ASTM D5795-16

(Test Method)Standard Test Method for Determination of Liquid Water Absorption of Coated Wood and Wood Based Products Via “Cobb Ring” Apparatus

Standard Test Method for Determination of Liquid Water Absorption of Coated Wood and Wood Based Products Via “Cobb Ring” Apparatus

SIGNIFICANCE AND USE

5.1 This test method provides a simple quantitative measure of water absorption by coated wood or wood based products.

5.2 This test method has demonstrated utility for wood or wood based products ranging in thickness from approximately 6 to 25 mm (1/4 to 1 in.).

5.3 Conditioning of substrate, coated sample preparation, application method, dry film thickness, cure conditions, and number of replicate specimens should be agreed upon between the purchaser and the supplier of the coating material.

5.4 Such measurements are used as indicators or predictors of the anticipated performance of coated wood or wood based products during exterior exposure. They may be used for developmental evaluation of coatings, substrates, or both. They may also be useful for quality control or monitoring of the production of coated wood and wood based products.

SCOPE

1.1 This test method is intended to serve as a means for measurement of liquid water that passes through a wetted paint film, and which is subsequently absorbed and retained by the underlying wood or wood-based substrate. Alternative techniques for the use of the “Cobb Ring” apparatus are described.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D5795 − 16

Standard Test Method for

Determination of Liquid Water Absorption of Coated Wood

1

and Wood Based Products Via “Cobb Ring” Apparatus

This standard is issued under the fixed designation D5795; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E691 Practice for Conducting an Interlaboratory Study to

Determine the Precision of a Test Method

1.1 This test method is intended to serve as a means for

measurement of liquid water that passes through a wetted paint

3. Terminology

film, and which is subsequently absorbed and retained by the

3.1 Definitions of Terms Specific to This Standard:

underlying wood or wood-based substrate. Alternative tech-

3.1.1 Cobb unit (C.U.), n—the weight of distilled water

niques for the use of the “Cobb Ring” apparatus are described.

absorbed by the underlying wood substrate in grams per 645

1.2 The values stated in SI units are to be regarded as the 2 2

cm (100 in. ) of surface area (discounting additional areas

standard. The values given in parentheses are for information

contributed by texturing or grooves) per 24-h time period.

only.

3.1.2 Cobb unit (C.U.) factor, n—a dimensionless math-

1.3 This standard does not purport to address all of the

ematical term which, for a given ring size, may be multiplied

safety concerns, if any, associated with its use. It is the

times the weight change after 24 h to calculate the Cobb unit

responsibility of the user of this standard to establish appro-

value.

