ASTM E746-07(2014)

(Practice)Standard Practice for Determining Relative Image Quality Response of Industrial Radiographic Imaging Systems

Standard Practice for Determining Relative Image Quality Response of Industrial Radiographic Imaging Systems

SIGNIFICANCE AND USE

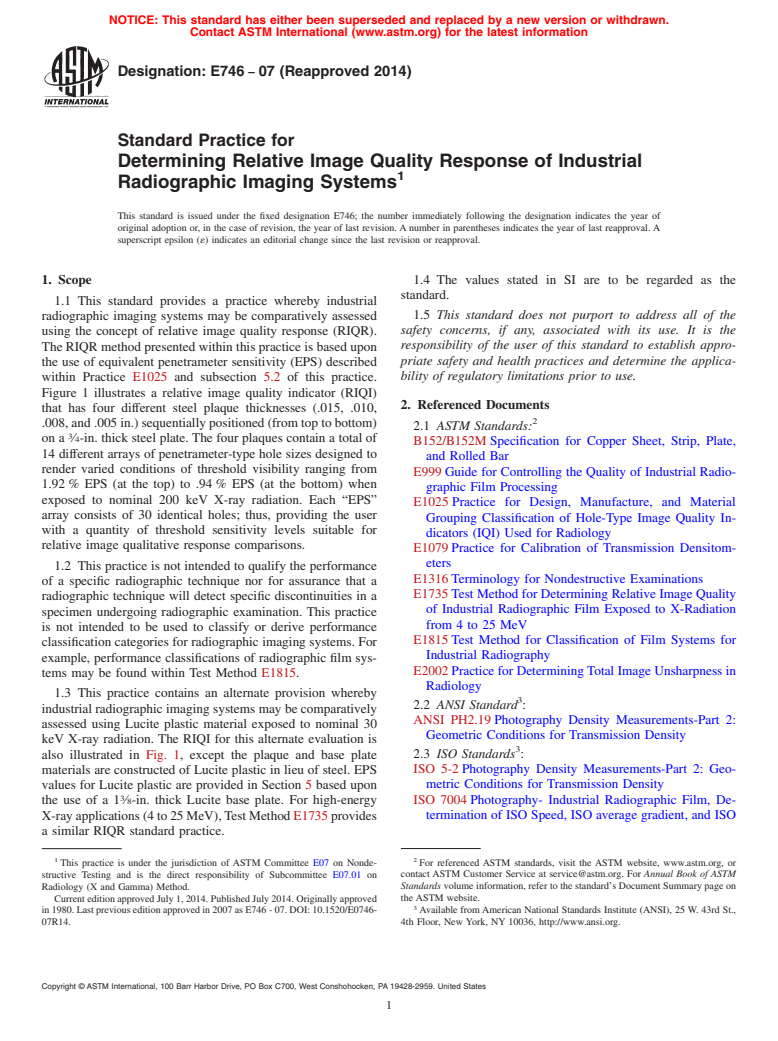

4.1 This standard provides a practice for RIQR evaluations of film and non-film imaging systems when exposed through steel or plastic materials. Three alternate data evaluation methods are provided in Section 9. Determining RIQR requires the comparison of at least two radiographs or radiographic processes whereby the relative degree of image quality difference may be determined using the EPS plaque arrangement of Fig. 1 as a relative image quality indicator (RIQI). In conjunction with the RIQI, a specified radiographic technique or method must be established and carefully controlled for each radiographic process. This practice is designed to allow the determination of subtle changes in EPS that may arise to radiographic imaging system performance levels resultant from process improvements/changes or change of equipment attributes. This practice does not address relative unsharpness of a radiographic imaging system as provided in Practice E2002. The common element with any relative comparison is the use of the same RIQI arrangement for both processes under evaluation.

4.2 In addition to the standard evaluation method described in Section 9, there may be other techniques/methods in which the basic RIQR arrangement of Fig. 1 might be utilized to perform specialized assessments of relative image quality performance. For example, other radiographic variables can be altered to facilitate evaluations provided these differences are known and documented for both processes. Where multiple radiographic process variables are evaluated, it is incumbent upon the user of this practice to control those normal process attributes to the degree suitable for the application. Specialized RIQR techniques may also be useful with micro focus X-ray, isotope sources of radiation or with the use of non-film radiographic imaging systems. RIQR may also be useful in evaluating imaging systems with alternate materials (RIQI and base plate) such as copper-nickel or aluminum. When using any of t...

