ASTM F2569-11(2019)

(Test Method)Standard Test Method for Evaluating the Force Reduction Properties of Surfaces for Athletic Use

Standard Test Method for Evaluating the Force Reduction Properties of Surfaces for Athletic Use

SIGNIFICANCE AND USE

5.1 The force reduction property is just one of the important properties of a surface used for athletic activity. It may be an indicator of the performance, safety, comfort, or suitability of the surface.

5.2 Manufacturers of athletic surfaces may use this test method to evaluate the effects of design changes on the impact forces generated on the surface.

5.3 Facility owners may use this standard to evaluate the performance of existing sport/athletic surfaces. Results may be useful during the selection process for a replacement surface, or for an additional athletic surface being added to the facility.

5.4 Facility owners may also use this test method to verify that newly installed surfaces perform at or near the levels included in project specifications.

SCOPE

1.1 This test method covers the quantitative measurement and normalization of impact forces generated through a mechanical impact test on an athletic surface. The impact forces simulated in this test method are intended to represent those produced by lower extremities of an athlete during landing events on sport or athletic surfaces.

1.2 This test method may be applied to any surface where athletic activity may be conducted.

1.3 The test methods described are applicable in both laboratory and field settings.

1.4 The values stated in SI units are to be regarded as standard. The values given in parentheses are for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F2569 − 11 (Reapproved 2019) An American National Standard

Standard Test Method for

Evaluating the Force Reduction Properties of Surfaces for

Athletic Use

This standard is issued under the fixed designation F2569; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope ASTM Test Methods

E691 Practice for Conducting an Interlaboratory Study to

1.1 This test method covers the quantitative measurement

Determine the Precision of a Test Method

and normalization of impact forces generated through a me-

2.2 DIN Standard:

chanical impact test on an athletic surface. The impact forces

DIN 18032-2 Halls for Gymnastics, Games and Multipur-

simulated in this test method are intended to represent those

pose Use, Part 2: Sports Floors, Requirements, Testing

produced by lower extremities of an athlete during landing

events on sport or athletic surfaces.

3. Terminology

1.2 This test method may be applied to any surface where

3.1 Definitions of Terms Specific to This Standard:

athletic activity may be conducted.

3.1.1 force reduction, n—ability of a surface to reduce

1.3 The test methods described are applicable in both impact forces as compared to a rigid surface using a specified

laboratory and field settings. impact. Force reduction expresses the difference between the

impact forces generated on the test and rigid surfaces as the

1.4 The values stated in SI units are to be regarded as

percentage of the impact force from the rigid surface.

standard. The values given in parentheses are for information

3.1.2 rigid surface, n—concrete surface covered by a steel

only.

plate used as the basis for measuring force reduction.

1.5 This standard does not purport to address all of the

3.1.3 test surface, n—athletic surface upon which force

safety concerns, if any, associated with its use. It is the

reduction testing is conducted (for example, indoor wood

responsibility of the user of this standard to establish appro-

courts, poured urethane courts, walk/jog tracks, and so forth).

priate safety, health, and environmental practices and deter-

mine the applicability of regulatory limitations prior to use.

4. Summary of Test Method

1.6 This international standard was developed in accor-

dance with internationally recognized principles on standard- 4.1 The dynamic interaction between the athlete and the

surface is significant to the performance, comfort, and possibly

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom- the safety of the athlete. Therefore, the ability of the surface to

reduce impact forces is important. This test method provides a

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee. non-destructive means for evaluating the force reduction prop-

erties of a surface in both laboratory and field settings. Impact

2. Referenced Documents

forces are recorded by releasing a 20 kg mass and allowing it

to impact a spring resting on a test foot resting on the surface.

2.1 ASTM Standards:

The force reduction of the surface is presented as a percentage

E177 Practice for Use of the Terms Precision and Bias in

of the reduction in the impact forces produced on the test

surface, compared to the impact force generated on a rigid

This test method is under the jurisdiction of ASTM Committee F08 on Sports

surface. This test method is more closely associated with the

Equipment, Playing Surfaces, and Facilities and is the direct responsibility of

impacts generated by the lower extremities, and is not an

Subcommittee F08.52 on Miscellaneous Playing Surfaces.

indication of the ability of the test surface to prevent head

Current edition approved Dec. 1, 2019. Published January 2020. Originally

approved in 2007. Last previous edition approved in 2011 as F2569 – 11. DOI: injury trauma.

