ASTM D1938-94

(Test Method)Standard Test Method for Tear-Propagation Resistance (Trouser Tear) of Plastic Film and Thin Sheeting by a Single-Tear Method

Standard Test Method for Tear-Propagation Resistance (Trouser Tear) of Plastic Film and Thin Sheeting by a Single-Tear Method

SCOPE

1.1 This test method covers the determination of the force necessary to propagate a tear in plastic film and thin sheeting (thickness of 1 mm (0.04 in.) or less) by a single-tear method. The method is not applicable for film or sheeting material where brittle failures occur during testing.

Note 1—Film has been arbitrarily defined as sheeting having nominal thickness not greater than 0.25 mm (0.010 in.).

1.2 Constant-Rate-of-Grip Separation Test—This test method employs a constant rate of separation of the grips holding the test specimen.

1.2.1 Specimen extension may be measured in this test method by grip separation.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are provided for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

Note 2—This standard is similar to ISO 6383-1, but is not considered technically equivalent. The specimen size for ISO 6383-1 is larger, and the method specifies different test speeds.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 1938 – 94 An American National Standard

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Test Method for

Tear-Propagation Resistance of Plastic Film and Thin

Sheeting by a Single-Tear Method

This standard is issued under the fixed designation D 1938; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

1.1 This test method covers the determination of the force 3.1 Definitions: Definitions of terms applying to this test

necessary to propagate a tear in plastic film and thin sheeting method appear in Terminology D 883.

(thickness of 1 mm (0.04 in.) or less) by a single-tear method.

4. Summary of Test Method

1.2 The values stated in SI units are to be regarded as the

4.1 The force to propagate a tear across a film or sheeting

standard. The values given in parentheses are for information

specimen is measured using a constant-rate-of-grip separation

only.

1.3 This standard does not purport to address all of the machine as described in Method A of Test Methods D 882. The

force necessary to propagate the tear is interpreted from the

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- load-time chart.

priate safety and health practices and determine the applica-

5. Significance and Use

bility of regulatory limitations prior to use.

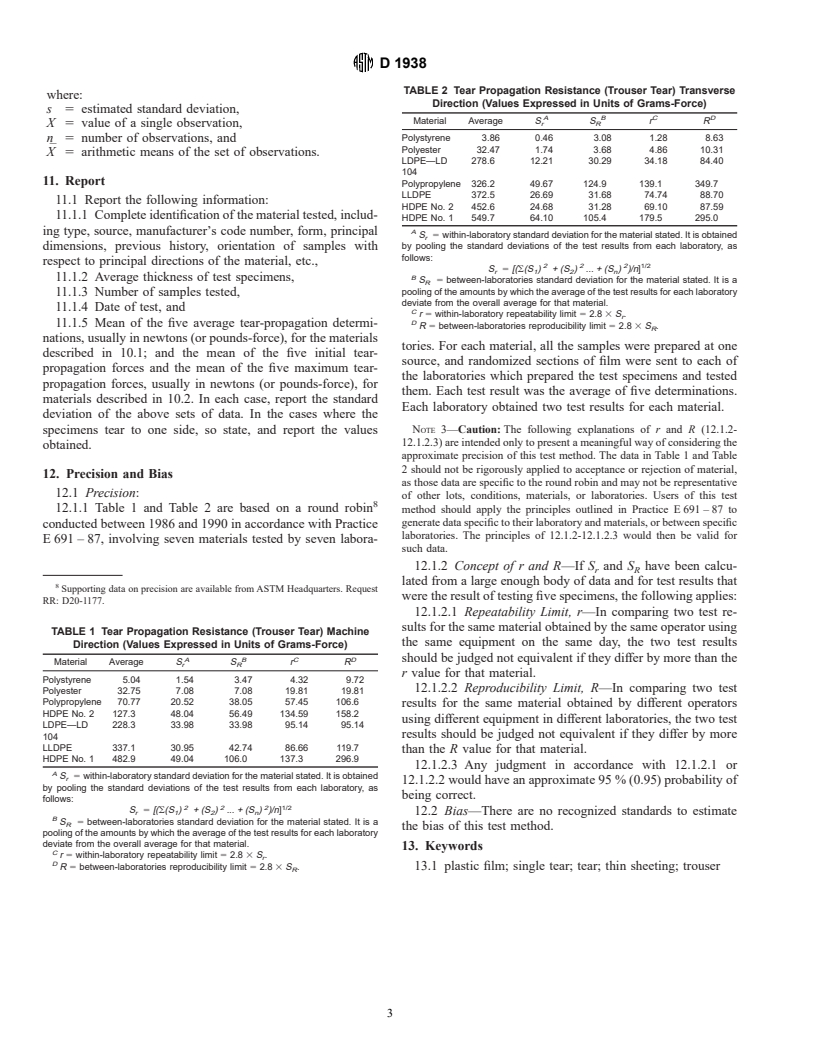

5.1 This test method is of value in rating the tear-

NOTE 1—This standard and ISO 6383-1 are technically equivalent.

