ASTM F136-13(2021)e1

(Specification)Standard Specification for Wrought Titanium-6Aluminum-4Vanadium ELI (Extra Low Interstitial) Alloy for Surgical Implant Applications (UNS R56401)

Standard Specification for Wrought Titanium-6Aluminum-4Vanadium ELI (Extra Low Interstitial) Alloy for Surgical Implant Applications (UNS R56401)

ABSTRACT

This specification covers the chemical, mechanical, and metallurgical requirements for wrought annealed titanium-6aluminum-4vanadium ELI (extra low interstitial) alloy (R56401) to be used in the manufacture of surgical implants. The products are classified into: strip, sheet, plate, bar, forging bar, and wire. The heat analysis shall conform to the chemical composition requirements specified. Product analysis tolerances do not broaden the specified heat analysis requirements but cover variations between laboratories in the measurement of chemical content. Tension test and bend test shall be performed to meet the requirements specified.

SCOPE

1.1 This specification covers the chemical, mechanical, and metallurgical requirements for wrought annealed titanium-6aluminum-4vanadium ELI (extra low interstitial) alloy (R56401) to be used in the manufacture of surgical implants.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

´1

Designation:F136 −13 (Reapproved 2021)

Standard Specification for

Wrought Titanium-6Aluminum-4Vanadium ELI (Extra Low

Interstitial) Alloy for Surgical Implant Applications (UNS

R56401)

ThisstandardisissuedunderthefixeddesignationF136;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—X2.2 was updated editorially in August 2021.

1. Scope nium and Titanium Alloys by Inert Gas Fusion Thermal

Conductivity/Infrared Detection Method

1.1 This specification covers the chemical, mechanical, and

E1941Test Method for Determination of Carbon in Refrac-

metallurgical requirements for wrought annealed titanium-

toryandReactiveMetalsandTheirAlloysbyCombustion

6aluminum-4vanadium ELI (extra low interstitial) alloy

Analysis

(R56401) to be used in the manufacture of surgical implants.

E2371Test Method for Analysis of Titanium and Titanium

1.2 Thevaluesstatedininch-poundunitsaretoberegarded

AlloysbyDirectCurrentPlasmaandInductivelyCoupled

as standard. The values given in parentheses are mathematical

Plasma Atomic Emission Spectrometry (Performance-

conversions to SI units that are provided for information only

Based Test Methodology)

and are not considered standard.

F981Practice for Assessment of Compatibility of Biomate-

1.3 This international standard was developed in accor-

rials for Surgical Implants with Respect to Effect of

dance with internationally recognized principles on standard- Materials on Muscle and Insertion into Bone

ization established in the Decision on Principles for the 3

2.2 ISO Standards:

Development of International Standards, Guides and Recom-

ISO 6892Metallic Materials Tensile Testing at Ambient

mendations issued by the World Trade Organization Technical

Temperature

Barriers to Trade (TBT) Committee.

ISO 9001Quality Management Systems Requirements

2.3 ASQ Standard:

2. Referenced Documents

2 ASQC1SpecificationsofGeneralRequirementsforaQual-

2.1 ASTM Standards:

ity Control Program

E8/E8MTest Methods for Tension Testing of Metallic Ma-

2.4 Aerospace Material Specifications:

terials

AMS 2249Chemical Check Analysis Limits, Titanium and

E29Practice for Using Significant Digits in Test Data to

Determine Conformance with Specifications Titanium Alloys

AMS 2631Ultrasonic Inspection—Titanium and Titanium

E290Test Methods for Bend Testing of Material for Ductil-

ity Alloy Bar and Billet

AMS 2380Approval and Control of Premium Quality Tita-

E539Test Method for Analysis of Titanium Alloys by

WavelengthDispersiveX-RayFluorescenceSpectrometry nium Alloys

E1409TestMethodforDeterminationofOxygenandNitro-

gen in Titanium and TitaniumAlloys by Inert Gas Fusion 3. Terminology

E1447Test Method for Determination of Hydrogen in Tita-

3.1 Definitions of Terms Specific to This Standard:

3.1.1 beta transus, n—the minimum temperature at which

the alpha plus beta phase can transform to 100% beta phase.

This specification is under the jurisdiction of ASTM Committee F04 on

Medical and Surgical Materials and Devices and is the direct responsibility of

Subcommittee F04.12 on Metallurgical Materials.

Current edition approved Aug. 15, 2021. Published August 2021. Originally

published in 1984. Last previous edition approved in 2013 as F136–13. DOI: Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

10.1520/F0136-13R21E01. 4th Floor, New York, NY 10036, http://www.ansi.org.

