ASTM D7232-06(2022)

(Test Method)Standard Test Method for Rapid Determination of the Nonvolatile Content of Coatings by Loss in Weight

Standard Test Method for Rapid Determination of the Nonvolatile Content of Coatings by Loss in Weight

SIGNIFICANCE AND USE

5.1 This test method is intended for use as a rapid quality control, acceptance, and assessment test. Results are obtained in five to fifteen minutes on most materials. Since the instrument parameters are adjusted to produce the same results as Test Method D2369, which takes over one hour to run, the time and effort expended on determining the optimal conditions for testing a coating with this instrumental method is valuable when numerous measurements are going to be made on different lots or batches of the same material. Also, the automation of the measurement and the calculations should lead to fewer mistakes being made by less-trained operators.

SCOPE

1.1 This test method is used to obtain rapid determination of the weight percent nonvolatile (solids) content via instrumental loss in weight technology. It is not meant as a replacement for Test Method D2369.

1.2 This test method is principally intended for quality control labs and manufacturing environments where previously characterized materials will be tested repeatedly for different batches or lots.

1.3 This test method can be used for waterborne and solventborne resins, intermediates and finished paint products. This test method may not be applicable to all types of coatings.

1.4 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

Note 1: There is no similar or equivalent ISO standard.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D7232 − 06 (Reapproved 2022)

Standard Test Method for

Rapid Determination of the Nonvolatile Content of Coatings

by Loss in Weight

This standard is issued under the fixed designation D7232; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D16TerminologyforPaint,RelatedCoatings,Materials,and

Applications

1.1 Thistestmethodisusedtoobtainrapiddeterminationof

D2369Test Method for Volatile Content of Coatings

theweightpercentnonvolatile(solids)contentviainstrumental

E180Practice for Determining the Precision of ASTM

loss in weight technology. It is not meant as a replacement for

Methods for Analysis and Testing of Industrial and Spe-

Test Method D2369.

cialty Chemicals (Withdrawn 2009)

1.2 This test method is principally intended for quality

controllabsandmanufacturingenvironmentswherepreviously

3. Terminology

characterized materials will be tested repeatedly for different

3.1 Definitions:

batches or lots.

3.1.1 The definitions used in this test method are in accor-

1.3 This test method can be used for waterborne and

dance with Terminology D16.

solventborne resins, intermediates and finished paint products.

3.1.2 nonvolatile content, n—the coating material that re-

Thistestmethodmaynotbeapplicabletoalltypesofcoatings.

mains in the pan at the conclusion of the test.

1.4 The values stated in SI units are to be regarded as the

3.2 Definitions of Terms Specific to This Standard:

standard. The values given in parentheses are for information

3.2.1 flip and squish, n—a testing technique that may be

only.

used when the expected nonvolatile content is greater than

1.5 This standard does not purport to address all of the 40%, or when the sample is highly viscous and does not

absorb well into the filter paper.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- 3.2.1.1 Discussion—The specimen is applied to the filter

paper on the sample pan, the filter paper is “flipped” over and

priate safety, health, and environmental practices and deter-

the specimen is then “squished” between the filter paper and

mine the applicability of regulatory limitations prior to use.

the sample pan in order to more uniformly distribute the

NOTE 1—There is no similar or equivalent ISO standard.

specimen. In addition, use of this technique forces the glass

1.6 This international standard was developed in accor-

fibers of the filter paper into the specimen, helping to create

dance with internationally recognized principles on standard-

pathways for volatiles release from the specimen and avoiding

ization established in the Decision on Principles for the

incomplete volatiles removal due to “skinning over” of the

Development of International Standards, Guides and Recom-

sample material.

mendations issued by the World Trade Organization Technical

3.2.2 lift, n—theresultofconvectioncurrentscreatedduring

Barriers to Trade (TBT) Committee.

theheatingofthespecimenthatraisesthesamplepanoffofits

support and falsely indicates a weight loss.

2. Referenced Documents

3.2.2.1 Discussion—This effect is compensated for by the

2.1 ASTM Standards:

use of an algorithm that is applied to the digital data.

3.2.3 syringe tare, n—a testing technique that may be used

when the expected nonvolatile content is less than 40%, or

This test method is under the jurisdiction of ASTM Committee D01 on Paint

when the sample is highly volatile and tends to evaporate

and Related Coatings, Materials, andApplications and is the direct responsibility of

rapidly.

