ASTM A1016/A1016M-01

(Specification)Standard Specification for General Requirements for Ferritic Alloy Steel, Austenitic Alloy Steel, and Stainless Steel Tubes

Standard Specification for General Requirements for Ferritic Alloy Steel, Austenitic Alloy Steel, and Stainless Steel Tubes

SCOPE

1.1 This specification covers a group of requirements that, unless otherwise specified in an individual specification, shall apply to the ASTM product specifications noted below.Title of SpecificationASTM DesignationSeamless Carbon-Molybdenum Alloy-Steel Boiler and Superheater Tubes A 209/A 209MSeamless Ferritic and Austenitic Alloy-Steel Boiler, Superheater, and Heat-Exchanger TubesA 213/A 213MWelded Austenitic Steel Boiler, Superheater, Heat-Exchanger, and Condenser TubesA 249/A 249MElectric-Resistance-Welded Ferritic Alloy-Steel Boiler and Superheater TubesA 250/A 250MSeamless and Welded Ferritic and Martensitic Stainless Steel Tubing for General ServiceA 268/A 268MSeamless and Welded Austenitic Stainless Steel Tubing for General Service A 269Seamless and Welded Austenitic Stainless Steel Sanitary TubingA 270Seamless and Welded Carbon and Alloy-Steel Tubes for Low-Temperature Service A 334/A 334MSeamless and Electric-Welded Low-Alloy Steel TubesA 423/A 423MWelded Austenitic Stainless Steel Feedwater Heater TubesA 688/A 688MAustenitic Stainless Steel Tubing for Breeder Reactor Core Components A 771Seamless and Welded Ferritic/Austenitic Stainless Steel Tubing for General ServiceA 789/A 789MWelded Ferritic Stainless Steel Feedwater Heater TubesA 803/A 803MAustenitic and Ferritic Stainless Steel Duct Tubes for Breeder Reactor Core ComponentsA 826High-Frequency Induction Welded, Unannealed Austenitic Steel Condenser Tubes A 851 These designations refer to the latest issue of the respective specifications.

1.2 In the case of conflict between a requirement of a product specification and a requirement of this general requirements specification, the product specification shall prevail. In the case of conflict between a requirement of the product specification or a requirement of this general requirements specification and a more stringent requirement of the purchase order, the purchase order shall prevail.

1.3 The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each System must be used independently of the other. Combining values from the two systems may result in nonconformance with the specification. The inch-pound units shall apply unless the "M" designation (SI) of the product specification is specified in the order.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: A 1016/A 1016M – 01 An American National Standard

Standard Specification for

General Requirements for Ferritic Alloy Steel, Austenitic

Alloy Steel, and Stainless Steel Tubes

This standard is issued under the fixed designation A 1016/A 1016M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope SI units are shown in brackets. The values stated in each

system are not exact equivalents; therefore, each System must

1.1 This specification covers a group of requirements that,

be used independently of the other. Combining values from the

unless otherwise specified in an individual specification, shall

two systems may result in nonconformance with the specifi-

apply to the ASTM product specifications noted below.

cation. The inch-pound units shall apply unless the “M”

Title of Specification ASTM

A

designation (SI) of the product specification is specified in the

Designation

order.

Seamless Carbon-Molybdenum Alloy-Steel Boiler and A 209/A 209M

Superheater Tubes

2. Referenced Documents

Seamless Ferritic and Austenitic Alloy-Steel Boiler, Superheater, A 213/A 213M

and Heat-Exchanger Tubes

2.1 ASTM Standards:

Welded Austenitic Steel Boiler, Superheater, Heat-Exchanger, A 249/A 249M

A 370 Test Methods and Definitions for Mechanical Testing

and Condenser Tubes

of Steel Products

Electric-Resistance-Welded Ferritic Alloy-Steel Boiler and A 250/A 250M

Superheater Tubes

A 530/A 530M Specification for General Requirements for

Seamless and Welded Ferritic and Martensitic Stainless Steel A 268/A 268M

Specialized Carbon and Alloy Steel Pipe

Tubing for General Service

Seamless and Welded Austenitic Stainless Steel Tubing for A 269 A 700 Practices for Packaging, Marking, and Loading