2 4

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available fromAmerican Society for Quality (ASQ), 600 N. PlankintonAve.,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Milwaukee, WI 53203, http://www.asq.org.

Standards volume information, refer to the standard’s Document Summary page on Available from Society of Automotive Engineers (SAE), 400 Commonwealth

the ASTM website. Dr., Warrendale, PA 15096-0001, http://www.sae.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

F136−13 (2021)

3.1.2 lot, n—the total number of mill products produced nonferrous plants. The alloy is usually multiple melted in arc

fromoneheatunderthesameconditionsatessentiallythesame furnaces (including furnaces such as plasma arc and electron

time. beam) of a type conventionally used for reactive metals.

6.2 Finish—The mill product may be furnished to the

4. Product Classification

implant manufacturer as mechanically descaled or pickled,

4.1 Strip—Any product under 0.1875 in. (4.76 mm) in

abrasively blasted, chemically milled, ground, machined,

thickness and under 24 in. (610 mm) wide.

peeled, polished, combinations of these operations, or as

4.2 Sheet—Any product under 0.1875 in. (4.76 mm) in specified by the purchaser. On billets, bars, plates, and

forgings, it is permissible to remove minor surface imperfec-

thickness and 24 in. (610 mm) or more in width.

tions by grinding if the resultant area meets the dimensional

4.3 Plate—Any product 0.1875 in. (4.76 mm) thick and

and surface finish requirements of this specification.

over and 10 in. (254 mm) wide and over, with widths greater

than five times thickness. Plate up to 4.00 in. (101.60 mm), 6.3 Condition—Material shall be furnished in the annealed

or cold-worked condition. Mechanical properties for condi-

thick inclusive is covered by this specification.

tions other than those listed in Tables 1 and 2 may be

4.4 Bar—Roundbarsandflatsfrom0.1875in.(4.76mm)to

established by agreement between the supplier and the pur-

4.00 in. (101.60 mm) in diameter or thickness (other sizes and

chaser.

shapes by special order).

4.5 Forging Bar—Bar as described in 4.4, used for produc-

7. Chemical Requirements

tionofforgings,maybefurnishedinthehotworkedcondition.

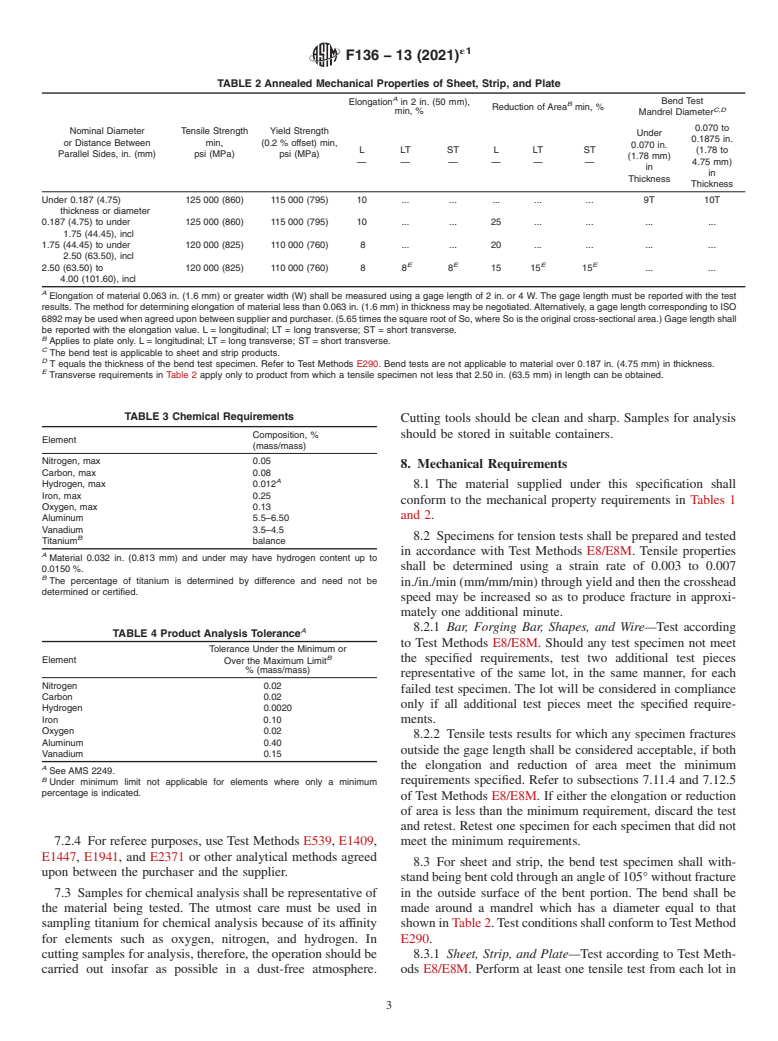

7.1 The heat analysis shall conform to the chemical com-

4.6 Wire—Rounds,flats,orothershapeslessthan0.1875in.

position specified in Table 3. Ingot analysis may be used for

(4.76 mm) in diameter.

