ASTM G174-22

(Test Method)Standard Test Method for Measuring Abrasion Resistance of Materials by Abrasive Loop Contact

Standard Test Method for Measuring Abrasion Resistance of Materials by Abrasive Loop Contact

SIGNIFICANCE AND USE

5.1 This test is useful for screening materials for use in tools that are subjected to abrasion from the material that is being machined, worked, or formed. It has been used to screen tool steels for punch press dies, hard-facings for earth-moving machinery, and wear coatings. This test apparatus is simpler to build and use than those used in the Test Method G132 abrasion test which, like this test, uses a fixed abrasive counterface to abrade a test material.

5.2 The one-hour test is intended for metals and materials that are softer than hardened steel (67 HRC), but may be applied to harder materials.

SCOPE

1.1 This test method covers ranking rigid engineering materials for abrasion resistance in rubbing against aluminum oxide abrasive finishing tape. Though most solids can be tested, this test method addresses its use for metals, and coatings applied to metals.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: G174 − 22

Standard Test Method for

Measuring Abrasion Resistance of Materials by Abrasive

1

Loop Contact

This standard is issued under the fixed designation G174; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

3

1. Scope sion Tests (Withdrawn 2016)

G132 Test Method for Pin Abrasion Testing

1.1 This test method covers ranking rigid engineering ma-

terials for abrasion resistance in rubbing against aluminum

3. Terminology

oxide abrasive finishing tape. Though most solids can be

3.1 Definitions from Terminology G40:

tested, this test method addresses its use for metals, and

3.1.1 abrasive wear, n—wear due to hard particles or hard

coatings applied to metals.

protuberances forced against, and moving along, a solid

1.2 The values stated in SI units are to be regarded as

surface.

standard. No other units of measurement are included in this

3.2 Definitions of Terms Specific to This Standard:

standard.

3.2.1 abrasion resistance, n—in tribology, the ability of a

1.3 This standard does not purport to address all of the

material to resist damage or attrition by abrasion.

safety concerns, if any, associated with its use. It is the

3.2.2 fixed abrasive tape, n—hard particles or grains bonded

responsibility of the user of this standard to establish appro-

(fixed) to one side of a flexible web with a resin or similar

priate safety, health, and environmental practices and deter-

binder. The particles can be of any hard material and vary in

mine the applicability of regulatory limitations prior to use.

size. (This abrasive medium is also known as “finishing tape,”

1.4 This international standard was developed in accor-

“microfinishing tape,” “microfinishing film,” or “finishing

dance with internationally recognized principles on standard-

film.”)

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom-

3.2.3 flexible web, n—plastic, paper, rubber, or other mate-

mendations issued by the World Trade Organization Technical

rial that is thin enough to conform to a 180° wrap around a

Barriers to Trade (TBT) Committee.

16 mm diameter cylinder under a tension of less than

1.8 kg⁄cm width.

2. Referenced Documents

3.2.4 pass, n—abrasion distance equivalent to one circum-

2

2.1 ASTM Standards:

ference of the abrading loop.

E177 Practice for Use of the Terms Precision and Bias in

ASTM Test Methods

4. Summary of Test Method

E178 Practice for Dealing With Outlying Observations

4.1 This test involves rubbing an abrasive tape loop initially

E691 Practice for Conducting an Interlaboratory Study to

in line-contact with a solid surface.The tape abrasion produces

Determine the Precision of a Test Method

a groove in the test surface, and the volume of material

G40 Terminology Relating to Wear and Erosion

removed in a designated amount of abrasive rubbing is

G117 Guide for Calculating and Reporting Measures of

measured by mass loss or by calculation from the groove

Precision Using Data from Interlaboratory Wear or Ero-

geometry. The continuous loop of abrasive is used for a

specified number of passes and then discarded.

1

This test method is under the jurisdiction of ASTM Committee G02 on Wear

4.2 The wear volume produced in this test provides a

and Erosion and is the direct responsibility of Subcommittee G02.30 on Abrasive

measure of the ability of a surface to resist wear damage from

Wear.

Current edition approved Nov. 1, 2022. Published December 2022. Originally

abrasive substances. The smaller the wear volume in this test,

approved in 2003. Last previous edition approved in 2017 as G174 – 04 (2017).

the better the abrasion resistance.

DOI: 10.1520/G0174-22.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on The last approved version of this historical standard is referenced on

