ASTM A801-04

(Specification)Standard Specification for Wrought Iron-Cobalt High Magnetic Saturation Alloys (UNS R30005 and K92650)

Standard Specification for Wrought Iron-Cobalt High Magnetic Saturation Alloys (UNS R30005 and K92650)

ABSTRACT

This specification covers wrought iron-cobalt high magnetic saturation alloys, UNS R30005 (49 % Co, 49 % Fe, 2 % V) and UNS K92650 (27 % Co, balance Fe), for use in magnetic components. The specification covers alloy supplied in form of forging billets, hot-rolled bar, hot rolled plate, cold-finished bar, and cold rolled strip. It does not cover alloy produced either by casting or by powder metallurgical techniques. The material shall conform to the chemical requirements prescribed in this specification. Magnetic property requirements and dimensional tolerances are listed. Appendices giving useful information on the heat treatment of these alloys and typical physical properties are included.

SCOPE

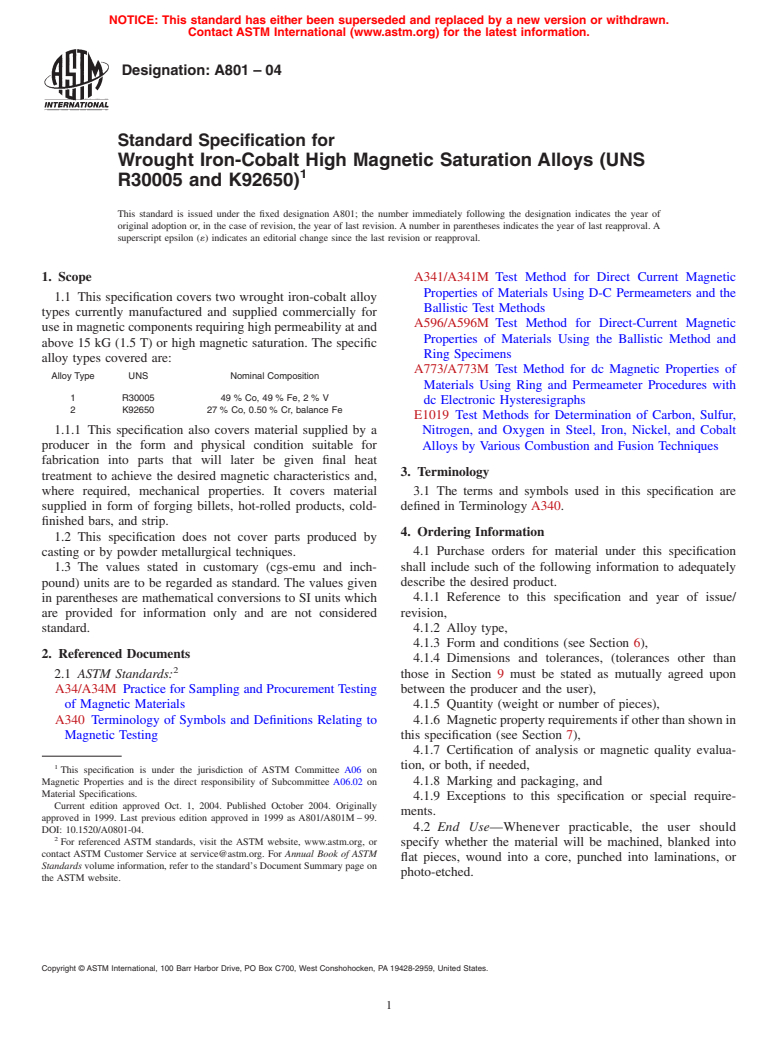

1.1 This specification covers two wrought iron-cobalt alloy types currently manufactured and supplied commercially for use in magnetic components requiring high permeability at and above 15 kG (1.5 T) or high magnetic saturation. The specific alloy types covered are:

Alloy TypeUNSNominal Composition1R3000549 % Co, 49 % Fe, 2 % V2K9265027 % Co, 0.50 % Cr, balance Fe

1.1.1 This specification also covers material supplied by a producer in the form and physical condition suitable for fabrication into parts that will later be given final heat treatment to achieve the desired magnetic characteristics and, where required, mechanical properties. It covers material supplied in form of forging billets, hot-rolled products, cold-finished bars, and strip.

