ASTM C24-01

(Test Method)Standard Test Method for Pyrometric Cone Equivalent (PCE) of Fireclay and High Alumina Refractory Materials

Standard Test Method for Pyrometric Cone Equivalent (PCE) of Fireclay and High Alumina Refractory Materials

SCOPE

1.1 This test method covers the determination of the Pyrometric Cone Equivalent (PCE) of fire clay, fireclay brick, high alumina brick, and silica fire clay refractory mortar by comparison of test cones with standard pyrometric cones under the conditions prescribed in this test method.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C 24–01

Standard Test Method for

Pyrometric Cone Equivalent (PCE) of Fireclay and High

1

Alumina Refractory Materials

ThisstandardisissuedunderthefixeddesignationC24;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 4.2 Temperature equivalent tables for the standard cones

have been determined by the National Institute of Standards

1.1 This test method covers the determination of the Pyro-

andTechnology when subjected to both slow and rapid heating

metric Cone Equivalent (PCE) of fire clay, fireclay brick, high

rates.

alumina brick, and silica fire clay refractory mortar by com-

parison of test cones with standard pyrometric cones under the

5. Significance and Use

conditions prescribed in this test method.

5.1 The deformation and end point of a cone corresponds to

1.2 The values stated in inch-pound units are to be regarded

a certain heat-work condition due to the effects of time,

as standard. The values given in parentheses are for informa-

temperature, and atmosphere.

tion only.

5.2 The precision of this test method is subject to many

1.3 This standard does not purport to address all of the

variables that are difficult to control.Therefore, an experienced

safety concerns, if any, associated with its use. It is the

operatormaybenecessarywherePCEvaluesarebeingutilized

responsibility of the user of this standard to establish appro-

for specification purposes.

priate safety and health practices and determine the applica-

5.3 PCE values are used to classify fireclay and high

bility of regulatory limitations prior to use.

alumina refractories.

2. Referenced Documents 5.4 This is an effective method of identifying fireclay

variations, mining control, and developing raw material speci-

2.1 ASTM Standards:

2

fications.

C 71 Terminology Relating to Refractories

5.5 Although not recommended, this test method is some-

E 11 Specification for Wire-Cloth Sieves for Testing Pur-

3 times applied to materials other than fireclay and high alumina.

poses

Such practice should be limited to in-house laboratories and

E 220 Method for Calibration of Thermocouples by Com-

4 never be used for specification purposes.

parison Techniques

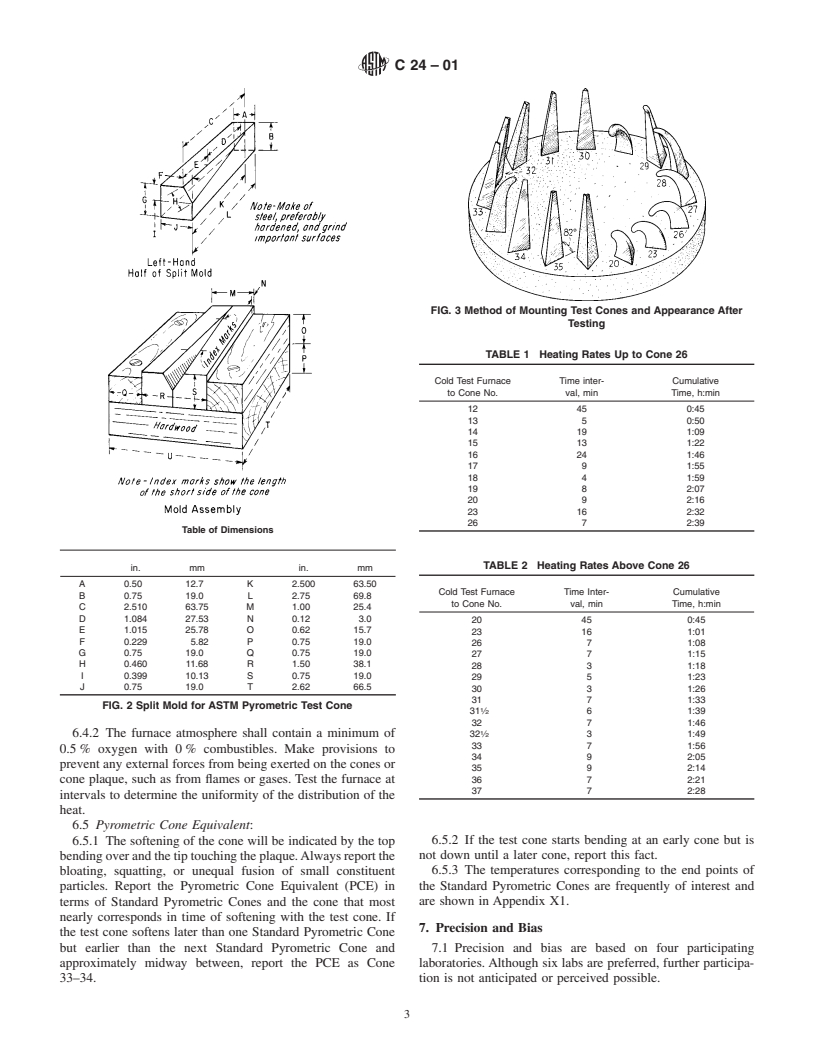

6. Procedure

3. Terminology

6.1 Preparation of Sample:

3.1 Definitions—For definitions of terms used in this test

6.1.1 Clay or Brick—Crush the entire sample of fire clay or

method, see Terminology C 71.

fireclay brick, in case the amount is small, by means of rolls or

1

4. Summary of Test Method

a jaw crusher to produce a particle size not larger than ⁄4 in. (6

mm). If the amount is large, treat a representative sample

4.1 This test method consists of preparing a test cone from

obtained by approved methods. Then mix the sample thor-

a refractory material and comparing its deformation end point

oughly and reduce the amount to about 250 g (0.5 lb) by

to that of a standard pyrometric cone. The resultant PCE value

quartering (see Note 1). Then grind this portion in an agate,

is a measure of the refractoriness of the material.

porcelain, or hard steel mortar and reduce the amount again by

quartering. The final size of the sample shall be 50 g and the

5

1

fineness capable of passing an ASTM No. 70 (212-µm) sieve

This test method is under the jurisdiction of ASTM Committee C08 on

Refractories and is the direct responsibility of Subcommittee C08.02 on Thermal

(equivalent to a 65-mesh Tyler Standard Series). In order to

Properties.

avoid excessive reduction to fines, remove them frequently

Current edition approved Feb. 10, 2001. PublishedApril 2001. Originally issued

e1

during the process of reduction by throwing the sample on the

as C 24 – 19 T. Last previous edition C 24 – 89 (1999) .

2

Annual Book of ASTM Standards, Vol 15.01.

3

Annual Book of ASTM Standards, Vol 14.02.

4 5

Annual Book of ASTM Standards, Vol 14.03. Detailed requirements for this sieve are given in Specification E 11.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

C24–01

sieve and continuing the grinding of the coarser particles until

all the sample passes through the sieve (see Note 2). Take

precautions to prevent contamination of the sample by steel

particles from the sampling equipment during crushing or

grinding.

NOTE 1—Take care during the crushing and grinding of the sample to

prevent the introduction of magnetic material.

NOTE 2—The requirement to grind the coarser particles is particularly

important for highly siliceous products;

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.