10.1520/F2569-11R19.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Available from Beuth Verlag GmbH (DIN-- DIN Deutsches Institut fur

Standards volume information, refer to the standard’s Document Summary page on Normunge.V.),Burggrafenstrasse6,10787,Berlin,Germany,http://www.en.din.de.

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F2569 − 11 (2019)

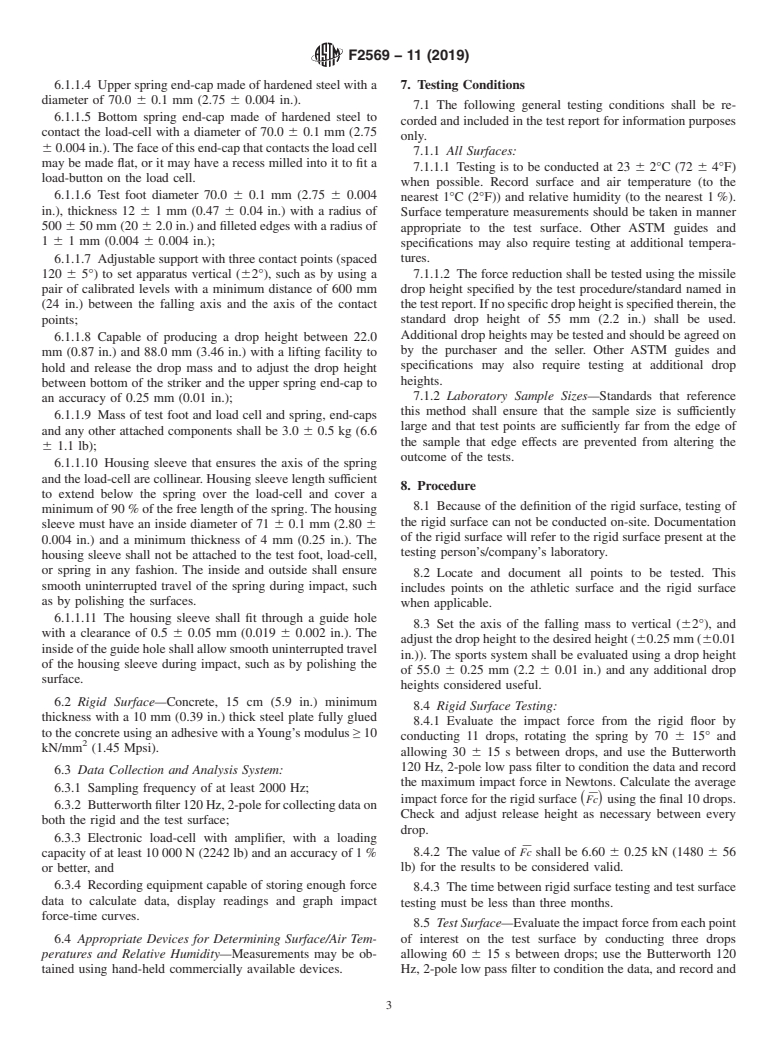

1 = drop mass and striker

2 = guide rod

3 = spring

4 = upper end-cap

5 = bottom end-cap

6 = test foot

7 = adjustable support

8 = height adjustment and

release mechanism

9 = load cell

10 = housing sleeve

11 = guide hole

FIG. 1 Force Reduction Test Apparatus

5. Significance and Use thepeakforceduringtheimpacteventtoberecorded.Thepeak

force is compared with the result obtained on a rigid floor, and

5.1 The force reduction property is just one of the important

thepercentageofforcereductioncalculatedforthetestsurface.

properties of a surface used for athletic activity. It may be an

6.1.1 The apparatus shall conform to the following require-

indicator of the performance, safety, comfort, or suitability of

ments:

the surface.

