ASTM D4468-85(2011)

(Test Method)Standard Test Method for Total Sulfur in Gaseous Fuels by Hydrogenolysis and

Rateometric Colorimetry

Standard Test Method for Total Sulfur in Gaseous Fuels by Hydrogenolysis and<br> Rateometric Colorimetry

SIGNIFICANCE AND USE

This test method can be used to determine specification, or regulatory compliance to requirements, for total sulfur in gaseous fuels. In gas processing plants, sulfur can be a contaminant and must be removed before gas is introduced into gas pipelines. In petrochemical plants, sulfur is a poison for many catalysts and must be reduced to acceptable levels, usually in the range from 0.01 to 1 ppm/v. This test method may also be used as a quality-control tool for sulfur determination in finished products, such as propane, butane, ethane, and ethylene.

SCOPE

1.1 This test method covers the determination of sulfur gaseous fuels in the range from 0.001 to 20 parts per million by volume (ppm/v).

1.2 This test method may be extended to higher concentration by dilution.

This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all of the safety concerns associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are given in 6.7, 6.8, and 7.3.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D4468 − 85(Reapproved 2011)

Standard Test Method for

Total Sulfur in Gaseous Fuels by Hydrogenolysis and

Rateometric Colorimetry

This standard is issued under the fixed designation D4468; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope metric reaction of H S with lead acetate. Units used are ppm/v,

which is equivalent to micromoles/mole.

1.1 This test method covers the determination of sulfur

gaseousfuelsintherangefrom0.001to20partspermillionby

4. Significance and Use

volume (ppm/v).

4.1 This test method can be used to determine specification,

1.2 This test method may be extended to higher concentra-

or regulatory compliance to requirements, for total sulfur in

tion by dilution.

gaseous fuels. In gas processing plants, sulfur can be a

1.3 The values stated in SI units are to be regarded as

contaminantandmustberemovedbeforegasisintroducedinto

standard. No other units of measurement are included in this

gas pipelines. In petrochemical plants, sulfur is a poison for

standard.

many catalysts and must be reduced to acceptable levels,

1.4 This standard may involve hazardous materials,

usually in the range from 0.01 to 1 ppm/v. This test method

operations, and equipment. This standard does not purport to

may also be used as a quality-control tool for sulfur determi-

address all of the safety concerns associated with its use. It is

nation in finished products, such as propane, butane, ethane,

the responsibility of the user of this standard to establish

and ethylene.

appropriate safety and health practices and determine the

applicability of regulatory limitations prior to use. Specific

5. Apparatus

precautionary statements are given in 6.7, 6.8, and 7.3.

