ASTM A960/A960M-08

(Specification)Standard Specification for Common Requirements for Wrought Steel Piping Fittings

Standard Specification for Common Requirements for Wrought Steel Piping Fittings

ABSTRACT

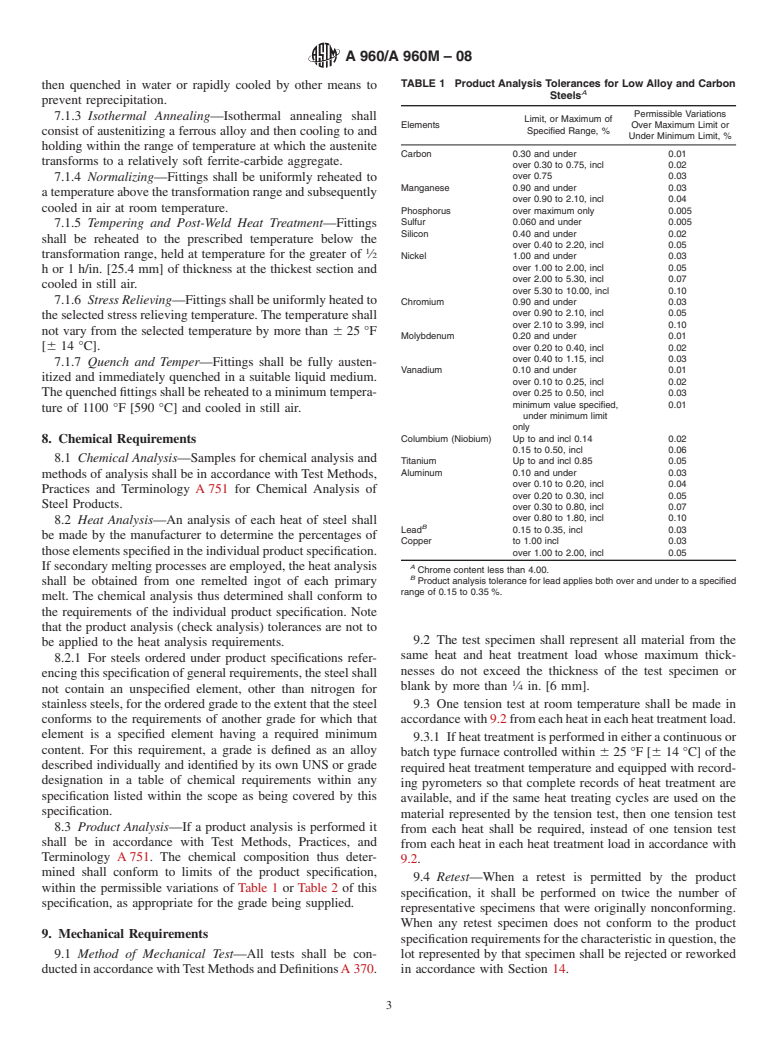

This specification covers the common requirements that shall apply to wrought steel piping fittings. The material shall consist of forgings, bars, plates, and seamless or welded tubular products. Ferritic steels shall be fully killed. Hollow cylindrically shaped parts up to and including NPS 4 may be machined from bar or seamless tubular material. Elbows, return bends, tees, and header tees shall not be machined directly from bar stock. The following procedures shall be done for heat treatment: full annealing, solution annealing, isothermal annealing, normalizing, tempering and post-weld heat treatment, stress relieving, and quench and temper. Chemical analysis, heat analysis, and product analysis shall also be done. The chemical requirements shall conform to the required compositions of carbon, manganese, phosphorus, sulfur, silicon, nickel, chromium, molybdenum, vanadium, columbium, titanium, aluminum, lead, and copper. The following tests shall be done for the mechanical requirements: tension, hardness, impact, and hydrostatic tests.

