ASTM D4625-14

(Test Method)Standard Test Method for Middle Distillate Fuel Storage Stability at 43 °C (110 °F)

Standard Test Method for Middle Distillate Fuel Storage Stability at 43 °C (110 °F)

SIGNIFICANCE AND USE

5.1 Fuel oxidation and other degradative reactions leading to formation of sediment (and color) are mildly accelerated by the test conditions compared with typical storage conditions. Test results have been shown to predict storage stability more reliably than other more accelerated tests. See Appendix X1 for information on the correlation of test results with actual field storage.

5.2 Because the storage periods are long (4 weeks to 24 weeks), the test method is not suitable for quality control testing, but does provide a tool for research on storage properties of fuels.

5.3 Because environmental effects and the materials and nature of tank construction affect storage stability, the results obtained by this test are not necessarily the same as those obtained during storage in a specific field storage situation.

SCOPE

1.1 This test method covers a method for evaluating the inherent storage stability of distillate fuels having flash points above 38 °C (100 °F), by Test Methods D93, and 90 % distilled points below 340 °C (644 °F), by Test Method D86.

Note 1: ASTM specification fuels falling within the scope of this test method are Specification D396, Grade Nos. 1 and 2; Specification D975, Grades 1-D and 2-D; and Specification D2880, Grades 1-GT and 2-GT.

1.2 This test method is not suitable for quality control testing but, rather it is intended for research use to shorten storage time relative to that required at ambient storage temperatures.

1.3 Appendix X1 presents additional information about storage stability and the correlation of Test Method D4625 results with sediment formation in actual field storage.

1.4 The values given in SI units are to be regarded as the standard. The values in parentheses are for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D4625 − 14

Designation: 378/87

Standard Test Method for

1

Middle Distillate Fuel Storage Stability at 43 °C (110 °F)

This standard is issued under the fixed designation D4625; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* D381 Test Method for Gum Content in Fuels by Jet Evapo-

ration

1.1 This test method covers a method for evaluating the

D396 Specification for Fuel Oils

inherent storage stability of distillate fuels having flash points

D975 Specification for Diesel Fuel Oils

above38 °C(100 °F),byTestMethodsD93,and90 %distilled

D1193 Specification for Reagent Water

points below 340 °C (644 °F), by Test Method D86.

D2880 Specification for Gas Turbine Fuel Oils

NOTE 1—ASTM specification fuels falling within the scope of this test

D4057 Practice for Manual Sampling of Petroleum and

method are Specification D396, Grade Nos. 1 and 2; Specification D975,

Petroleum Products

Grades 1-D and 2-D; and Specification D2880, Grades 1-GT and 2-GT.

D4177 Practice for Automatic Sampling of Petroleum and

1.2 This test method is not suitable for quality control

Petroleum Products

testing but, rather it is intended for research use to shorten

3. Terminology

storage time relative to that required at ambient storage

temperatures.

3.1 Definitions of Terms Specific to This Standard:

3.1.1 adherent insolubles, n—gums formed during storage

1.3 Appendix X1 presents additional information about

that remain tightly attached to the walls of the vessel after fuel

storage stability and the correlation of Test Method D4625

has been flushed from the container.

results with sediment formation in actual field storage.

3.1.2 filterable insolubles, n—solids formed during storage

1.4 The values given in SI units are to be regarded as the

that can be removed from the fuel by filtration.

standard. The values in parentheses are for information only.

3.1.3 inherent storage stability, n—of middle distillate

1.5 This standard does not purport to address all of the

fuel—the resistance of the fuel to change during storage in

safety concerns, if any, associated with its use. It is the

contact with air, but in the absence of other environmental

responsibility of the user of this standard to establish appro-

factors such as water, or reactive metals and dirt.

priate safety and health practices and determine the applica-

3.1.4 total insolubles, n—thearithmeticsumofthefilterable

bility of regulatory limitations prior to use.

insolubles plus the adherent insolubles.

