ASTM E2297-04

(Guide)Standard Guide for Use of UV-A and Visible Light Sources and Meters used in the Liquid Penetrant and Magnetic Particle Methods

Standard Guide for Use of UV-A and Visible Light Sources and Meters used in the Liquid Penetrant and Magnetic Particle Methods

SIGNIFICANCE AND USE

UV-A and Visible light sources are used to provide adequate light levels for liquid penetrant and magnetic particle examination. Light meters are used to verify that specified light levels are available.

Fluorescence is produced by irradiating the fluorescent dyes/pigments with UV-A radiation. The fluorescent dyes/pigments absorb the energy from the UV-A radiation and re-emit light energy in the visible spectrum. This energy transfer allows fluorescence to be observed by the human eye.

High Intensity UV-A light sources produce light intensity greater than 10,000 µW/cm2 at 38.1 cm [15 in.].

SCOPE

1.1 This guide describes the use of UV-A/Visible light sources and meters used for the examination of materials by the liquid penetrant and magnetic particle processes. This guide may be used to help support the needs for appropriate light intensities and light measurement.

1.2 This guide also provides a reference:

1.2.1 To assist in the selection of light sources and meters that meet the applicable specifications or standards.

1.2.2 For use in the preparation of internal documentation dealing with liquid penetrant or magnetic particle examination of materials and parts.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E2297–04

Standard Guide for

Use of UV-A and Visible Light Sources and Meters used in

the Liquid Penetrant and Magnetic Particle Methods

This standard is issued under the fixed designation E2297; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E1417 Practice for Liquid Penetrant Testing

E1418 Practice for Visible Penetrant Testing Using the

1.1 This guide describes the use of UV-A/Visible light

Water-Washable Process

sourcesandmetersusedfortheexaminationofmaterialsbythe

E1444 Practice for Magnetic Particle Testing

liquid penetrant and magnetic particle processes. This guide

may be used to help support the needs for appropriate light

3. Terminology

intensities and light measurement.

3.1 The definitions that appear in E1316, relating to UV-A

1.2 This guide also provides a reference:

radiation and visible light used in liquid penetrant and mag-

1.2.1 To assist in the selection of light sources and meters

neticparticleexaminations,shallapplytothetermsusedinthis

that meet the applicable specifications or standards.

guide.

1.2.2 For use in the preparation of internal documentation

dealing with liquid penetrant or magnetic particle examination

4. Summary of Guide

of materials and parts.

4.1 Thisguideshowshowthepropermeteriscorrectlyused

1.3 This standard does not purport to address all of the

to determine if adequate light levels (UV-Aand/or visible) are

safety concerns, if any, associated with its use. It is the

available for use while conducting a liquid penetrant or

responsibility of the user of this standard to establish appro-

magnetic particle examination.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

5. Significance and Use

5.1 UV-A and Visible light sources are used to provide

2. Referenced Documents

2 adequate light levels for liquid penetrant and magnetic particle

2.1 ASTM Standards:

examination.Lightmetersareusedtoverifythatspecifiedlight

E165 PracticeforLiquidPenetrantExaminationforGeneral

levels are available.

Industry

5.2 Fluorescence is produced by irradiating the fluorescent

E709 Guide for Magnetic Particle Testing

dyes/pigments with UV-A radiation. The fluorescent dyes/

E1208 Practice for Fluorescent Liquid Penetrant Testing

pigments absorb the energy from the UV-A radiation and

Using the Lipophilic Post-Emulsification Process

re-emit light energy in the visible spectrum. This energy

E1209 Practice for Fluorescent Liquid Penetrant Testing

transfer allows fluorescence to be observed by the human eye.

Using the Water-Washable Process

5.3 High Intensity UV-A light sources produce light inten-

E1210 Practice for Fluorescent Liquid Penetrant Testing

sity greater than 10,000 µW/cm at 38.1 cm (15 in.).

