ASTM D198-99

(Test Method)Standard Test Methods of Static Tests of Lumber in Structural Sizes

Standard Test Methods of Static Tests of Lumber in Structural Sizes

SCOPE

1.1 These test methods cover the evaluation of lumber in structural size by various testing procedures.

1.2 The test methods appear in the following order: Sections Flexure 4 to 11 Compression (Short Column) 12 to 19 Compression (Long Member) 20 to 27 Tension 28 to 35 Torsion 36 to 43 Shear Modulus 44 to 51

1.3 Notations and symbols relating to the various testing procedures are given in Table X1.1.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 198 – 99

Standard Test Methods of

Static Tests of Lumber in Structural Sizes

This standard is issued under the fixed designation D 198; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

Numerous evaluations of structural members of solid sawn lumber have been conducted in

accordance with ASTM Test Methods D 198 – 27. While the importance of continued use of a

satisfactory standard should not be underestimated, the original standard (1927) was designed

primarily for sawn material such as solid wood bridge stringers and joists. With the advent of

laminated timbers, wood-plywood composite members, and even reinforced and prestressed timbers,

a procedure adaptable to a wider variety of wood structural members is required.

The present standard expands the original standard to permit its application to wood members of all

types. It provides methods of evaluation under loadings other than flexure in recognition of the

increasing need for improved knowledge of properties under such loadings as tension to reflect the

increasing use of dimensions lumber in the lower chords of trusses. The standard establishes practices

that will permit correlation of results from different sources through the use of a uniform procedure.

Provision is made for varying the procedure to take account of special problems.

1. Scope D 1165 Nomenclature of Domestic Hardwoods and Soft-

woods

1.1 These test methods cover the evaluation of lumber in

D 2395 Test Methods for Specific Gravity of Wood and

structural size by various testing procedures.

Wood-Base Materials

1.2 The test methods appear in the following order:

D 4442 Test Methods for Direct Moisture Content Measure-

ment of Wood and Wood-Base Materials

Sections

E 4 Practices for Force Verification of Testing Machines

Flexure 4 to 11

Compression (Short Column) 12 to 19

E 6 Terminology Relating to Methods of Mechanical Test-

Compression (Long Member) 20 to 27

ing

Tension 28 to 35

E 83 Practice for Verification and Classification of Exten-

Torsion 36 to 43

Shear Modulus 44 to 51

someters

3. Terminology

1.3 Notations and symbols relating to the various testing

3.1 Definitions—See Terminology E 6, Terminology D 9,

procedures are given in Table X1.1.

and Nomenclature D 1165. A few related terms not covered in

1.4 This standard does not purport to address all of the

these standards are as follows:

safety concerns, if any, associated with its use. It is the

3.1.1 span—the total distance between reactions on which a

responsibility of the user of this standard to establish appro-

beam is supported to accommodate a transverse load (Fig. 1).

priate safety and health practices and determine the applica-

3.1.2 shear span—two times the distance between a reac-

bility of regulatory limitations prior to use.

tion and the nearest load point for a symmetrically loaded beam

2. Referenced Documents

(Fig. 1).

2.1 ASTM Standards: 3.1.3 depth of beam—that dimension of the beam which is

perpendicular to the span and parallel to the direction in which

D 9 Terminology Relating to Wood

the load is applied (Fig. 1).

3.1.4 span-depth ratio—the numerical ratio of total span

divided by beam depth.

These methods are under the jurisdiction of ASTM Committee D-7 on Wood

and are the direct responsibility of Subcommittee D07.01 on Fundamental Test

3.1.5 shear span-depth ratio—the numerical ratio of shear

Methods and Properties.

span divided by beam depth.

Current edition approved Dec. 10, 1999. Published April 2000. Originally

published as D 198 – 24. Last previous edition D 198 – 98.

2 3

Annual Book of ASTM Standards, Vol 04.10. Annual Book of ASTM Standards, Vol 03.01.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 198

FIG. 1 Flexure Method

3.1.6 structural wood beam—solid wood, laminated wood, 6.1.6 Data on the effects of chemical or environmental

or composite structural members for which strength or stiff- conditions on mechanical properties.

ness, or both are primary criteria for the intended application

6.1.7 Data on effects of fabrication variables such as depth,

and which usually are used in full length and in cross-sectional

taper, notches, or type of end joint in laminations.

sizes greater than nominal 2 by 2 in. (38 by 38 mm).