SCOPE

1.1 This specification covers a group of common requirements that shall apply to wrought steel piping fittings covered in any of the following individual product specifications or any other ASTM specification that invokes this specification or portions thereof: Title of SpecificationASTM

Designation Specification for Piping Fittings of Wrought

Carbon Steel and Alloy Steel for Moderate and

Elevated TemperaturesA 234/A 234M Specification for Wrought Austenitic Stainless

Steel Piping FittingsA 403/A 403M Specification for Piping Fittings of Wrought Carbon

Steel and Alloy Steel for Low-Temperature ServiceA 420/A 420M Specification for Butt-Welding, Wrought-Carbon

Steel, Piping Fittings with Improved Notch ToughnessA 758/A 758M Specification for As-Welded Wrought Austenitic

Stainless Steel Fittings for General Corrosive

Service at Low and Moderate TemperaturesA 774/A 774M Specification for Wrought Ferritic, Ferritic/Austenitic,

and Martensitic Stainless Steel Piping FittingsA 815/A 815M Specification for Heat-Treated Carbon Steel

Fittings for Low-Temperature and Corrosive ServiceA 858/A 858M Specification for Wrought High-Strength

Low-Alloy Steel Butt-Welded FittingsA 860/A 860M

1.2 In case of conflict between a requirement of the individual product specification and a requirement of this general requirement specification, the requirements of the individual product specification shall prevail over those of this specification.

1.3 By mutual agreement between the purchaser and the supplier, additional requirements may be specified (See 4.1.7). The acceptance of any such additional requirements shall be dependent on negotiations with the supplier and must be included in the order as agreed upon by the purchaser and supplier.

1.4 The values stated in either inch-pound units or SI units [metric] are to be regarded separately as standard. Within the text and the tables, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore each system must be used independently of the other. Combining values from the two systems may result in nonconformance with the specification. The inch-pound units shall apply unless the “M” designation [SI] of the product specification is specified in the order.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A 960/A 960M – 08

Standard Specification for

1

Common Requirements for Wrought Steel Piping Fittings

This standard is issued under the fixed designationA 960/A 960M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* Combining values from the two systems may result in noncon-

formance with the specification. The inch-pound units shall

1.1 This specification covers a group of common require-

apply unless the “M” designation [SI] of the product specifi-

ments that shall apply to wrought steel piping fittings covered

cation is specified in the order.

in any of the following individual product specifications or any

other ASTM specification that invokes this specification or

2. Referenced Documents

portions thereof:

2

2.1 ASTM Standards:

Title of Specification ASTM

A 29/A 29M SpecificationforSteelBars,CarbonandAlloy,

Designation

Specification for Piping Fittings of Wrought A 234/A 234M

Hot-Wrought, General Requirements for

Carbon Steel and Alloy Steel for Moderate and

A 234/A 234M Specification for Piping Fittings ofWrought

Elevated Temperatures

Carbon Steel and Alloy Steel for Moderate and High

Specification for Wrought Austenitic Stainless A 403/A 403M

Steel Piping Fittings

Temperature Service

Specification for Piping Fittings of Wrought Carbon A 420/A 420M

A 262 Practices for Detecting Susceptibility to Intergranu-

Steel and Alloy Steel for Low-Temperature Service

lar Attack in Austenitic Stainless Steels

Specification for Butt-Welding, Wrought-Carbon A 758/A 758M

Steel, Piping Fittings with Improved Notch Toughness

A 370 Test Methods and Definitions for MechanicalTesting

Specification for As-Welded Wrought Austenitic A 774/A 774M

of Steel Products

Stainless Steel Fittings for General Corrosive

A 388/A 388M Practice for Ultrasonic Examination of

Service at Low and Moderate Temperatures

Specification for Wrought Ferritic, Ferritic/Austenitic, A 815/A 815M

Heavy Steel Forgings

and Martensitic Stainless Steel Piping Fittings

A 403/A 403M Specification for Wrought Austenitic Stain-

Specification for Heat-Treated Carbon Steel A 858/A 858M

Fittings for Low-Temperature and Corrosive Service less Steel Piping Fittings

Specification for Wrought High-Strength A 860/A 860M

A 420/A 420M Specification for Piping Fittings ofWrought

Low-Alloy Steel Butt-Welded Fittings

Carbon Steel and Alloy Steel for Low-Temperature Ser-

1.2 In case of conflict between a requirement of the indi-

vice

vidual product specification and a requirement of this general

A 700 Practices for Packaging, Marking, and Loading

requirement specification, the requirements of the individual

Methods for Steel Products for Shipment

product specification shall prevail over those of this specifica-

A 751 Test Methods, Practices, and Terminology for

tion.

Chemical Analysis of Steel Products

1.3 By mutual agreement between the purchaser and the

A 758/A 758M Specification for Wrought-Carbon Steel

supplier, additional requirements may be specified (See 4.1.7).