priate safety and health practices and determine the applica-

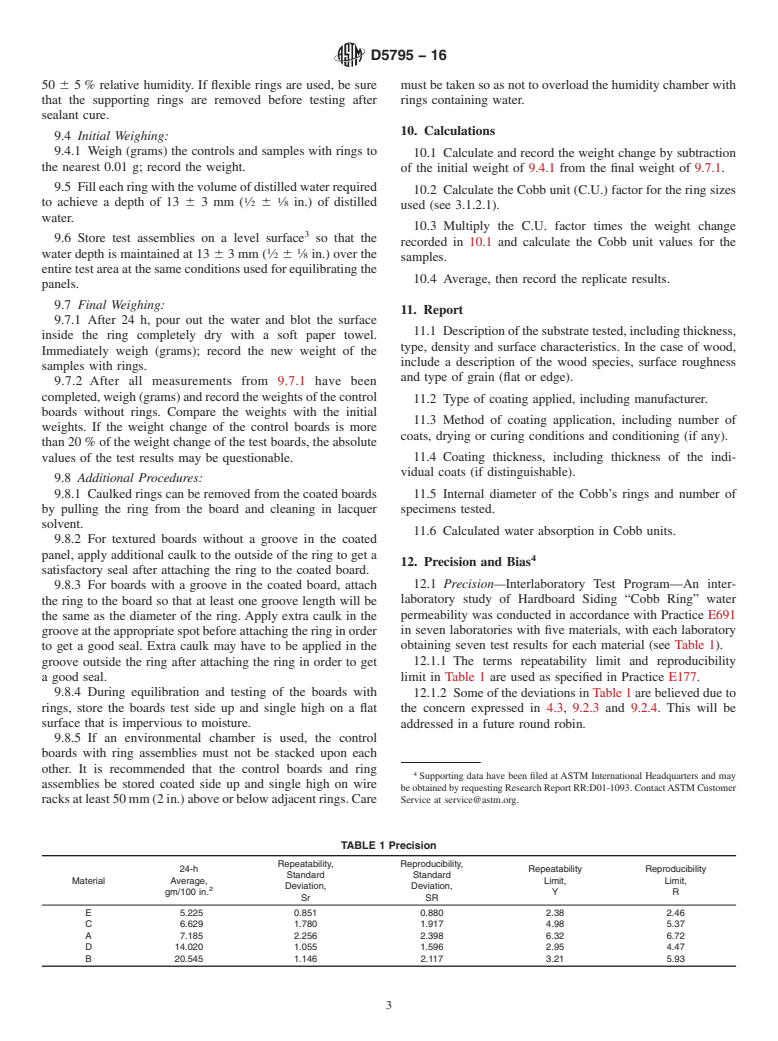

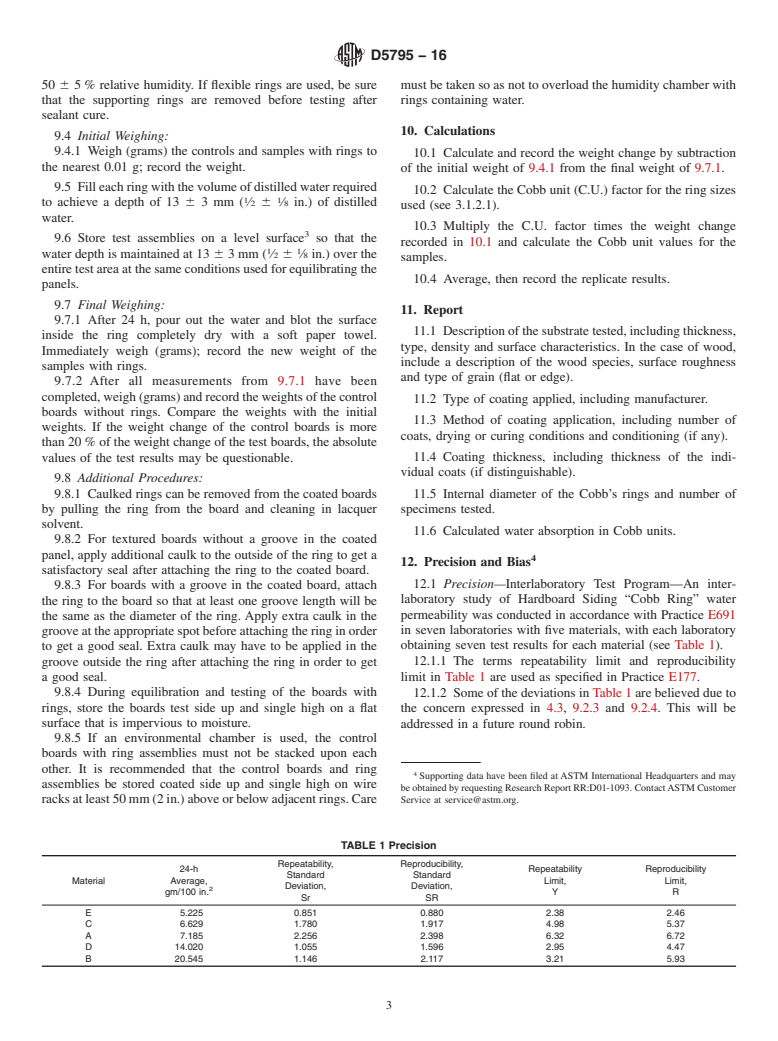

3.1.2.1 Discussion—The C.U. factor is calculated as fol-

bility of regulatory limitations prior to use.

lows:

SI Units

2. Referenced Documents

2 64516 64516

2.1 ASTM Standards:

C.U.Factor 5 5 (1)

2 2

RingArea~mm ! πr

D9 Terminology Relating to Wood and Wood-Based Prod-

Imperial Units

ucts

100 100

D16 TerminologyforPaint,RelatedCoatings,Materials,and

C.U.Factor 5 5 (2)

2 2

RingArea in. πr

~ !

Applications

D1193 Specification for Reagent Water

where:

D5235 Test Method for Microscopic Measurement of Dry

r = radius, mm (in.)

Film Thickness of Coatings on Wood Products

For example, for 100 mm (4 in.) inside diameter or 50 mm

D6132 Test Method for Nondestructive Measurement of Dry

(2 in.) internal radius ring:

Film Thickness of Applied Organic Coatings Using an

Ultrasonic Coating Thickness Gage

64516 64516

C.U. Factor 5 2 2 8.22 (3)

2

E177 Practice for Use of the Terms Precision and Bias in

3.14 50! 7850

~

ASTM Test Methods

3.1.3 wood based products, n—boards or other form of

structured or decorative materials manufactured from wood

1

fibers, flakes or strands or veneers and various resin binders

This test method is under the jurisdiction of ASTM Committee D01 on Paint

and Related Coatings, Materials, andApplications and is the direct responsibility of

otherwise known as engineered wood products or wood

Subcommittee D01.52 on Factory Coated Wood Products.

composite.