SCOPE

1.1 This standard provides a practice whereby industrial radiographic imaging systems may be comparatively assessed using the concept of relative image quality response (RIQR). The RIQR method presented within this practice is based upon the use of equivalent penetrameter sensitivity (EPS) described within Practice E1025 and subsection 5.2 of this practice. Figure 1 illustrates a relative image quality indicator (RIQI) that has four different steel plaque thicknesses (.015, .010, .008, and .005 in.) sequentially positioned (from top to bottom) on a 3/4-in. thick steel plate. The four plaques contain a total of 14 different arrays of penetrameter-type hole sizes designed to render varied conditions of threshold visibility ranging from 1.92 % EPS (at the top) to .94 % EPS (at the bottom) when exposed to nominal 200 keV X-ray radiation. Each “EPS” array consists of 30 identical holes; thus, providing the user with a quantity of threshold sensitivity levels suitable for relative image qualitative response comparisons.

1.2 This practice is not intended to qualify the performance of a specific radiographic technique nor for assurance that a radiographic technique will detect specific discontinuities in a specimen undergoing radiographic examination. This practice is not intended to be used to classify or derive performance classification categories for radiographic imaging systems. For example, performance classifications of radiographic film systems may be found within Test Method E1815.

1.3 This practice contains an alternate provision whereby industrial radiographic imaging systems may be comparatively assessed using Lucite plastic material exposed to nominal 30 keV X-ray radiation. The RIQI for this alternate evaluation is also illustrated in Fig. 1, except the plaque and base plate materials are constructed of Lucite plastic in lieu of steel. EPS values for Lucite plastic are provided in Section 5 based upon the us...

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E746 − 07 (Reapproved 2014)

Standard Practice for

Determining Relative Image Quality Response of Industrial

Radiographic Imaging Systems

This standard is issued under the fixed designation E746; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.4 The values stated in SI are to be regarded as the

standard.

1.1 This standard provides a practice whereby industrial

1.5 This standard does not purport to address all of the

radiographic imaging systems may be comparatively assessed

safety concerns, if any, associated with its use. It is the

using the concept of relative image quality response (RIQR).

responsibility of the user of this standard to establish appro-

TheRIQRmethodpresentedwithinthispracticeisbasedupon

priate safety and health practices and determine the applica-

the use of equivalent penetrameter sensitivity (EPS) described

bility of regulatory limitations prior to use.

within Practice E1025 and subsection 5.2 of this practice.

Figure 1 illustrates a relative image quality indicator (RIQI)

2. Referenced Documents

that has four different steel plaque thicknesses (.015, .010,

.008,and.005in.)sequentiallypositioned(fromtoptobottom)

2.1 ASTM Standards:

on a ⁄4-in. thick steel plate.The four plaques contain a total of

B152/B152MSpecification for Copper Sheet, Strip, Plate,

14 different arrays of penetrameter-type hole sizes designed to

and Rolled Bar

render varied conditions of threshold visibility ranging from

E999Guide for Controlling the Quality of Industrial Radio-

1.92% EPS (at the top) to .94% EPS (at the bottom) when

graphic Film Processing

exposed to nominal 200 keV X-ray radiation. Each “EPS”

E1025 Practice for Design, Manufacture, and Material

array consists of 30 identical holes; thus, providing the user

Grouping Classification of Hole-Type Image Quality In-

with a quantity of threshold sensitivity levels suitable for

dicators (IQI) Used for Radiology

relative image qualitative response comparisons.

E1079Practice for Calibration of Transmission Densitom-

eters

1.2 This practice is not intended to qualify the performance

E1316Terminology for Nondestructive Examinations

of a specific radiographic technique nor for assurance that a

E1735Test Method for Determining Relative Image Quality

radiographic technique will detect specific discontinuities in a

of Industrial Radiographic Film Exposed to X-Radiation

specimen undergoing radiographic examination. This practice

from4to25MeV

is not intended to be used to classify or derive performance

E1815Test Method for Classification of Film Systems for

classification categories for radiographic imaging systems. For

Industrial Radiography

example, performance classifications of radiographic film sys-

E2002PracticeforDeterminingTotalImageUnsharpnessin

tems may be found within Test Method E1815.

Radiology

1.3 This practice contains an alternate provision whereby

2.2 ANSI Standard :

industrialradiographicimagingsystemsmaybecomparatively

ANSI PH2.19Photography Density Measurements-Part 2:

assessed using Lucite plastic material exposed to nominal 30

Geometric Conditions for Transmission Density

keV X-ray radiation. The RIQI for this alternate evaluation is

2.3 ISO Standards :

also illustrated in Fig. 1, except the plaque and base plate

ISO 5-2Photography Density Measurements-Part 2: Geo-

materials are constructed of Lucite plastic in lieu of steel. EPS

metric Conditions for Transmission Density

values for Lucite plastic are provided in Section 5 based upon

the use of a 1 ⁄8-in. thick Lucite base plate. For high-energy ISO 7004Photography- Industrial Radiographic Film, De-

termination of ISO Speed, ISO average gradient, and ISO

X-rayapplications(4to25MeV),TestMethodE1735provides

a similar RIQR standard practice.

