ASTM D7169-05

(Test Method)Standard Test Method for Boiling Point Distribution of Samples with Residues Such as Crude Oils and Atmospheric and Vacuum Residues by High Temperature Gas Chromatography

Standard Test Method for Boiling Point Distribution of Samples with Residues Such as Crude Oils and Atmospheric and Vacuum Residues by High Temperature Gas Chromatography

SIGNIFICANCE AND USE

The determination of the boiling point distribution of crude oils and vacuum residues, as well as other petroleum fractions, yields important information for refinery operation. These boiling point distributions provide information as to the potential mass percent yield of products. This test method may provide useful information that can aid in establishing operational conditions in the refinery. Knowledge of the amount of residue produced is important in determining the economics of the refining process.

SCOPE

1.1 This test method covers the determination of the boiling point distribution and cut point intervals of crude oils and residues by using high temperature gas chromatography. The amount of residue (or sample recovery) is determined using an external standard.

1.2 This test method extends the applicability of simulated distillation to samples that do not elute completely from the chromatographic system. This test method is used to determine the boiling point distribution through a temperature of 720C. This temperature corresponds to the elution of n-C100.

1.3 This test method is used for the determination of boiling point distribution of crude oils. This test method uses capillary columns with thin films, which results in the incomplete separation of C 4-C8 in the presence of large amounts of carbon disulfide, and thus yields an unreliable boiling point distribution corresponding to this elution interval. In addition, quenching of the response of the detector employed to hydrocarbons eluting during carbon disulfide elution, results in unreliable quantitative analysis of the boiling distribution in the C 4-C8 region. Since the detector does not quantitatively measure the carbon disulfide, its subtraction from the sample using a solvent-only injection and corrections to this region via quenching factors, results in an approximate determination of the net chromatographic area. A separate, higher resolution gas chromatograph (GC) analysis of the light end portion of the sample may be necessary in order to obtain a more accurate description of the boiling point curve in the interval in question (see ).

1.4 This test method is also designed to obtain the boiling point distribution of other incompletely eluting samples such as atmospheric residues, vacuum residues, etc., that are characterized by the fact that the sample components are resolved from the solvent.

1.5 This test method is not applicable for the analysis of materials containing a heterogeneous component such as polyesters and polyolefins.

1.6 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific warning statements are given in Section 8.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7169 – 05

Standard Test Method for

Boiling Point Distribution of Samples with Residues Such

as Crude Oils and Atmospheric and Vacuum Residues by

High Temperature Gas Chromatography

This standard is issued under the fixed designation D7169; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.5 This test method is not applicable for the analysis of

materials containing a heterogeneous component such as

1.1 Thistestmethodcoversthedeterminationoftheboiling

polyesters and polyolefins.

point distribution and cut point intervals of crude oils and

1.6 Thevaluesstatedininch-poundunitsaretoberegarded

residues by using high temperature gas chromatography. The

as standard. The values given in parentheses are mathematical

amountofresidue(orsamplerecovery)isdeterminedusingan

conversions to SI units that are provided for information only

external standard.

and are not considered standard.

1.2 This test method extends the applicability of simulated

1.7 This standard does not purport to address all of the

distillation to samples that do not elute completely from the

safety concerns, if any, associated with its use. It is the

chromatographicsystem.Thistestmethodisusedtodetermine

responsibility of the user of this standard to establish appro-

the boiling point distribution through a temperature of 720°C.

priate safety and health practices and determine the applica-

This temperature corresponds to the elution of n-C .

bility of regulatory limitations prior to use. Specific warning

1.3 Thistestmethodisusedforthedeterminationofboiling

statements are given in Section 8.

point distribution of crude oils.This test method uses capillary

columns with thin films, which results in the incomplete

2. Referenced Documents

separationofC -C inthepresenceoflargeamountsofcarbon

4 8

2.1 ASTM Standards:

disulfide, and thus yields an unreliable boiling point distribu-

D2887 Test Method for Boiling Range Distribution of

tioncorrespondingtothiselutioninterval.Inaddition,quench-

Petroleum Fractions by Gas Chromatography

ing of the response of the detector employed to hydrocarbons

D2892 Test Method for Distillation of Crude Petroleum

eluting during carbon disulfide elution, results in unreliable

(15-Theoretical Plate Column)

quantitative analysis of the boiling distribution in the C -C

4 8

D4057 Practice for Manual Sampling of Petroleum and

region. Since the detector does not quantitatively measure the

Petroleum Products

carbon disulfide, its subtraction from the sample using a

D6352 Test Method for Boiling Range Distribution of

solvent-only injection and corrections to this region via

Petroleum Distillates in Boiling Range from 174 to 700°C

quenching factors, results in an approximate determination of

by Gas Chromatography

thenetchromatographicarea.Aseparate,higherresolutiongas

D6729 Test Method for Determination of Individual Com-

chromatograph (GC) analysis of the light end portion of the

ponents in Spark Ignition Engine Fuels by 100 Metre

sample may be necessary in order to obtain a more accurate

Capillary High Resolution Gas Chromatography

descriptionoftheboilingpointcurveintheintervalinquestion

D6730 Test Method for Determination of Individual Com-

(see Appendix X1).

