ASTM D7476-08(2020)

(Test Method)Standard Test Method for Brine Saturation Value of Cured (Salt-Preserved) Hides and Skins

Standard Test Method for Brine Saturation Value of Cured (Salt-Preserved) Hides and Skins

SIGNIFICANCE AND USE

5.1 This test method is intended to evaluate whether sufficient salt (NaCl) has been retained by the hides or skins to slow down degradation by bacterial (enzymatic) action, and to slow down autolysis by inherent enzymatic action, until they are preserved by a tanning process.

Note 2: Osmosis occurs during brine curing because moisture is drawn out by salt through the epidermis.4 Low moisture (

SCOPE

1.1 This test method covers the estimation of degree of saturation of the brine content of cured (salt-preserved) hides and skins containing 40 % or more moisture.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D7476 − 08 (Reapproved 2020)

Standard Test Method for

Brine Saturation Value of Cured (Salt-Preserved) Hides and

Skins

This standard is issued under the fixed designation D7476; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

3.1 Definitions:

1.1 This test method covers the estimation of degree of

3.1.1 The terms and definitions employed within this test

saturation of the brine content of cured (salt-preserved) hides

method are commonly used in normal laboratory practice and

and skins containing 40% or more moisture.

require no special comment.

1.2 The values stated in inch-pound units are to be regarded

as standard. The values given in parentheses are mathematical

4. Summary of Test Method

conversions to SI units that are provided for information only

4.1 The moisture (volatile matter by oven drying) and ash

and are not considered standard.

contentofacompositehideorskinsamplearedetermined.For

1.3 This standard does not purport to address all of the

purposes of calculation the ash is assumed to be equivalent to

safety concerns, if any, associated with its use. It is the

sodium chloride and the moisture is assumed to be equivalent

responsibility of the user of this standard to establish appro-

towater.Thepercentratioofashtomoistureiscalculated.This

priate safety, health, and environmental practices and deter-

ratio times 100 is divided by 35.9 (which is the percent salt to

mine the applicability of regulatory limitations prior to use.

moistureratioinasaturatedsodiumchloride(brine)solutionat

1.4 This international standard was developed in accor-

20°C (68°F)) to estimate the percent of saturation in the brine

dance with internationally recognized principles on standard-

solution in the hides or skins.

ization established in the Decision on Principles for the

NOTE 1—A saturated solution of sodium chloride at 20°C (68°F)

Development of International Standards, Guides and Recom-

contains 26.4 % by weight of NaCl. Therefore, in 100 g of that saturated

mendations issued by the World Trade Organization Technical

solution only 73.6 g (100 − 26.4 g) is contributed by water.As such on a

Barriers to Trade (TBT) Committee.

weight basis, 100 parts by weight of water will dissolve 35.9 parts [(100

x 26.4)/73.6] by weight of NaCl.

2. Referenced Documents

5. Significance and Use

2,3

2.1 ASTM Standards:

5.1 This test method is intended to evaluate whether suffi-

D6715Practice for Sampling and Preparation of Fresh or

cientsalt(NaCl)hasbeenretainedbythehidesorskinstoslow

Salt-Preserved (Cured) Hides and Skins for Chemical and

down degradation by bacterial (enzymatic) action, and to slow

Physical Tests

down autolysis by inherent enzymatic action, until they are

E177Practice for Use of the Terms Precision and Bias in

preserved by a tanning process.

ASTM Test Methods

NOTE 2—Osmosis occurs during brine curing because moisture is

E691Practice for Conducting an Interlaboratory Study to

drawn out by salt through the epidermis. Low moisture (< 40 %) in the

Determine the Precision of a Test Method

hides does not necessarily indicate poor cure. A hide may have low

moisture due to osmosis; to increased fat content; or to drying out

conditions. In all instances the hides would still show adequate cure if the

moisture was saturated to approximately 85 % salt, because the ash:

This test method is under the jurisdiction ofASTM Committee D31 on Leather

moisture ratio would be adequate.

and is the direct responsibility of Subcommittee D31.02 on Wet Blue.

Current edition approved April 1, 2020. Published April 2020. Originally

6. Apparatus

approved in 2008. Last previous edition approved in 2013 as D7476 – 08(2013).

DOI: 10.1520/D7476-08R20.

6.1 Crucible, 30 to 50 mL, high-form, platinum or porce-

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

lain. Prepare crucible by heating it for 15 min in a muffle

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standardsvolume information, refer to the standard’s Document Summary page on furnace set at 600 6 25°C. Cool in a desiccator before use.

the ASTM website.

