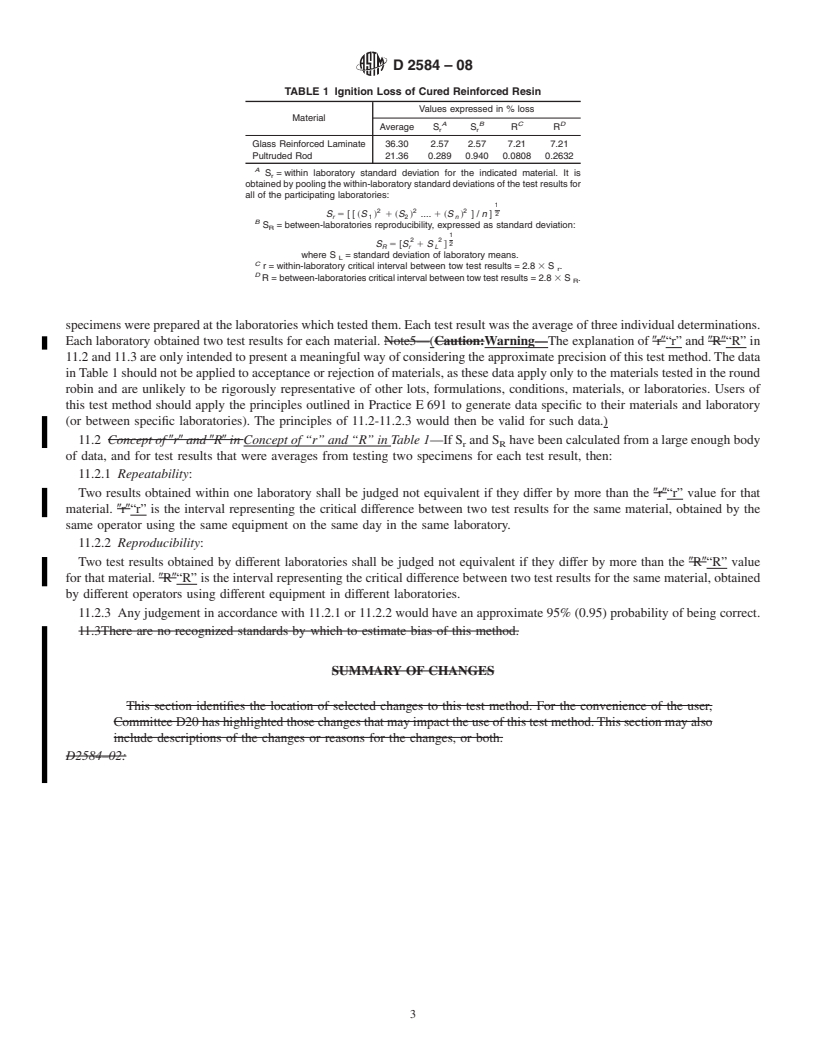

ASTM D2584-08

(Test Method)Standard Test Method for Ignition Loss of Cured Reinforced Resins

Standard Test Method for Ignition Loss of Cured Reinforced Resins

SIGNIFICANCE AND USE

This test method can be used to obtain the ignition loss of a cured reinforced resin sample. This test method can also be used to examine the fiber architecture of pultruded structural shapes.

If only glass fabric or filament is used as the reinforcement of an organic resin that is completely decomposed to volatile materials under the conditions of this test and the small amount of volatiles (water, residual solvent) that may be present is ignored, the ignition loss can be considered to be the resin content of the sample.

This test method does not provide a measure of resin content for samples containing reinforcing materials that lose weight under the conditions of the test or containing resins or fillers that do not decompose to volatile materials released by ignition.

SCOPE

1.1 This test method covers the determination of the ignition loss of cured reinforced resins. This ignition loss can be considered to be the resin content within the limitations of 4.2.

1.2 The values stated in SI units are to be regarded as the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of whoever uses this standard to consult and establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

Note 1—There is no known ISO equivalent to this standard.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D2584–08

Standard Test Method for

1

Ignition Loss of Cured Reinforced Resins

This standard is issued under the fixed designation D2584; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 4.2 If only glass fabric or filament is used as the reinforce-

ment of an organic resin that is completely decomposed to

1.1 Thistestmethodcoversthedeterminationoftheignition

volatile materials under the conditions of this test and the small

loss of cured reinforced resins. This ignition loss can be

amount of volatiles (water, residual solvent) that may be

considered to be the resin content within the limitations of 4.2.

present is ignored, the ignition loss can be considered to be the

1.2 The values stated in SI units are to be regarded as the

resin content of the sample.

standard.

4.2.1 This test method does not provide a measure of resin

1.3 This standard does not purport to address all of the

content for samples containing reinforcing materials that lose

safety concerns, if any, associated with its use. It is the

weight under the conditions of the test or containing resins or

responsibility of whoever uses this standard to consult and

fillers that do not decompose to volatile materials released by

establish appropriate safety and health practices and deter-

ignition.

mine the applicability of regulatory limitations prior to use.

NOTE 1—There is no known ISO equivalent to this standard. 5. Apparatus

5.1 Crucible, platinum or porcelain, approximately 30-mL

2. Referenced Documents

capacity.

2

2.1 ASTM Standards:

5.2 Electric Muffle Furnace, capable of maintaining a tem-

D618 Practice for Conditioning Plastics for Testing

perature of 565 6 28°C (10506 50°F).

E691 Practice for Conducting an Interlaboratory Study to

Determine the Precision of a Test Method

6. Test Specimen

6.1 A minimum of three specimens shall be tested for each

3. Summary of Test Method

sample.