propagation force of various plastic films and thin sheeting of

However, the specimen size is larger for ISO 6383-1.

comparable thickness. The tear-propagation resistance in

highly extensible film or sheeting is distinguished from the

2. Referenced Documents

tear-propagation resistance in slightly extensible or nonexten-

2.1 ASTM Standards:

sible film or sheeting in Fig. 1 and Fig. 2 in 10.1 and 10.2,

D 374 Test Methods for Thickness of Solid Electrical Insu-

respectively.

lation

5.2 This test method should be used for specification accep-

D 618 Practice for Conditioning Plastics and Electrical

tance testing only after it has been demonstrated that the data

Insulating Materials for Testing

for the particular material are acceptably reproducible.

D 882 Test Methods for Tensile Properties of Thin Plastic

5.3 The data obtained by this test method furnish informa-

Sheeting

3 tion for ranking the tear-propagation resistance of plastic films

D 883 Terminology Relating to Plastics

and sheeting of similar composition. Actual use performance

D 4000 Classification System for Specifying Plastic Mate-

4 may not necessarily correlate with data from this test method.

rials

5 Sets of data from specimens of dissimilar thickness are usually

E 4 Practices for Load Verification of Testing Machines

not comparable.

E 691 Practice for Conducting an Interlaboratory Study to

6 5.4 For many materials, there may be a specification that

Determine the Precision of a Test Method

requires the use of this test method, but with some procedural

2.2 ISO Standard:

modifications that take precedence when adhering to the

ISO 6383-1 Film and Sheeting—Determination of Tear

7 specification. Therefore, it is advisable to refer to that material

Resistance Part 1 Trouser Tear Method

specification before using this test method. Table 1 of Classi-

fication System D 4000 lists the ASTM materials standards that

currently exist.

This test method is under the jurisdiction of ASTM Committee D-20 on Plastics

and is the direct responsibility of Subcommittee D20.10 on Mechanical Properties.

6. Apparatus

Current edition approved Feb. 15, 1994. Published April 1994. Originally

published as D 1938 – 62 T. Last previous edition D 1938 – 93.

6.1 Film-Testing Machine, with a force-indicating head that

Annual Book of ASTM Standards, Vol 10.01.

can measure the load applied to tear the specimen. It should be

Annual Book of ASTM Standards, Vol 08.01.

equipped with a device for recording the load carried by the

Annual Book of ASTM Standards, Vol 08.02.

Annual Book of ASTM Standards, Vol 03.01.

specimen and the amount of separation of the grips during the

Annual Book of ASTM Standards, Vol 14.02.

test. The testing machine shall be essentially free from inertia

Available from American National Standards Institute, 11 W. 42nd St., 13th

lag at the specified rate of testing and shall indicate the load

Floor, New York, NY 10036.

D 1938

7.2 Measure the thickness of the specimen below the slit

(see Fig. 3) in several places and record it in millimetres to the

nearest 0.0025 mm (0.0001 in.).

7.3 Cut enough specimens to provide a minimum of five

tear-propagation force determinations each in the machine

direction and in the transverse direction of the material being

tested.

