ASTM D7318-11

(Test Method)Standard Test Method for Existent Inorganic Sulfate in Ethanol by Potentiometric Titration

Standard Test Method for Existent Inorganic Sulfate in Ethanol by Potentiometric Titration

SIGNIFICANCE AND USE

Ethanol is used as a blending agent added to gasoline. Sulfates are indicated in filter plugging deposits and fuel injector deposits. When fuel ethanol is burned, sulfates may contribute to sulfuric acid emissions. Ethanol acceptability for use depends on the sulfate content. Sulfate content, as measured by this test method, can be used as one measure of determination of the acceptability of ethanol for automotive spark-ignition engine fuel use.

SCOPE

1.1 This test method covers a potentiometric titration procedure for determining the existent inorganic sulfate content of hydrous, anhydrous ethanol, and anhydrous denatured ethanol, which is added as a blending agent with spark ignition fuels. It is intended for the analysis of denatured ethanol samples containing between 1.0–20 mg/kg existent inorganic sulfate.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Material Safety Data Sheets are available for reagents and materials. Review them for hazards prior to usage.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7318 − 11

StandardTest Method for

Existent Inorganic Sulfate in Ethanol by Potentiometric

1

Titration

This standard is issued under the fixed designation D7318; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 3.1.1 existent inorganic sulfate, n—sulfate species present

as sulfuric acid, ionic salts of this acid, or mixtures of these.

1.1 This test method covers a potentiometric titration pro-

3.1.1.1 Discussion—Specifically in this test method, inor-

cedure for determining the existent inorganic sulfate content of

ganic sulfate is present as sulfate in ethanol.

hydrous, anhydrous ethanol, and anhydrous denatured ethanol,

which is added as a blending agent with spark ignition fuels. It

4. Summary of Test Method

is intended for the analysis of denatured ethanol samples

4.1 An ethanol sample containing inorganic sulfate is

containing between 1.0–20 mg/kg existent inorganic sulfate.

titrated in ethanolic medium with a standard lead nitrate

1.2 The values stated in SI units are to be regarded as

solution. Lead sulfate precipitate is formed during the titration.

standard. No other units of measurement are included in this

Perchloric acid is added to remove possible interference from

standard.

carbonate. The endpoint is signaled by an increase in lead ion

1.3 This standard does not purport to address all of the

activity, as measured by a lead–selective electrode.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

5. Significance and Use

priate safety and health practices and determine the applica-

5.1 Ethanol is used as a blending agent added to gasoline.

bility of regulatory limitations prior to use. Material Safety

Sulfates are indicated in filter plugging deposits and fuel

Data Sheets are available for reagents and materials. Review

injector deposits. When fuel ethanol is burned, sulfates may

them for hazards prior to usage.

contribute to sulfuric acid emissions. Ethanol acceptability for

use depends on the sulfate content. Sulfate content, as mea-

2. Referenced Documents

sured by this test method, can be used as one measure of

2

2.1 ASTM Standards:

determination of the acceptability of ethanol for automotive

D1193 Specification for Reagent Water

spark-ignition engine fuel use.

D4052 Test Method for Density, Relative Density, and API

Gravity of Liquids by Digital Density Meter

6. Apparatus

D4057 Practice for Manual Sampling of Petroleum and

6.1 Potentiometric Titration Assembly—A titration assem-

Petroleum Products

bly consisting of an automatic titrator fitted with a lead

D4177 Practice for Automatic Sampling of Petroleum and

ion-selective electrode, a double-junction reference electrode,

Petroleum Products

buret, and stirring is used. Stirring may be accomplished by

D6299 Practice for Applying Statistical Quality Assurance

means of magnetic or propeller type stirrer mechanisms. The

and Control Charting Techniques to Evaluate Analytical

buret size should ideally be 10 or 20 mL.

Measurement System Performance

6.2 Reference Electrode—A double junction reference elec-

3. Terminology

trode with the inner electrode composed of silver/silver chlo-

3.1 Definitions:

ride with a potassium chloride solution as internal electrolyte.