General Service

Methods for Steel Products for Domestic Shipment

Seamless and Welded Austenitic Stainless Steel Sanitary Tubing A 270

A 751 Test Methods, Practices, and Terminology for

Seamless and Welded Carbon and Alloy-Steel Tubes for A 334/A 334M

Low-Temperature Service Chemical Analysis of Steel Products

Seamless and Electric-Welded Low-Alloy Steel Tubes A 423/A 423M

A 941 Terminology Relating to Steel, Stainless Steel, Re-

Welded Austenitic Stainless Steel Feedwater Heater Tubes A 688/A 688M

lated Alloys, and Ferroalloys

Austenitic Stainless Steel Tubing for Breeder Reactor Core A 771

Components D 3951 Practice for Commercial Packaging

Seamless and Welded Ferritic/Austenitic Stainless Steel Tubing A 789/A 789M

E 92 Test Method for Vickers Hardness of Metallic Mate-

for General Service

rials

Welded Ferritic Stainless Steel Feedwater Heater Tubes A 803/A 803M

Austenitic and Ferritic Stainless Steel Duct Tubes for Breeder A 826 E 213 Practice for Ultrasonic Examination of Metal Pipe

Reactor Core Components 7

and Tubing

High-Frequency Induction Welded, Unannealed Austenitic Steel A 851

E 273 Practice for Ultrasonic Examination of Longitudinal

Condenser Tubes

Welded Pipe and Tubing

A

These designations refer to the latest issue of the respective specifications.

E 309 Practice for Eddy-Current Examination of Steel Tu-

1.2 In the case of conflict between a requirement of a

bular Products Using Magnetic Saturation

product specification and a requirement of this general require-

E 426 Practice for Electromagnetic (Eddy-Current) Testing

ments specification, the product specification shall prevail. In

of Seamless and Welded Tubular Products, Austenitic

the case of conflict between a requirement of the product

Stainless Steel and Similar Alloys

specification or a requirement of this general requirements

E 570 Practice for Flux Leakage Examination of Ferromag-

specification and a more stringent requirement of the purchase

netic Steel Tubular Products

order, the purchase order shall prevail.

2.2 ASME Boiler and Pressure Vessel Code:

1.3 The values stated in either inch-pound units or SI units

Section IX, Welding Qualifications

are to be regarded separately as standard. Within the text, the

Annual Book of ASTM Standards, Vol 01.01.

1 4

This specification is under the jurisdiction of ASTM Committee A01 on Steel, Annual Book of ASTM Standards, Vol 01.05.

Stainless Steel, and Related Alloysand is the direct responsibility of Subcommittee Annual Book of ASTM Standards, Vol 15.09.

A01.10on Stainless and Alloy Steel Tubular Products. Annual Book of ASTM Standards, Vol 03.01.

Current edition approved Mar. 10, 2001. Published June 2001. Annual Book of ASTM Standards, Vol 03.03.

2 8

For ASME Boiler and Pressure Vessel Code applications see related Specifi- Available from the American Society of Mechanical Engineers, 345 E. 47th St.,

cation SA XXX in Section II of that Code. New York, NY 10017.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

A 1016/A 1016M

2.3 Federal Standard: 5.1.7 End finish if required,

Fed. Std. No. 183 Continuous Identification Marking of Iron 5.1.8 Optional requirements,

and Steel Products 5.1.9 Specific type of melting, if required,

2.4 Military Standards: 5.1.10 Test report requirements,

MIL-STD-271 Nondestructive Testing Requirements for 5.1.11 Specification designation and year of issue, and

Metals 5.1.12 Special requirements or any supplementary require-

MIL-STD-163 Steel Mill Products Preparation for Ship- ments, or both.

ment and Storage

6. Chemical Composition

MIL-STD-792 Identification Marking Requirements for

6.1 Chemical Analysis—Samples for chemical analysis, and

Special Purpose Equipment

method of analysis, shall be in accordance with Test Methods,

2.5 Steel Structures Painting Council:

Practices, and Terminology A 751.