6.1.8 Data on relationships between mechanical and physi-

3.1.7 composite wood beam—a laminar construction com-

cal properties.

prising a combination of wood and other simple or complex

6.2 Procedures are described here in sufficient detail to

materials assembled and intimately fixed in relation to each

permit duplication in different laboratories so that comparisons

other so as to use the properties of each to attain specific

of results from different sources will be valid. Special circum-

structural advantage for the whole assembly.

stances may require deviation from some details of these

procedures. Any variations shall be carefully described in the

FLEXURE

report (see Section 11).

4. Scope

7. Apparatus

4.1 This test method covers the determination of the flexural

7.1 Testing Machine— A device that provides (1) a rigid

properties of structural beams made of solid or laminated

frame to support the specimen yet permit its deflection without

wood, or of composite constructions. This test method is

restraint, ( 2) a loading head through which the force is applied

intended primarily for beams of rectangular cross section but is

without high-stress concentrations in the beam, and (3)a

also applicable to beams of round and irregular shapes, such as

force-measuring device that is calibrated to ensure accuracy in

round posts, I-beams, or other special sections.

accordance with Practices E 4.

5. Summary of Test Method

7.2 Support Apparatus:

7.2.1 Reaction Bearing Plates—The beam shall be sup-

5.1 The structural member, usually a straight or a slightly

ported by metal bearing plates to prevent damage to the beam

cambered beam of rectangular cross section, is subjected to a

at the point of contact between beam and reaction support (Fig.

bending moment by supporting it near its ends, at locations

1). The size of the bearing plates may vary with the size and

called reactions, and applying transverse loads symmetrically

shape of the beam. For rectangular beams as large as 12 in.

imposed between these reactions. The beam is deflected at a

(305 mm) deep by 6 in. (152 mm) wide, the recommended size

prescribed rate, and coordinate observations of loads and

of bearing plate is ⁄2 in. (13 mm) thick by 6 in. (152 mm)

deflections are made until rupture occurs.

lengthwise and extending entirely across the width of the

6. Significance and Use beam.

7.2.2 Reaction Bearing Roller—The bearing plates shall be

6.1 The flexural properties established by this test method

supported by either rollers and a fixed knife edge reaction or a

provide:

rocker type-knife edge reaction so that shortening and rotation

6.1.1 Data for use in development of grading rules and

of the beam about the reaction due to deflection will be

specifications.

unrestricted (Fig. 1).

6.1.2 Data for use in development of working stresses for

structural members. 7.2.3 Reaction Bearing Alignment—Provisions shall be

6.1.3 Data on the influence of imperfections on mechanical made at the reaction to allow for initial twist in the length of the

properties of structural members. beam. If the bearing surfaces of the beam at its reactions are

6.1.4 Data on strength properties of different species or not parallel, the beam shall be shimmed or the individual

grades in various structural sizes. bearing plates shall be rotated about an axis parallel to the span

6.1.5 Data for use in checking existing equations or hypoth- to provide full bearing across the width of the specimen (Fig.

