ASTM E1257-16

(Guide)Standard Guide for Evaluating Grinding Materials Used for Surface Preparation in Spectrochemical Analysis

Standard Guide for Evaluating Grinding Materials Used for Surface Preparation in Spectrochemical Analysis

SIGNIFICANCE AND USE

4.1 The grinding materials used for the preparation of the surfaces of specimens prior to analysis by spark atomic emission or X-ray fluorescence spectrometry can contaminate the surface and thus produce erroneous results. This guide provides examples of the effects of these contaminations and recommendations for evaluating grinding materials to eliminate or reduce these effects in spectrochemical analysis.

4.2 The examples given in this guide are not the only contaminations that can occur. Especially in X-ray spectrometry, all phases of the surface preparation should be examined for potential contamination effects.

4.3 Analytical significance of the contaminations observed depends on the needs of the analyst for the particular application at a given composition.

SCOPE

1.1 This guide covers recommendations for the evaluation of various grinding materials used to prepare the surfaces of specimens to be analyzed by spark atomic emission or X-ray fluorescence spectrometry.

1.2 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: E1257 − 16

Standard Guide for

Evaluating Grinding Materials Used for Surface Preparation

1

in Spectrochemical Analysis

This standard is issued under the fixed designation E1257; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 4.3 Analytical significance of the contaminations observed

depends on the needs of the analyst for the particular applica-

1.1 This guide covers recommendations for the evaluation

tion at a given composition.

of various grinding materials used to prepare the surfaces of

specimens to be analyzed by spark atomic emission or X-ray

5. Evaluation of Grinding Materials by Direct Analysis

fluorescence spectrometry.

5.1 Table 1 shows an example of semiquantitative spectro-

1.2 This standard does not purport to address all of the

metric analysis of various grinding belts from different pro-

safety problems, if any, associated with its use. It is the

ducers. An examination of these analyses identifies the ele-

responsibility of the user of this standard to establish appro-

ments most likely to contaminate the surface of the specimen.

priate safety and health practices and determine the applica-

The more critical the element and the lower its mass fraction in

bility of regulatory limitations prior to use.

the specimen, the more important are low-level contaminants

in the belts.

2. Referenced Documents

5.1.1 For example, using the 80-grit zircon belt in the

2

2.1 ASTM Standards:

determination of 0.5 % chromium, the trace level of chromium

E135 Terminology Relating to Analytical Chemistry for

in the belt should cause no problem, but in the determination of

Metals, Ores, and Related Materials

0.02 % aluminum, that belt probably will cause a problem. In

the determination of calcium at µg/g levels in steel, even low

3. Terminology

levels of calcium in the belts cause problems.

