ASTM D6286-98(2006)

(Guide)Standard Guide for Selection of Drilling Methods for Environmental Site Characterization

Standard Guide for Selection of Drilling Methods for Environmental Site Characterization

SIGNIFICANCE AND USE

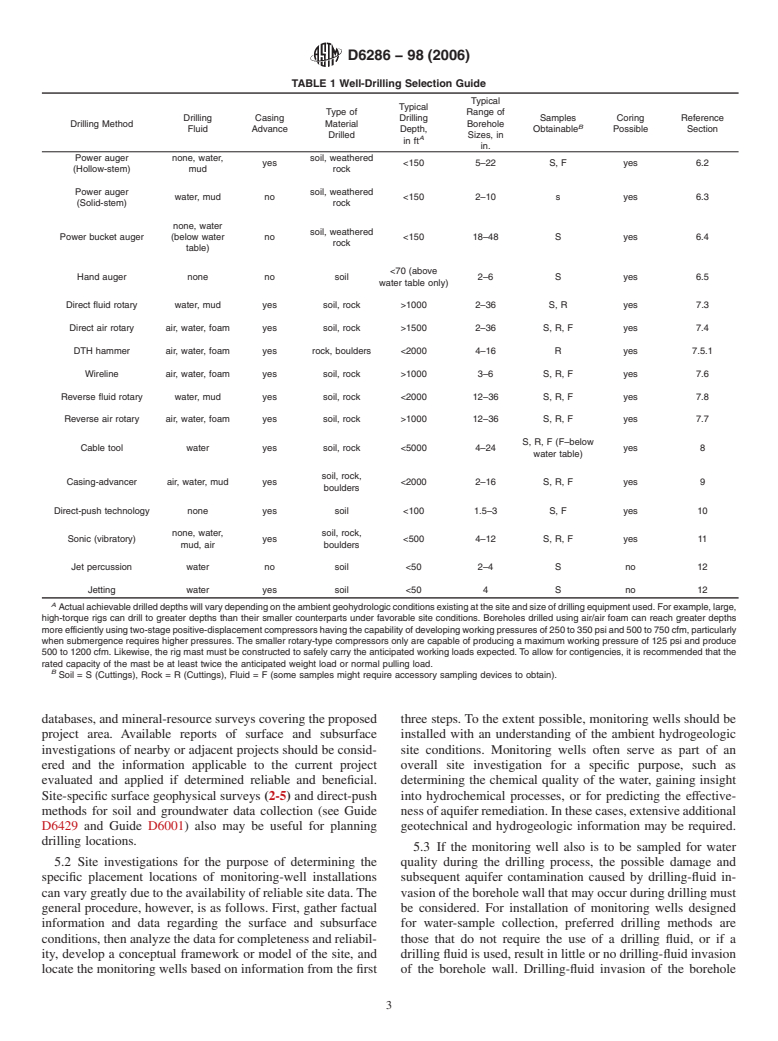

The selection of particular method(s) for drilling monitoring wells (see Table 1) requires that specific characteristics of each site be considered. These characteristics would include, but are not limited to, the ambient hydrogeologic parameters and conditions existing at the site. This guide is intended to make the user aware of some of the various drilling methods available and the applications, advantages and disadvantages of each with respect to determing groundwater chemistry and other hydrogeologic properties data.

This guide can be used in conjunction with Guide D6169. There are several guides that deal with individual drilling methods (see Guides D5781, D5782, D5783, D5784, D5872, D5875, and D5876) and how to the complete them for water quality monitoring device installation (see Practice D5092).

