ASTM E1806-96(2001)

(Practice)Standard Practice for Sampling Steel and Iron for Determination of Chemical Composition

Standard Practice for Sampling Steel and Iron for Determination of Chemical Composition

SCOPE

1.1 This practice covers the sampling of all grades of steel, both cast and wrought, and all types (grades) of cast irons and blast furnace iron for chemical and spectrochemical determination of composition. This practice is similar to ISO 14284.

1.2 This practice is divided into the following sections. SectionsRequirements for Sampling and Sample Preparation6General6.1Sample6.2Selection of a Sample6.3Preparation of a Sample6.4Liquid Iron for Steelmaking and Pig Iron Production7General7.1Spoon Sampling7.2Probe Sampling7.3Preparation of a Sample for Analysis7.4Liquid Iron for Cast Iron Production8General8.1Spoon Sampling8.2Probe Sampling8.3Preparation of a Sample for Analysis8.4Sampling and Sample Preparation for the Determination ofOxygen and Hydrogen8.5Liquid Steel for Steel Production9General9.1Probe Sampling9.2Spoon Sampling9.3Preparation of a Sample for Analysis8.4Sampling and Sample Preparation for the Determinationof Oxygen9.5Sampling and Sample Preparation for the Determinationof Hydrogen9.6Pig Irons10General10.1Increment Sampling10.2Preparation of a Sample for Analysis10.3Cast Iron Products11General11.1Sampling and Sample Preparation11.2Steel Products12General12.1Selection of a Laboratory Sample or a Sample forAnalysis from a Cast Product12.2Selection of a Laboratory Sample or a Sample forAnalysis from a Wrought Product12.3Preparation of a Sample for Analysis12.4Sampling of Leaded Steel12.5Sampling and Sample Preparation for the Determinationof Oxygen12.6Sampling and Sample Preparation for the Determinationof Hydrogen12.7Keywords13 AnnexesSampling Probes for Use with Liquid Iron and SteelAnnex A1Sampling Probes for Use with Liquid Steel for theAnnex A2Determination of Hydrogen

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.4 For specific precautions, see 6.4.3.5, 9.4.4.3, and 12.5.1.1 as well as Section 5.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E 1806 – 96 (Reapproved 2001)

Standard Practice for

Sampling Steel and Iron for Determination of Chemical

Composition

This standard is issued under the fixed designation E 1806; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

Selection of a Laboratory Sample or a Sample for 12.2

Analysis from a Cast Product

1.1 This practice covers the sampling of all grades of steel,

Selection of a Laboratory Sample or a Sample for 12.3

both cast and wrought, and all types (grades) of cast irons and

Analysis from a Wrought Product

Preparation of a Sample forAnalysis 12.4

blast furnace iron for chemical and spectrochemical determi-

Sampling of Leaded Steel 12.5

nation of composition. This practice is similar to ISO 14284.

Sampling and Sample Preparation for the Determination 12.6

1.2 This practice is divided into the following sections.

of Oxygen

Sections

Sampling and Sample Preparation for the Determination 12.7

Requirements for Sampling and Sample Preparation 6

of Hydrogen

General 6.1

Sample 6.2

Keywords 13

Selection of a Sample 6.3

Preparation of a Sample 6.4

Annexes

Sampling Probes for Use with Liquid Iron and Steel AnnexA1

Liquid Iron for Steelmaking and Pig Iron Production 7

Sampling Probes for Use with Liquid Steel for the AnnexA2

General 7.1

Determination of Hydrogen

Spoon Sampling 7.2

Probe Sampling 7.3

1.3 This standard does not purport to address all of the

Preparation of a Sample forAnalysis 7.4

safety concerns, if any, associated with its use. It is the

Liquid Iron for Cast Iron Production 8

responsibility of the user of this standard to establish appro-

General 8.1

priate safety and health practices and determine the applica-

Spoon Sampling 8.2

bility of regulatory limitations prior to use.

Probe Sampling 8.3

Preparation of a Sample forAnalysis 8.4

1.4 For specific precautions, see 6.4.3.5, 9.4.4.3, and

Sampling and Sample Preparation for the Determination of 8.5

12.5.1.1 as well as Section 5.