Butt-WeldingPipingFittingswithImprovedNotchTough-

The acceptance of any such additional requirements shall be

ness

dependent on negotiations with the supplier and must be

A 763 Practices for Detecting Susceptibility to Intergranu-

included in the order as agreed upon by the purchaser and

lar Attack in Ferritic Stainless Steels

supplier.

A 774/A 774M Specification for As-Welded Wrought Aus-

1.4 The values stated in either inch-pound units or SI units

tenitic Stainless Steel Fittings for General Corrosive Ser-

[metric] are to be regarded separately as standard. Within the

vice at Low and Moderate Temperatures

text and the tables, the SI units are shown in brackets. The

A 815/A 815M Specification for Wrought Ferritic, Ferritic/

values stated in each system are not exact equivalents; there-

Austenitic, and Martensitic Stainless Steel Piping Fittings

fore each system must be used independently of the other.

A 858/A 858M Specification for Heat-Treated Carbon Steel

Fittings for Low-Temperature and Corrosive Service

1

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

2

A01.22 on Steel Forgings andWrought Fittings for PipingApplications and Bolting For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Materials for Piping and Special Purpose Applications. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Current edition approved May 1, 2008. Published June 2008. Originally Standards volume information, refer to the standard’s Document Summary page on

approved in 1996. La

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:A 960/A 960M–07 Designation: A 960/A 960M – 08

Standard Specification for

1

Common Requirements for Wrought Steel Piping Fittings

This standard is issued under the fixed designationA 960/A 960M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This specification covers a group of common requirements that shall apply to wrought steel piping fittings covered in any

of the following individual product specifications or any other ASTM specification that invokes this specification or portions

thereof:

Title of Specification ASTM

Designation

Specification for Piping Fittings of Wrought A 234/A 234M A234/A234M

Carbon Steel and Alloy Steel for Moderate and

Elevated Temperatures

Specification for Wrought Austenitic Stainless A 403/A 403M A403/A403M

Steel Piping Fittings

Specification for Piping Fittings of Wrought Carbon A 420/A 420M A420/A420M

Steel and Alloy Steel for Low-Temperature Service

Specification for Butt-Welding, Wrought-Carbon A 758/A 758M A758/A758M

Steel, Piping Fittings with Improved Notch Toughness

Specification for As-Welded Wrought Austenitic A 774/A 774M A774/A774M

Stainless Steel Fittings for General Corrosive

Service at Low and Moderate Temperatures

Specification for Wrought Ferritic, Ferritic/Austenitic, A 815/A 815M A815/A815M

and Martensitic Stainless Steel Piping Fittings

Specification for Heat-Treated Carbon Steel A 858/A 858M A858/A858M

Fittings for Low-Temperature and Corrosive Service

Specification for Wrought High-Strength A 860/A 860M A860/A860M

Low-Alloy Steel Butt-Welded Fittings

1.2 In case of conflict between a requirement of the individual product specification and a requirement of this general

requirement specification, the requirements of the individual product specification shall prevail over those of this specification.

1.3 By mutual agreement between the purchaser and the supplier, additional requirements may be specified (See 4.1.7). The

acceptance of any such additional requirements shall be dependent on negotiations with the supplier and must be included in the

order as agreed upon by the purchaser and supplier.

1.4 The values stated in either inch-pound units or SI units [metric] are to be regarded separately as standard. Within the text

andthetables,theSIunitsareshowninbrackets.Thevaluesstatedineachsystemarenotexactequivalents;thereforeeachsystem

must be used independently of the other. Combining values from the two systems may result in nonconformance with the

specification.Theinch-poundunitsshallapplyunlessthe“M”designation[SI]oftheproductspecificationisspecifiedintheorder.

2. Referenced Documents

2

2.1 ASTM Standards:

A29/A29M Specification for Steel Bars, Carbon and Alloy, Hot-Wrought, General Requirements for

A234/A234M Specification for Piping Fittings of Wrought Carbon Steel and Alloy Steel for Moderate and High Temperature

Service

A262 Practices for Detecting Susceptibility to Intergranular Attack in Austenitic Stainless Steels

A370 Test Methods and Definitions for Mechanical Testing of Steel Products

A388/A388M Practice for Ultrasonic Examination of Steel Forgings

A403/A403M Specification for Wrought Austenitic Stainless Steel Piping Fittings

A420/A420M Specification for Piping Fittings of Wrought Carbon Steel and Alloy Steel for Low-Temperature Service

1

This specification is under the jurisdiction ofASTM CommitteeA01 on Steel, Stainless Steel and RelatedAlloys and is the direct responsibility of SubcommitteeA01.22

on Steel Forgings and Wrought Fittings for Piping Applications and Bolting Materials for Piping and Special Purpose Applications.