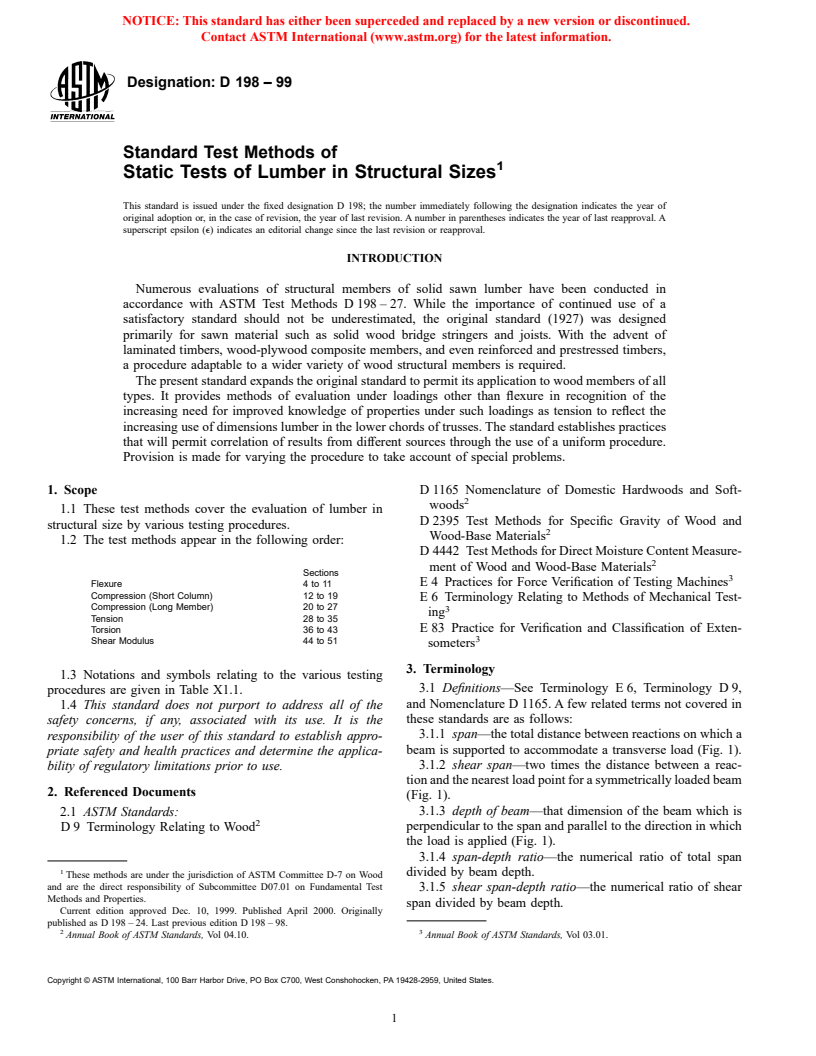

eses relating to the structural behavior of beams. 2).

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 198

curvature equal to two to four times the beam depth for a chord

length at least equal to the depth of the beam. Load shall be

applied to the blocks in such a manner that the blocks may

rotate about an axis perpendicular to the span (Fig. 4).

Provisions such as rotatable bearings or shims shall be made to

ensure full contact between the beam and both loading blocks.

Metal bearing plates and rollers shall be used in conjunction

with one load bearing block to permit beam deflection without

restraint (Fig. 4). The size of these plates and rollers may vary

with the size and shape of the beam, the same as for the

reaction bearing plates. Beams having circular or irregular

cross sections shall have bearing blocks which distribute the

load uniformly to the bearing surface and permit, unrestrained

deflections.

7.3.2 Load Points— The total load on the beam shall be

applied equally at two points equidistant from the reactions.

The two load points will normally be at a distance from their

reaction equal to one third of the span, but for special purposes

other distances may be specified.

