ASTM B215-04

(Practice)Standard Practices for Sampling Metal Powders

Standard Practices for Sampling Metal Powders

SIGNIFICANCE AND USE

Since many tests are performed using very small amounts of powder, it is most important that the test portions be obtained in a standardized manner. The practices described here take into account the possibility of segregation of the metal powder during and after filling of containers. PRACTICE A Top FOR POWDERS BEING TRANSFERRED FROM BLENDERS OR STORAGE TANKS Top

SCOPE

1.1 These practices describe two procedures for obtaining samples of metal powders for subsequent testing:

1.1.1 Practice AFor powders being transferred from blenders or storage tanks.

1.1.2 Practice BFor powders already packaged in containers.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:B215–04

Standard Practices for

1

Sampling Metal Powders

This standard is issued under the fixed designation B 215; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope

1.1 These practices describe two procedures for obtaining

samples of metal powders for subsequent testing:

1.1.1 Practice A—For powders being transferred from

blenders or storage tanks.

1.1.2 Practice B—For powders already packaged in con-

tainers.

1.2 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

2

B 243 Terminology of Powder Metallurgy

3. Terminology

3.1 Definitions —Definitions of powder metallurgy terms

can be found in Terminology B 243. Additional descriptive

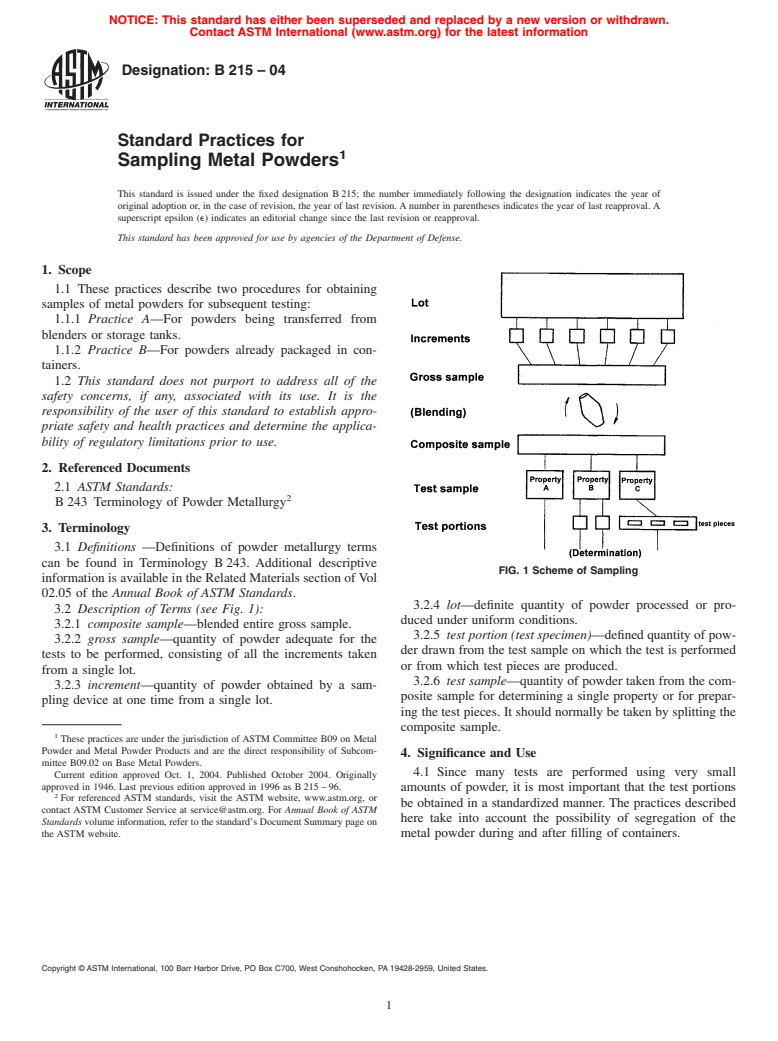

FIG. 1 Scheme of Sampling

information is available in the Related Materials section of Vol

02.05 of the Annual Book of ASTM Standards.

3.2.4 lot—definite quantity of powder processed or pro-

3.2 Description of Terms (see Fig. 1):

duced under uniform conditions.

3.2.1 composite sample—blended entire gross sample.

3.2.5 test portion (test specimen)—defined quantity of pow-

3.2.2 gross sample—quantity of powder adequate for the

der drawn from the test sample on which the test is performed

tests to be performed, consisting of all the increments taken

or from which test pieces are produced.

from a single lot.

3.2.6 test sample—quantity of powder taken from the com-

3.2.3 increment—quantity of powder obtained by a sam-

posite sample for determining a single property or for prepar-

pling device at one time from a single lot.

ing the test pieces. It should normally be taken by splitting the

composite sample.

1

These practices are under the jurisdiction of ASTM Committee B09 on Metal

Powder and Metal Powder Products and are the direct responsibility of Subcom-

4. Significance and Use

mittee B09.02 on Base Metal Powders.