Using the Hydrophilic Post-Emulsification Process

E1219 Practice for Fluorescent Liquid Penetrant Testing

6. Equipment

Using the Solvent-Removable Process

6.1 Ultraviolet (UV)/Visible Light Spectrum

E1220 PracticeforVisiblePenetrantTestingUsingSolvent-

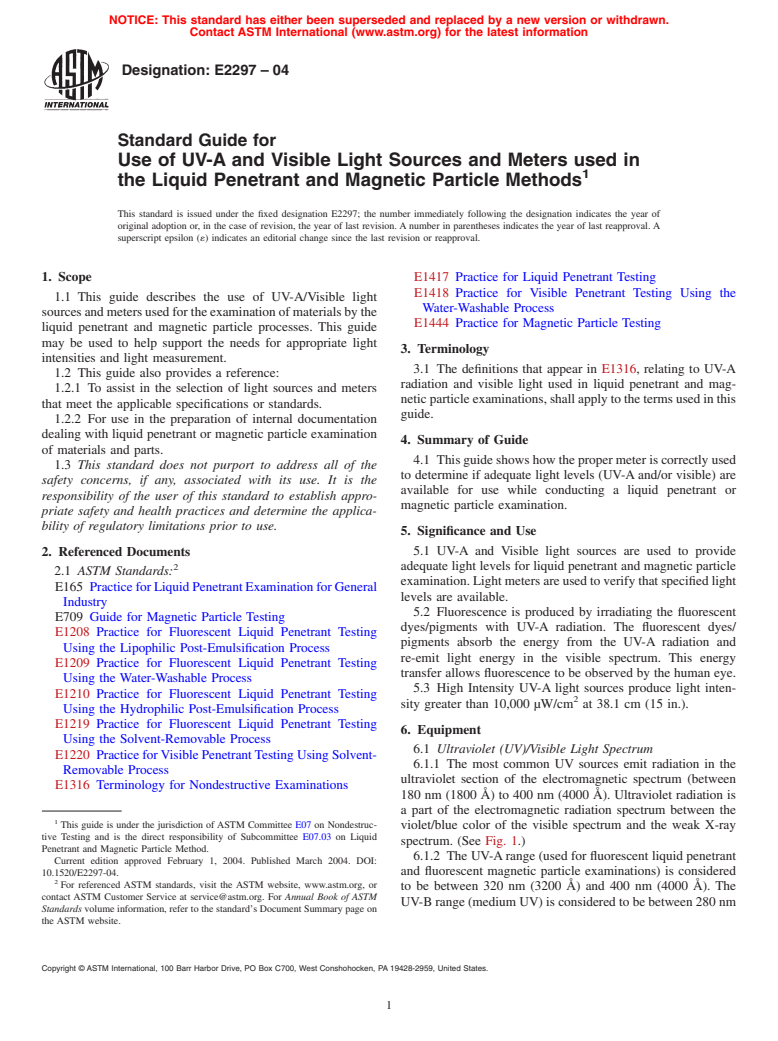

6.1.1 The most common UV sources emit radiation in the

Removable Process

ultraviolet section of the electromagnetic spectrum (between

E1316 Terminology for Nondestructive Examinations

180 nm (1800 Å) to 400 nm (4000 Å). Ultraviolet radiation is

a part of the electromagnetic radiation spectrum between the

This guide is under the jurisdiction of ASTM Committee E07 on Nondestruc-

violet/blue color of the visible spectrum and the weak X-ray

tive Testing and is the direct responsibility of Subcommittee E07.03 on Liquid

spectrum. (See Fig. 1.)

Penetrant and Magnetic Particle Method.

6.1.2 The UV-Arange (used for fluorescent liquid penetrant

Current edition approved February 1, 2004. Published March 2004. DOI:

10.1520/E2297-04. and fluorescent magnetic particle examinations) is considered

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

to be between 320 nm (3200 Å) and 400 nm (4000 Å). The

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

UV-Brange(mediumUV)isconsideredtobebetween280nm

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E2297–04

FIG. 1 The Electromagnetic Radiation Spectrum

(2800 Å) and 320 nm (3200 Å).The UV-C range (short UV) is Other newer lamps using the same bulb but with the Kopp

considered to be between 180 nm (1800 Å) and 280 nm (2800 1071 UV filter or bulbs based on the Philips HPW 125-watt

Å). The visible spectrum is considered to be between 400 nm bulb will not differ greatly in UV-Aoutput, but in general will

(4000 Å) and 760 nm (7600 Å). produce more visible light in the blue/violet part of the

6.2 Mercury Vapor UV-A Sources spectrum. Warning—Certain high-intensity UV-A light

6.2.1 Most UV-Asources used in fluorescent NDT utilize a sources may emit unacceptable amounts of visible light, which

lamp containing a mercury-gas plasma that emits radiation will cause fluorescent indications to disappear. Care should be

specific to the mercury atomic transition spectrum. There are taken to use only bulbs certified by the supplier to be suitable

several discrete lines of the mercury spectrum in the ultraviolet for such examination purposes.

section of the electromagnetic spectrum (between 180 nm

NOTE 1—The Philips HPW 125-watt bulb has been restricted from use

(1800 Å) and 400 nm (4000 Å)). The irradiance output is

in the inspection station by many aerospace companies.

dependent on the gas pressure and the amount of mercury

6.3 UV-A Borescope, Fiberscope, Videoimagescope and

content. Higher values of gas pressure and mercury content

Special UV-A Light Source Systems

result in significant increase in its UV emission.

