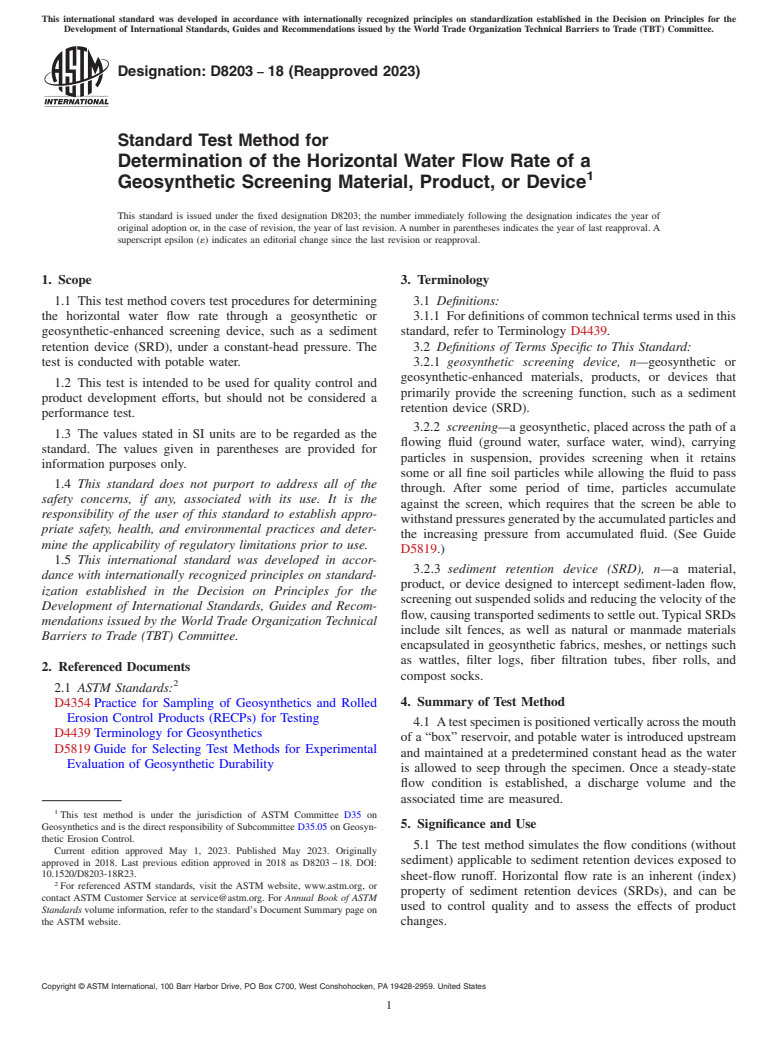

6.1 Upper “Box” Reservoir, constructed from marine-grade 8.1 Test Setup and Installation of Sediment Retention De-

plywood, plexiglas, aluminum, or other material. The box vice:

should be watertight and constructed as shown in Fig. 1. 8.1.1 SRD Installation—The sediment retention device

(SRD) is installed across the open end of the upper box, using

NOTE 1—The box end opening is approximately the size of a straw bale.

any effective sealing material to seal the bottom and ends

A typical upper box reservoir is 122 cm (48 in.) wide by 244 cm (96 in.)

against the box bottom and walls. The SRD rests against a

long by 61 cm (24 in.) deep.

mesh on the downstream side that provides horizontal support

6.2 Lower “Receiving” Reservoir, constructed from marine-

against deformation during testing.

grade plywood, plexiglas, aluminum, or other material. The

8.1.2 A “door” is placed across the downstream opening of

flume should be watertight and constructed as shown in Fig. 1.

the box to minimize box discharge during initial filling, which

NOTE 2—The lower receiving reservoir is much larger than the upper

permits the water to penetrate and surround the SRD prior to it

reservoir. A typical receiving reservoir is at least 122 cm (48 in.) wide by

experiencing seepage forces.

600 cm (20 ft) long by 122 cm (48 in.) deep. This size reservoir facilitates

8.1.3 Clear water is then allowed to flow

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.