3.1 The specimen contained in a crucible is ignited and

NOTE 2—Itisoftenconvenienttousesamplesobtainedfromspecimens

allowed to burn until only ash and carbon remain. The

that have been tested for mechanical properties such as flexural or tensile

carbonaceous residue is reduced to an ash by heating in a

strength. Specimens obtained from these samples must be dry and the

muffle furnace at 565°C (1050°F), cooled in a desiccator, and

fractured areas removed, leaving square, unfrayed faces, before being

weighed.

weighed and ignited.

6.2 The specimen shall weigh approximately 5 g with a

4. Significance and Use

maximum size of 2.5 by 2.5 cm by thickness (1 by 1 in. by

4.1 This test method can be used to obtain the ignition loss

thickness).

ofacuredreinforcedresinsample.Thistestmethodcanalsobe

used to examine the fiber architecture of pultruded structural NOTE 3—Materials that have gross differences in the ratio of resin to

reinforcement within an area as small as 2.5 by 2.5 cm (1 by 1 in.) may

shapes.

require a larger specimen area than that listed in 6.2. If larger specimens

are utilized, it will be necessary to cut into approximately 2.5 by 2.5-cm

(1 by 1-in.) pieces and place in a crucible of sufficient size to contain the

1

This test method is under the jurisdiction ofASTM Committee D20 on Plastics

specimen.

and is the direct responsibility of Subcommittee D20.18 on Reinforced Thermoset-

ting Plastics.

7. Conditioning

Current edition approved May 1, 2008. Published June 2008. Originally

7.1 Conditioning—Conditionthetestspecimensat2362°C

approved in 1967. Last previous edition approved in 2002 as D2584 - 02. DOI:

10.1520/D2584-08.

(73.4 6 3.6°F) and 50 6 5 % relative humidity for not less

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

than 40 h prior to test in accordance with Procedure A of

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Practice D618 for those tests where conditioning is required. In

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. cases of disagreement, the tolerances shall be 61°C (61.8°F)

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D2584–08

and 62 %relativehumidity.Theconditioningisnotrequiredif 10.1.2 The ignition loss, weight percent of the sample, and

the test is only performed to examine the fiber architecture. standard deviation. If only glass reinforcement and organic

7.2 Test Conditions—Conduct tests in the sta

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D2584–02 Designation:D2584–08

Standard Test Method for

1

Ignition Loss of Cured Reinforced Resins

This standard is issued under the fixed designation D 2584; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope *

1.1 Thistestmethodcoversthedeterminationoftheignitionlossofcuredreinforcedresins.Thisignitionlosscanbeconsidered

to be the resin content within the limitations of 4.2.

1.2 The values stated in SI units are to be regarded as the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of whoever uses this standard to consult and establish appropriate safety and health practices and determine the applicability of

regulatory limitations prior to use.

NOTE 1—There is no known ISO equivalent to this standard.

2. Referenced Documents

2

2.1 ASTM Standards:

D 618 Practice for Conditioning Plastics for Testing

E 691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

3. Summary of Test Method

3.1 The specimen contained in a crucible is ignited and allowed to burn until only ash and carbon remain. The carbonaceous

residue is reduced to an ash by heating in a muffle furnace at 565°C (1050°F), cooled in a desiccator, and weighed.

4. Significance and Use

4.1This test method can be used to obtain the ignition loss of a cured reinforced resin sample.

4.1 This test method can be used to obtain the ignition loss of a cured reinforced resin sample. This test method can also be

used to examine the fiber architecture of pultruded structural shapes.

4.2 If only glass fabric or filament is used as the reinforcement of an organic resin that is completely decomposed to volatile

materials under the conditions of this test and the small amount of volatiles (water, residual solvent) that may be present is ignored,

the ignition loss can be considered to be the resin content of the sample.

4.2.1 This test method does not provide a measure of resin content for samples containing reinforcing materials that lose weight

under the conditions of the test or containing resins or fillers that do not decompose to volatile materials released by ignition.

5. Apparatus

5.1 Crucible, platinum or porcelain, approximately 30-mL capacity.

5.2 Electric Muffle Furnace, capable of maintaining a temperature of 565 6 28°C (10506 50°F).

6. Test Specimen

6.1 A minimum of three specimens shall be tested for each sample.

NOTE1—It 2—It is often convenient to use samples obtained from specimens that have been tested for mechanical properties such as flexural or tensile

strength. Specimens obtained from these samples must be dry and the fractured areas removed, leaving square, unfrayed faces, before being weighed and

ignited.

6.2 The specimen shall weigh approximately 5 g with a maximum size of 2.5 by 2.5 cm by thickness (1 by 1 in. by thickness).

1

This test method is under the jurisdiction of ASTM Committee D20 on Plastics and is the direct responsibility of Subcommittee D20.18 on Reinforced Thermosetting

Plastics.

Current edition approved March 10, 2002. Published May 2002. Originally published as D2584–67T. Last previous edition D2584–94.

Current edition approved May 1, 2008. Published June 2008. Originally approved in 1967. Last previous edition approved in 2002 as D 2584 - 02.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book ofASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D2584–08

NOTE 23—Materials that have gross differences in the ratio of resin to reinforcement within an area as small as 2.5 by 2.5 cm (1 by 1 in.) may require

a larger specimen area than that listed in 6.2. If larger specimens are utilized, it will be necessary to cut into approximately 2.5 by 2.5-cm (1 by 1-in.)

pieces and place in a crucible of sufficient size to contain the specimen.

7. Conditionin

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.