3.1 For definitions of terms used in this guide, refer to

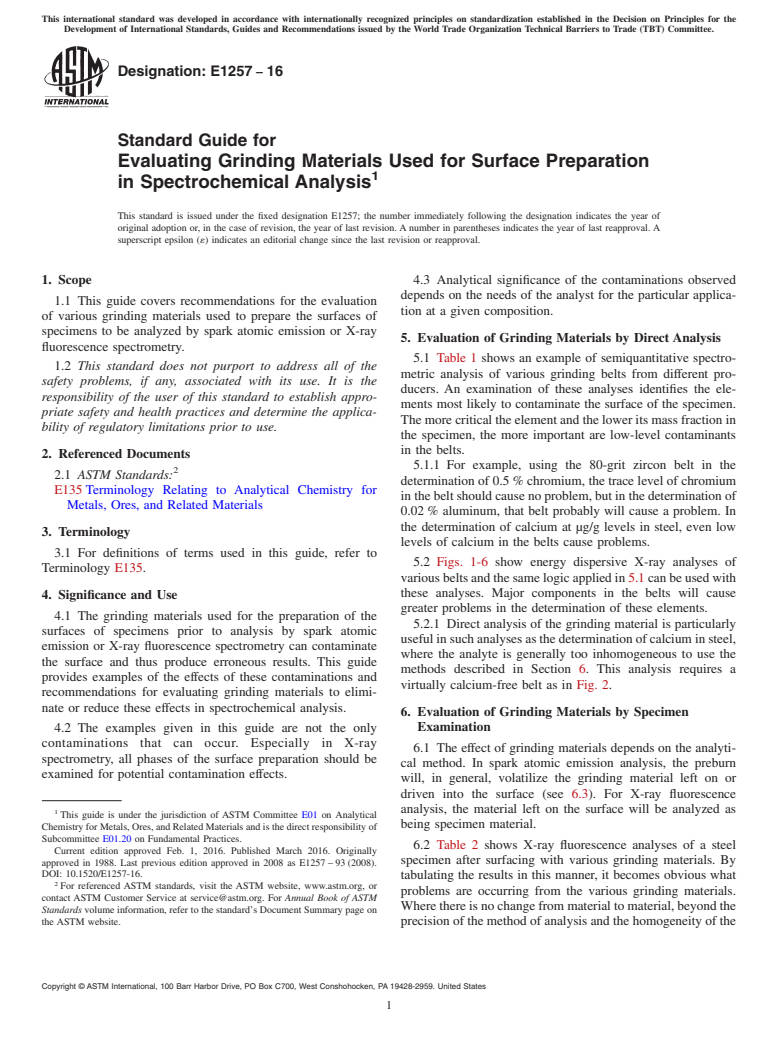

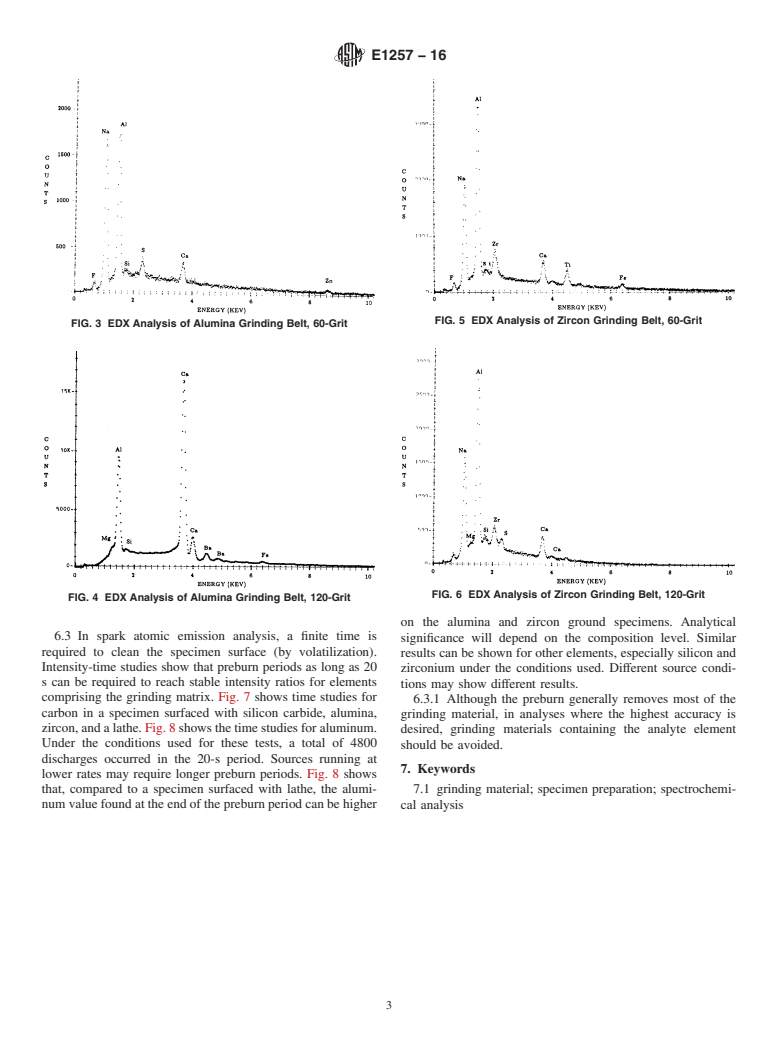

5.2 Figs. 1-6 show energy dispersive X-ray analyses of

Terminology E135.

variousbeltsandthesamelogicappliedin5.1canbeusedwith

these analyses. Major components in the belts will cause

4. Significance and Use

greater problems in the determination of these elements.

4.1 The grinding materials used for the preparation of the

5.2.1 Direct analysis of the grinding material is particularly

surfaces of specimens prior to analysis by spark atomic

usefulinsuchanalysesasthedeterminationofcalciuminsteel,

emission or X-ray fluorescence spectrometry can contaminate

where the analyte is generally too inhomogeneous to use the

the surface and thus produce erroneous results. This guide

methods described in Section 6. This analysis requires a

provides examples of the effects of these contaminations and

virtually calcium-free belt as in Fig. 2.

recommendations for evaluating grinding materials to elimi-

nate or reduce these effects in spectrochemical analysis.