1.2 This specification does not cover parts produced by casting or by powder metallurgical techniques.

1.3 The values stated in customary (cgs-emu and inch-pound) units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units which are provided for information only and are not considered standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

Designation: A801 – 04

Standard Specification for

Wrought Iron-Cobalt High Magnetic Saturation Alloys (UNS

R30005 and K92650)

This standard is issued under the fixed designation A801; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope A341/A341M Test Method for Direct Current Magnetic

Properties of Materials Using D-C Permeameters and the

1.1 This specification covers two wrought iron-cobalt alloy

Ballistic Test Methods

types currently manufactured and supplied commercially for

A596/A596M Test Method for Direct-Current Magnetic

use in magnetic components requiring high permeability at and

Properties of Materials Using the Ballistic Method and

above 15 kG (1.5 T) or high magnetic saturation. The specific

Ring Specimens

alloy types covered are:

A773/A773M Test Method for dc Magnetic Properties of

Alloy Type UNS Nominal Composition

Materials Using Ring and Permeameter Procedures with

1 R30005 49 % Co, 49 % Fe, 2 % V

dc Electronic Hysteresigraphs

2 K92650 27 % Co, 0.50 % Cr, balance Fe

E1019 Test Methods for Determination of Carbon, Sulfur,

1.1.1 This specification also covers material supplied by a

Nitrogen, and Oxygen in Steel, Iron, Nickel, and Cobalt

producer in the form and physical condition suitable for Alloys by Various Combustion and Fusion Techniques

fabrication into parts that will later be given final heat

3. Terminology

treatment to achieve the desired magnetic characteristics and,

where required, mechanical properties. It covers material 3.1 The terms and symbols used in this specification are

supplied in form of forging billets, hot-rolled products, cold- defined in Terminology A340.

finished bars, and strip.

4. Ordering Information

1.2 This specification does not cover parts produced by

casting or by powder metallurgical techniques. 4.1 Purchase orders for material under this specification

1.3 The values stated in customary (cgs-emu and inch- shall include such of the following information to adequately

describe the desired product.

pound) units are to be regarded as standard. The values given

in parentheses are mathematical conversions to SI units which 4.1.1 Reference to this specification and year of issue/

revision,

are provided for information only and are not considered

standard. 4.1.2 Alloy type,

4.1.3 Form and conditions (see Section 6),

2. Referenced Documents

4.1.4 Dimensions and tolerances, (tolerances other than

2.1 ASTM Standards: those in Section 9 must be stated as mutually agreed upon

A34/A34M Practice for Sampling and Procurement Testing between the producer and the user),

of Magnetic Materials 4.1.5 Quantity (weight or number of pieces),

A340 Terminology of Symbols and Definitions Relating to 4.1.6 Magneticpropertyrequirementsifotherthanshownin

Magnetic Testing this specification (see Section 7),

4.1.7 Certification of analysis or magnetic quality evalua-

1 tion, or both, if needed,

This specification is under the jurisdiction of ASTM Committee A06 on

Magnetic Properties and is the direct responsibility of Subcommittee A06.02 on 4.1.8 Marking and packaging, and

Material Specifications.

4.1.9 Exceptions to this specification or special require-

Current edition approved Oct. 1, 2004. Published October 2004. Originally

ments.

approved in 1999. Last previous edition approved in 1999 as A801/A801M – 99.

4.2 End Use—Whenever practicable, the user should

DOI: 10.1520/A0801-04.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

specify whether the material will be machined, blanked into

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

flat pieces, wound into a core, punched into laminations, or

Standards volume information, refer to the standard’s Document Summary page on

photo-etched.

