ASTM C24-89(1999)e1

(Test Method)Standard Test Method for Pyrometric Cone Equivalent (PCE) of Fireclay and High Alumina Refractory Materials

Standard Test Method for Pyrometric Cone Equivalent (PCE) of Fireclay and High Alumina Refractory Materials

SCOPE

1.1 This test method covers the determination of the Pyrometric Cone Equivalent (PCE) of fire clay, fireclay brick, high alumina brick, and silica fire clay refractory mortar by comparison of test cones with standard pyrometric cones under the conditions prescribed in this test method.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

e1

Designation: C 24 – 89 (Reapproved 1999)

Standard Test Method for

Pyrometric Cone Equivalent (PCE) of Fireclay and High

Alumina Refractory Materials

This standard is issued under the fixed designation C 24; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

e NOTE—Editorial changes were made in Table 2 in October 1999.

1. Scope have been determined by the National Institute of Standards

and Technology when subjected to both slow and rapid heating

1.1 This test method covers the determination of the Pyro-

rates.

metric Cone Equivalent (PCE) of fire clay, fireclay brick, high

alumina brick, and silica fire clay refractory mortar by com-

5. Significance and Use

parison of test cones with standard pyrometric cones under the

5.1 The deformation and end point of a cone corresponds to

conditions prescribed in this test method.

a certain heat-work condition due to the effects of time,

1.2 The values stated in inch-pound units are to be regarded

temperature, and atmosphere.

as standard. The values given in parentheses are for informa-

5.2 The precision of this test method is subject to many

tion only.

variables that are difficult to control. Therefore, an experienced

1.3 This standard does not purport to address all of the

operator may be necessary where PCE values are being utilized

safety concerns, if any, associated with its use. It is the

for specification purposes.

responsibility of the user of this standard to establish appro-

5.3 PCE values are used to classify fireclay and high

priate safety and health practices and determine the applica-

alumina refractories.

bility of regulatory limitations prior to use.

5.4 This is an effective method of identifying fireclay

2. Referenced Documents variations, mining control, and developing raw material speci-

fications.

2.1 ASTM Standards:

5.5 Although not recommended, this test method is some-

C 71 Terminology Relating to Refractories

times applied to materials other than fireclay and high alumina.

E 11 Specification for Wire-Cloth Sieves for Testing Pur-

Such practice should be limited to in-house laboratories and

poses

never be used for specification purposes.

E 220 Method for Calibration of Thermocouples by Com-

parison Techniques

6. Procedure

3. Terminology 6.1 Preparation of Sample:

6.1.1 Clay or Brick—Crush the entire sample of fire clay or

3.1 Definitions—For definitions of terms used in this test

fireclay brick, in case the amount is small, by means of rolls or

method, see Terminology C 71.

a jaw crusher to produce a particle size not larger than ⁄4 in. (6

4. Summary of Test Method

mm). If the amount is large, treat a representative sample

obtained by approved methods. Then mix the sample thor-

4.1 This test method consists of preparing a test cone from

oughly and reduce the amount to about 250 g (0.5 lb) by

a refractory material and comparing its deformation end point

quartering (see Note 1). Then grind this portion in an agate,

to that of a standard pyrometric cone. The resultant PCE value

porcelain, or hard steel mortar and reduce the amount again by

is a measure of the refractoriness of the material.

quartering. The final size of the sample shall be 50 g and the

4.2 Temperature equivalent tables for the standard cones

fineness capable of passing an ASTM No. 70 (212-μm) sieve

(equivalent to a 65-mesh Tyler Standard Series). In order to

This test method is under the jurisdiction of ASTM Committee C-8 on avoid excessive reduction to fines, remove them frequently

Refractories and is the direct responsibility of Subcommittee C08.07 on High

during the process of reduction by throwing the sample on the

Alumina, Silica, and Special Refractories.

sieve and continuing the grinding of the coarser particles until

Current edition approved July 28, 1989. Published November 1989. Originally

all the sample passes through the sieve (see Note 2). Take

issued as C 24 – 19 T. Last previous edition C 24 – 84 (1988).

Annual Book of ASTM Standards, Vol 15.01.

Annual Book of ASTM Standards, Vol 14.02.

4 5

Annual Book of ASTM Standards, Vol 14.03. Detailed requirements for this sieve are given in Specification E 11.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

C24

precautions to prevent contamination of the sample by steel

particles from the sampling equipment during crushing or

grinding.