1 2

This practice is under the jurisdiction of ASTM Committee E07 on Nonde- For referenced ASTM standards, visit the ASTM website, www.astm.org, or

structive Testing and is the direct responsibility of Subcommittee E07.01 on contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Radiology (X and Gamma) Method. Standards volume information, refer to the standard’s Document Summary page on

CurrenteditionapprovedJuly1,2014.PublishedJuly2014.Originallyapproved the ASTM website.

in1980.Lastpreviouseditionapprovedin2007asE746-07.DOI:10.1520/E0746- Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

07R14. 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E746 − 07 (2014)

Step Identification Shim Thickness, mm (in.) Hole Identification Hole Size, mm (in.)

15 0.38 ± 0.012 (0.015 ± 0.0005) 32 0.81 ± 0.025 (0.032 ± 0.001)

10 0.25 ± 0.012 (0.010 ± 0.0005) 31 0.79 ± 0.025 (0.031 ± 0.001)

8 0.20 ± 0.012 (0.008 ± 0.0005) 28 0.71 ± 0.025 (0.028 ± 0.001)

5 0.13 ± 0.012 (0.005 ± 0.0005) 25 0.64 ± 0.025 (0.025 ± 0.001)

23 0.58 ± 0.025 (0.023 ± 0.001)

20 0.50 ± 0.025 (0.020 ± 0.001)

Hole Spacing (horizontal): 5 ± 0.1 mm (0.2 ± 0.004 in.) Nonaccumulative

Row Spacing: 3 ± 0.1 mm (0.2 ± 0.004 in.)

Spacing between hole sets: 5 ± 0.1 mm (0.2 ± 0.004 in.)

All other dimensions shall be in accordance with standard engineering practice.

FIG. 1 Relative Image Quality Indicator

gradients G2 and G4 when exposed to X- and gamma- 3.2.4 pixel intensity value (PV)—a positive integer numeri-

radiation cal value of gray scale level of a picture data element (pixel)

directlyproportionalwithoriginatingdigitalimagedatavalues.

3. Terminology

3.2.4.1 Discussion—PV is directly related to radiation dose

3.1 Definitions—The definitions of terms relating to gamma

receivedbyadigitaldetector,thatis,PVis“0”ifradiationdose

and X-radiology in Terminology E1316 shall apply to terms

was “0”. The number of available PV integers is associated

used in this practice.

with gray scale bit depth of the digital image. For example: a

12-bit gray scale image will have a range from “0” to “4095”

3.2 Definitions of Terms Specific to This Standard:

levels (shades) of gray (4096 total pixel value integers) and

3.2.1 detector—an imaging device used to store a radio-

will become saturated when PV reaches “4095”.

graphic latent image or directly convert ionizing radiation into

electrical signals in proportion to the quantity of radiation

4. Significance and Use

absorbed.

3.2.2 cassette—a device that is either flexible or rigid used

4.1 This standard provides a practice for RIQR evaluations

to hold or protect a detector

of film and non-film imaging systems when exposed through

3.2.3 Relative Image Quality Indicator (RIQI)— an image steel or plastic materials. Three alternate data evaluation

methodsareprovidedinSection9.DeterminingRIQRrequires

quality measuring device that is capable of determining mean-

ingful differences between two or more radiographic imaging the comparison of at least two radiographs or radiographic

processes whereby the relative degree of image quality differ-

systems or changes of individual components of radiographic

imaging systems. ence may be determined using the EPS plaque arrangement of

E746 − 07 (2014)

Fig. 1 as a relative image quality indicator (RIQI). In conjunc- 1illustratesEPSvaluesforthesteelmethod).DescendingEPS

tion with the RIQI, a specified radiographic technique or values for Lucite plastic are: 1.05%, 1.00%, .96%, .91%,

method must be established and carefully controlled for each .86%, .81%, .77%, .73%, .70%, .65%, .61%, .58%, .55%

radiographic process. This practice is designed to allow the and .51% for the plaque steps of Fig. 1.

determination of subtle changes in EPS that may arise to

5.3 The absorber base plate shall be made of mild steel for

radiographicimagingsystemperformancelevelsresultantfrom

the 200 keVmethod and Lucite plastic for the 30 keVmethod.

process improvements/changes or change of equipment attri-

Both base plates shall be at least 200 by 250 mm (8 by 10 in.)

butes. This practice does not address relative unsharpness of a

wide and long. The steel plate shall be 19 6 0.12 mm (0.750

radiographic imaging system as provided in Practice E2002.