Current edition approved July 15, 2016. Published October 2016. Originally

approved in 1995. Last previous edition approved in 2008 as D5795 – 95 (2008).

4. Summary of Test Method

DOI: 10.1520/D5795-16.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

4.1 Suitable size rings of metal or plastic are adhered or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

clampedtotheflat,coatedsurfaceofcompositewoodpanelsto

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. be tested.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D5795 − 16

4.2 The assembly is equilibrated at a constant temperature 6.5 Balance, with sufficient capacity (typically 400 g) and

and humidity and weighed. 0.01-g accuracy.

3

4.3 The weighed assembly is placed on horizontal surface

7. Materials

in a controlled temperature and humidity room or environmen-

7.1 Butyl or Silicone Caulk, which has been determined not

tal chamber. Water is placed in the ring and left in contact with

to contribute to assembly weight change through absorption of

the board face for 24 h.

water or interaction with the coating.

4.4 After24htheremainingwaterisremovedfromthering,

7.2 Distilled Water, (see Specification D1193).

the assembly blotted dry and reweighed.

7.3 Test Boards, appropriately identified, coated or

4.5 The increase i

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D5795 − 95 (Reapproved 2008) D5795 − 16

Standard Test Method for

Determination of Liquid Water Absorption of Coated

HardboardWood and Other Composite Wood Based

Products Via

1

“Cobb Ring” Apparatus

This standard is issued under the fixed designation D5795; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method is intended to serve as a means for measurement of liquid water that passes through a wetted paint film,

and which is subsequently absorbed and retained by the underlying wood or wood-based substrate. Alternative techniques for the

use of the “Cobb Ring” apparatus are described.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D9 Terminology Relating to Wood and Wood-Based Products

D16 Terminology for Paint, Related Coatings, Materials, and Applications

D1193 Specification for Reagent Water

D5235 Test Method for Microscopic Measurement of Dry Film Thickness of Coatings on Wood Products

D6132 Test Method for Nondestructive Measurement of Dry Film Thickness of Applied Organic Coatings Using an Ultrasonic

Coating Thickness Gage

E177 Practice for Use of the Terms Precision and Bias in ASTM Test Methods

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

2

3.1.1 Cobb unit (C.U.), n—Thethe weight of distilled water absorbed by the underlying wood substrate in grams per 645 cm

2

(100 in. ) of surface area (discounting additional areas contributed by texturing or grooves) per 24-h time period.

3.1.2 Cobb unit (C.U.) factor, n—a dimensionless mathematical term which, for a given ring size, may be multiplied times the

weight change after 24 h to calculate the Cobb unit value.

1

This test method is under the jurisdiction of ASTM Committee D01 on Paint and Related Coatings, Materials, and Applications and is the direct responsibility of

Subcommittee D01.52 on Factory Coated Wood Products.

Current edition approved June 1, 2008July 15, 2016. Published June 2008October 2016. Originally approved in 1995. Last previous edition approved in 20002008 as

D5795 - 95 (2000).D5795 – 95 (2008). DOI: 10.1520/D5795-95R08.10.1520/D5795-16.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’sstandard’s Document Summary page on the ASTM website.

3.1.2.1 Discussion—

The C.U. factor is calculated as follows:

SI Units

100 100

C.U. Factor 5 5 (1)

2

Area ring πr

~ !

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D5795 − 16

64516 64516

C.U. Factor 5 5 (1)

2 2

RingArea~mm ! πr

Imperial Units

100 100

C.U.Factor 5 5 (2)

2 2

RingArea in. πr

~ !

where:

r = radius, mm (in.)

where:

r = radius

For example, for 101.6-mm (4-in.) 100 mm (4 in.) inside diameter ring.or

or50

100 100

C.U. Factor 5 5 5 7.96 (2)

2

3.14~2! 12.56

mm (2 in.) internal radius ring:

64516 64516

C.U. Factor 5 2 2 8.22 (3)

2

3.14~50! 7850

3.1.3 composite wood based products, n—boards or other form of structured or decorative materials manufactured from wood

fibers, flakes or strands or veneers and various resin binders.binders otherwise known as engineered wood products or wood

composite.

3.1.3.1 Discussion—

One example is hardboard.