SSPC-SP6 Surface Preparation Specification No.6 Com-

6.2 Heat Analysis—An analysis of each heat of steel shall

mercial Blast Cleaning

be made by the steel manufacturer to determine the percentages

2.6 Other Documents:

of the elements specified. If secondary melting processes are

SNT-TC-1A Recommended Practice for Nondestructive

employed, the heat analysis shall be obtained from one

Personnel Qualification and Certification

remelted ingot or the product of one remelted ingot of each

AIAG Bar Code Symbology Standard

primary melt. The chemical composition thus determined, or

that determined from a product analysis made by the tubular

3. Terminology

product manufacturer, shall conform to the requirements speci-

3.1 Definitions:

fied in the product specification.

3.1.1 The definitions in A 370, A 751, and A 941 are appli-

6.3 Product Analysis—Product analysis requirements and

cable to this specification and to those listed in 1.1.

options, if any, shall be as contained in the product specifica-

3.1.2 heat, n—in secondary melting, all of the ingots

tion.

remelted from a single primary heat.

3.1.3 imperfection, n—any discontinuity or irregularity

7. Tensile Properties

found in a tube.

7.1 The material shall conform to the tensile property

requirements prescribed in the individual product specification.

4. Manufacture

7.2 The yield strength, when specified, shall be determined

4.1 The steel shall made by any process.

corresponding to a permanent offset of 0.2 % of the gage length

4.2 The primary melting is permitted to incorporate separate

or to a total extension of 0.5 % of the gage length under load.

degassing or refining and is permitted to be followed by

7.3 If the percentage of elongation of any test specimen is

secondary melting, such as electroslag remelting or vacuum-

less than that specified and any part of the fracture is more than

arc remelting.

⁄4 in. [19.0 mm] from the center of the gage length, as

4.3 When steel of different grades is sequentially strand

indicated by scribe marks on the specimen before testing, a

cast, the resultant transition material shall be removed using an

retest shall be allowed.

established procedure that positively separates the grades.

8. Standard Mass per Unit Length

5. Ordering Information

8.1 The calculated mass per foot, based upon a specified

5.1 It is the responsibility of the purchaser to specify all minimum wall thickness, shall be determined by the following

requirements that are necessary for product ordered under the

equation (see Note 1):

product specification. Such requirements to be considered

W 5 C~D–t!t (1)

include, but are not limited to, the following:

5.1.1 Quantity (feet, metres, or number of pieces), where:

C = 10.69 [0.0246615],

5.1.2 Name of material (stainless steel tubing),

W = mass per unit length, lb/ft [kg/m],

5.1.3 Method of manufacture, when applicable (seamless or

D = specified outside diameter, in. [mm], and

welded),

t = specified minimum wall thickness, in. [mm].

5.1.4 Grade or UNS number,

5.1.5 Size (outside diameter and average or minimum wall

NOTE 1—The calculated masses given by Eq 1 are based on the masses

thickness), for carbon steel tubing. The mass of tubing made of ferritic stainless steels

may be up to about 5 % less, and that made of austenitic stainless steel up

5.1.6 Length (specific or random),

to about 2 % greater than the values given. Mass of ferritic/austenitic

(duplex) stainless steel will be intermediate to the mass of fully austenitic

and fully ferritic stainless steel tubing.