Current edition approved Feb.May 1, 2007.2008. Published February 2007.June 2008. Originally approved in 1996. Last previous edition approved in 20062007 as

A 960/A 960M–067.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

A 960/A 960M – 08

A700 Practices for Packaging, Marking, and Loading Methods for Steel Product

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:A960/A960M–07 Designation: A 960/A 960M – 08

Standard Specification for

1

Common Requirements for Wrought Steel Piping Fittings

This standard is issued under the fixed designationA 960/A 960M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This specification covers a group of common requirements that shall apply to wrought steel piping fittings covered in any

of the following individual product specifications or any other ASTM specification that invokes this specification or portions

thereof:

Title of Specification ASTM

Designation

Specification for Piping Fittings of Wrought A 234/A 234M

Carbon Steel and Alloy Steel for Moderate and

Elevated Temperatures

Specification for Wrought Austenitic Stainless A 403/A 403M

Steel Piping Fittings

Specification for Piping Fittings of Wrought Carbon A 420/A 420M

Steel and Alloy Steel for Low-Temperature Service

Specification for Butt-Welding, Wrought-Carbon A 758/A 758M

Steel, Piping Fittings with Improved Notch Toughness

Specification for As-Welded Wrought Austenitic A 774/A 774M

Stainless Steel Fittings for General Corrosive

Service at Low and Moderate Temperatures

Specification for Wrought Ferritic, Ferritic/Austenitic, A 815/A 815M

and Martensitic Stainless Steel Piping Fittings

Specification for Heat-Treated Carbon Steel A 858/A 858M

Fittings for Low-Temperature and Corrosive Service

Specification for Wrought High-Strength A 860/A 860M

Low-Alloy Steel Butt-Welded Fittings

1.2 In case of conflict between a requirement of the individual product specification and a requirement of this general

requirement specification, the requirements of the individual product specification shall prevail over those of this specification.

1.3 By mutual agreement between the purchaser and the supplier, additional requirements may be specified (See 4.1.7). The

acceptance of any such additional requirements shall be dependent on negotiations with the supplier and must be included in the

order as agreed upon by the purchaser and supplier.

1.4 The values stated in either inch-pound units or SI units [metric] are to be regarded separately as standard. Within the text

andthetables,theSIunitsareshowninbrackets.Thevaluesstatedineachsystemarenotexactequivalents;thereforeeachsystem

must be used independently of the other. Combining values from the two systems may result in nonconformance with the

specification.Theinch-poundunitsshallapplyunlessthe“M”designation[SI]oftheproductspecificationisspecifiedintheorder.

2. Referenced Documents

2

2.1 ASTM Standards:

A 29/A 29M Specification for Steel Bars, Carbon and Alloy, Hot-Wrought, General Requirements for

A 234/A 234M Specification for Piping Fittings of Wrought Carbon Steel andAlloy Steel for Moderate and High Temperature

Service

A 262 Practices for Detecting Susceptibility to Intergranular Attack in Austenitic Stainless Steels

A 370 Test Methods and Definitions for Mechanical Testing of Steel Products

A 388/A 388M Practice for Ultrasonic Examination of Heavy Steel Forgings

A 403/A 403M Specification for Wrought Austenitic Stainless Steel Piping Fittings

A 420/A 420M Specification for Piping Fittings of Wrought Carbon Steel and Alloy Steel for Low-Temperature Service

1

This specification is under the jurisdiction ofASTM CommitteeA01 on Steel, Stainless Steel and RelatedAlloys and is the direct responsibility of SubcommitteeA01.22

on Steel Forgings and Wrought Fittings for Piping Applications and Bolting Materials for Piping and Special Purpose Applications.

Current edition approved Feb.May 1, 2007.2008. Published February 2007.June 2008. Originally approved in 1996. Last previous edition approved in 20062007 as

A 960/A 960M–067.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

A 960/A 960M – 08

A 700 Practices for Packaging, Marking, and Loading Methods for Steel Products for Shipment

A 751 Test Methods, Practices, and Terminology for Chemic

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.