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

A801 – 04

5. Chemical Composition user or a procedure recommended by the producer to achieve

the magnetic properties described in this specification (see

5.1 The material shall conform to the requirements pre-

Appendix X1).

scribed in Table 1. Since magnetic and possibly mechanical

7.5 Test Methods—Magnetic testing shall be conducted in

properties are of primary importance, analysis variations are

accordance with Test Method A341/A341M, Test Method

permitted subject to mutual agreement between the producer

A596/A596M, or Test Method A773/A773M. Testing shall be

and user.

conducted at the magnetic field strengths as shown in Table 2

5.2 Determination of metallic constituents shall be by a

for the alloy type.

method acceptable to both producer and user. Analysis of

7.6 Requirements—The material shall meet the require-

carbon, nitrogen, sulfur, and oxygen shall be done in accor-

ments listed in Table 2.

dance with Test Method E1019.

8. Typical Physical and Mechanical Properties

6. Form and Condition

8.1 For typical physical and mechanical properties, see

6.1 These materials are capable of being produced in forms

Appendix X2.

and conditions described suitable for further manufacture into

specific magnetic components. The desired form and condition

9. Dimensions and Tolerances

should be discussed with the producer to ensure receiving the

9.1 Forging Billet and Hot-Rolled Products—As agreed

correct product. Available forms and conditions are:

upon between the producer and user.

6.1.1 Forging Billet—Hot-worked and surface prepared by

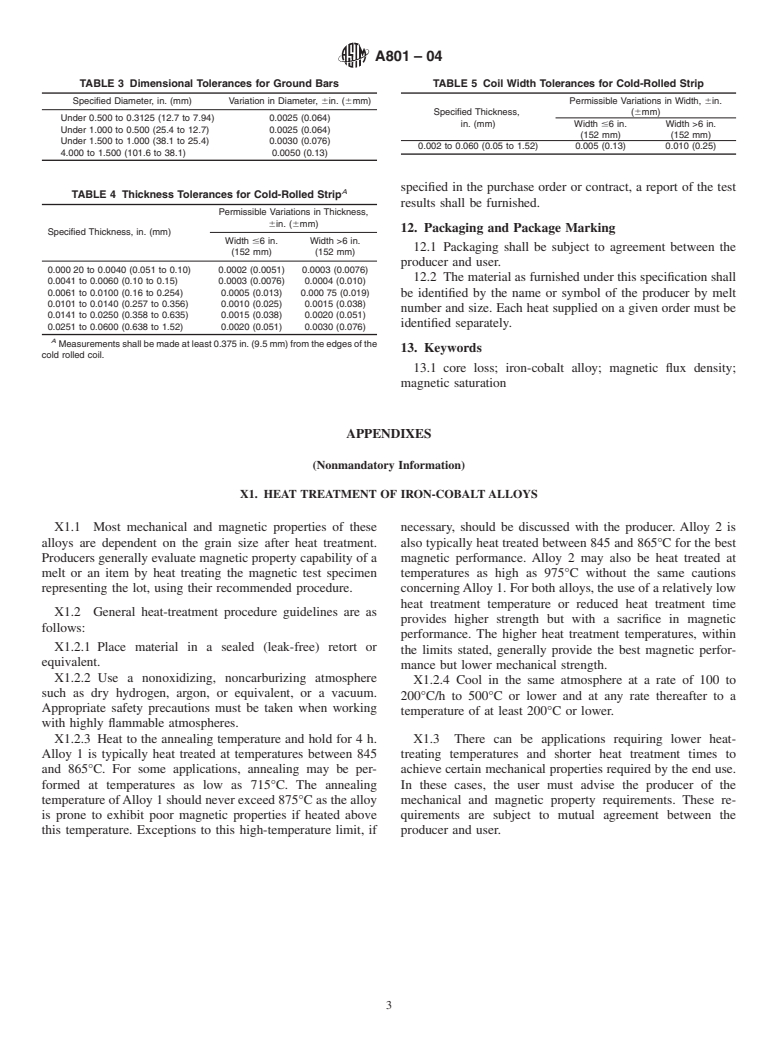

9.2 Cold-Finished Bars—See Table 3.

grinding.

