ASTM A234/A234M-07

(Specification)Standard Specification for Piping Fittings of Wrought Carbon Steel and Alloy Steel for Moderate and High Temperature Service

Standard Specification for Piping Fittings of Wrought Carbon Steel and Alloy Steel for Moderate and High Temperature Service

ABSTRACT

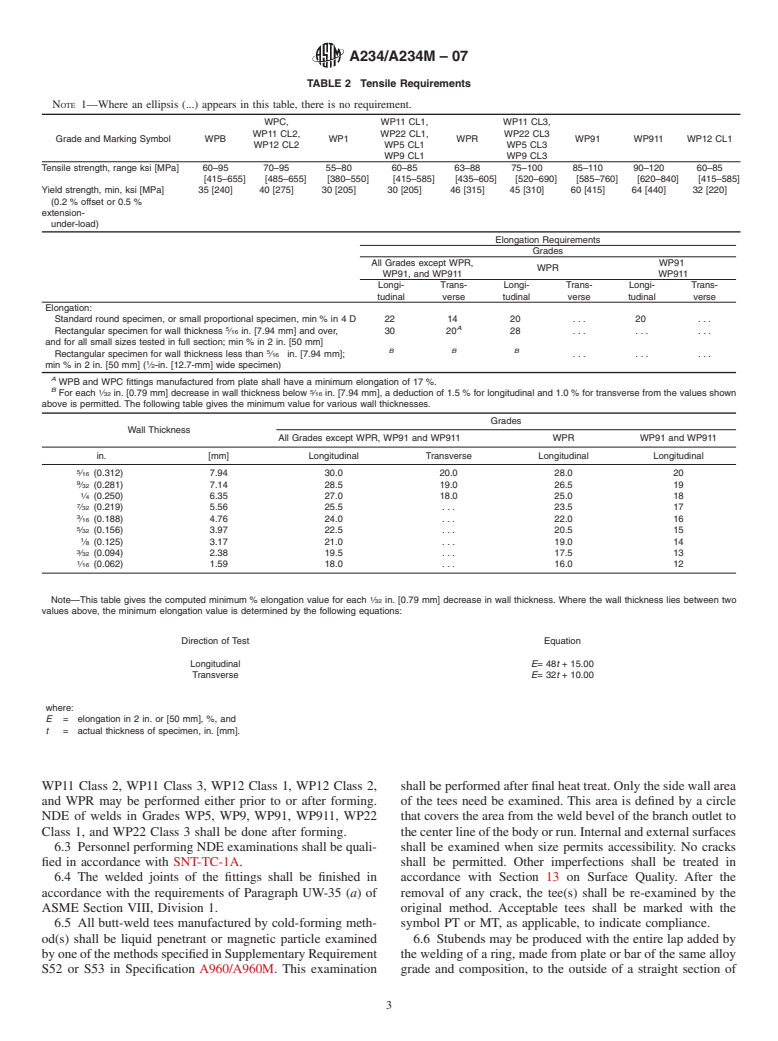

This specification covers wrought carbon steel and alloy steel fittings of seamless and welded construction. These fittings are for use in pressure piping and in pressure vessel fabrication for service at moderate and elevated temperatures. The material for fittings shall consist of killed steel, forgings, bars, plates, seamless or fusion-welded tubular products with filler metal added. Forging or shaping operations may be performed by hammering, pressing, piercing, extruding, upsetting, rolling, bending, fusion welding, machining, or by a combination of two or more of these operations. The forming procedure shall be so applied that it will not produce injurious imperfections in the fittings. Fittings, after forming at an elevated temperature, shall be cooled to a temperature below the critical range under suitable conditions to prevent injurious defects caused by too rapid cooling, but in no case more rapidly than the cooling rate in still air. The fittings shall be subjected to tension test, hardness test, and hydrostatic test.

SCOPE

1.1 This specification covers wrought carbon steel and alloy steel fittings of seamless and welded construction covered by the latest revision of ASME B16.9, B16.11, MSS-SP-79, MSS-SP-83, and MSS-SP-95. These fittings are for use in pressure piping and in pressure vessel fabrication for service at moderate and elevated temperatures. Fittings differing from these ASME and MSS standards shall be furnished in accordance with Supplementary Requirement S58 of Specification A 960/A 960M.

1.2 Optional supplementary requirements are provided for fittings where a greater degree of examination is desired. When desired, one or more of these supplementary requirements may be specified in the order.

1.3 This specification does not cover cast welding fittings or fittings machined from castings. Cast steel welding fittings are governed by Specifications A 216/A 216M and A 217/A 217M.