ponents in Spark Ignition Engine Fuels by 100−Metre

1.4 This test method is also designed to obtain the boiling

Capillary(withPrecolumn)High-ResolutionGasChroma-

pointdistributionofotherincompletelyelutingsamplessuchas

tography

atmospheric residues, vacuum residues, etc., that are charac-

terized by the fact that the sample components are resolved

from the solvent.

This test method is under the jurisdiction of ASTM Committee D02 on

PetroleumProductsandLubricantsandisthedirectresponsibilityofSubcommittee For referenced ASTM standards, visit the ASTM website, www.astm.org, or

D02.04 on Hydrocarbon Analysis. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Current edition approved July 1, 2005. Published September 2005. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/D7169-05. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D7169 – 05

E594 Practice for Testing Flame Ionization Detectors Used 3.1.14 %recovery(RC),n—percentageofthesampleeluted.

in Gas or Supercritical Fluid Chromatography 3.1.14.1 Discussion—%Recovery is calculated from the

E1510 Practice for Installing Fused Silica Open Tubular samplearea(A ),theresponsefactor(RF),thesamplemass,

SMP

Capillary Columns in Gas Chromatographs (M ), and the solvent mass (M ) used in sample

SMP SLSMP

dissolution.

3. Terminology

3.1.15 %recovery threshold (R), n—if the %recovery falls

t

3.1 Definitions of Terms Specific to This Standard:

above a preset limit, the sample is considered fully eluted and

3.1.1 cut point interval, n—the mass% obtained between

its recovery is assumed to be 100%.

two selected temperatures of the interval.

3.1.15.1 Discussion—If the %recovery values found for

3.1.2 data acquisition rate, n—the speed of conversion of

duplicate analyses of a nearly completely eluting sample are

the analog signal to a digital signal, expressed in Hz (cycles/

99.6 and 101.2%, the %recovery threshold (R) may be set to

t

second).

99.6% and thus either of these results may be considered as

3.1.3 final boiling point (FBP), n—the temperature, for

fully eluted and set to 100%.

fully eluting samples (recovery = 100%), at which 99.5% of

3.2 Symbols:

the sample is eluted.

A =net area of the sample

SMP

3.1.4 final elution time (FEt), n—the retention time of the

A =net area of the response factor standard

STD

component of the reference time standard sample that elutes at

M =mass of solvent used in preparing sample solution

SL

the end of the temperature ramp of the oven.

M =mass of solvent used in preparing the response

SLSTD

3.1.5 final elution temperature (FET), n—the boiling point

factor standard solution

of the normal paraffin that elutes at the time when the oven

M =sample mass used in sample preparation

SMP

reaches its final temperature.

M =mass of the standard used in preparing the response

STD

3.1.6 initial boiling point (IBP), n—the temperature corre-

factor solution

spondingtoanaccumulated0.5%ofthetotalareaoftheeluted

sample after correcting for the percent of sample recovery.

4. Summary of Test Method

3.1.7 quenching factor (QF), n—a number that corrects for

4.1 This is a gas chromatographic method utilizing an inlet

the diminished response due to the solvent profile co-eluting

and a capillary column, both of which are subject to a

with sample components.

temperature program. A flame ionization detector is used as a

3.1.7.1 Discussion—Data acquired during the quenching

transducer that converts mass to an electrical signal A data

interval (QI) shall be corrected by applying the quenching

acquisition system operating in the slice mode and chromatog-

factor.

raphy software is used to accumulate the electronic signal. A

3.1.8 quenching interval (QI), n—the time interval of the

retentiontimecalibrationmixtureisusedtodeveloparetention

start and end of elution of the CS used as a solvent.

timeversusboilingpointcurve.AsolutionoftheReferenceOil

3.1.8.1 Discussion—Sample components that elute during

5010, which fully elutes from the column under the conditions

this time interval shall be corrected by a factor due to their

of the test method and whose boiling point distribution has

diminished response resulting from the co-elution of the

beencharacterizedinTestMethodD6352,isusedtodetermine

relatively large amount of solvent present in the sample with

the detector response factor. Solvent injections are made, and

the light sample components.

the resulting signal is subtracted from both the response factor

3.1.9 residue (R), n—the mass% of the sample that has not

standard and the sample chromatogram. Finally, the sample

eluted at the temperature of calculation.

solution is injected and with the use of the response factor, the

3.1.9.1 Discussion—Residueiscalculatedfromthe%recov-

amountofsamplerecoverediscalculated.Afterconvertingthe

ery.

retention times of the sample slices to temperature, the boiling

3.1.10 response factor (RF), n—the factor used in order to

point distribution can be calculated up to the recovered

calculate the %recovery of the sample.

amount.