6. Evaluation of Grinding Materials by Specimen

Examination

4.2 The examples given in this guide are not the only

contaminations that can occur. Especially in X-ray

6.1 The effect of grinding materials depends on the analyti-

spectrometry, all phases of the surface preparation should be

cal method. In spark atomic emission analysis, the preburn

examined for potential contamination effects.

will, in general, volatilize the grinding material left on or

driven into the surface (see 6.3). For X-ray fluorescence

analysis, the material left on the surface will be analyzed as

1

This guide is under the jurisdiction of ASTM Committee E01 on Analytical

being specimen material.

Chemistry for Metals, Ores, and Related Materials and is the direct responsibility of

Subcommittee E01.20 on Fundamental Practices.

6.2 Table 2 shows X-ray fluorescence analyses of a steel

Current edition approved Feb. 1, 2016. Published March 2016. Originally

specimen after surfacing with various grinding materials. By

approved in 1988. Last previous edition approved in 2008 as E1257 – 93 (2008).

DOI: 10.1520/E1257-16.

tabulating the results in this manner, it becomes obvious what

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

problems are occurring from the various grinding materials.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Where there is no change from material to material, beyond the

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. precision of the method of analysis and the homogenei

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: E1257 − 93 (Reapproved 2008) E1257 − 16

Standard Guide for

Evaluating Grinding Materials Used for Surface Preparation

1

in Spectrochemical Analysis

This standard is issued under the fixed designation E1257; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This guide covers recommendations for the evaluation of various grinding materials used to prepare the surfaces of

specimens to be analyzed by optical spark atomic emission or X-ray emission spectroscopy.fluorescence spectrometry.

1.2 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

E135 Terminology Relating to Analytical Chemistry for Metals, Ores, and Related Materials

3. Terminology

3.1 For definitions of terms used in this guide, refer to Terminology E135.

4. Significance and Use

4.1 The grinding materials used for the preparation of the surfaces of specimens prior to analysis by optical spark atomic

emission or X-ray emission spectroscopyfluorescence spectrometry can contaminate the surface and thus produce erroneous

results. This guide provides examples of the effects of these contaminations and recommendations for evaluating grinding materials

to eliminate or reduce these effects in spectrochemical analysis.

4.2 The examples given in this guide are not the only contaminations whichthat can occur. Especially in X-ray spectrometry,

all phases of the surface preparation should be examined for potential contamination effects.

4.3 Analytical significance of the contaminations observed depends on the needs of the analyst for the particular application at

a given concentration level.composition.

5. Evaluation of Grinding Materials by Direct Analysis

5.1 Table 1 shows an example of semiquantitative spectrographicspectrometric analysis of various grinding belts from different

producers. An examination of these analyses identifies the elements most likely to contaminate the surface of the specimen. The

more critical the element and the lower its concentration mass fraction in the specimen, the more important are low-level

concentrationscontaminants in the belts.

5.1.1 For example, using the 80-grit zircon belt in the determination of 0.5 % chromium, the trace level of chromium in the belt

should cause no problem, but in the determination of 0.02 % aluminum, that belt probably will cause a problem. In the

determination of calcium at ppmμg/g levels in steel, even low levels of calcium in the belts cause problems.

5.2 Figs. 1-6 show energy dispersive X-ray analyses of various belts and the same logic applied in 5.1 can be used with these

analyses. Major components in the belts will cause greater problems in the determination of these elements.

1

This guide is under the jurisdiction of ASTM Committee E01 on Analytical Chemistry for Metals, Ores, and Related Materials and is the direct responsibility of

Subcommittee E01.20 on Fundamental Practices.

Current edition approved May 1, 2008Feb. 1, 2016. Published June 2008March 2016. Originally approved in 1988. Last previous edition approved in 20032008 as

E1257 – 93 (2003).(2008). DOI: 10.1520/E1257-93R08.10.1520/E1257-16.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E1257 − 16

TABLE 1 Semiquantitative (Spectrographic) Analysis of Grinding Belt Abrasives

80-Grit Silicon Carbide 80-Grit Alumina

Concentration,% 80-Grit Zircon

No. 1 No. 2 No. 3 No. 1 No. 2 No. 3

10+ Si Si Si Al Al, Ca Al Al, Ca, Zr

1–10 Ca Ca Ti Si, Na, Fe

0.1–1 Ba, Mg Fe, Al, Na Mg, Si, Ca, Ti Fe, Si, Na Ca Ti, Zn

0.05–0.5 B Fe, B Mg

0.01–0.1 Mn, Na B, Mg Al Ba, B Zr Na Mg

0.005–0.05 V, Cu, Ti, Ni Mn, Ti V, Ca, Na, Ni Mn, Zr, Cu, Na B B, Fe, Si B, Mn, Sr

Trace–0.01 Mo, Zr, Sr Ba, V, Zr, Cu, Ba, Mn, Mg, Pb, Cr

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.