ASTM A47/A47M-99

(Specification)Standard Specification for Ferritic Malleable Iron Castings

Standard Specification for Ferritic Malleable Iron Castings

SCOPE

1.1 This specification covers ferritic malleable castings for general engineering usage at temperatures from normal ambient to approximately 750°F.

1.2 No precise quantitative relationship can be stated between the properties of the iron in various locations of the same casting and those of a test specimen cast from the same iron (see Appendix X1.). Note-A complete metric companion to Specification A47 has been developed-A47M; therefore, no metric equivalents are presented in this specification.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A 47/A 47M – 99

Standard Specification for

1

Ferritic Malleable Iron Castings

This standard is issued under the fixed designation A 47/A 47M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope Fed. Std. No. 123 Marking for Domestic Shipment (Civilian

6

2

Agencies)

1.1 This specification covers ferritic malleable castings for

general engineering usage at temperatures from normal ambi-

3. Terminology

ent to approximately 400°C (750°F).

3.1 Definitions—Definitions for many terms common to

1.2 No precise quantitative relationship can be stated be-

iron are found in Terminology A 644.

tween the properties of the iron in various locations of the same

casting and those of a test specimen cast from the same iron

4. Classification

(see Appendix X1).

4.1 Castings ordered and produced under this specification

1.3 The values stated in either inch-pound units or SI units

are classified under the following grades based on tests on

are to be regarded separately as standard. Within the text, the

separately cast test bars. Separately cast test bars shall be

SI units are shown in brackets. The values stated in each

poured from the same lot of iron as the castings they represent

system are not exact equivalents; therefore, each system shall

and shall be heat treated with those castings except as provided

be used independently of the other. Combining values from the

in 7.2.3.

two systems may result in nonconformance with the specifi-

4.1.1 Grade 32510 [Grade 22010]:

cation.

4.1.1.1 The first three digits of the grade designation indi-

2. Referenced Documents cate the minimum yield strength (3100 psi [MPa]) and the last

two digits indicate the minimum elongation (% in 2 in. [50

2.1 ASTM Standards:

mm]).

A 153 Specification for Zinc Coating (Hot-Dip) on Iron and

3

Steel Hardware

5. Ordering Information

A 247 Test Method for Evaluating the Microstructure of

4 5.1 The purchase order for castings ordered under this

Graphite in Iron Castings

4 specification shall state the specification designation, the year

A 644 Terminology Relating to Iron Castings

5 in which the specification was issued, and the grade of

E 8 Test Methods for Tension Testing of Metallic Materials

malleable iron to be supplied. Any option or special additions

E 10 Test Method for Brinell Hardness of Metallic Materi-

5 to the basic requirements of this specification shall be clearly

als

and fully stipulated.

E 18 Test Methods for Rockwell Hardness and Rockwell

5

Superficial Hardness of Metallic Materials

6. Chemical Composition

5

E 140 Hardness Conversion Tables for Metals

6.1 The chemical composition of the iron shall be such as to

2.2 Military Standard:

produce the structural and mechanical properties required by

6

MIL-STD-129 Marking for Shipment and Storage

this specification.

2.3 Federal Standard:

7. Mechanical Properties

1

7.1 Factors influencing the properties of castings and their

This specification is under the jurisdiction of ASTM Committee A-4 on Iron

Castings and is the direct responsibility of Subcommittee A04.02 on Malleable Iron

relationship to those of test specimens and separate test

Castings.

castings are discussed in Appendix X1.

Current edition approved July 10, 1999. Published September 1999. Originally

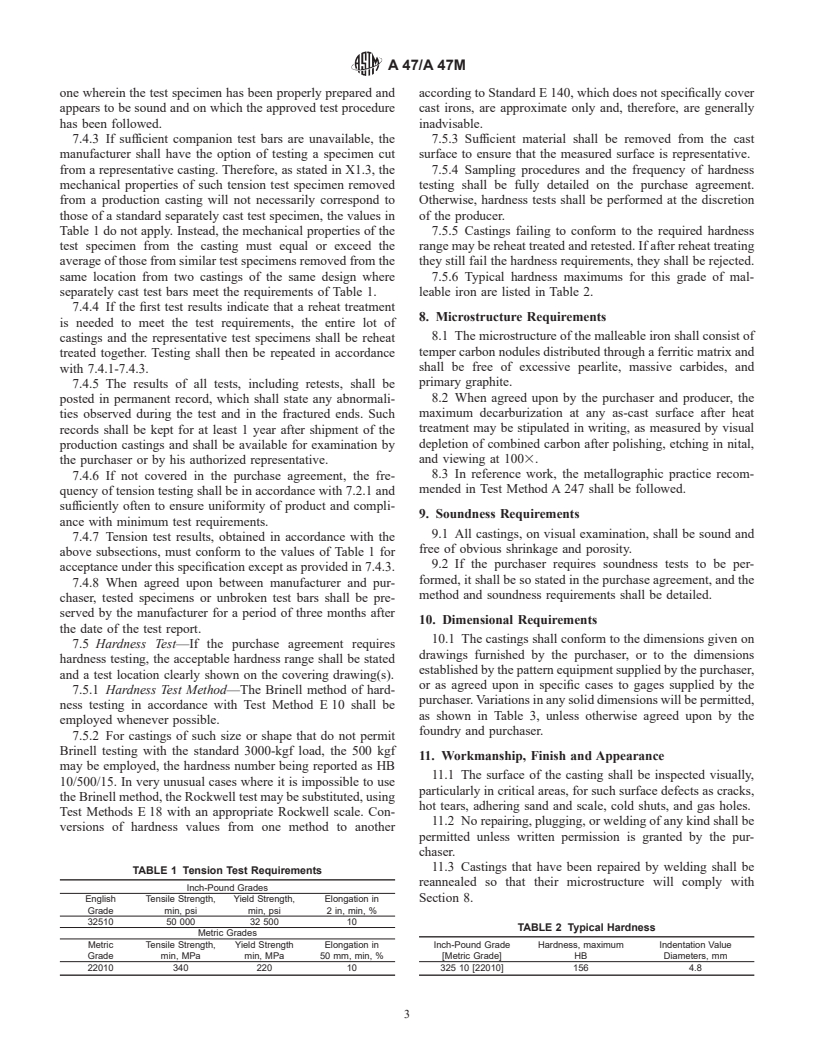

7.2 Tension Test Specimens:

published as A 47 – 84. Last previous edition A 47 – 90 (1995).

2

For ASME Boiler and Pressure Vessel Code applications see related Specifi- 7.2.1 The tension test specimens shall be cast to the form

cation SA-47 in Section II of that code.

and dimensions shown in Fig. 1 or Fig. 2, in the same kind of

3

Annual Book of ASTM Standards, Vol 01.06.

molding material used for the production castings. At least

4

Annual Book of ASTM Standards, Vol 01.02.

5

three such specimens shall be cast from a representative ladle

Annual Book of ASTM Standards, Vol 03.01.

6

Available from Standardization Documents, Order Desk, Building 4, Section D,

700 Robbins Ave., Philadelphia, PA 19111–5094, Attn: NPODS.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

A 47/A 47M

FIG. 1 Tension Test Specimen

NOTE 1—The gage length and fillets shall be as shown, but the ends

may be of any shape to fit the holders of the testing machine in such a way

NOTE 1—Modifications may be made in the dimensions indicated

that the load shall be axial. The reduced section shall have a gradual taper

above for those details of the specimen outside of the g

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.