reportingallchemicalrequirements,excepthydrogen.Samples

forhydrogenshallbetakenfromthefinishedmillproduct.The

4.7 Other—Other forms and shapes, including tubing, may

supplier shall not ship material with chemistry outside the

be provided by agreement between purchaser and supplier.

requirements specified in Table 3.

5. Ordering Information 7.1.1 Requirements for the major and minor elemental

constituents are listed in Table 3. Also listed are important

5.1 Include with inquiries and orders for material under this

residualelements.AnalysisforelementsnotlistedinTable3is

specification the following information:

not required to verify compliance with this specification.

5.1.1 Quantity,

5.1.2 ASTM designation and date of issue,

7.2 Product Analysis:

5.1.3 Form (sheet, strip, plate, bar, forging bar, or wire),

7.2.1 Product analysis tolerances do not broaden the speci-

5.1.4 Condition (see Section 3 and 6.3),

fied heat analysis requirements but cover variations between

5.1.5 Mechanical properties (if applicable, for special

laboratories in the measurement of chemical content. The

conditions),

product analysis tolerances shall conform to the product

5.1.6 Finish (see 6.2),

tolerances in Table 4.

5.1.7 Applicable dimensions including size, thickness,

7.2.2 The product analysis is either for the purpose of

width, length, or drawing number,

verifying the composition of a heat or manufacturing lot or

5.1.8 Special tests, if any, and

determining variations in the composition within the heat.

5.1.9 Other requirements. 7.2.3 Acceptanceorrejectionofaheatormanufacturinglot

of material may be made by the purchaser on the basis of this

6. Materials and Manufacture

product analysis. Product analysis outside the tolerance limits

6.1 The various titanium mill products covered in this allowed in Table 4 is cause for rejection of the product. A

specification normally are formed with the conventional forg- refereeanalysismaybeusedifagreeduponbythesupplierand

ing and rolling equipment found in primary ferrous and purchaser.

TABLE 1 Annealed Mechanical Properties of Bar, Wire, and Forgings

A B

Elongation in 4D or 4W min, % Reduction of Area min, %

Yield Strength

Nominal Diameter or Distance Tensile Strength min,

(0.2 % offset) min,

L LT ST L LT ST

Between Parallel Sides, in. (mm) psi (MPa)

psi (MPa)

— — — — — —

Under 0.187 (4.75) thickness or diameter 125 000 (860) 115 000 (795) 10 . . . . .

0.187 (4.75) to under 1.75 (44.45), incl 125 000 (860) 115 000 (795) 10 . . 25 . .

1.75 (44.45) to under 2.50 (63.50), incl 120 000 (825) 110 000 (760) 8 . . 20 . .

C C C C

2.50 (63.50) to 4.00 (101.60), incl 120 000 (825) 110 000 (760) 8 8 8 15 15 15

A

Elongation of material 0.063 in. (1.6 mm) or greater in diameter (D) or width (W) shall be measured using a gage length of 2 in. or4Dor4W. The gage length must

be reported with the test results. The method for determining elongation of material under 0.063 in. (1.6 mm) in diameter or thickness may be negotiated. Alternatively,

a gage length corresponding to ISO 6892 may be used when agreed upon between supplier and purchaser. (5.65 times the square root of So, where So is the original

cross-sectional area.) Gage length shall be reported with the elongation value. L = longitudinal; LT = long transverse; ST = short transverse.

B

Applies to bar and forgings only. L = longitudinal; LT = long transverse; ST = short transverse. For round bar, the long and short transverse are identical tests, therefore

only one transverse is required.

C

Transverse requirements in Table 1 apply only to product from which a tensile specimen not less that 2.50 in. (63.5 mm) in length can be obtained.

´1

F136−13 (2021)

TABLE 2 Annealed Mechanical Properties of Sheet, Strip, and Plate

A

Bend Test

Elongation in 2 in. (50 mm), B

Reduction of Area min, %

C,D

min, % Mandrel Diameter

0.070 to

Nomi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.