Oxygen and Hydrogen

2. Referenced Documents

Liquid Steel for Steel Production 9

General 9.1 2

2.1 ASTM Standards:

Probe Sampling 9.2

A 48 Specification for Gray Iron Castings

Spoon Sampling 9.3

Preparation of a Sample forAnalysis 9.4

A 751 Test Methods, Practices, and Definitions for Chemi-

Sampling and Sample Preparation for the Determination 9.5

cal Analysis of Steel Products

of Oxygen

E 135 Terminology Relating to Analytical Chemistry for

Sampling and Sample Preparation for the Determination 9.6

of Hydrogen

Metals, Ores, and Related Materials

E 415 Test Method for Optical Emission Vacuum Spectro-

Pig Irons 10

metric Analysis of Carbon and Low-Alloy Steel

General 10.1

Increment Sampling 10.2

E 1010 Practice for Preparation of Disk Specimens of Steel

Preparation of a Sample forAnalysis 10.3

and Iron for Spectrochemical Analysis by Remelting

E 1087 Practice for Sampling Molten Steel from a Ladle

Cast Iron Products 11

General 11.1

Using an Immersion Sampler to Produce a Sample for

Sampling and Sample Preparation 11.2

Spectrochemical Analysis

2.2 ISO Documents:

Steel Products 12

General 12.1

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

This practice is under the jurisdiction of ASTM Committee E01 on Analytical contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Chemistry for Metals, Ores, and Related Materials and is the direct responsibility of Standards volume information, refer to the standard’s Document Summary page on

Subcommittee E01.01 on Iron, Steel, and Ferroalloys. the ASTM website.

Current edition approved April 10, 1996. Published June 1996. Withdrawn.

Copyright ©ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA19428-2959, United States.

E 1806 – 96 (2001)

ISO 9147 Pig irons–Definition and classification 3.2.18 wrought product, n—item of steel which has been

ISO 14284 Steel and iron—Sampling and preparation of subject to deformation by rolling, drawing, forging, or some

samples for the determination of chemical composition other method, for example, a bar, billet, plate, strip, tube, or

wire.

3. Terminology

3.1 Definitions—For definitions of terms in this practice, 4. Significance and Use

refer to Terminology E 135.

4.1 This practice covers all aspects of sampling and prepar-

3.2 Definitions of Terms Specific to This Standard:

ing steel and iron for chemical analysis as defined in Test

3.2.1 cast product, n—item of iron or steel which has not

Methods, Practices, and Definitions A 751 and Specification

been subject to deformation, for example, an ingot, a semi

A 48. Such subjects as sampling location and the sampling of

finished product obtained by continuous casting, or a shaped

lots are defined.

casting.

4.2 It is intended that this practice include most require-

3.2.2 consignment, n—quantity of metal delivered at one

ments for sampling steel and iron for analysis. Standard

time.

analytical methods that reference this practice need contain

3.2.3 grinding, n—method of preparing a sample of metal

only special modifications and exceptions.

for a spectrochemical method of analysis in which the surface

4.3 It is assumed that all who use these procedures will be

of the sample for analysis is abraded using an abrasive wheel.

trained samplers capable of performing common sampling

3.2.4 increment, n—in sampling, a portion of material

operations skillfully and safely. It is expected that only proper

removed from a lot by a single operation.

sampling equipment will be used.

3.2.5 linishing, n—method of preparing a sample of metal

for a spectrochemical method of analysis in which the surface

5. Hazards and Safety Precautions

of the sample for analysis is abraded using a rotating disk or

5.1 Provide personal protective equipment to minimize the

continuous belt coated with an abrasive substance.

risk of injury during sampling and sample preparation meth-

3.2.6 lot, n—in sampling, a collection of material regarded

ods. Provisions shall include protective clothing, hand protec-

as a unit. See Specification A 48.

tion,andfacevisorsresistanttosplashesofliquidmetalforuse

3.2.7 melt, n—liquid metal from which a sample is re-

during the sampling of liquid metal; protective clothing and

moved.

hand, eye, and hearing protection for use during the sampling

3.2.8 sampling, immersion, n—method of probe sampling

and sample preparation of solid metal; and respiratory protec-

in which the probe is immersed in the melt where the sample

tion for use where necessary.

chamber in the probe fills by ferrostatic pressure or gravity.

5.2 The use of machinery for sampling and sample prepa-

3.2.9 sample, probe, n—sample taken from the melt using a

ration shall be in accordance with appropriate national stan-

sampling probe.

dards.Grindingoperationsusedforsurfacepreparationmaybe

3.2.10 sampling, probe, n—method in which the sample is

covered by national legislation.

taken using a sampling probe inserted into the melt.

5.3 Reference should be made to appropriate national regu-

3.2.11 sample product, n—specific item of iron or steel

lations with respect to the use of solvents for the cleaning and

selected from a supplied quantity for the purpose of obtaining

drying of samples and test portions.

a sample.

3.2.12 sample, spoon, n—sample taken from the melt using

6. Requirements for Sampling and Sample Preparation

a spoon and cast into a small mold.

