ASTM A1127/A1127M-23

(Specification)Standard Specification for Stainless Steel Laser and Laser-Hybrid Welded, Sharp-Cornered Profile (SCP) or Built-Up Rounded Corner Square, Rectangular, and Special Shape Structural Tube

Standard Specification for Stainless Steel Laser and Laser-Hybrid Welded, Sharp-Cornered Profile (SCP) or Built-Up Rounded Corner Square, Rectangular, and Special Shape Structural Tube

SCOPE

1.1 This specification covers laser or laser-hybrid welded stainless steel square, rectangular, or custom shape structural tubing for welded, riveted, or bolted construction. This tube has either a sharp-cornered profile (SCP) or is built-up tube with rounded corners. This product is used in, but not limited to, the following applications: buildings and structures, including architecturally exposed steel structures (AESS); architectural steel profiles such as curtain wall, staircases, and others; industrial; and general structural applications.

Note 1: The term laser fusion is also used to describe laser welding.

1.2 This tubing is manufactured from multiple pieces of plate, bar, sheet, strip, or shapes, potentially in different thicknesses by laser or laser-hybrid welding in accordance with the requirements of Specification A1069/A1069M. It is available in sizes up to 36 in. (914 mm) outside dimension, and the wall thickness tolerance is ±5 % of the specified wall thickness. Corner welds are permissible.

1.3 This specification establishes the minimum requirements for manufacturing of laser and laser hybrid welded stainless steel tube and requires the welds to, at a minimum, match the tensile and yield strength of the base metal. If base metals of different strengths are used, the lower strength base metal shall be matched.

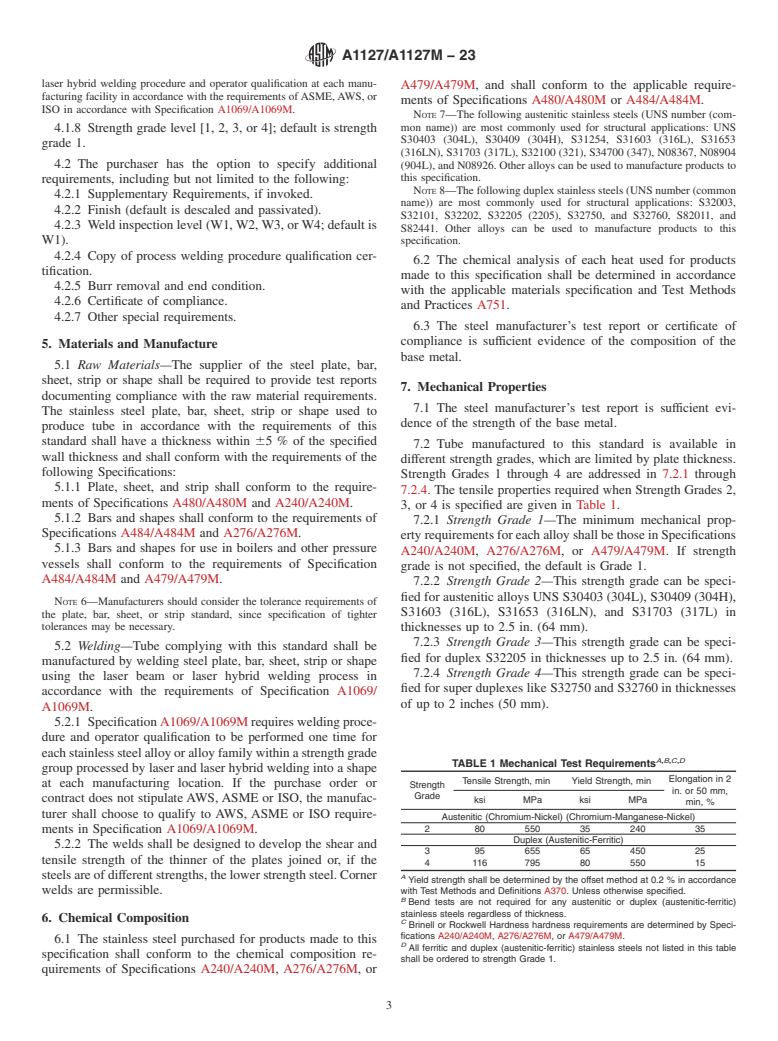

1.4 This specification refers to Specifications A240/A240M, A276/A276M or A479/A479M for chemical requirements, but the mechanical test requirements are determined by the mechanical properties section of this standard. This standard includes four strength grades. The default strength grade 1 is determined by the base metal standard. Grades 2 through 4 are for specification of higher strength levels.