8. Conditioning

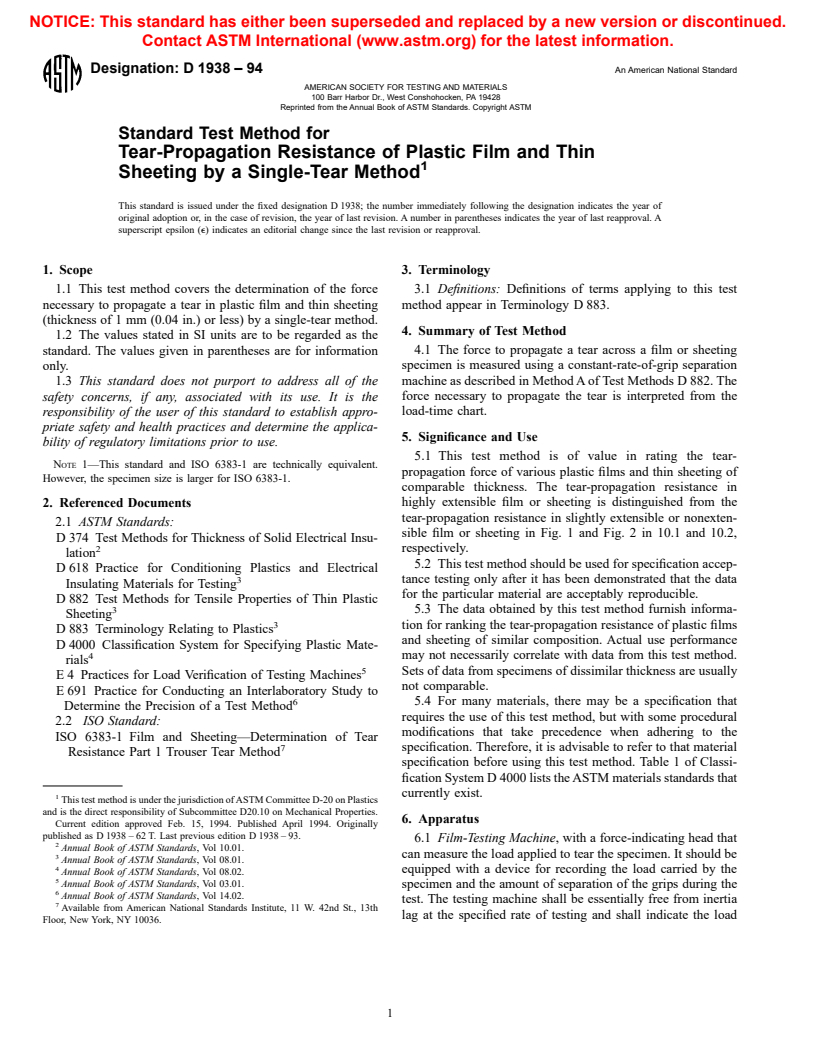

FIG. 1 Load-Time Chart for Low-Extensible Film

8.1 Conditioning—Condition the test specimens at 23 6

2°C (73.4 6 3.6°F) and 50 6 5 % relative humidity for not less

than 40 h prior to test in accordance with Procedure A of

Practice D 618, for those tests where conditioning is required.

In cases of disagreement, the tolerances shall be6 1°C

(61.8°F) and 62 % relative humidity.

8.2 Test Conditions—Conduct tests in the standard labora-

tory atmosphere of 23 6 2°C (73.4 6 3.6°F) and 50 6 5%

relative humidity, unless otherwise specified in the test meth-

ods. In cases of disagreement, the tolerances shall be 61°C

(61.8°F) and6 2 % relative humidity.

9. Procedure

9.1 Secure Tongue A (Fig. 3) in one grip and Tongue B in

the other grip of the constant-rate-of-grip separation-testing

FIG. 2 Load-Time Chart for Highly Extensible Film

machine, using an initial grip separation of 50 mm (2 in.).

Align the specimen so that its major axis coincides with an

imaginary line joining the centers of the grips.

with an accuracy of 62 % of the indicated value or better. The

9.2 Using a grip-separation speed of 250 mm (10 in.)/min,

accuracy of the testing machine shall be verified in accordance

start the machine, and record the load necessary to propagate

with Practices E 4. A device shall be included to control the

the tear through the entire unslit 25-mm (1-in.) portion.

grip-separation rate at 250 mm (10 in.)6 5 %/min.

9.3 Test not less than five specimens in each of the principal

6.2 Thickness-Measuring Devices, in accordance with Test

film or sheeting directions.

Methods D 374 or a method of equivalent accuracy.

6.3 Cutter—A sharp razor blade or the equivalent.

10. Calculation

6.4 Conditioning Apparatus, in accordance with Procedure

10.1 For thin films and sheeting that have load-time charts

A of Practice D 618.

characterized by Fig. 1, obtain the average tear propagation

7. Test Specimens

force by averaging the load indicated on the chart over the time

period, disregarding the initial and final portions of the curve.

7.1 The specimens shall be of the single-tear type and shall

This can be done with an integrator or a planimeter. In some

consist of strips 75 mm (3 in.) long by 25 mm (1 in.) wide and

cases, a fairly accurate estimate can be made by eye.

shall have a clean longitudinal slit 50 mm (2 in.) 62 % long cut

10.2 For thin films and sheeting that have

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.