3.1.10.1 Discussion—The response factor is determined

from the net area of the standard (A ), mass of standard

STD

5. Significance and Use

(M ), and mass of solvent (M ) used in the solution of

STD SLSTD

5.1 The determination of the boiling point distribution of

the standard. A fully eluting sample, such as Reference Oil

crude oils and vacuum residues, as well as other petroleum

5010, is used in obtaining the response factor.

fractions, yields important information for refinery operation.

3.1.11 sample area obtained (A ), n—the net chromato-

SMP

These boiling point distributions provide information as to the

graphic area (after baseline subtraction) obtained for the

potentialmasspercentyieldofproducts.Thistestmethodmay

sample at the final elution time or temperature.

provide useful information that can aid in establishing opera-

3.1.12 slice, n—the reciprocal of the data acquisition rate;

tional conditions in the refinery. Knowledge of the amount of

the time interval used to accumulate data, expressed in sec-

residueproducedisimportantindeterminingtheeconomicsof

onds.

the refining process.

3.1.12.1 Discussion—Normally 0.1 s is used. In cases

wheresampleelutesimmediatelyafterinjection,0.05sisused.

6. Apparatus

3.1.13 start elution temperature (SET), n—the temperature

at which the first amount of hydrocarbon is detected by the 6.1 Gas Chromatograph—A gas chromatograph provided

flame ionization detector above a predetermined threshold. with a cryogenic valve for cooling the oven to sub ambient

D7169 – 05

A

TABLE 1 Gas Chromatographic Conditions

necessary to obtain a minimum number of slices void of

Initial Oven Temperature −20ºC sample or solvent elution immediately after injection. Data

Initial Oven Time 0 min

acquisition systems facilitate the inspection of the baseline

Oven Temperature Program 15ºC/min

under high magnification and allow the inspection of the

Final Oven Temperature 425ºC

Final Hold Time 10 min retention time calibration mixture chromatogram. Retention

timeshiftscanbemeasured.Overlayingchromatogramsisalso

Inlet Initial Temperature 50ºC

possible to ascertain similar signal amplitude.

Inlet Temperature Program 15ºC/min

Inlet Final Temperature 425ºC

6.4 Integrator—An integrator that digitizes the signal can

also be used to acquire chromatograms of the retention time

Column 5 m 3 0.53 mm 3 0.15 µm PDMS

calibration mixture, the sample, the solvent and the reference

Column Flow 20 mL/min

Carrier Control Constant Flow oil standard.

6.5 Automatic Sample Injector—It is mandatory to use an

B

Detector FID

auto sampler since the external standard technique used in this

Detector Temperature 435°C

Detector Gases:

analysisrequiresidenticalvolumesforallinjections.Addition-

Hydrogen 40 mL/min

ally, small volumes (0.1 to 0.2 µL) shall be injected in a

Air 450 mL/min

reproducible manner. Syringes of 5 to 10 µL having needle

Make-Up (N , He) 15 mL/min

gauges of size 23 to 26 are to be used.

Volume Injected 0.2 µL

6.6 Carrier Gas Control—The gas chromatograph shall be

Sample Concentration 2.0 % (m/m)

operated under constant flow conditions. The flow rate at the

Data Acquisition Rate 10 Hz

Total Acquisition Time 40-50 min

beginning of the oven temperature program shall not differ by

A

Conditions used for the interlaboratory study. more than 1% from the flow measured at the final oven

B

Use GC manufacturer’s recommendations.

temperature. Electronic pneumatic control is highly recom-

mended.