6.3.1 Borescopes, fiberscopes and videoimagescopes are

6.2.2 UV-A sources used for NDT, employ appropriate

thin rigid or flexible tubular optical telescopes. They are non

filters,eitherinternalorexternaltothelightsourcetominimize

destructiveinspectionqualitycontrolinstrumentsforthevisual

the visible light output (400 nm (4000 Å) to 760 nm (7600 Å))

detection of surface discontinuities in small bores, castings,

that is detrimental to the fluorescent inspection process. These

pipe interiors, and on internal components of complex machin-

filtersshouldalsoblockharmfulradiationbelow320nm(3200

ery.

Å).

6.3.2 The conventional optical glass fiber used as a light

6.2.3 UV-A sources are generally low or medium pressure

vapor sources. Low pressure lamps are coated with a special guideinborescopes,fiberscopesandvideoimagescopesmaybe

phosphor in order to maximize the UV-A output. Medium a poor transmitter of UV-A radiation. These fibers transmit

pressure lamps do not have phosphor coatings but operate at white light in the 450 nm (4500 Å) to 760 nm (7600 Å) range,

higher electrical power levels, resulting in significantly higher but do not effectively transmit light in the 350 nm (3500 Å) to

UV-A output. 380 nm (3800 Å) range.

6.2.4 Typically,lowpressurelamps(tubes)areusedinwash

6.3.3 Three non traditional light guide materials for im-

stations or for general UV-A lighting in the inspection room.

proved UV-A transmission in borescopes, fiberscopes or

Medium pressure lamps are used in fluorescent inspection

videoimagescopes, are liquid light guides, silica or quartz

stations.Awell designed medium pressure UV-Alamp should fibers, or special new glass fibers.

emit less that 0.25 % to 1 % of its total intensity under 320 nm

6.3.3.1 Silica or quartz fibers are good transmitters of UV-A

(3200 Å) and above 400 nm (4000 Å).AUV-Abulb based on

energy, but are brittle and cannot be bent into a tight radius

theAmerican National Standards Institute’s Specification H 44

without breaking, nor can they accommodate the punishing

GS-R100 is a 100 watt mercury-vapor bulb in the Par 38

stresses of repeated scope articulation.

configuration and normally using a Kopp 1041 UV filter.

3 4

Kopp 1041 UV and Kopp 1071 UV are registered trademarks of Kopp Glass Philips HPW 125 watt is a registered trademark of Philips Lighting Co.,

Inc., Pittsburgh, PA. Somerset, NJ.

E2297–04

NOTE 4—ASTM E1220, E1417, E1418, and E1444 provide visible

6.3.3.2 Liquid light guides are very effective transmitters of

light requirements for magnetic particle and penetrant examination.

UV-A, but have minimum diameter limitations at 2.5 mm and

also exhibit problems with collapsing, kinking or loss of fluids.

6.7 Light Meters

6.3.3.3 AspecialglassfiberconfigurationoffersthebestUV

6.7.1 UV-A Light Intensity Meter:

performance plus durability. Special glass fiber light bundles

Radiant energy is a physical quantity that can be measured

combine high UV output with the necessary flexibility and

directly in the laboratory by several types of optical radiation

durability required in these scopes.

detectors; such as thermopiles, bolometers, pyroelectric instru-

6.4 UV-A Pencil Lamps

ments, and radiometric meters. All UV measuring devices are

6.4.1 The pencil lamp is one of the smallest sources of

selective, and their sensitivity depends upon the wavelength of

UV-A radiation. It is generally a lamp coated with conversion

the radiation being measured.

phosphors that absorb the 254 nm (2540 Å) line of energy and

6.7.1.1 The thermopile uses two dissimilar metals and

convert this energy into a band peaking at 365 nm (3650 Å).

depends on electromotive force (EMF) to measure UV radia-

The lamp may be encased in a tubular glass filter that absorbs

tion.

visible light while transmitting maximum ultraviolet intensity.

6.7.1.2 The bolometer is a wheatstone bridge, one arm of

The pencil lamp is useful for fluorescent analysis and boro-

which is heated by the optical radiation to produce a response

scopic inspection in inaccessible locations.

to UV radiation.

NOTE 2—Pencil Lamps produce low levels of UV-A radiation.

6.7.1.3 Even though the above two instruments are very

sensitive, they are extremely delicate and their use is restricted

6.4.2 As with all metal vapor discharge lamps, the output of

to the laboratory.

a

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.