4.1 Since many tests are performed using very small

Current edition approved Oct. 1, 2004. Published October 2004. Originally

approved in 1946. Last previous edition approved in 1996 as B 215 – 96.

amounts of powder, it is most important that the test portions

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

be obtained in a standardized manner. The practices described

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

here take into account the possibility of segregation of the

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. metal powder during and after filling of containers.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

B215–04

PRACTICE A 7. Frequency of Increments

7.1 Take at least three increments for each lot of powder.

FOR POWDERS BEING TRANSFERRED FROM

The actual number depends on the size of the lot and the

BLENDERS OR STORAGE TANKS

powder involved and shall be agreed upon by the parties

involved.

5. Apparatus

5.1 Rectangular Receptacle, capable of being moved com- PRACTICE B

pletely across the stream of flowing powder at a constant speed

FOR POWDERS ALREADY PACKAGED IN

and having a length and width greater than the stream of

CONTAINERS

powder. It must be large enough so that no overflow of powder

occurs when collecting the sample.

8. Apparatus

5.2 Small Blender.

8.1 Keystone Sampler, see Fig. 4.

5.3 Sample Splitter, see Fig. 2.

8.2 Small Blender.

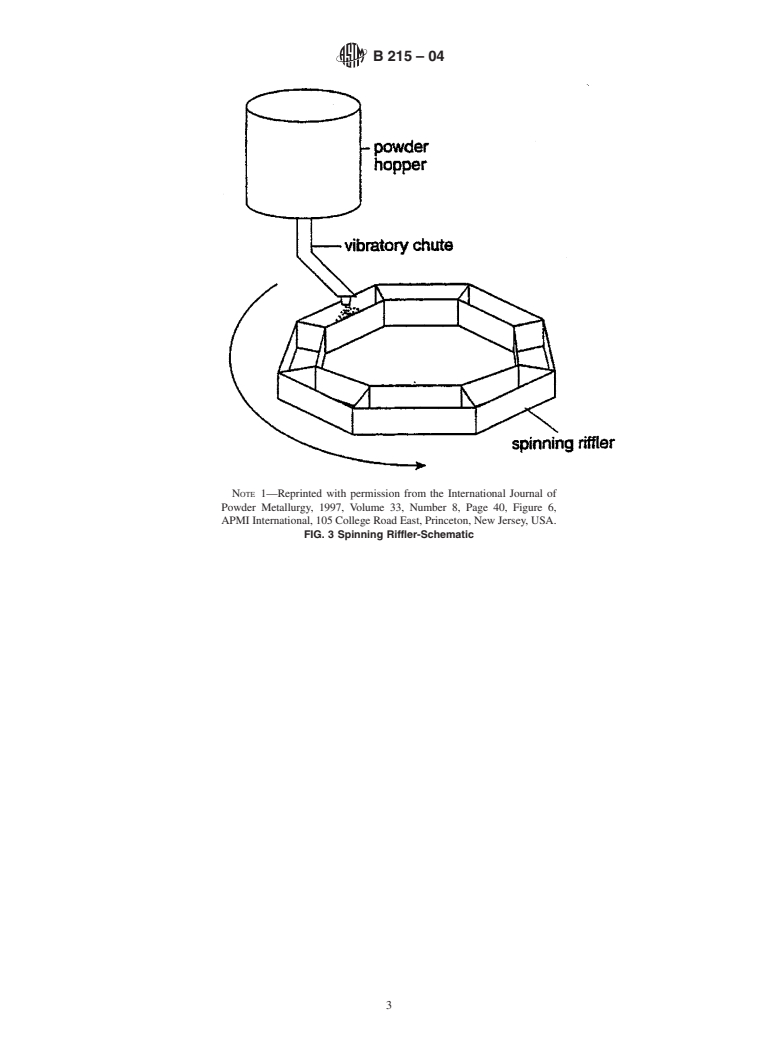

5.4 Spinning Riffler, see Fig. 3.

8.3 Sample Splitter, see Fig. 2.

5.5 Micro-sample Splitter.

8.4 Spinning Riffler, see Fig. 3.

5.6 Micro-sample Spinning Riffler.

8.5 Micro-sample Splitter.

8.6 Micro-sample Spinning Riffler.

6. Procedure

9. Procedure

6.1 Pass the rectangular receptacle at a constant speed

9.1 Insert the Keystone sampler in the closed position into

completely through the stream of flowing powder. If the entire

the powder at a point 70 % of the distance from the center of

contents of one lot of powder are being packed in a single

1 1 3

the cross section to the periphery and straight down to the

container, take increments when the container is ⁄4 , ⁄2 , and ⁄4

bottom of the container. Then twist the sampler to the open

filled.Ifseveralcontainersaretobefilledbyonelotofpowder,

1

position allowing powder to flow into

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.