6.1 General:

3.2.13 sampling, spoon, n—method in which the sample is

6.1.1 Thissectiondescribesthegeneralrequirementsforthe

taken from the melt, or during the pouring of the melt, using a

sample and for the sampling and sample preparation of iron

long-handled spoon and cast into a small mold.

andsteel.Specialrequirementsapplytoeachcategoryofliquid

3.2.14 sampling, stream, n—method of probe sampling in

and solid metal, and these requirements are described in the

which the probe is inserted into a stream of liquid metal where

relevant section.

the sample chamber in the probe fills by force of metal flow.

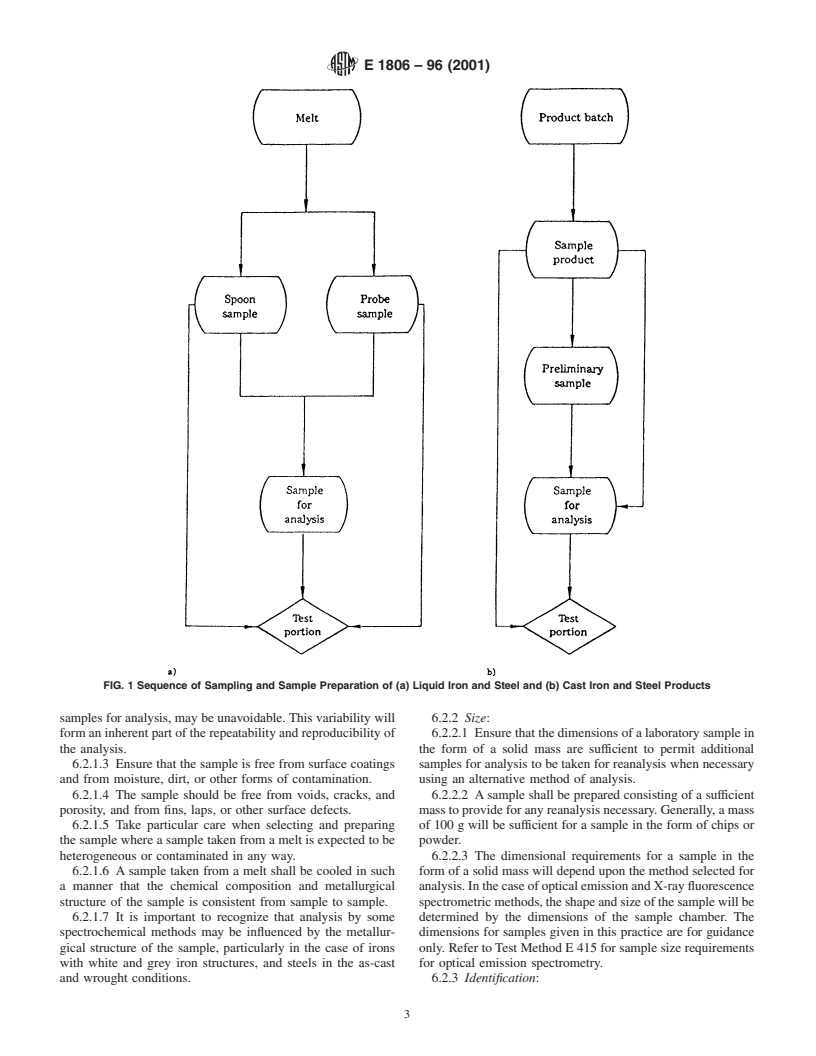

6.1.2 The sequence of sampling and sample preparation of

3.2.15 sampling, suction, n—method of probe sampling in

liquid iron and steel and cast iron and steel products is shown

which the probe is inserted into the melt where the sample

in Fig. 1. Special considerations apply to pig irons (see Section

chamber in the probe fills by aspiration.

10).

3.2.16 test portion, n—part of the sample for analysis, or

6.2 Sample:

part of the sample taken from the melt, actually analyzed. In

6.2.1 Quality:

certain cases, the test portion may be selected from the sample

6.2.1.1 Sampling practices shall be designed to provide an

product itself.

analytical sample that is representative of the mean chemical

3.2.17 thermal method of analysis, n—method for the de-

composition of the melt or of the sample product.

termination of chemical composition in which the sample is

6.2.1.2 Ensure that the sample is sufficiently homogeneous

submitted to a process of heating, combustion, or fusion.

with respect to chemical composition so that inhomogeneity

does not appreciably contribute to the error variability of the

method of analysis. In the case of a sample taken from a melt,

Available from American National Standards Institute, 25 W. 43rd St., 4th

Floor, New York, NY 10036. however, some variability in analysis, both within and between

E 1806 – 96 (2001)

FIG. 1 Sequence of Sampling and Sample Preparation of (a) Liquid Iron and Steel and (b) Cast Iron and Steel Products

samples for analysis, may be unavoidable. This variability will 6.2.2 Size:

form an inherent part of the repeatability and reproducibility of 6.2.2.1 Ensure that the dimensions of a laboratory sample in

the analysis. the form of a solid mass are sufficient to permit additional

6.2.1.3 Ensure that the sample is free from surface coatings samples for analysis to be taken for reanalysis when necessary

and from moisture, dirt, or other forms of contamination. using an alternative method of analysis.