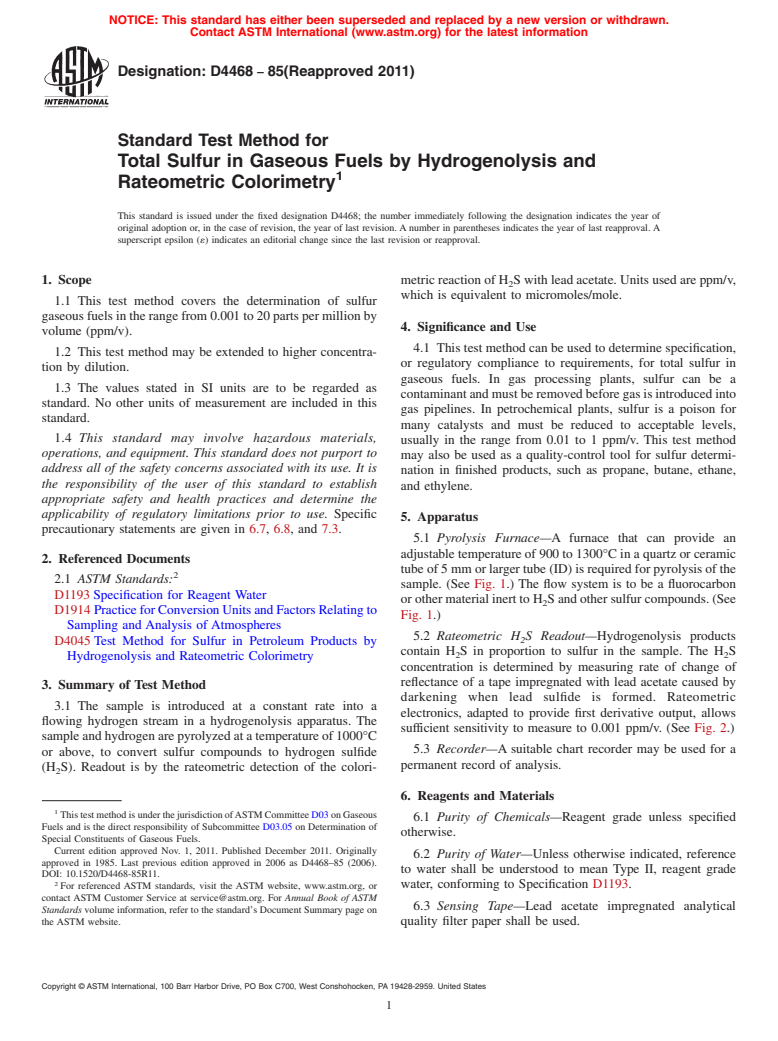

5.1 Pyrolysis Furnace—A furnace that can provide an

adjustable temperature of 900 to 1300°C in a quartz or ceramic

2. Referenced Documents

tube of 5 mm or larger tube (ID) is required for pyrolysis of the

2.1 ASTM Standards:

sample. (See Fig. 1.) The flow system is to be a fluorocarbon

D1193 Specification for Reagent Water

orothermaterialinerttoH Sandothersulfurcompounds.(See

D1914 PracticeforConversionUnitsandFactorsRelatingto

Fig. 1.)

Sampling and Analysis of Atmospheres

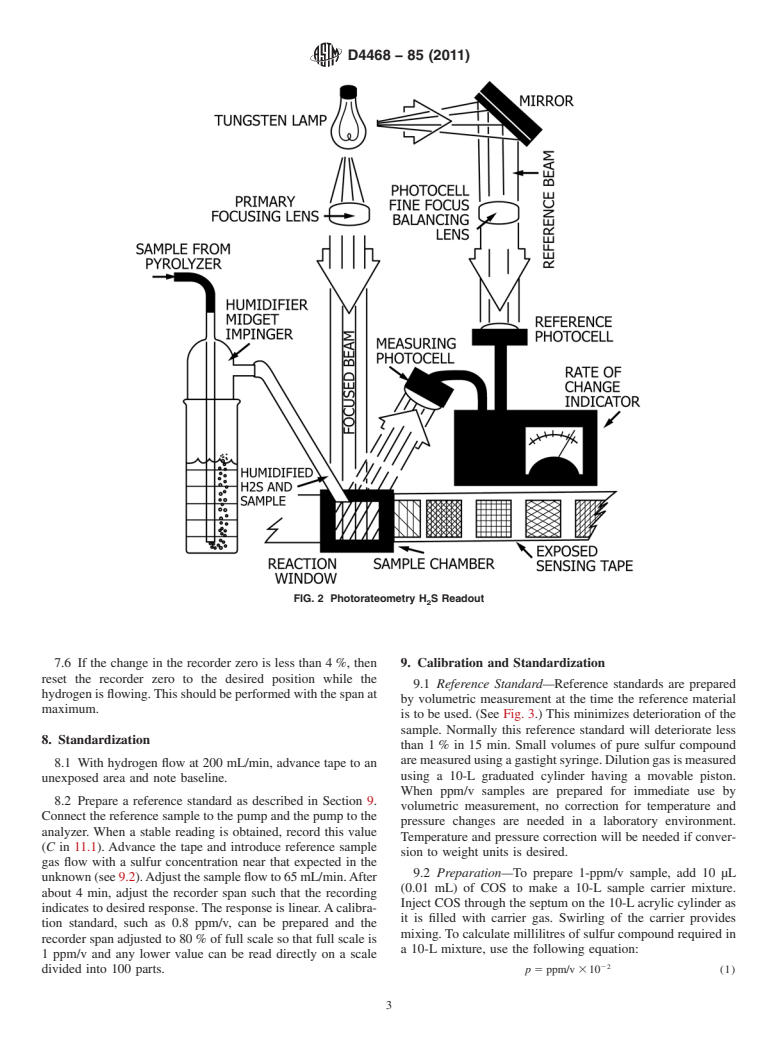

5.2 Rateometric H S Readout—Hydrogenolysis products

D4045 Test Method for Sulfur in Petroleum Products by

contain H S in proportion to sulfur in the sample. The H S

2 2

Hydrogenolysis and Rateometric Colorimetry

concentration is determined by measuring rate of change of

reflectance of a tape impregnated with lead acetate caused by

3. Summary of Test Method

darkening when lead sulfide is formed. Rateometric

3.1 The sample is introduced at a constant rate into a

electronics, adapted to provide first derivative output, allows

flowing hydrogen stream in a hydrogenolysis apparatus. The

sufficient sensitivity to measure to 0.001 ppm/v. (See Fig. 2.)

sampleandhydrogenarepyrolyzedatatemperatureof1000°C

5.3 Recorder—A suitable chart recorder may be used for a

or above, to convert sulfur compounds to hydrogen sulfide

permanent record of analysis.