7. Column and Column Performance Criteria

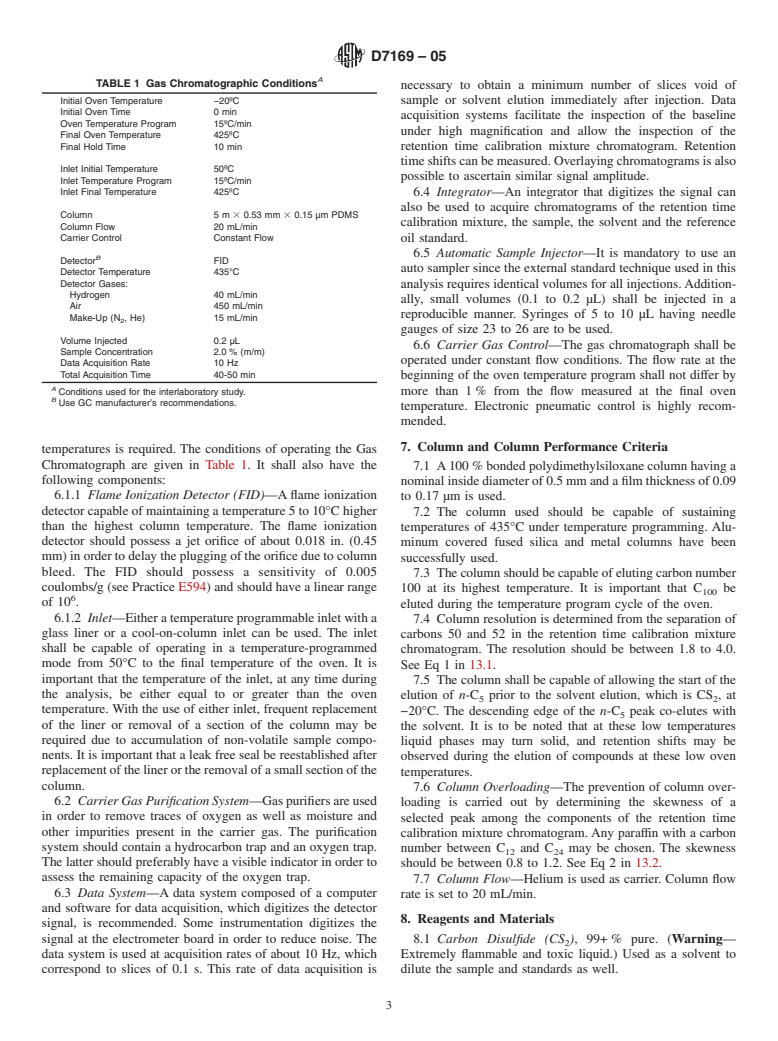

temperatures is required. The conditions of operating the Gas

Chromatograph are given in Table 1. It shall also have the

7.1 A100%bondedpolydimethylsiloxanecolumnhavinga

following components:

nominalinsidediameterof0.5mmandafilmthicknessof0.09

6.1.1 Flame Ionization Detector (FID)—Aflame ionization

to 0.17 µm is used.

detectorcapableofmaintainingatemperature5to10°Chigher

7.2 The column used should be capable of sustaining

than the highest column temperature. The flame ionization

temperatures of 435°C under temperature programming. Alu-

detector should possess a jet orifice of about 0.018 in. (0.45

minum covered fused silica and metal columns have been

mm)inordertodelaythepluggingoftheorificeduetocolumn

successfully used.

bleed. The FID should possess a sensitivity of 0.005

7.3 Thecolumnshouldbecapableofelutingcarbonnumber

coulombs/g(seePracticeE594)andshouldhavealinearrange

100 at its highest temperature. It is important that C be

of 10 .

eluted during the temperature program cycle of the oven.

6.1.2 Inlet—Eitheratemperatureprogrammableinletwitha

7.4 Column resolution is determined from the separation of

glass liner or a cool-on-column inlet can be used. The inlet

carbons 50 and 52 in the retention time calibration mixture

shall be capable of operating in a temperature-programmed

chromatogram. The resolution should be between 1.8 to 4.0.

mode from 50°C to the final temperature of the oven. It is

See Eq 1 in 13.1.

important that the temperature of the inlet, at any time during

7.5 The column shall be capable of allowing the start of the

the analysis, be either equal to or greater than the oven

elution of n-C prior to the solvent elution, which is CS,at

5 2

temperature. With the use of either inlet, frequent replacement

−20°C. The descending edge of the n-C peak co-elutes with

of the liner or removal of a section of the column may be the solvent. It is to be noted that at these low temperatures

required due to accumulation of non-volatile sample compo-

liquid phases may turn solid, and retention shifts may be

nents. It is important that a leak free seal be reestablished after

observed during the elution of compounds at these low oven

replacementofthelinerortheremovalofasmallsectionofthe

temperatures.

column.

7.6 Column Overloading—The prevention of column over-

6.2 CarrierGasPurificationSystem—Gaspurifiersareused

loading is carried out by determining the skewness of a

in order to remove traces of oxygen as well as moisture and

selected peak among the components of the retention time

other impurities present in the carrier gas. The purification

calibration mixture chromatogram.Any paraffin with

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.