6.1.1.1 Falling mass with a striker screwed into the bottom

5.2 Manufacturers of athletic surfaces may use this test

sideofthemass.Thestrikerhasadiameterof50 610mm(2.0

method to evaluate the effects of design changes on the impact

6 0.4 in.) and a length of 75 6 25 mm (3 6 1 in.). The total

forces generated on the surface.

mass of the falling weight and the striker is 20 6 0.05 kg (44

6 0.1 lb);

5.3 Facility owners may use this standard to evaluate the

performance of existing sport/athletic surfaces. Results may be 6.1.1.2 Ensure the drop mass travels in a vertical path from

release to impact, such as by using guide rods;

useful during the selection process for a replacement surface,

or for an additional athletic surface being added to the facility. 6.1.1.3 Spring withaspringrate2000 6100kN/m(11 420

6 571 lb/in.), an outside diameter of 70.0 6 0.1 mm (2.75 6

5.4 Facility owners may also use this test method to verify

0.004 in.), a free length of 75 6 10 mm (3.95 6 0.39 in.);

that newly installed surfaces perform at or near the levels

(1) Spring rate shall be determined by linear regression

included in project specifications.

throughforce-deflectiondatarecordedthefollowingloads;200

N, 2000 N, 4000 N, 6000 N, 8000 N, and 10 000 N (45 lb, 448

6. Apparatus

lb, 897 lb, 1346 lb, 1794 lb, and 2243 lb).

6.1 Force Reduction Test Apparatus—This test method

utilizes a force reduction test device similar to the one outlined

The sole source of supply of the apparatus known to the committee at this time

in DIN 18032-2.The force reduction device is shown in Fig. 1.

is Rein Kratmessegerate, D-89150 Laichingen, Gottlieb-Diamler-Str. 62 Germany.

A mass of 20 kg is allowed to fall onto an anvil, which

If you are aware of alternative suppliers, please provide this information to ASTM

transmits the load via a spring to a test foot resting on the

International Headquarters. Your comments will receive careful consideration at a

surface. The foot is fitted with a force transducer that enables meeting of the responsible technical committee, which you may attend.

F2569 − 11 (2019)

6.1.1.4 Upper spring end-cap made of hardened steel with a 7. Testing Conditions

diameter of 70.0 6 0.1 mm (2.75 6 0.004 in.).

7.1 The following general testing conditions shall be re-

6.1.1.5 Bottom spring end-cap made of hardened steel to

corded and included in the test report for information purposes

contact the load-cell with a diameter of 70.0 6 0.1 mm (2.75

only.

60.004in.).Thefaceofthisend-capthatcontactstheloadcell

7.1.1 All Surfaces:

may be made flat, or it may have a recess milled into it to fit a

7.1.1.1 Testing is to be conducted at 23 6 2°C (72 6 4°F)

load-button on the load cell.

when possible. Record surface and air temperature (to the

6.1.1.6 Test foot diameter 70.0 6 0.1 mm (2.75 6 0.004

nearest 1°C (2°F)) and relative humidity (to the nearest 1 %).

in.), thickness 12 6 1 mm (0.47 6 0.04 in.) with a radius of

Surface temperature measurements should be taken in manner

500 6 50 mm (20 6 2.0 in.) and filleted edges with a radius of

appropriate to the test surface. Other ASTM guides and

1 6 1 mm (0.004 6 0.004 in.);

specifications may also require testing at additional tempera-

6.1.1.7 Adjustable support with three contact points (spaced tures.

120 6 5°) to set apparatus vertical (62°), such as by using a 7.1.1.2 The force reduction shall be tested using the missile

drop height specified by the test procedure/standard named in

pair of calibrated levels with a minimum distance of 600 mm

(24 in.) between the falling axis and the axis of the contact thetestreport.Ifnospecificdropheightisspecifiedtherein,the

standard drop height of 55 mm (2.2 in.) shall be used.

points;

Additional drop heights may be tested and should be agreed on

6.1.1.8 Capable of producing a drop height between 22.0

by the purchaser and the seller. Other ASTM guides and

mm (0.87 in.) and 88.0 mm (3.46 in.) with a lifting facility to

specifications may also require testing at additional drop

hold and release the drop mass and to adjust the drop height

heights.

between bottom of the striker and the upper spring end-cap to

7.1.2 Laboratory Sample Sizes—Standards that reference

an accuracy of 0.25 mm (0.01 in.);

this method shall ensure that the sample size is sufficiently

6.1.1.9 Mass of test foot and load cell and spring, end-caps

large and that test points are sufficiently far from the edge of

and any other attached components shall be 3.0 6 0.5 kg (6.6

the sample that edge effects are prevented from altering the

6 1.1 lb);

outcome of the tests.

6.1.1.10 Housing sleeve that ensures the axis of the spring

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.