1.4 This specification is expressed in both inch-pound units and in SI units. However, unless the order specifies the applicable "M" specification designation (SI units), the material shall be furnished to inch-pound units.

1.5 The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other. Combining values from the two systems may result in nonconformance with the specification.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

Used in USDOE-NE Standards

Designation: A234/A234M – 07

Standard Specification for

Piping Fittings of Wrought Carbon Steel and Alloy Steel for

1

Moderate and High Temperature Service

This standard is issued under the fixed designationA234/A234M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

3

1. Scope* 2.2 ASTM Standards:

2 A216/A216M Specification for Steel Castings, Carbon,

1.1 This specification covers wrought carbon steel and

Suitable for Fusion Welding, for High-Temperature Ser-

alloysteelfittingsofseamlessandweldedconstructioncovered

vice

by the latest revision of ASME B16.9, B16.11, MSS-SP-79,

A217/A217M Specification for Steel Castings, Martensitic

MSS-SP-83, and MSS-SP-95. These fittings are for use in

Stainless and Alloy, for Pressure-Containing Parts, Suit-

pressure piping and in pressure vessel fabrication for service at

able for High-Temperature Service

moderate and elevated temperatures. Fittings differing from

A960/A960M Specification for Common Requirements for

these ASME and MSS standards shall be furnished in accor-

Wrought Steel Piping Fittings

dance with Supplementary Requirement S58 of Specification

4

2.3 ASME Standards:

A960/A960M.

B16.9 Steel Butt-Welding Fittings

1.2 Optional supplementary requirements are provided for

B16.11 Forged Steel Fittings, SocketWelding andThreaded

fittingswhereagreaterdegreeofexaminationisdesired.When

4

2.4 ASME Boiler and Pressure Vessel Code:

desired, one or more of these supplementary requirements may

Section V Nondestructive Examination

be specified in the order.

Section VIII, Division 1, Pressure Vessels

1.3 This specification does not cover cast welding fittings or

Section IX Welding Qualifications

fittings machined from castings. Cast steel welding fittings are

5

2.5 MSS Standards:

governed by Specifications A216/A216M and A217/A217M.

MSS-SP-25 Standard Marking System for Valves, Fittings,

1.4 This specification is expressed in both inch-pound units

Flanges, and Unions

and in SI units. However, unless the order specifies the

MSS-SP-79 Socket Welding Reducer Inserts

applicable “M” specification designation (SI units), the mate-

MSS-SP-83 Steel Pipe Unions, Socket-Welding and

rial shall be furnished to inch-pound units.

Threaded

1.5 The values stated in either inch-pound units or SI units

MSS-SP-95 Swage(d) Nipples and Bull Plugs

are to be regarded separately as standard. Within the text, the

2.6 ASNT Standard:

SI units are shown in brackets. The values stated in each

SNT-TC-1A Recommended Practice for Nondestructive

system are not exact equivalents; therefore, each system must

6

Testing Personnel Qualification and Certification

be used independently of the other. Combining values from the

two systems may result in nonconformance with the specifi-

3. Ordering Information

cation.

3.1 See Specification A960/A960M.

2. Referenced Documents

4. General Requirements

2.1 In addition to those reference documents listed in

4.1 Product furnished to this specification shall conform to

Specification A960/A960M, the following list of standards

the requirements of SpecificationA960/A960M, including any

apply to this specification.

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

1

This specification is under the jurisdiction ofASTM CommitteeA01 on Steel, contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee Standards volume information, refer to the standard’s Document Summary page on

A01.22 on Steel Forgings andWrought Fittings for PipingApplications and Bolting the ASTM website.

4

Materials for Piping and Special Purpose Applications. Available from American Society of Mechanical Engineers (ASME), ASME

Current edition approved March 1, 2007. Published April 2007. Originally International Headquarters, Three Park Ave., New York, NY 10016-5990.

5

approved in 1940. Last previous edition approved in 2006 as A234/A234M – 06a. AvailablefromManufacturersStandardizationSocietyoftheValveandFittings

DOI: 10.1520/A0234_A0234M-07. Industry (MSS), 127 Park St., NE, Vienna, VA 22180-4602.

2 6

For ASME Boiler and Pressure Vessel Code applications see related Specifi- AvailablefromAmericanSocietyforNondestructiveTesting(ASNT),P.O.Box

cation SA-234 in Section II of that Code. 28518, 1711 Arlingate Ln., Columbus, OH 43228-0518.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-295

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.