9.3 Cold-Rolled Strip—See Tables 4 and 5.

6.1.2 Hot-Rolled Product—Hot-rolled, hot-rolled and acid

cleaned, and hot-rolled and mechanically cleaned.

10. Rejection and Rehearing

6.1.3 Cold-Finished Bars—Centerless ground.

10.1 Where any material fails to meet the requirements of

6.1.4 Strip—Cold-rolled.

this specification, the material shall be handled in accordance

with the procedure mutually agreed upon by the producer and

7. Magnetic Property Requirements

the user.

7.1 General—Material supplied under terms of this speci-

fication shall be tested only by use of dc test methods. AC

11. Certification

magnetic property measurements and requirements are subject

11.1 When specified in the purchase order or contract, the

to mutual agreement between the producer and user.

user shall be furnished certification that samples representing

7.2 Test Specimen—Whenever possible, test specimen size

each lot have been either tested or inspected as directed in this

and shape shall conform to Practice A34/A34M. Shapes such

specification and the requirements have been met. When

as stacked ring laminations, solid rings, and tape wound cores

are the preferred test specimens. If, however, it is impossible to

prepare a preferred test specimen shape from the item, the

TABLE 2 DC Magnetic Property Requirements

specimen shape used shall be mutually agreed upon between

Alloy Type 1 (UNS R30005)

the producer and the user.

Minimum Magnetic Flux Density kG, (T)

7.3 Density—The assumed densities of these materials for

for Magnetic Field Strengths of

magnetic test purposes are:

Product 10 Oe 20 Oe 50 Oe 100 Oe

3 3

Form Size (800 A/m) (1.6 kA/m) (4 kA/m) (8 kA/m)

Alloy Type UNS Density g/cm (kg/m )

Strip all 20.0 (2.00) 21.0 (2.10) 22.0 (2.20) 22.5 (2.25)

1 R30005 8.12 (8120)

2 K92650 7.95 (7950)

0.500 to 1

Bar in. (12.7 to 16.0 (1.60) 18.0 (1.80) 20.0 (2.00) 21.5 (2.15)

7.4 Test Specimen Heat Treatment—The heat treatment

25.4 mm)

applied to the test specimen shall be in accordance with a

procedure mutually agreed upon between the producer and the over 1 in.

Bar-billet 15.0 (1.50) 17.5 (1.75) 19.5 (1.95) 21.5 (2.15)

(25.4 mm)

Alloy Type 2 (UNS K92650)

TABLE 1 Chemical Requirements (Weight Percent) Minimum Magnetic Flux Density kG, (T)

for Magnetic Field Strengths of:

Alloy 1 Alloy 2

UNS R30005 UNS K92650

Product 50 Oe 100 Oe 150 Oe 200 Oe

Form Size (4 kA/m) (8 kA/m) (12 kA/m) (16 kA/m)

Carbon, max 0.025 0.025

Manganese, max 0.15 0.35 Strip all 18.7 (1.87) 20.3 (2.03) 21.2 (2.12) 21.7 (2.17)

Silicon, max 0.15 0.35

Phosphorus, max 0.015 0.015 up to

Sulfur, max 0.010 0.015 Bar 0.250 in. 18.7 (1.87) 20.3 (2.03) 21.2 (2.12) 21.7 (2.17)

Chromium, max 0.15 0.75 (6.35 mm)

Nickel, max 0.25 0.75

Cobalt 47.50 to 49.50 26.50 to 28.50 over 0.250

Vanadium 1.75 to 2.10 0.35 max Bar-billet in. (6.35 11.0 (1.10) 17.5 (1.75) 19.5 (1.95) 21.0 (2.10)

Iron remainder remainder mm)

A801 – 04

TABLE 3 Dimensional Tolerances for Ground Bars TABLE 5 Coil Width Tolerances for Cold-Rolled Strip

Specified Diameter, in. (mm) Variation

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.