the ASTM website. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

G174 − 22

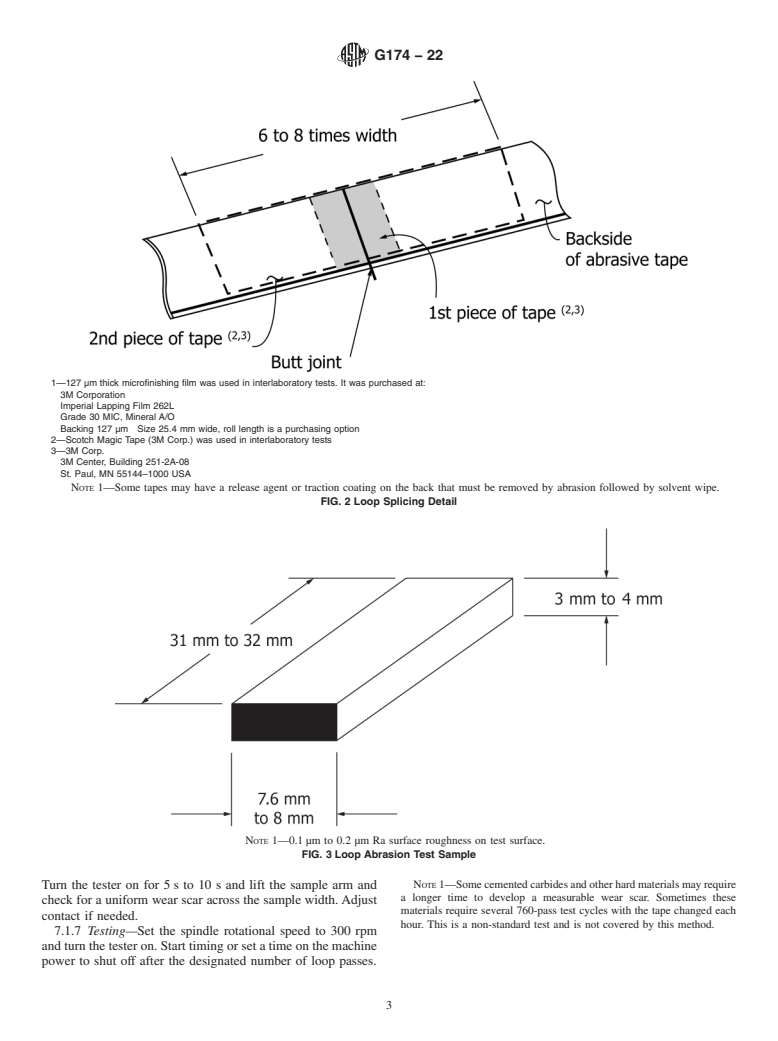

FIG. 1 Photo and Schematic of Test Apparatus

4.3 The test was developed using 30 µm mean diameter shall be 16 mm in diameter and have a total indicated run-out

aluminum oxide abrasive on a 127 µm thick polyester support, of less than 20 µm at a rotational sp

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: G174 − 04 (Reapproved 2017) G174 − 22

Standard Test Method for

Measuring Abrasion Resistance of Materials by Abrasive

1

Loop Contact

This standard is issued under the fixed designation G174; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers ranking rigid engineering materials for abrasion resistance in rubbing against aluminum oxide abrasive

finishing tape. Though most solids can be tested, this test method addresses its use for metals, and coatings applied to metals.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

E177 Practice for Use of the Terms Precision and Bias in ASTM Test Methods

E178 Practice for Dealing With Outlying Observations

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

G40 Terminology Relating to Wear and Erosion

G117 Guide for Calculating and Reporting Measures of Precision Using Data from Interlaboratory Wear or Erosion Tests

3

(Withdrawn 2016)

G132 Test Method for Pin Abrasion Testing

3. Terminology

3.1 Definitions:Definitions from Terminology G40:

3.1.1 abrasive wear, n—wear due to hard particles or hard protuberances forced against, and moving along, a solid surface.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 abrasion, n—the process of abrasive wear.

1

This test method is under the jurisdiction of ASTM Committee G02 on Wear and Erosion and is the direct responsibility of Subcommittee G02.30 on Abrasive Wear.

Current edition approved July 15, 2017Nov. 1, 2022. Published August 2017December 2022. Originally approved in 2003. Last previous edition approved in 20092017

ɛ1

as G174 – 04 (2009)(2017). . DOI: 10.1520/G0174-04R17.10.1520/G0174-22.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’sstandard’s Document Summary page on the ASTM website.

3

The last approved version of this historical standard is referenced on www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

G174 − 22

3.2.1.1 Discussion—

Terminology G40 does not define abrasion.

3.2.1 abrasion resistance, n—in tribology, the ability of a material to resist damage or attrition by abrasion.

3.2.2 fixed abrasive tape, n—hard particles or grains bonded (fixed) to one side of a flexible web with a resin or similar binder.

The particles can be of any hard material and vary in size. (This abrasive medium is also known as “finishing tape,” “microfinishing

tape,” “microfinishing film,” or “finishing film.”)

3.2.3 flexible web, n—plastic, paper, rubber, or other material that is thin enough to conform to a 180° wrap around a 16-mm16 mm

diameter cylinder under a tension of less than 1.8 kg ⁄cm width.

3.2.4 pass, n—abrasion distance equivalent to one circumference of the abrading loop.

4. Summary of Test Method

4.1 This test involves rubbing an abrasive tape loop initially in line-contact with a solid surface. The tape abrasion produces a

groove in the test surface, and the volume of material removed in a designated amount of abrasive rubbing is measured by mass

loss or by calculation from the groove geometry. The continuous loop of abrasive is used for the duration of the test a specified

number of passes and then discarded. A fresh loop is used for each one-hour test.

4.2 The wear volume produced in this test provides a measure o

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.