The external solution is composed of 1 M lithium chloride in

1

This test method is under the jurisdiction of ASTM Committee D02 on

ethanol. This configuration is used to prevent silver ion, a lead

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

electrodepoison,fromleachingintotheanalytesolutionduring

D02.03 on Elemental Analysis.

titration. Preferred electrolytes for use in double junction

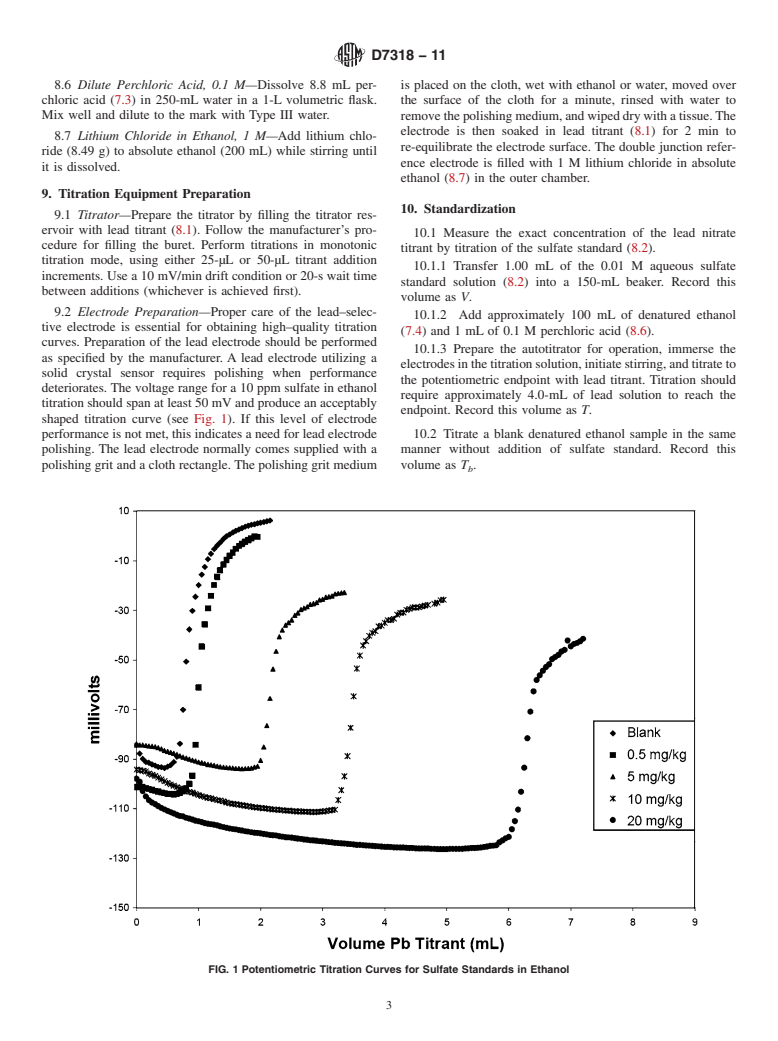

Current edition approved July 1, 2011. Published August 2011. Originally

electrodes may vary with the manufacturer; use the manufac-

approved in 2007. Last previous edition approved in 2007 as D7318–07. DOI:

10.1520/D7318-07.

turer’s recommended electrolytes for the application. Other

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

types of reference electrodes may be considered with some

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

caveats (for example, single junction, combination, or glassy

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. carbon), but the data presented in this test method were

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United State

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D7318–07 Designation:D7318–11

Standard Test Method for

TotalExistent Inorganic Sulfate in Ethanol by Potentiometric

1

Titration

This standard is issued under the fixed designation D7318; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This test method covers a potentiometric titration procedure for determining the totalexistent inorganic sulfate content of

hydrous, anhydrous ethanol, and anhydrous denatured ethanol, which is added as a blending agent with spark ignition fuels. It is

intended for the analysis of denatured ethanol samples containing between 1.0–20 mg/kg totalexistent inorganic sulfate.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parenthesesNo other units of

measurement are for information only. included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.Material Safety Data Sheets are available for reagents and materials. Review them for hazards prior to

usage.

2. Referenced Documents

2

2.1 ASTM Standards:

D1193 Specification for Reagent Water

D4052 Test Method for Density, Relative Density, and API Gravity of Liquids by Digital Density Meter

D4057 Practice for Manual Sampling of Petroleum and Petroleum Products

D4177 Practice for Automatic Sampling of Petroleum and Petroleum Products

D6299 Practice for Applying Statistical Quality Assurance and Control Charting Techniques to Evaluate Analytical

Measurement System Performance

3. Terminology

3.1 Definitions:

3.1.1 inorganic sulfateexistent inorganic sulfate, n—sulfate species present as sulfuric acid, ionic salts of this acid, or mixtures

of these.