“Trade Practices for Proper Packer Cattlehide Delivery,” issued by Leather

Industries of America and U.S. Hide, Skin & Leather Association (printed May

1985). JALCA, 1963, p. 143.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

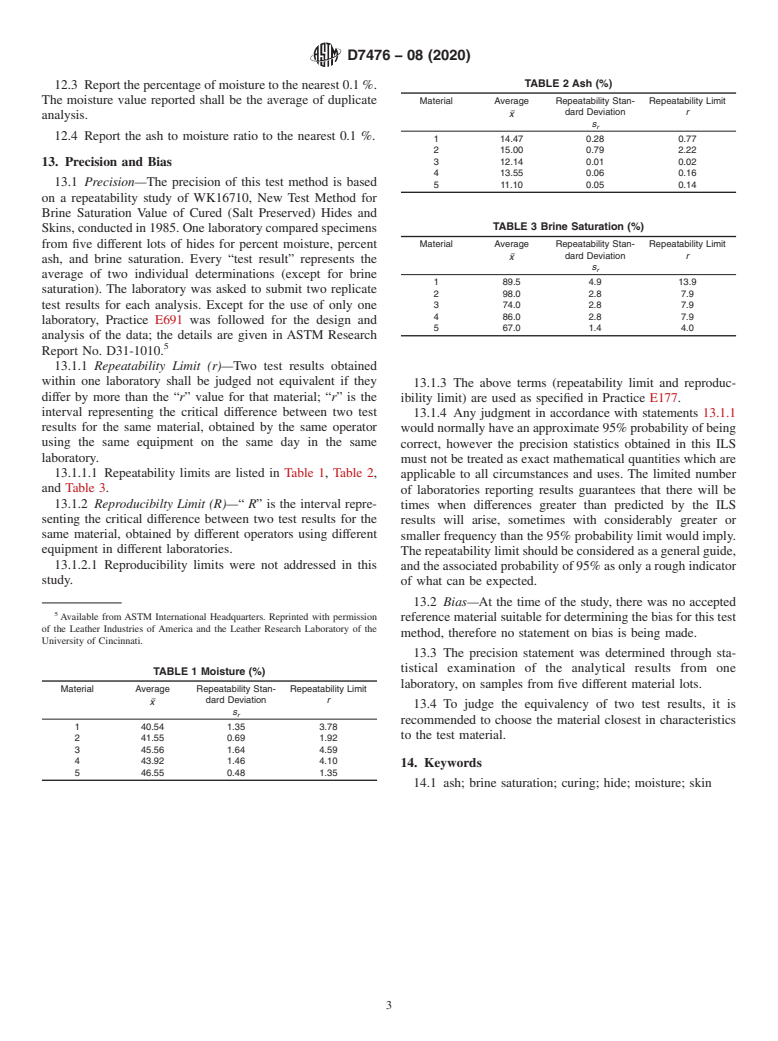

D7476 − 08 (2020)

6.2 Electric Muffle Furnace, with controller or rheostat and 10.2 Pre-dry the crucible and sample at 60 − 65°C (140 −

pyrometer, capable of maintaining a temperature of 650 6 149°F) for 3 h 6 15 min to prevent gelation.

25°C.

10.3 Placethepre-driedcrucibleandsampleintheovenand

6.3 Desiccator, of appropriate size and charged with fresh

maintain at 100 − 105°C for 16 6 ⁄2 h.

desiccant.

10.4 Remove crucible from the oven, cool in desiccator,

6.4 Analytical Balance, capable of weighing to 0.001 g.

weigh and record to the nearest 60.001 g.

6.5 Oven, forced air, capable of maintaining 100 − 105°C.

10.5 Place the crucible and dried sample in a cool muffle

furnace(≤100°C)andraisethetemperaturegraduallyto600 6

7. Reagents and Materials

25°C. Leave the crucible and sample in the hot furnace for a

7.1 Distilled or de-ionized water. minimum of3hupto16hat600 6 25°C.

10.6 To prevent any loss of ash, very carefully remove the

8. Hazards

crucible from the furnace. Warning—The crucible is ex-

8.1 The crucibles will be extremely hot when they are

tremely hot!

removed from the muffle furnace. Therefore, it is suggested

10.7 Check the ash condition:

that the analyst handle the hot crucibles using furnace tongs or

Ash condition Action

equivalent.

White/Gray-white (complete ashing) Proceed to 10.9

9. Sampling

Dark gray or Black (incomplete ashing) Proceed to 10.8

9.1 Sampling shall be per Practice D6715.

10.8 Coolthecrucibletoroomtemperature.Moistentheash

with10–15mLofDIwater,thenplacethecrucibleintheoven

9.2 Timeiscrucialinthepreparationofsalt-preservedhides

until visibly dry. Transfer the crucible to a cool muffle furnace

for chemical testing. Samples should not be prepared if

(≤ 100°C) and repeat steps 10.5 to 10.7.

analysis can not be done immediately. The following proce-

dures should be executed with a minimum of hide exposure to

10.9 Cool the crucible to room temperature in a desiccator.

either air or moisture or salt-absorbent materials (including

10.10 Weigh the crucible immediately and record the

human skin). Ensuring this will prevent or minimize any

weight.

significant or salt loss from the samples.

9.3 Duringallstagesofpreparation,samplesshallalwaysbe

11. Calculation

cut on a non-porous, non-absorbing hard surface using a clean

11.1 Calculate the percentage of moisture (volatile matter

sharp cutting tool, preferably a new razor or scalpel blade.

by oven drying) as follows:

Avoid excess pressure on the sample that could

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.