6 0.005 in.) thick and the plastic plate shall be 36 6 0.12 mm

The common element with any relative comparison is the use

(1.375 6 0.005 in.) thick. The surface finish of both absorber

of the same RIQI arrangement for both processes under

base plates shall be a maximum of 6.3 µm (250 µin.) Ra,

evaluation.

ground finish (both faces).

4.2 In addition to the standard evaluation method described

5.4 The RIQI shown in Fig. 1 shall be placed on the

in Section 9, there may be other techniques/methods in which

radiation source side and within the approximate center of the

the basic RIQR arrangement of Fig. 1 might be utilized to

appropriate absorber base plate as illustrated in Fig. 2(B).

perform specialized assessments of relative image quality

performance.Forexample,otherradiographicvariablescanbe

6. Calibration of X-Ray Source

altered to facilitate evaluations provided these differences are

known and documented for both processes. Where multiple 6.1 Use a target to detector distance at least 750 mm (29.5

radiographic process variables are evaluated, it is incumbent in.) for all exposures.

upon the user of this practice to control those normal process

6.2 ThevoltagecalibrationoftheX-raysourcefor200–keV

attributestothedegreesuitablefortheapplication.Specialized

is based on ISO 7004.With an 8-mm (0.32-in.) copper filter at

RIQR techniques may also be useful with micro focus X-ray,

the X-ray tube, adjust the kilovoltage until the half value layer

isotope sources of radiation or with the use of non-film

(HVL) in copper is 3.5 mm (0.14 in.) (see Specification

radiographic imaging systems. RIQR may also be useful in

B152/B152M). Using a calibrated ionization chamber or simi-

evaluating imaging systems with alternate materials (RIQI and

lar radiation measurement device, make a reading of the

base plate) such as copper-nickel or aluminum. When using

detector with 8 mm (0.32 in.) of copper at the tube, and then,

any of these specialized applications, the specific method or

make a second reading with a total of 11.5 mm (0.45 in.) of

techniques used shall be as specified and approved by the

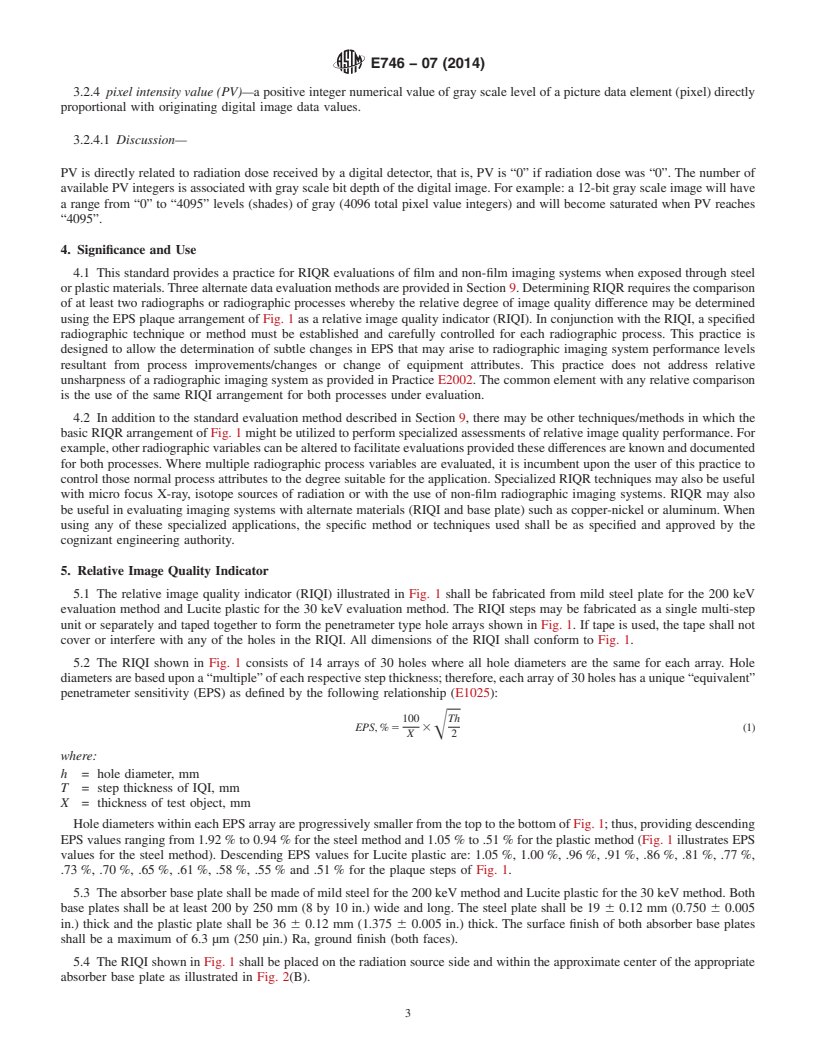

copper at the tube as shown in Fig. 2(A).

cognizant engineering authority.

6.3 The voltage calibration of the X-ray source for 30–keV

is based on ISO 7004 method for 100–keV calibration,

5. Relative Image Quality Indicator

modified for 30–keV. With a 7.62-mm (0.30-in.) aluminum

5.1 Therelativeimagequalityindicator(RIQI)illustratedin

filterattheX-raytubeport,adjustthekilovoltageuntilthehalf

Fig. 1 shall be fabricated from mild steel plate for the 200 keV

value layer (HVL) in aluminum is 1.52 mm (0.06 in.). That is,

evaluationmethodandLuciteplasticforthe30keVevaluation