Available from Standardization Documents Order Desk, Bldg. 4 Section D, 700

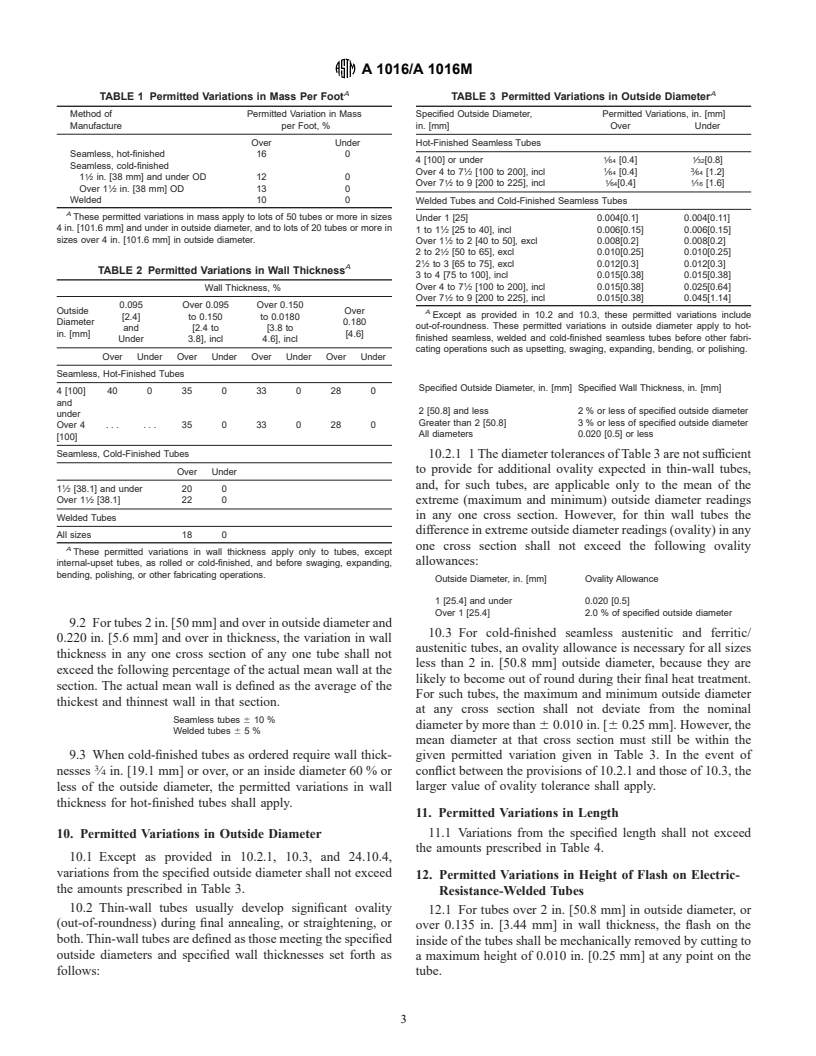

8.2 The permitted variations from the calculated mass per

Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

Available from Steel Structures Painting Council, 4400 Fifth Ave., Pittsburgh,

foot [kilogram per meter] shall be as prescribed in Table 1.

PA 15213.

Available from American Society for Nondestructive Testing, 1711 Arlingate

9. Permitted Variations in Wall Thickness

Plaza, Columbus, OH 43228.

12 9.1 Variations from the specified minimum wall thickness

Available from Automotive Industry Action Group, 26200 Lahser, Suite 200,

Southfield, MI 48034. shall not exceed the amounts prescribed in Table 2.

A 1016/A 1016M

A A

TABLE 1 Permitted Variations in Mass Per Foot TABLE 3 Permitted Variations in Outside Diameter

Method of Permitted Variation in Mass Specified Outside Diameter, Permitted Variations, in. [mm]

Manufacture per Foot, % in. [mm] Over Under

Over Under Hot-Finished Seamless Tubes

Seamless, hot-finished 16 0

1 1

4 [100] or under ⁄64 [0.4] ⁄32[0.8]

Seamless, cold-finished

1 1 3

Over4to7 ⁄2 [100 to 200], incl ⁄64 [0.4] ⁄64 [1.2]

1 ⁄2 in. [38 mm] and under OD 12 0

1 1 1

Over 7 ⁄2 to 9 [200 to 225], incl ⁄64[0.4] ⁄16 [1.6]

Over 1 ⁄2 in. [38 mm] OD 13 0

Welded 10 0 Welded Tubes and Cold-Finished Seamless Tubes

A

These permitted variations in mass apply to lots of 50 tubes or more in sizes

Under 1 [25] 0.004[0.1] 0.004[0.11]

4 in. [101.6 mm] and under in outside diameter, and to lots of 20 tubes or more in

1to1 ⁄2 [25 to 40], incl 0.006[0.15] 0.006[0.15]

sizes over 4 in. [101.6 mm] in outside diameter. 1

Over 1 ⁄2 to 2 [40 to 50], excl 0.008[0.2] 0.008[0.2]