NOTE 1—Take care during the crushing and grinding of the sample to

prevent the introduction of magnetic material.

NOTE 2—The requirement to grind the coarser particles is particularly

important for highly siliceous products; excessively fine grinding may

reduce their PCE by as much as two cones.

6.1.2 Silica Fire Clay (see 3.1)—In the case of silica fire

clay, test the sample obtained by approved methods as received

without grinding or other treatment.

6.2 Preparation of Test Cones:

6.2.1 After preparing samples of unfired clays (Note 3), or

of mixes containing appreciable proportions of raw clay, in

accordance with 6.1.1, heat them in an oxidizing atmosphere in

the temperature range from 1700 to 1800°F (925 to 980°C) for

not less than 30 min.

NOTE 3—Some unfired clays bloat when they are formed into cones and

are carried through the high-temperature heat treatment prescribed in 5.4.1

without preliminary calcining. The substances that cause bloating can, in

most cases, be expelled by heating the clay samples before testing.

6.2.2 The clay sample may be given the heat treatment

prescribed in 6.2.1 after it has been formed into a cone (see

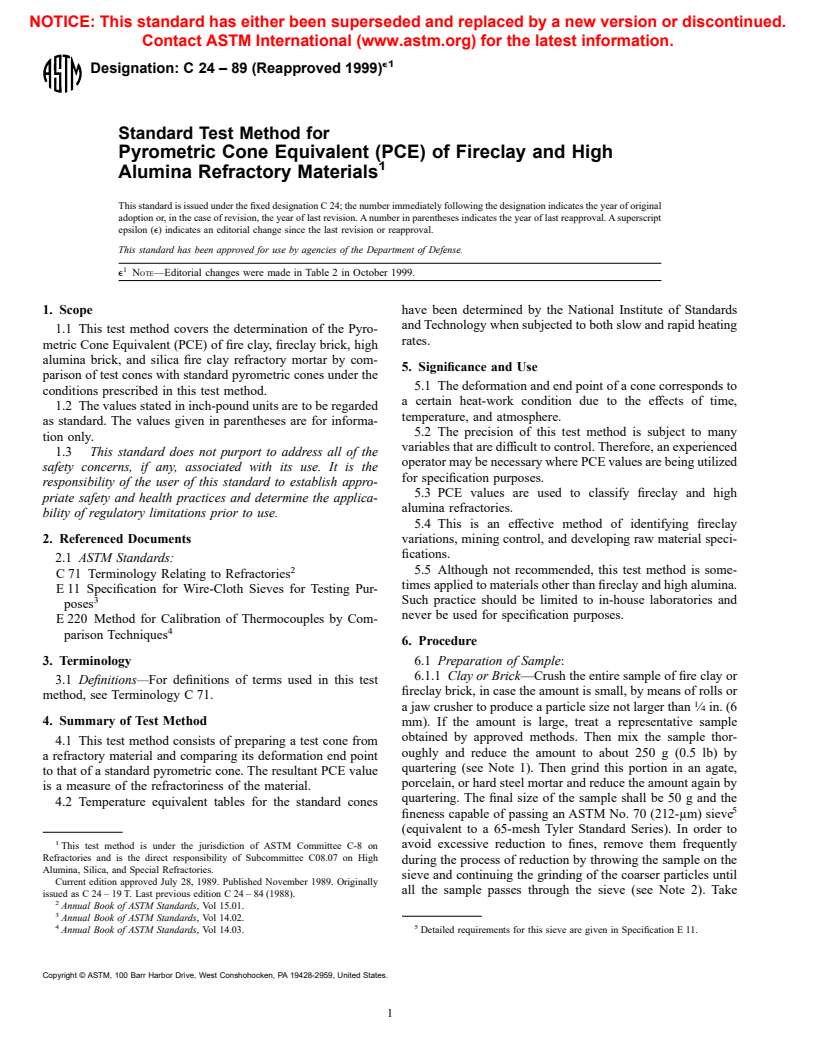

NOTE 1—Dimensions are in inches.