the intensity of the X-ray beam with 9.14–mm (0.36–in.)

method. The RIQI steps may be fabricated as a single multi-

aluminum at the tube port shall be one-half that with 7.62–mm

stepunitorseparatelyandtapedtogethertoformthepenetram-

(0.30–in.) aluminum at the tube port.

eter type hole arrays shown in Fig. 1. If tape is used, the tape

6.4 For both 200–keV and 30–keV X-ray beam calibration

shall not cover or interfere with any of the holes in the RIQI.

All dimensions of the RIQI shall conform to Fig. 1. methods, calculate the ratio of the two readings. If this ratio is

not 2, adjust the kilovoltage up or down and repeat the

5.2 The RIQI shown in Fig. 1 consists of 14 arrays of 30

measurementuntilaratioof2(within5%)isobtained.Record

holes where all hole diameters are the same for each array.

the X-ray machine voltage settings and use these same values

Hole diameters are based upon a “multiple” of each respective

for the RIQR evaluations. Prior to RIQR performance evalua-

step thickness; therefore, each array of 30 holes has a unique

tions for both 200–keVand 30–keVmethods, remove all HVL

“equivalent” penetrameter sensitivity (EPS) as defined by the

and filter materials at the X-ray tube port.

following relationship (E1025):

100 Th 7. Procedure

EPS,% 5 3Π(1)

X 2

7.1 Basic—Use the physical set up as shown in Fig. 2(B).

PositiontheX-raytubedirectlyovertheapproximatecenterof

where:

the RIQI and detector cassette. The plane of the detector and

h = hole diameter, mm

RIQImustbenormaltothecentralrayoftheX-raybeam.Use

T = step thickness of IQI, mm

adiaphragmatthetubetolimitthefieldofradiationtothefilm

X = thickness of test object, mm

area.

Hole diameters within each EPS array are progressively

smaller from the top to the bottom of Fig. 1; thus, providing 7.2 Source-to-detector distance (SDD) is based upon

descending EPS values ranging from 1.92% to 0.94% for the achieving a geometrical unsharpness (Ug) of 0.05 mm (0.002

steel method and 1.05% to .51% for the plastic method (Fig. in.) or less on a 36 mm (1.375 in.) thick plastic plate for

E746 − 07 (2014)

FIG. 2 (A) Setup for Energy Calibration (B) Setup for RIQR Exposures

7.5 Identify the detector number, type, exposure, and other

30–keV and a 19 mm (0.750 in.) thick absorber plate for

200–keV. Calculate the minimum SDD, in millimetres, as technique data by means of lead letters, or numerals, placed in

follows:

the upper right hand corner of the base absorber plate(s). Do

not place so as to interfere with the image of the holes in the

SDD 5381φ

RIQI. Make these identification symbols as small and unob-

where:

trusive as possible. Record this identification number on the

SDD = source-to-detector distance, mm, and

data sheet for this exposure (see Section 8).

φ = focal spot size, mm.