6.2.1.4 The sample should be free from voids, cracks, and 6.2.2.2 Asample shall be prepared consisting of a sufficient

porosity, and from fins, laps, or other surface defects. masstoprovideforanyreanalysisnecessary.Generally,amass

6.2.1.5 Take particular care when selecting and preparing of 100 g will be sufficient for a sample in the form of chips or

the sample where a sample taken from a melt is expected to be powder.

heterogeneous or contaminated in any way. 6.2.2.3 The dimensional requirements for a sample in the

6.2.1.6 A sample taken from a melt shall be cooled in such form of a solid mass will depend upon the method selected for

a manner that the chemical composition and metallurgical analysis.InthecaseofopticalemissionandX-rayfluorescence

structure of the sample is consistent from sample to sample. spectrometricmethods,theshapeandsizeofthesamplewillbe

6.2.1.7 It is important to recognize that analysis by some determined by the dimensions of the sample chamber. The

spectrochemical methods may be influenced by the metallur- dimensions for samples given in this practice are for guidance

gical structure of the sample, particularly in the case of irons only. Refer to Test Method E 415 for sample size requirements

with white and grey iron structures, and steels in the as-cast for optical emission spectrometry.

and wrought conditions. 6.2.3 Identification:

E 1806 – 96 (2001)

6.2.3.1 Assign the sample a unique identification to deter- 6.3.2.3 In the case of a forging, the sample can be selected

mine the melt or sample product from which it was taken, and from the initial starting material from which the forging has

if necessary, the process conditions of the melt or the location been made or from prolongations of the forging or from

of the laboratory sample in the sample product. For pig iron, additional forgings.

thisshallidentifytheconsignmentorpartofaconsignmentand

6.3.2.4 In the absence of requirements given in the product

the increment from which it was taken.

standard or of a specification when ordering the product, the

6.2.3.2 Use labeling or some equivalent method of marking sample may, following agreement between the supplier and the

to ensure that the assigned identification remains associated purchaser, be selected from the sample for mechanical testing

with the sample for analysis. or from the test piece, or directly from the sample product.

6.2.3.3 Recordtheidentification,status,andconditionofthe 6.3.2.5 The laboratory sample can be obtained from the

sample to ensure that confusion cannot arise as to the identity

sample product by machining or by using a cutting torch.

of the item to which the analysis and records refer. Special considerations apply in the case of sampling for the

6.2.4 Conservation: determination of certain elements.

6.2.4.1 Provide adequate storage facilities to segregate and 6.4 Preparation of a Sample:

protect the sample. During and after preparation, store the

6.4.1 Preliminary Preparation:

sample in a manner which prevents contamination or chemical

6.4.1.1 If any part of the sample is liable to be nonrepre-

change.

sentative in chemical composition, remove those parts that

6.2.4.2 Keep the sample, or the laboratory sample in the

have changed. Following this operation, the sample shall be

form of a solid mass, for a sufficient period of time to permit

protected from any change in composition.

retesting if necessary.

6.4.1.2 Remove any coating that has been applied during

6.2.5 Arbitration:

manufacturing. If necessary, degrease the surface of the metal

6.2.5.1 Samples intended for arbitration shall be prepared

withasuitablesolvent,takingcaretoensurethatthemannerof

jointly by the supplier and purchaser or by their representa-

degreasing does not affect the correctness of analysis.

tives.Keeparecordofthemethodsusedforpreparingsamples.

6.4.2 Sample in the Form of Chips:

6.2.5.2 Both parties or their representatives seal containers

6.4.2.1 Obtainthesamplebydrillingormillingorturningto

with the samples intended for arbitration. Unless agreed to the

produce chips of a regular size and shape. Do not machine on

contrary, the representatives of each party responsible for the

a part of the sample that has been affected by the heat of a

preparation of samples will keep these containers.

cutting torch.

6.3 Selection of a Sample:

6.4.2.2 Clean the tools, machines, and containers used

6.3.1 Sample from a Melt:

during preparation of the sample beforehand to prevent any

6.3.1.1 Melts are sampled at

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.