6.2.3), but this procedure has been found not as effective as the

SI Equivalents

treatment of the powdered material. If cones so prepared bloat

during the PCE test, heat a portion of the original sample in its

powdered condition as prescribed in 6.2.1 and then retest it.

in. mm

6.2.3 Thoroughly mix the dried sample, and after the

0.075 1.90

addition of sufficient dextrine, glue, gum tragacanth, or other 0.272 6.91

0.281 7.14

alkali-free organic binder and water, form it in a metal mold

1.081 27.46

into test cones in the shape of a truncated trigonal pyramid with

1.125 28.58

its base at a small angle to the trigonal axis, and in accordance

FIG. 1 Standard Pyrometric Test Cone

with dimensions shown in Fig. 1. In forming the test cone use

the mold shown in Fig. 2.

face outward, if so desired.

6.3 Mounting:

6.4 Heating:

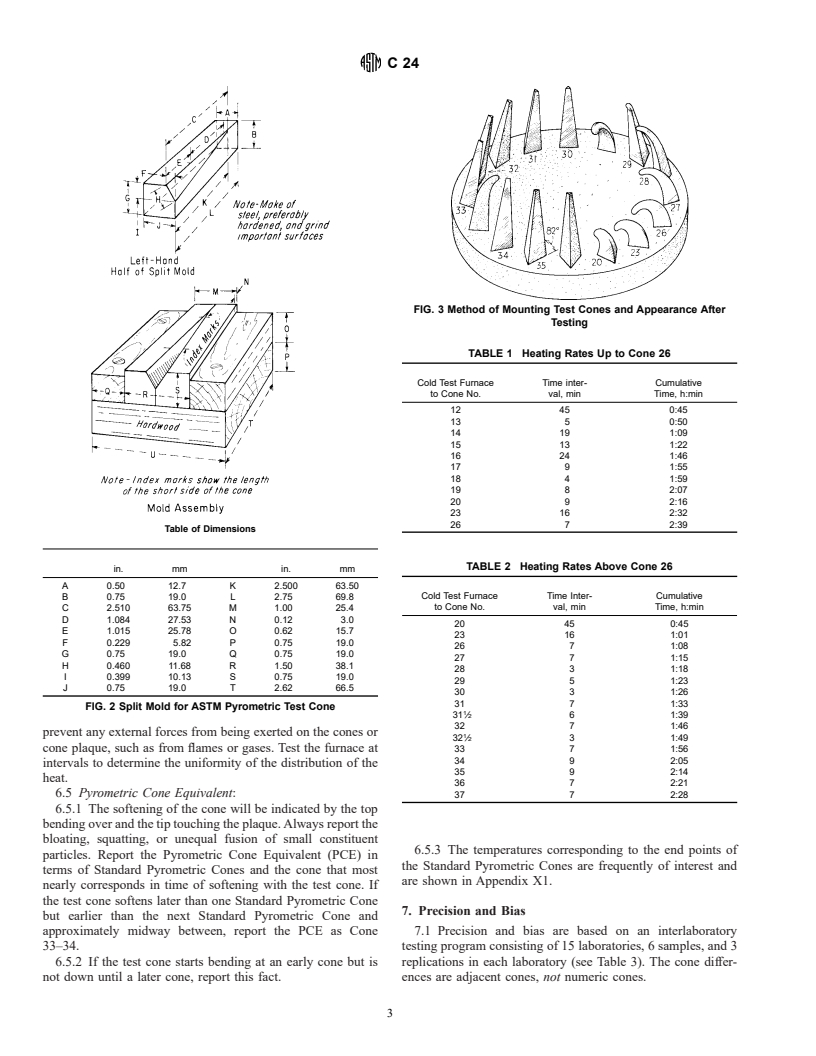

6.3.1 Mount both the test cones and the Standard Pyromet-

6.4.1 Perform the heating in a suitable furnace, operating

ric Cones on plaques of refractory material that have a

with an oxidizing atmosphere, at rates to conform to the

composition that will not affect the fusibility of the cones (see

following requirements (see Note 6 and Note 7). It is advisable,

Note 4). Mount both test and PCE cones with the base

but not mandatory that the furnace temperature be controlled

embedded so that the length of the sloping face of the cone

with a calibrated thermocouple or radiation pyrometer con-

above the plaque shall be ⁄16 in. (24 mm) and the face of the

nected to a program-controlled recorder.

cone (about which bending takes place) shall be inclined at an

6.4.1.1 For PCE tests expected to have an end point of PC

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.