3.1.4 hardboard—a generic term for a panel manufactured primarily from interfelted lignocellulose fibers consolidated under

3

heat and pressures in a hot press to density of at least 31 lbs (13.95 kg) per cubic foot (cubic metre).

4. Summary of Test Method

4.1 Suitable size rings of metal or plastic are adhered or clamped to the flat, coated surface of composite wood panels to be

tested.

4.2 The assembly is equilibrated at a constant temperature and

...

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D5795 − 16

Standard Test Method for

Determination of Liquid Water Absorption of Coated Wood

1

and Wood Based Products Via “Cobb Ring” Apparatus

This standard is issued under the fixed designation D5795; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E691 Practice for Conducting an Interlaboratory Study to

Determine the Precision of a Test Method

1.1 This test method is intended to serve as a means for

measurement of liquid water that passes through a wetted paint

3. Terminology

film, and which is subsequently absorbed and retained by the

3.1 Definitions of Terms Specific to This Standard:

underlying wood or wood-based substrate. Alternative tech-

3.1.1 Cobb unit (C.U.), n—the weight of distilled water

niques for the use of the “Cobb Ring” apparatus are described.

absorbed by the underlying wood substrate in grams per 645

1.2 The values stated in SI units are to be regarded as the 2 2

cm (100 in. ) of surface area (discounting additional areas

standard. The values given in parentheses are for information

contributed by texturing or grooves) per 24-h time period.

only.

3.1.2 Cobb unit (C.U.) factor, n—a dimensionless math-

1.3 This standard does not purport to address all of the

ematical term which, for a given ring size, may be multiplied

safety concerns, if any, associated with its use. It is the

times the weight change after 24 h to calculate the Cobb unit

responsibility of the user of this standard to establish appro-

value.

priate safety and health practices and determine the applica-

3.1.2.1 Discussion—The C.U. factor is calculated as fol-

bility of regulatory limitations prior to use.

lows:

SI Units

2. Referenced Documents

2

64516 64516

2.1 ASTM Standards:

C.U.Factor 5 5 (1)

2 2

RingArea mm πr

~ !

D9 Terminology Relating to Wood and Wood-Based Prod-

Imperial Units

ucts

100 100

D16 Terminology for Paint, Related Coatings, Materials, and

C.U.Factor 5 5 (2)

2 2

RingArea in. πr

~ !

Applications

D1193 Specification for Reagent Water

where:

D5235 Test Method for Microscopic Measurement of Dry

r = radius, mm (in.)

Film Thickness of Coatings on Wood Products

For example, for 100 mm (4 in.) inside diameter or 50 mm

D6132 Test Method for Nondestructive Measurement of Dry

(2 in.) internal radius ring:

Film Thickness of Applied Organic Coatings Using an

Ultrasonic Coating Thickness Gage

64516 64516

C.U. Factor 5 2 2 8.22 (3)

2

E177 Practice for Use of the Terms Precision and Bias in

3.14 50! 7850

~

ASTM Test Methods

3.1.3 wood based products, n—boards or other form of

structured or decorative materials manufactured from wood

1

This test method is under the jurisdiction of ASTM Committee D01 on Paint fibers, flakes or strands or veneers and various resin binders

and Related Coatings, Materials, and Applications and is the direct responsibility of

otherwise known as engineered wood products or wood

Subcommittee D01.52 on Factory Coated Wood Products.

composite.

Current edition approved July 15, 2016. Published October 2016. Originally

approved in 1995. Last previous edition approved in 2008 as D5795 – 95 (2008).

4. Summary of Test Method

DOI: 10.1520/D5795-16.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

4.1 Suitable size rings of metal or plastic are adhered or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

clamped to the flat, coated surface of composite wood panels to

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. be tested.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D5795 − 16

4.2 The assembly is equilibrated at a constant temperature 6.5 Balance, with sufficient capacity (typically 400 g) and

and humidity and weighed. 0.01-g accuracy.

3

4.3 The weighed assembly is placed on horizontal surface

7. Materials

in a controlled temperature and humidity room or environmen-

7.1 Butyl or Silicone Caulk, which has been determined not

tal chamber. Water is placed in the ring and left in contact with

to contribute to assembly weight change through absorption of

the board face for 24 h.

water or interaction with the coating.

4.4 After 24 h the remaining water is removed from the ring,

7.2 Distilled Water, (see Specification D1193).

the assembly blotted dry and reweighed.

7.3 Test Boards, appropriately identified, coated or

4.5 The increase in weight of the assembly due to water

uncoated, cut to a square size that is 25.4 mm (1 in.) greater

uptake is calcula

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.