(H S). Readout is by the rateometric detection of the colori-

6. Reagents and Materials

ThistestmethodisunderthejurisdictionofASTMCommitteeD03onGaseous

6.1 Purity of Chemicals—Reagent grade unless specified

Fuels and is the direct responsibility of Subcommittee D03.05 on Determination of

otherwise.

Special Constituents of Gaseous Fuels.

Current edition approved Nov. 1, 2011. Published December 2011. Originally

6.2 Purity of Water—Unless otherwise indicated, reference

approved in 1985. Last previous edition approved in 2006 as D4468–85 (2006).

to water shall be understood to mean Type II, reagent grade

DOI: 10.1520/D4468-85R11.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or water, conforming to Specification D1193.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

6.3 Sensing Tape—Lead acetate impregnated analytical

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. quality filter paper shall be used.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D4468 − 85 (2011)

FIG. 1 Hydrogenolysis Flow Diagram

6.4 Acetic Acid (5 %)—Mix 1 part by volume reagent grade 7. Preparation of Apparatus

glacial acetic acid with 19 parts water to prepare 5 % acetic

7.1 Turnonthefurnaceandallowtemperaturetostabilizeat

acid solution.

1000°C. If thiophenic sulfur could be present, use 1300°C

6.5 Gastight Syringe—A gastight 0.1- and 0.5-mL syringe

temperature setting.

for preparing calibration standard. Volumetric measurement

NOTE 1—Reduced operating temperature extends furnace life. Thio-

accuracy of the syringe shall be 1 % or better.

phenic compound conversion increases from about 60 % at 1000°C to

6.6 Piston Cylinder—Usea10-Lacryliccylinderwithafree

100 % at 1300°C.

moving piston and silicone rubber “O” ring lubricated with a

7.2 Connect all flow tubing between components and fill

free-flowing silicone lubricant. This cylinder is used to prepare

humidifier inside the cabinet to 30 mL with a 5 % by volume

ppm/v calibration samples volumetrically.

acetic acid solution. Purge all flow systems with inert gas then

6.7 Carbonyl Sulfide (COS)—Alecture bottle of COS, 99 %

close valve. Check all connections for leaks with soap solution

purity, with a needle valve connected to the lecture bottle

and repair any leaks. Connect hydrogen and set flow at 200

outlet. Connect 2 ft of tygon tubing to allow insertion of a

mL/min and allow temperature to stabilize. Sample flow must

hypodermic syringe to withdraw pure COS while tubing is

be ⁄3 or less of the H flow. Total flow can be up to 500

purged from the lecture bottle. Other sulfur compounds can be

mL/min, except when the sample has thiophenic compounds

used with adequate odor control. If the sulfur compound has

that require 200 mL/min of H flow for conversion. Make final

two sulfur atoms per molecule, reduce the volume by one half.

temperature adjustment to 1000 6 15°C or a minimum 1300°C

(Warning —Work with COS should be done in a well-

if the sample contains thiophenic sulfur compounds.

ventilated area, or under a fume hood.)

7.3 Install sensing tape and turn H S readout analyzer on.

6.8 Hydrogen Gas—Use sulfur-free hydrogen of laboratory

Use adequate safety precautions in handling lead acetate tape.

grade. (Warning—Hydrogen has wide explosive limits when

mixed with air. See 1.4 regarding precautions.)

7.4 Adjust the zero of the analyzer indicator meter (and

recorder if used) to desired position with no flow. This should

6.9 Carrier Gas for Calibration Standards—Use sulfur-free

be performed with span at maximum.

laboratory grade bottled gas of the same type or similar density

as the gas to be analyzed or calibrate the flowmeter to establish

7.5 Test hydrogen purity by turning on hydrogen flow and

correct flow setting for an available carrier gas. Test, as in 7.5,

noting any change in zero position after 5 min. If the reading

adding the carrier gas flow to the hydrogen flow.

is upscale from the zero set point by greater than 4 %, then the

6.10 Purge Gas—Sulfur-free purge gas, nitrogen, CO,or hydrogen source should be suspect as not being sulfur free and

other inert gas. Commercial grade cylinder gas is satisfactory. should be changed.

----------------------

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.