7.6 Make three separate exposures as specified in 9.1

The SDD shall be not less than 1 m (39.4 in.).

through 9.3. Expose the detector at the keV setting as deter-

7.3 Detector Cassettes and Screens—Low absorption cas-

mined in Section 6. Remove all filters at the tube before

settes shall be used to maximize the effectiveness of the RIQI

conducting exposures. Adjust exposure time to criteria speci-

andonlyasingledetectorshallbeusedwithinthecassette.For

fied in 7.2 (film systems) or 7.3 (non-film systems). In order to

the 200–keV method, place the detector between lead-foil

preclude any detector latent image instability, process (as

screens, the front screen being 0.130 6 0.013 mm (0.005 6

applicable) any exposed detector within eight hours of expo-

0.0005in.)thickandthebackscreen0.250 60.025mm(0.010

sure.

60.001in.)thick.Thecassetteshallprovideameansf

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: E746 − 07 E746 − 07 (Reapproved 2014)

Standard Practice for

Determining Relative Image Quality Response of Industrial

Radiographic Imaging Systems

This standard is issued under the fixed designation E746; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This standard provides a practice whereby industrial radiographic imaging systems may be comparatively assessed using

the concept of relative image quality response (RIQR). The RIQR method presented within this practice is based upon the use of

equivalent penetrameter sensitivity (EPS) described within Practice E1025 and subsection 5.2 of this practice. Figure 1 illustrates

a relative image quality indicator (RIQI) that has four different steel plaque thicknesses (.015, .010, .008, and .005 in.) sequentially

positioned (from top to bottom) on a ⁄4-in. thick steel plate. The four plaques contain a total of 14 different arrays of

penetrameter-type hole sizes designed to render varied conditions of threshold visibility ranging from 1.92 % EPS (at the top) to

.94 % EPS (at the bottom) when exposed to nominal 200 keV X-ray radiation. Each “EPS” array consists of 30 identical holes;

thus, providing the user with a quantity of threshold sensitivity levels suitable for relative image qualitative response comparisons.

1.2 This practice is not intended to qualify the performance of a specific radiographic technique nor for assurance that a

radiographic technique will detect specific discontinuities in a specimen undergoing radiographic examination. This practice is not

intended to be used to classify or derive performance classification categories for radiographic imaging systems. For example,

performance classifications of radiographic film systems may be found within Test Method E1815.

1.3 This practice contains an alternate provision whereby industrial radiographic imaging systems may be comparatively

assessed using Lucite plastic material exposed to nominal 30 keV X-ray radiation. The RIQI for this alternate evaluation is also

illustrated in Fig. 1, except the plaque and base plate materials are constructed of Lucite plastic in lieu of steel. EPS values for

Lucite plastic are provided in Section 5 based upon the use of a 1 ⁄8-in. thick Lucite base plate. For high-energy X-ray applications

(4 to 25 MeV), Test Method E1735 provides a similar RIQR standard practice.

1.4 The values stated in SI are to be regarded as the standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

B152/B152M Specification for Copper Sheet, Strip, Plate, and Rolled Bar

E999 Guide for Controlling the Quality of Industrial Radiographic Film Processing

E1025 Practice for Design, Manufacture, and Material Grouping Classification of Hole-Type Image Quality Indicators (IQI)

Used for Radiology

E1079 Practice for Calibration of Transmission Densitometers

E1316 Terminology for Nondestructive Examinations

E1735 Test Method for Determining Relative Image Quality of Industrial Radiographic Film Exposed to X-Radiation from 4 to

25 MeV

E1815 Test Method for Classification of Film Systems for Industrial Radiography

E2002 Practice for Determining Total Image Unsharpness in Radiology

This practice is under the jurisdiction of ASTM Committee E07 on Nondestructive Testing and is the direct responsibility of Subcommittee E07.01 on Radiology (X and

Gamma) Method.

Current edition approved Dec. 1, 2007July 1, 2014. Published January 2008July 2014. Originally approved in 1980. Last previous edition approved in 20022007 as

E746 - 02.E746 - 07. DOI: 10.1520/E0746-07.10.1520/E0746-07R14.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E746 − 07 (2014)

Step Identification Shim Thickness, mm (in.) Hole Identification Hole Size, mm (in.)

15 0.38 ± 0.012 (0.015 ± 0.0005) 32 0.81 ± 0.025 (0.032 ± 0.001)

10 0.25 ± 0.012 (0.010 ± 0.0005) 31 0.79 ± 0.025 (0.031 ± 0.001)

8 0.20 ± 0.012 (0.008 ± 0.0005) 28 0.71 ± 0.025 (0.028 ± 0.001)

5 0.13 ± 0.012 (0.005 ± 0.0005) 25 0.64 ± 0.025 (0.025 ± 0.001)

23 0.58 ± 0.025 (0.023 ± 0.001)

20 0.50 ± 0.025 (0.020 ± 0.001)

Hole Spacing (horizontal): 5 ± 0.1 mm (0.2 ± 0.004 in.) Nonaccumulative

Row Spacing: 3 ± 0.1 mm (0.2 ± 0.004 in.)