2to2 ⁄2 [50 to 65], excl 0.010[0.25] 0.010[0.25]

2 ⁄2 to 3 [65 to 75], excl 0.012[0.3] 0.012[0.3]

A

TABLE 2 Permitted Variations in Wall Thickness

3 to 4 [75 to 100], incl 0.015[0.38] 0.015[0.38]

Over4to7 ⁄2 [100 to 200], incl 0.015[0.38] 0.025[0.64]

Wall Thickness, %

Over 7 ⁄2 to 9 [200 to 225], incl 0.015[0.38] 0.045[1.14]

0.095 Over 0.095 Over 0.150

Outside Over A

Except as provided in 10.2 and 10.3, these permitted variations include

[2.4] to 0.150 to 0.0180

Diameter 0.180

out-of-roundness. These permitted variations in outside diameter apply to hot-

and [2.4 to [3.8 to

in. [mm] [4.6]

finished seamless, welded and cold-finished seamless tubes before other fabri-

Under 3.8], incl 4.6], incl

cating operations such as upsetting, swaging, expanding, bending, or polishing.

Over Under Over Under Over Under Over Under

Seamless, Hot-Finished Tubes

Specified Outside Diameter, in. [mm] Specified Wall Thickness, in. [mm]

4 [100] 400350330280

and

2 [50.8] and less 2 % or less of specified outside diameter

under

Greater than 2 [50.8] 3 % or less of specified outside diameter

Over 4 . . 350330280

All diameters 0.020 [0.5] or less

[100]

Seamless, Cold-Finished Tubes

10.2.1 1 The diameter tolerances of Table 3 are not sufficient

to provide for additional ovality expected in thin-wall tubes,

Over Under

and, for such tubes, are applicable only to the mean of the

1 ⁄2 [38.1] and under 20 0

Over 1 ⁄2 [38.1] 22 0 extreme (maximum and minimum) outside diameter readings

in any one cross section. However, for thin wall tubes the

Welded Tubes

difference in extreme outside diameter readings (ovality) in any

All sizes 18 0

one cross section shall not exceed the following ovality

A

These permitted variations in wall thickness apply only to tubes, except

allowances:

internal-upset tubes, as rolled or cold-finished, and before swaging, expanding,

bending, polishing, or other fabricating operations.

Outside Diameter, in. [mm] Ovality Allowance

1 [25.4] and under 0.020 [0.5]

Over 1 [25.4] 2.0 % of specified outside diameter

9.2 For tubes 2 in. [50 mm] and over in outside diameter and

10.3 For cold-finished seamless austenitic and ferritic/

0.220 in. [5.6 mm] and over in thickness, the variation in wall

austenitic tubes, an ovality allowance is necessary for all sizes

thickness in any one cross section of any one tube shall not

less than 2 in. [50.8 mm] outside diameter, because they are

exceed the following percentage of the actual mean wall at the

likely to become out of round during their final heat treatment.

section. The actual mean wall is defined as the average of the

For such tubes, the maximum and minimum outside diameter

thickest and thinnest wall in that section.

at any cross section shall not deviate from the nominal

Seamless tubes 6 10 %

diameter by more than 6 0.010 in. [6 0.25 mm]. However, the

Welded tubes 6 5%

mean diameter at that cross section must still be within the

9.3 When cold-finished tubes as ordered require wall thick-

given permitted variation given in Table 3. In the event of

nesses ⁄4 in. [19.1 mm] or over, or an inside diameter 60 % or conflict between the provisions of 10.2.1 and those of 10.3, the

less of the outside diameter, the permitted variations in wall larger value of ovality tolerance shall apply.

thickness for hot-finished tubes shall apply.

11. Permitted Variations in Length

11.1 Variations from the specified length shall not exceed

10. Permitted Variations in Outside Diameter

the amounts prescribed in Table 4.

10.1 Except as provided in 10.2.1, 10.3, and 24.10.4,

variations from the specified outside diameter shall not exceed

12. Permitted Variations in Height of Flash on Electric-

the amounts prescribed i

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.