TABLE 1 Well-Drilling Selection Guide Drilling MethodDrilling

FluidCasing

AdvanceType of

Material

DrilledTypical

Drilling

Depth,

in ftATypical

Range of

Borehole

Sizes, in

in.Samples

ObtainableBCoring

PossibleReference

Section Power auger

(Hollow-stem)none, water, mudyessoil, weathered rock1505–22S, Fyes6.2 Power auger

(Solid-stem)water, mudnosoil, weathered rock1502–10syes6.3 Power bucket augernone, water (below water table)nosoil, weathered rock15018–48Syes6.4 Hand augernonenosoil70 (above water table only)2–6Syes6.5 Direct fluid rotarywater, mudyessoil, rock>10002–36S, Ryes7.3 Direct air rotaryair, water, foamyessoil, rock>15002–36S, R, Fyes7.4 DTH hammerair, water, foamyesrock, boulders20004–16Ryes7.5.1 Wirelineair, water, foamyessoil, rock>10003–6S, R, Fyes7.6 Reverse fluid rotarywater, mudyessoil, rock200012–36S, R, Fyes7.8 Reverse air rotaryair, water, foamyessoil, rock>100012–36S, R, Fyes7.7 Cable toolwateryessoil, rock50004–24S, R, F (F–below water table)yes8 Casing-advancerair, water, mudyessoil, rock, boulders20002–16S, R, Fyes9 Direct-push technologynoneyessoil1001.5–3S, Fyes10 Sonic (vibratory)none, wa...

SCOPE

1.1 This guide provides descriptions of various drilling methods for environmental site characterization along with advantages and disadvantages associated with each method discussed. A comprehensive description of these drilling methods can be found in individual ASTM standards, see Section 2. This guide is intended to aid in the selection of drilling method(s) for environmental soil and rock borings and the installation of monitoring wells and other water-quality monitoring devices.

1.2 This guide does not address methods of well construction, well development, or well completion. These topics are covered in other ASTM documents, see Section 2.

1.3 This guide cannot address all possible subsurface conditions that may occur such as, geologic, topographic, climatic, or anthropogenic. Site evaluation for engineering, design, and construction purposes is addressed in Guide D420.

1.4 The values stated in SI units are to be regarded as the standard. Because dimensions of materials used in the drilling industry are given in inch-pound units by convention, inch-pound units also are used in this guide.

1.5 This guide does not specifically address methods of lithologic sample collection, such as coring, that may require the use of a specific drilling method. Other ASTM guides should be consulted for sampling methods (see Guide D6169) and equipment necessary for specific projects.

1.6 This guide does not purport to comprehensively address all of the methods and the issues associated with drilling for environmental purposes. Users should seek qualified professionals for decisions as to the proper equipment and methods that would be most successful for their site investigation. Other methods may be available for drilling and qualified professionals should have flexibility to exercise judgment as to possible alternatives not covered in this guide. The guide is current at the time of issue, but new alternative methods may b...

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D6286 − 98 (Reapproved2006)

Standard Guide for

Selection of Drilling Methods for Environmental Site

Characterization

This standard is issued under the fixed designation D6286; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope the time of issue, but new alternative methods may become

available prior to revisions; therefore, users should consult

1.1 This guide provides descriptions of various drilling

with manufacturers or producers prior to specifying program

methods for environmental site characterization along with

requirements.

advantages and disadvantages associated with each method

discussed.Acomprehensive description of these drilling meth- 1.7 Pertinent guides addressing specific drilling methods,

ods can be found in individualASTM standards, see Section 2. equipment and procedures are listed in 2.1. A comprehensive

This guide is intended to aid in the selection of drilling list of guides, methods, practices, and terminology for drilling

method(s) for environmental soil and rock borings and the is contained in Guide D5730. Other documents covering

installation of monitoring wells and other water-quality moni- procedures for environmental site investigations with specific

toring devices. objectives or in particular geographic settings may be available

from federal, state, and other agencies or organizations. The

1.2 This guide does not address methods of well

appropriate agency or organization should be contacted to

construction, well development, or well completion. These

determine the availability and most current edition of such

topics are covered in other ASTM documents, see Section 2.

documents.