Spacing between hole sets: 5 ± 0.1 mm (0.2 ± 0.004 in.)

All other dimensions shall be in accordance with standard engineering practice.

FIG. 1 Relative Image Quality Indicator

2.2 ANSI Standard :

ANSI PH2.19 Photography Density Measurements-Part 2: Geometric Conditions for Transmission Density

2.3 ISO Standards :

ISO 5-2 Photography Density Measurements-Part 2: Geometric Conditions for Transmission Density

ISO 7004 Photography- Industrial Radiographic Film, Determination of ISO Speed, ISO average gradient, and ISO gradients G2

and G4 when exposed to X- and gamma-radiation

3. Terminology

3.1 Definitions—The definitions of terms relating to gamma and X-radiology in Terminology E1316 shall apply to terms used

in this practice.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 detector—an imaging device used to store a radiographic latent image or directly convert ionizing radiation into electrical

signals in proportion to the quantity of radiation absorbed.

3.2.2 cassette—a device that is either flexible or rigid used to hold or protect a detector

3.2.3 Relative Image Quality Indicator (RIQI)— an image quality measuring device that is capable of determining meaningful

differences between two or more radiographic imaging systems or changes of individual components of radiographic imaging

systems.

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036, http://www.ansi.org.

E746 − 07 (2014)

3.2.4 pixel intensity value (PV)—a positive integer numerical value of gray scale level of a picture data element (pixel) directly

proportional with originating digital image data values.

3.2.4.1 Discussion—

PV is directly related to radiation dose received by a digital detector, that is, PV is “0” if radiation dose was “0”. The number of

available PV integers is associated with gray scale bit depth of the digital image. For example: a 12-bit gray scale image will have

a range from “0” to “4095” levels (shades) of gray (4096 total pixel value integers) and will become saturated when PV reaches

“4095”.

4. Significance and Use

4.1 This standard provides a practice for RIQR evaluations of film and non-film imaging systems when exposed through steel

or plastic materials. Three alternate data evaluation methods are provided in Section 9. Determining RIQR requires the comparison

of at least two radiographs or radiographic processes whereby the relative degree of image quality difference may be determined

using the EPS plaque arrangement of Fig. 1 as a relative image quality indicator (RIQI). In conjunction with the RIQI, a specified

radiographic technique or method must be established and carefully controlled for each radiographic process. This practice is

designed to allow the determination of subtle changes in EPS that may arise to radiographic imaging system performance levels

resultant from process improvements/changes or change of equipment attributes. This practice does not address relative

unsharpness of a radiographic imaging system as provided in Practice E2002. The common element with any relative comparison

is the use of the same RIQI arrangement for both processes under evaluation.

4.2 In addition to the standard evaluation method described in Section 9, there may be other techniques/methods in which the

basic RIQR arrangement of Fig. 1 might be utilized to perform specialized assessments of relative image quality performance. For

example, other radiographic variables can be altered to facilitate evaluations provided these differences are known and documented

for both processes. Where multiple radiographic process variables are evaluated, it is incumbent upon the user of this practice to

control those normal process attributes to the degree suitable for the application. Specialized RIQR techniques may also be useful

with micro focus X-ray, isotope sources of radiation or with the use of non-film radiographic imaging systems. RIQR may also

be useful in evaluating imaging systems with alternate materials (RIQI and base plate) such as copper-nickel or aluminum. When

using any of these specialized applications, the specific method or techniques used shall be as specified and approved by the

cognizant engineering authority.

5. Relative Image Quality Indicator

5.1 The relative image quality indicator (RIQI) illustrated in Fig. 1 shall be fabricated from mild steel plate for the 200 keV

evaluation method and Lucite plastic for the 30 keV evaluation method. The RIQI steps may be fabricated as a single multi-step

unit or separately and taped together to form the penetrameter type hole arrays shown in Fig. 1. If tape is used, the tape shall not

cover or interfere with any of the holes in the RIQI. All dimensions of the RIQI shall conform to Fig. 1.