Subcommittee D01.21 on Chemical Analysis of Paints and Paint Materials.

3.2.3.1 Discussion—The specimen weight is determined

Current edition approved Dec. 1, 2022. Published December 2022. Originally

approved in 2006. Last previous edition approved in 2016 as D7232 – 06 (2016).

usinganexternalbalancebycalculatingthedifferencebetween

DOI: 10.1520/D7232-06R22.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on The last approved version of this historical standard is referenced on

the ASTM website. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7232 − 06 (2022)

the syringe weight before (initial weight) and after (final 6.6 Compressed gas regulator(s), as needed to supply N

weight) the specimen is applied to the pan. This difference from high-pressure sources to controlled delivery pressures

between initial and final weight is the actual weight of that are appropriate for the apparatus.

specimen(see10.2),andisusedtominimizeerrorduetorapid

7. Reagents

change of the specimen weight after addition to a heated

sample pan.

7.1 Sodium Tartrate Dihydrate—ACS certified reagent

grade.

4. Summary of Test Method

8. Calibration and Standardization

4.1 The specimen is spread onto a sample pan that is

supported on a balance in a heating chamber that has been 8.1 To maintain the integrity of the test results, the balance

preheated and equilibrated to the specified idle temperature. It

shallbecalibratedusingNIST-traceableweightsandtheheater

is then heated to the specified test temperature to vaporize the shall be calibrated using an NIST-traceable temperature cali-

volatiles. The analysis is completed when the indicated rate of

bration interface per the analyzer manufacturer’s guidelines.

weight loss falls below a rate specified in the test conditions.

8.2 The calibration may be verified using sodium tartrate

The total weight loss is calculated and reported as weight

dihydrate, which has a theoretical water content of 15.66%,

percent nonvolatiles. Both the analyzer’s balance and heater

with an acceptable result range of 15.61% to 15.71%. Other

arecalibratedwithNIST-traceablestandardstoachieveprecise

procedures for materials with known theoretical water content

and accurate results.

are acceptable for verification as specified by the analyzer

4.2 Through adjustment of the analyzer’s parameter manufacturer.

settings, a set of optimal conditions is developed for each

8.3 Prepare the analyzer for use, select the preprogrammed

material type to measure the percent nonvolatiles. These

instrument parameters for sodium tartrate dihydrate (or other

optimal conditions are recorded and may be used for repeat

standard material if applicable) and prepare analyzer for

testing of that material.

analysisasdescribedin9.1usingaflatpanwithoutfilterpaper.

8.4 Initiate the test on the analyzer and follow the prompts

5. Significance and Use

for placing the specimen on the sample pan.

5.1 This test method is intended for use as a rapid quality

8.5 Spreadathin,evenlayerof sodium tartrate dihydrateof

control, acceptance, and assessment test. Results are obtained

appropriate specimen size onto the pan, then close lid to begin

in five to fifteen minutes on most materials. Since the instru-

test. Specimen size shall be determined by analyzer manufac-

ment parameters are adjusted to produce the same results as

turer.

TestMethodD2369,whichtakesoveronehourtorun,thetime

8.6 If results are not within the acceptable range, first

and effort expended on determining the optimal conditions for

perform a temperature calibration, temperature calibration

testing a coating with this instrumental method is valuable

verification, and then a balance calibration to ensure proper

when numerous measurements are going to be made on

analyzer performance. Retest with sodium tartrate dihydrate

different lots or batches of the same material. Also, the

(or other standard material as specified by the instrument

automation of the measurement and the calculations should

manufacturer). If results still are not within the acceptable

lead to fewer mistakes being made by less-trained operators.

range, contact analyzer manufacturer.

6. Apparatus

9. Procedure

6.1 Analyzer, containing:

9.1 Preparing Analyzer for Sample Analysis:

6.1.1 An oven capable of heating the sample to at least

9.1.1 Place the analyzer on a flat, level surface.

225°C.

9.1.2 Establish N purge to the heating chamber per the

6.1.2 A balance capable of measuring to the nearest

instrument manufacturer’s instructions.

0.0001g.

9.1.3 Turn the analyzer on and allow equilibration at the

6.1.3 An electronic means of compensating for lift caused

recommended idle temperature for balance calibration for

by convection currents created during testing.

30min.

6.1.4 A processor that is capable of converting the loss of

9.1.4 Performbalancecalibrationpertheanalyzermanufac-

weight to digital data.

turer’s instructions.