1.3 This guide cannot address all possible subsurface con-

1.8 This standard does not purport to address all of the

ditions that may occur such as, geologic, topographic, climatic,

safety concerns, if any, associated with its use. It is the

or anthropogenic. Site evaluation for engineering, design, and

responsibility of the user of this standard to establish appro-

construction purposes is addressed in Guide D420.

priate safety and health practices and determine the applica-

1.4 The values stated in SI units are to be regarded as the

bility of regulatory limitations prior to use.

standard. Because dimensions of materials used in the drilling

1.9 This guide offers an organized collection of information

industry are given in inch-pound units by convention, inch-

or a series of options and does not recommend a specific

pound units also are used in this guide.

course of action. This document cannot replace education and

experienceandshouldbeusedinconjunctionwithprofessional

1.5 This guide does not specifically address methods of

judgement. Not all aspects of this guide may be applicable in

lithologic sample collection, such as coring, that may require

all circumstances. This ASTM standard is not intended to

the use of a specific drilling method. Other ASTM guides

represent or replace the standard of care by which the

should be consulted for sampling methods (see Guide D6169)

adequacy of a given professional service must be judged, nor

and equipment necessary for specific projects.

should this document be applied without consideration of a

1.6 This guide does not purport to comprehensively address

project’s many unique aspects. The word “Standard” in the

all of the methods and the issues associated with drilling for

title of this document means only that the document has been

environmental purposes. Users should seek qualified profes-

approved through the ASTM consensus process.

sionals for decisions as to the proper equipment and methods

thatwouldbemostsuccessfulfortheirsiteinvestigation.Other

2. Referenced Documents

methods may be available for drilling and qualified profession-

2.1 ASTM Standards:

als should have flexibility to exercise judgment as to possible

D420 Guide to Site Characterization for Engineering Design

alternatives not covered in this guide. The guide is current at

and Construction Purposes (Withdrawn 2011)

1 2

This guide is under the jurisdiction ofASTM Committee D18 on Soil and Rock For referenced ASTM standards, visit the ASTM website, www.astm.org, or

and is the direct responsibility of Subcommittee D18.21 on Groundwater and contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Vadose Zone Investigations. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved July 1, 2006. Published July 2006. Originaly approved the ASTM website.

in 1998. Last previous edition approved in 1998 as D6286 – 98. DOI: 10.1520/ The last approved version of this historical standard is referenced on

D6286-98R06. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D6286 − 98 (2006)

D653 Terminology Relating to Soil, Rock, and Contained 3.2.2 kelly bar, n—a formed or machined section of hollow

Fluids drill steel used in rotary drilling, which is joined directly to the

swivelatthetopandtothedrillpipebelow.Theflatsorsplines

D1586 Test Method for Penetration Test (SPT) and Split-

Barrel Sampling of Soils of the kelly engage the rotary table so that the rotation of the

rotary table turns the kelly, which in turn, rotates the drill pipe

D1587 Practice for Thin-Walled Tube Sampling of Soils for

and the rotary bit.

Geotechnical Purposes

D2113 Practice for Rock Core Drilling and Sampling of

3.2.3 mud rings, n—soil or rock cuttings that form a ring or

Rock for Site Investigation

rings on the drill rod(s) during a rotary-drilling method, and as

D2488 Practice for Description and Identification of Soils

such,preventdrillcuttingsfrombeingcarriedupandoutofthe

(Visual-Manual Procedure)

borehole. These rings can cause drill rods to become stuck in

D3550 Practice for Thick Wall, Ring-Lined, Split Barrel,

theboreholeifsufficientdrillingfluidisnotinjectedorpumped

Drive Sampling of Soils

downhole to keep the cuttings fluid so that the ring(s) cannot

D5092 Practice for Design and Installation of Ground Water

form on the drill rods and block the cuttings return as drilling

Monitoring Wells progresses.