3.1.1.1 Discussion—Specifically in this test method, inorganic sulfate is present as sulfate in ethanol.

4. Summary of Test Method

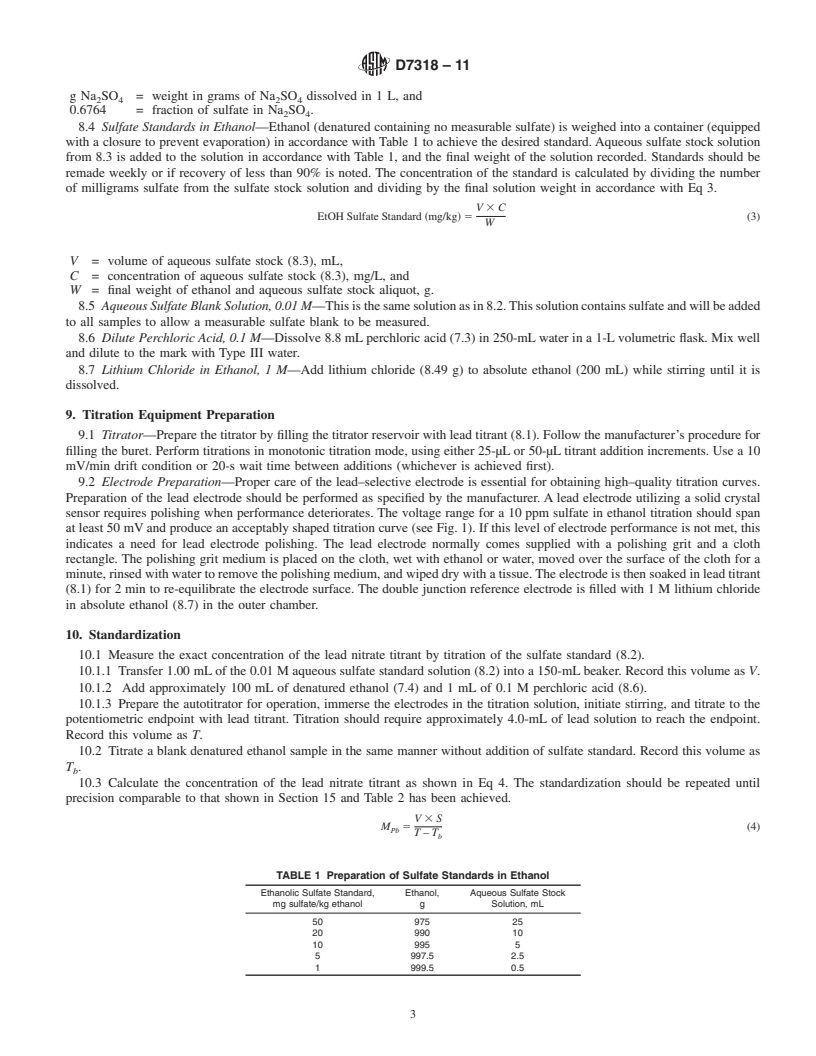

4.1 An ethanol sample containing inorganic sulfate is titrated in ethanolic medium with a standard lead nitrate solution. Lead

sulfate precipitate is formed during the titration. Perchloric acid is added to remove possible interference from carbonate. The

endpoint is signaled by an increase in lead ion activity, as measured by a lead–selective electrode.

5. Significance and Use

5.1 Ethanol is used as a blending agent added to gasoline. Sulfates are indicated in filter plugging deposits and fuel injector

deposits. When fuel ethanol is burned, sulfates may contribute to sulfuric acid emissions. Ethanol acceptability for use depends

on the sulfate content. Sulfate content, as measured by this test method, can be used as one measure of determination of the

acceptability of ethanol for automotive spark-ignition engine fuel use.

1

This test method is under the jurisdiction of ASTM Committee D02 on Petroleum Products and Lubricants and is the direct responsibility of Subcommittee D02.03 on

Elemental Analysis.

Current edition approved Feb. 1, 2007. Published March 2007. DOI: 10.1520/D7318-07.

Current edition approved July 1, 2011. Published August 2011. Originally approved in 2007. Last previous edition approved in 2007 as D7318–07. DOI:

10.1520/D7318-07.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D7318–11

6. Apparatus

6.1 Potentiometric Titration Assembly—A titration assembly consisting of an automatic titrator fitted with a lead ion-selective

electrode, a double-junction reference electrode, buret, and stirring is used. Stirring may be accomplished by means of magnetic

or propeller type stirrer mechanisms. The buret size should ideally be 10 or 20 mL.

6.2 Reference Electrode—Adoublejunctionreferenceelectrodewiththeinnerelectrodecomposedofsilver/silverchloridewith

a potassium chloride solution as internal electrolyte. The external solution is compose

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.