6.1.5 Digital display for presenting the digital data as

9.2 Performing Sample Analysis:

weight percent nonvolatiles.

9.2.1 Programtheanalyzerwiththedesiredtestparameters,

6.2 Flat disposable pan, of aluminum alloy 3003, with

or select the suggested test conditions from Annex A1. See

smooth, uncoated, oil-free surface.

9.3.1 for determining the optimal conditions for testing a

coating. See 9.3.5 for repeat testing of a coating using

6.3 Round glass-fiber filter paper, Grade 111.

previously determined optimal conditions.

6.4 Syringe, 3 cc plastic slip-tip without needle but with

9.2.2 Place a clean, flat sample pan with glass filter paper,

cap, capable of dispensing specimen onto pan.

rough side up, on the pan support and close the lid.Allow the

6.5 Nitrogen compressed gas (N ) – dry and oil-free. analyzer to equilibrate at the desired idle temperature.

D7232 − 06 (2022)

9.2.3 Ensure sample material is thoroughly mixed before 9.2.6 At the end of the test, allow the analyzer to cool and

drawingspecimenintosyringe. Ifusingsyringetaretechnique remove the sample pan. If syringe tare was used, input the

(see 3.2.3), proceed to step 9.2.4. If using flip and squish (see actual specimen weight at the completion of the test to obtain

3.2.1) technique, proceed to step 9.2.5. the final result.

9.2.4 If syringe tare is used: 9.2.7 Record the result as displayed in percent nonvolatiles.

9.2.4.1 Initiate the test on the analyzer and follow the

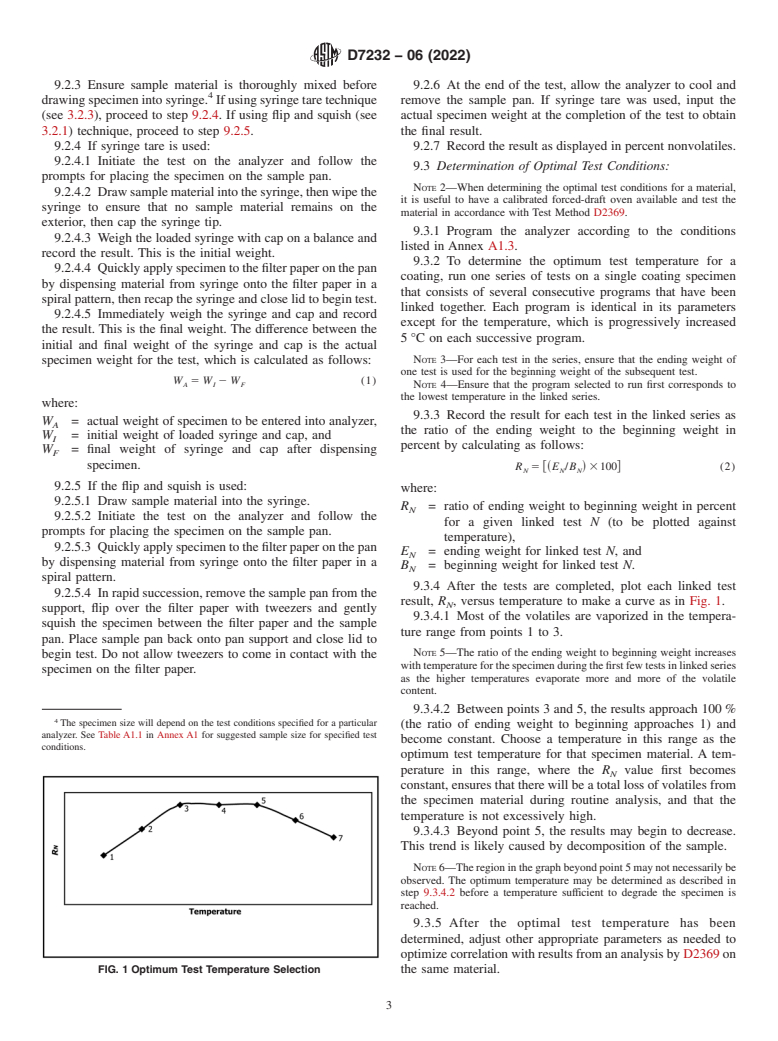

9.3 Determination of Optimal Test Conditions:

prompts for placing the specimen on the sample pan.

NOTE 2—When determining the optimal test condit

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.