D5730 Guide for Site Characterization for Environmental

3.2.4 orange-peel bucket or boulder catcher, n—a bucket-

Purposes With Emphasis on Soil, Rock, the Vadose Zone

typedevice,somewhatellipticalinshaperesemblinganorange

and Ground Water

peel, that is lowered down the borehole and used to remove

D5753 Guide for Planning and Conducting Borehole Geo-

boulders from the bottom of a borehole.

physical Logging

D5781 Guide for Use of Dual-Wall Reverse-Circulation

4. Significance and Use

Drilling for Geoenvironmental Exploration and the Instal-

4.1 The selection of particular method(s) for drilling moni-

lation of Subsurface Water-Quality Monitoring Devices

toring wells (see Table 1) requires that specific characteristics

D5782 Guide for Use of Direct Air-Rotary Drilling for

ofeachsitebeconsidered.Thesecharacteristicswouldinclude,

Geoenvironmental Exploration and the Installation of

but are not limited to, the ambient hydrogeologic parameters

Subsurface Water-Quality Monitoring Devices

and conditions existing at the site. This guide is intended to

D5783 Guide for Use of Direct Rotary Drilling with Water-

make the user aware of some of the various drilling methods

Based Drilling Fluid for Geoenvironmental Exploration

available and the applications, advantages and disadvantages

and the Installation of Subsurface Water-Quality Monitor-

of each with respect to determing groundwater chemistry and

ing Devices

other hydrogeologic properties data.

D5784 Guide for Use of Hollow-Stem Augers for Geoenvi-

4.2 This guide can be used in conjunction with Guide

ronmental Exploration and the Installation of Subsurface

D6169. There are several guides that deal with individual

Water-Quality Monitoring Devices

drilling methods (see Guides D5781, D5782, D5783, D5784,

D5872 Guide for Use of Casing Advancement Drilling

D5872, D5875, and D5876) and how to the complete them for

Methods for Geoenvironmental Exploration and Installa-

water quality monitoring device installation (see Practice

tion of Subsurface Water-Quality Monitoring Devices

D5092).

D5875 Guide for Use of Cable-Tool Drilling and Sampling

Methods for Geoenvironmental Exploration and Installa-

5. Program Planning and Drilling Considerations

tion of Subsurface Water-Quality Monitoring Devices

5.1 All factors affecting both surface and subsurface envi-

D5876 Guide for Use of Direct Rotary Wireline Casing

ronment at a specific site requires professional judgment and

Advancement Drilling Methods for Geoenvironmental

mustbeconsideredbythegeologist/hydrologistorexperienced

Exploration and Installation of Subsurface Water-Quality

driller before a drilling method is selected. Significant soil and

Monitoring Devices

rock masses and groundwater conditions within a given site

D6001 Guide for Direct-Push Ground Water Sampling for

should be described and defined, both vertically and horizon-

Environmental Site Characterization

tally, before drilling. Site planning requires a reconnaissance

D6151 Practice for Using Hollow-StemAugers for Geotech-

site investigation that considers access to the drilling site and

nical Exploration and Soil Sampling

conditionsforsettingupthedrillingequipment (1). Theextent

D6169 Guide for Selection of Soil and Rock Sampling

of site characterization and specific methods used will be

Devices Used With Drill Rigs for Environmental Investi-

determined by study objectives. Study objectives also will

gations

affect the type and complexity of data collected. Sources of

D6429 Guide for Selecting Surface Geophysical Methods

data that may be useful during initial site evaluation include,

but are not limited to, topographic maps, aerial photography,

3. Terminology

satellite imagery, information from reconnaissance drilling,

borehole geophysical-log data, geologic maps and reports,

3.1 Definitions—Terminologyusedwithinthisguide,except

where noted, is in accordance with Terminology D653. statewide or county soil surveys, water-resource reports, well

3.2 Definitions of Terms Specific to This Standard:

3.2.1 borehole wall, n—refers to the naturally-occurring

The boldface numbers in parentheses refer to the list of references at the end of

soil(s)/rock(s) surrounding the borehole. this standard.