NOTE 1—One of the objectives of two-point loading is to subject the

portion of the beam between load points to a uniform bending moment,

free of shear, and with comparatively small loads at the load points. For

example, loads applied at one-third span length from reactions would be

FIG. 2 Example of Bearing Plate, A, Rollers, B, and Reaction-

less than if applied at one-fourth span length from reaction to develop a

Alignment-Rocker, C, for Small Beams

moment of similar magnitude. When loads are applied at the one-third

points the moment distribution of the beam simulates that for loads

uniformly distributed across the span to develop a moment of similar

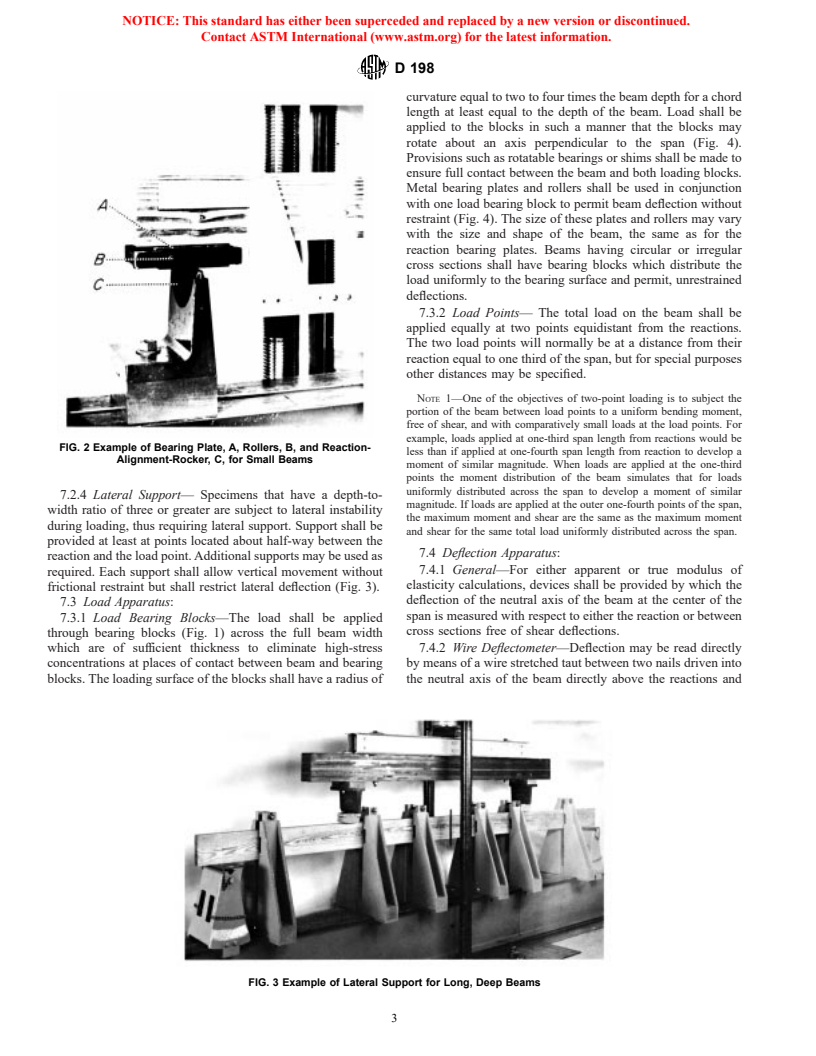

7.2.4 Lateral Support— Specimens that have a depth-to-

magnitude. If loads are applied at the outer one-fourth points of the span,

width ratio of three or greater are subject to lateral instability

the maximum moment and shear are the same as the maximum moment

during loading, thus requiring lateral support. Support shall be

and shear for the same total load uniformly distributed across the span.

provided at least at points located about half-way between the

7.4 Deflection Apparatus:

reaction and the load point. Additional supports may be used as

7.4.1 General—For either apparent or true modulus of

required. Each support shall allow vertical movement without

elasticity calculations, devices shall be provided by which the

frictional restraint but shall restrict lateral deflection (Fig. 3).

deflection of the neutral axis of the beam at the center of the

7.3 Load Apparatus:

span is measured with respect to either the reaction or between

7.3.1 Load Bearing Blocks—The load shall be applied

cross sections free of shear deflections.

through bearing blocks (Fig. 1) across the full beam width

which are of sufficient thickness to eliminate high-stress 7.4.2 Wire Deflectometer—Deflection may be read directly

concentrations at places of contact between beam and bearing by means of a wire stretched taut between two nails driven into

blocks. The loading surface of the blocks shall have a radius of the neutral axis of the beam directly above the reactions and

FIG. 3 Example of Lateral Support for Long, Deep Beams

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 198

wood, that is, species, source, etc., whereas composite wooden

beams would be identified by the characteristics of the dissimi-

lar materials and their size and location in the beam.

8.3 Specimen Measurements—The weight and dimensions

as well as moisture content of the specimen shall be accurately

determined before test. Weights and dimensions (length and

cross section) shall be measured to three significant figures.

Sufficient measurements of the cross section shall be made

along the length of the beam to describe the width and depth of

rectangular specimen and to accurately describe the critical

section or sections of nonuniform beams. The physical char-

acteristics of the specimen as described by its density and

moisture content may be determined in accordance with Test

Methods D 2395 and Test Methods D 4442.

8.4 Specimen Description—The inherent imperfections or

intentional modifications of the composition of the beam shall

be fully described by recording the size and location of such

factors as knots, checks, and reinforcements. Size and location

of intentional modifications such as placement of laminations,

glued joints, and reinforcing steel shall be recorded during the

fabrication process. The size and location of imperfections in

FIG. 4 Example of Curved Loading Block, A, Load-Alignment

the interior of any beam must be deduced from those on the

Rocker, B, Roller-Curved Loading Block, C, Load Evener, D, and

Deflection-Measuring Apparatus, E

surface, especially in the case of large sawn members. A sketch

or photographic record shall be made of each face and the ends

showing the size, location, and type of growth characteristics,

extending across a scale attached at the neutral axis of the beam

including slope of grain, knots, distribution of sapwood and

at midspan. Deflections may be read with a telescope or

heartwood, location of pitch pockets, direction of annual rings,

reading glass to magnify the area where the wire crosses the

and such abstract factors as crook, bow, cup, or twist which

scale. When a reading glass is used, a reflective surface placed

might affect the strength of the beam.

adjacent to the scale will help to avoid parallax.

8.5 Rules for Determination of Specimen Length—The

7.4.3 Yoke Deflectometer—A satisfactory device commonly

cross-sectional dimensions of solid wood structural beams and

used for short, small beams or to measure deflection of the

composite wooden beams usually have established sizes,

center of the beam with respect to any point along the neutral

depending upon the manufacturing process and intended use,

axis consists of a lightweight U-shaped yoke suspended

so that no modification of these dimensions is involved. The

between nails driven into the beam at its neutral axis and a dial

length, however, w

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.