5.2 The RIQI shown in Fig. 1 consists of 14 arrays of 30 holes where all hole diameters are the same for each array. Hole

diameters are based upon a “multiple” of each respective step thickness; therefore, each array of 30 holes has a unique “equivalent”

penetrameter sensitivity (EPS) as defined by the following relationship (E1025):

100 Th

EPS, %5 3Π(1)

X 2

where:

h = hole diameter, mm

T = step thickness of IQI, mm

X = thickness of test object, mm

Hole diameters within each EPS array are progressively smaller from the top to the bottom of Fig. 1; thus, providing descending

EPS values ranging from 1.92 % to 0.94 % for the steel method and 1.05 % to .51 % for the plastic method (Fig. 1 illustrates EPS

values for the steel method). Descending EPS values for Lucite plastic are: 1.05 %, 1.00 %, .96 %, .91 %, .86 %, .81 %, .77 %,

.73 %, .70 %, .65 %, .61 %, .58 %, .55 % and .51 % for the plaque steps of Fig. 1.

5.3 The absorber base plate shall be made of mild steel for the 200 keV method and Lucite plastic for the 30 keV method. Both

base plates shall be at least 200 by 250 mm (8 by 10 in.) wide and long. The steel plate shall be 19 6 0.12 mm (0.750 6 0.005

in.) thick and the plastic plate shall be 36 6 0.12 mm (1.375 6 0.005 in.) thick. The surface finish of both absorber base plates

shall be a maximum of 6.3 μm (250 μin.) Ra, ground finish (both faces).

5.4 The RIQI shown in Fig. 1 shall be placed on the radiation source side and within the approximate center of the appropriate

absorber base plate as illustrated in Fig. 2(B).

E746 − 07 (2014)

FIG. 2 (A) Setup for Energy Calibration (B) Setup for RIQR Exposures

6. Calibration of X-Ray Source

6.1 Use a target to detector distance at least 750 mm (29.5 in.) for all exposures.

6.2 The voltage calibration of the X-ray source for 200–keV is based on ISO 7004. With an 8-mm (0.32-in.) copper filter at the

X-ray tube, adjust the kilovoltage until the half value layer (HVL) in copper is 3.5 mm (0.14 in.) (see Specification B152/B152M).

Using a calibrated ionization chamber or similar radiation measurement device, make a reading of the detector with 8 mm (0.32

in.) of copper at the tube, and then, make a second reading with a total of 11.5 mm (0.45 in.) of copper at the tube as shown in

Fig. 2(A).

6.3 The voltage calibration of the X-ray source for 30–keV is based on ISO 7004 method for 100–keV calibration, modified

for 30–keV. With a 7.62-mm (0.30-in.) aluminum filter at the X-ray tube port, adjust the kilovoltage until the half value layer

(HVL) in aluminum is 1.52 mm (0.06 in.). That is, the intensity of the X-ray beam with 9.14–mm (0.36–in.) aluminum at the tube

port shall be one-half that with 7.62–mm (0.30–in.) aluminum at the tube port.

6.4 For both 200–keV and 30–keV X-ray beam calibration methods, calculate the ratio of the two readings. If this ratio is not

2, adjust the kilovoltage up or down and repeat the measurement until a ratio of 2 (within 5 %) is obtained. Record the X-ray

machine voltage settings and use these same values for the RIQR evaluations. Prior to RIQR performance evaluations for both

200–keV and 30–keV methods, remove all HVL and filter materials at the X-ray tube port.

7. Procedure

7.1 Basic—Use the physical set up as shown in Fig. 2(B). Position the X-ray tube directly over the approximate center of the

RIQI and detector cassette. The plane of the detector and RIQI must be normal to the central ray of the X-ray beam. Use a

diaphragm at the tube to limit the field of radiation to the film area.

7.2 Source-to-detector distance (SDD) is based upon achieving a geometrical unsharpness (Ug) of 0.05 mm (0.002 in.) or less

on a 36 mm (1.375 in.) thick plastic plate for 30–keV and a 19 mm (0.750 in.) thick absorber plate for 200–keV. Calculate the

minimum SDD, in millimetres, as follows:

SDD 5 381 φ

where:

SDD = source-to-detector distance, mm, and

E746 − 07 (2014)

φ = focal spot size, mm.

The SDD shall be not less than 1 m (39.4 in.).

7.3 Detector Cassettes and Screens—Low absorption cassettes shall be used to maximize the effectiveness of the RIQI and only

a single detector shall be used within the cassette. For the 200–keV method, place the detector between lead-foil screens, the front

screen being 0.130 6 0.013 mm (0.005 6 0.0005 in.) thick and the back screen 0.250 6 0.025 mm (0.010 6 0.001 in.) thick. The

cassette shall provide a means for good detector-screen contact. No lead screens shall be used with the 30 keV method. The same

type cassette and screens (absorption characteristics and thicknesses) shall

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.