1.5 Supplementary requirements (S1 Charpy V- notch, S2 Corrosion, S3 Tensile, and S4 Bend) of an optional nature are provided. They shall apply only when specified by the purchaser.

Note 2: Because of the varying requirements of the end-use applications, different length tolerance, weld inspection levels, strength levels and other requirements may be specified.

Note 3: Product covered by this specification is manufactured in small lots on dedicated production lines. Product quality requirements are ensured through welding procedure and operator qualification at each manufacturing facility in accordance with Specification A1069/A1069M. The country of origin and base metal heat numbers are identified by wall thickness on the product test report.

1.6 The text of this specification contains notes and footnotes that provide explanatory material. Such notes and footnotes, excluding those in tables and figures, do not contain any mandatory requirements.

1.7 Units—This specification is expressed in both inch-pound units and in SI units; however, unless the purchase order or contract specifies the applicable M specification designation (SI units), the inch-pound units shall apply. The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the standard.

1.8 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.9 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: A1127/A1127M − 23

Standard Specification for

Stainless Steel Laser and Laser-Hybrid Welded, Sharp-

Cornered Profile (SCP) or Built-Up Rounded Corner Square,

1

Rectangular, and Special Shape Structural Tube

This standard is issued under the fixed designation A1127/A1127M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

NOTE 2—Because of the varying requirements of the end-use

1. Scope

applications, different length tolerance, weld inspection levels, strength

1.1 This specification covers laser or laser-hybrid welded

levels and other requirements may be specified.

stainless steel square, rectangular, or custom shape structural NOTE 3—Product covered by this specification is manufactured in small

lots on dedicated production lines. Product quality requirements are

tubing for welded, riveted, or bolted construction. This tube

ensured through welding procedure and operator qualification at each

has either a sharp-cornered profile (SCP) or is built-up tube

manufacturing facility in accordance with Specification A1069/A1069M.

with rounded corners. This product is used in, but not limited

The country of origin and base metal heat numbers are identified by wall

to, the following applications: buildings and structures, includ-

thickness on the product test report.

ing architecturally exposed steel structures (AESS); architec-

1.6 The text of this specification contains notes and foot-

tural steel profiles such as curtain wall, staircases, and others;

notes that provide explanatory material. Such notes and

industrial; and general structural applications.

footnotes, excluding those in tables and figures, do not contain

NOTE 1—The term laser fusion is also used to describe laser welding.

any mandatory requirements.

1.2 This tubing is manufactured from multiple pieces of

1.7 Units—This specification is expressed in both inch-

plate, bar, sheet, strip, or shapes, potentially in different

pound units and in SI units; however, unless the purchase order

thicknesses by laser or laser-hybrid welding in accordance with

or contract specifies the applicable M specification designation

the requirements of Specification A1069/A1069M. It is avail-

(SI units), the inch-pound units shall apply. The values stated in

able in sizes up to 36 in. (914 mm) outside dimension, and the

either inch-pound units or SI units are to be regarded separately

wall thickness tolerance is 65 % of the specified wall

as standard. Within the text, the SI units are shown in brackets.

thickness. Corner welds are permissible.

The values stated in each system may not be exact equivalents;

1.3 This specification establishes the minimum require-

therefore, each system shall be used independently of the other.

ments for manufacturing of laser and laser hybrid welded

Combining values from the two systems may result in noncon-

stainless steel tube and requires the welds to, at a minimum,

formance with the standard.

match the tensile and yield strength of the base metal. If base

1.8 This standard does not purport to address all of the

metals of different strengths are used, the lower strength base

safety concerns, if any, associated with its use. It is the

metal shall be matched.

responsibility of the user of this standard to establish appro-

1.4 This specification refers to Specifications A240/A240M,

priate safety, health, and environmental practices and deter-

A276/A276M or A479/A479M for chemical requirements, but

mine the applicability of regulatory limitations prior to use.

the mechanical test requirements are determined by the me-

1.9 This international standard was developed in accor-

chanical properties section of this standard. This standard

dance with internationally recognized principles on standard-

includes four strength grades. The default strength grade 1 is

ization established in the Decision on Principles for the

determined by the base metal standard. Grades 2 through 4 are

Development of International Standards, Guides and Recom-

for specification of higher strength levels.

mendations issued by the World Trade Organization Technical

1.5 Supplementary requirements (S1 Charpy V- notch, S2 Barriers to Trade (TBT) Committee.

Corrosion, S3 Tensile, and S4 Bend) of an optional nature are

2. Referenced Documents

provided. They shall apply only when specified by the pur-

2

chaser.

2.1 ASTM Standards:

1

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

2

Stainless Steel and Rela

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.