D6286 − 98 (2006)

TABLE 1 Well-Drilling Selection Guide

Typical

Typical

Type of Range of

Drilling Casing Drilling Samples Coring Reference

Drilling Method Material Borehole

B

Fluid Advance Depth, Obtainable Possible Section

Drilled Sizes, in

A

in ft

in.

Power auger none, water, soil, weathered

yes <150 5–22 S, F yes 6.2

(Hollow-stem) mud rock

Power auger soil, weathered

water, mud no <150 2–10 s yes 6.3

(Solid-stem) rock

none, water

soil, weathered

Power bucket auger (below water no <150 18–48 S yes 6.4

rock

table)

<70 (above

Hand auger none no soil 2–6 S yes 6.5

water table only)

Direct fluid rotary water, mud yes soil, rock >1000 2–36 S, R yes 7.3

Direct air rotary air, water, foam yes soil, rock >1500 2–36 S, R, F yes 7.4

DTH hammer air, water, foam yes rock, boulders <2000 4–16 R yes 7.5.1

Wireline air, water, foam yes soil, rock >1000 3–6 S, R, F yes 7.6

Reverse fluid rotary water, mud yes soil, rock <2000 12–36 S, R, F yes 7.8

Reverse air rotary air, water, foam yes soil, rock >1000 12–36 S, R, F yes 7.7

S, R, F (F–below

Cable tool water yes soil, rock <5000 4–24 yes 8

water table)

soil, rock,

Casing-advancer air, water, mud yes <2000 2–16 S, R, F yes 9

boulders

Direct-push technology none yes soil <100 1.5–3 S, F yes 10

none, water, soil, rock,

Sonic (vibratory) yes <500 4–12 S, R, F yes 11

mud, air boulders

Jet percussion water no soil <50 2–4 S no 12

Jetting water yes soil <50 4 S no 12

A

Actual achievable drilled depths will vary depending on the ambient geohydrologic conditions existing at the site and size of drilling equipment used. For example, large,

high-torque rigs can drill to greater depths than their smaller counterparts under favorable site conditions. Boreholes drilled using air/air foam can reach greater depths

more efficiently using two-stage positive-displacement compressors having the capability of developing working pressures of 250 to 350 psi and 500 to 750 cfm, particularly

when submergence requires higher pressures. The smaller rotary-type compressors only are capable of producing a maximum working pressure of 125 psi and produce

500 to 1200 cfm. Likewise, the rig mast must be constructed to safely carry the anticipated working loads expected. To allow for contigencies, it is recommended that the

rated capacity of the mast be at least twice the anticipated weight load or normal pulling load.

B

Soil = S (Cuttings), Rock=R(Cuttings), Fluid=F(some samples might require accessory sampling devices to obtain).

databases, and mineral-resource surveys covering the proposed three steps. To the extent possible, monitoring wells should be

project area. Available reports of surface and subsurface installed with an understanding of the ambient hydrogeologic

investigations of nearby or adjacent projects should be consid- site conditions. Monitoring wells often serve as part of an

ered and the information applicable to the current project overall site investigation for a specific purpose, such as

evaluated and applied if determined reliable and beneficial. determining the chemical quality of the water, gaining insight

Site-specific surface geophysical surveys (2-5) and direct-push into hydrochemical processes, or for predicting the effective-

methods for soil and groundwater data collection (see Guide nessofaquiferremediation.Inthesecases,extensiveadditional

D6429 and Guide D6001) also may be useful for planning geotechnical and hydrogeologic information may be required.

drilling locations.

5.3 If the monitoring well also is to be sampled for water

5.2 Site investigations for the purpose of determining the quality during the drilling process, the possible damage and

specific placement locations of monitoring-well installations subsequent aquifer contamination caused by drilling-fluid in-

can vary greatly due to the availability of reliable site data.The vasionoftheboreholewallthatmayoccurduringdrillingmust

general procedure, however, is as follows. First, gather factual be considered. For installation of monitoring wells designed

information and data regarding the surface and subsurface for water-sample collection, preferred dril

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.