2. Referenced Documents

4. Summary of Test Method

2

2.1 ASTM Standards:

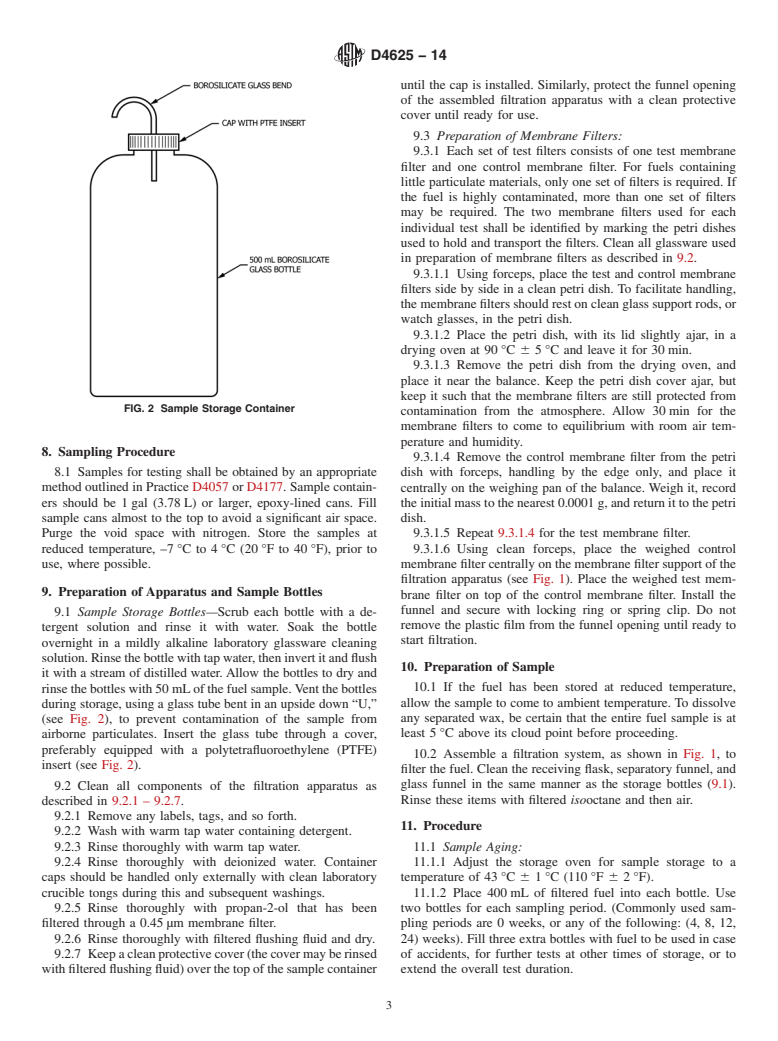

4.1 Four-hundred millilitre volumes of filtered fuel are aged

D86 Test Method for Distillation of Petroleum Products at

by storage in borosilicate glass containers at 43 °C (110 °F) for

Atmospheric Pressure

periods of (0, 4, 8, 12, 18, 24) weeks.After aging for a selected

D93 Test Methods for Flash Point by Pensky-Martens

time period, a sample is removed from storage, cooled to room

Closed Cup Tester

temperature, and analyzed for filterable insolubles and for

adherent insolubles.

1

This test method is under the jurisdiction of ASTM Committee D02 on

5. Significance and Use

Petroleum Products, Liquid Fuels, and Lubricantsand is the direct responsibility of

Subcommittee D02.14 on Stability and Cleanliness of Liquid Fuels.

5.1 Fuel oxidation and other degradative reactions leading

Current edition approved Dec. 1, 2014. Published March 2015. Originally

to formation of sediment (and color) are mildly accelerated by

approved in 1986. Last previous edition approved in 2009 as D4625 – 04 (2009).

the test conditions compared with typical storage conditions.

This test method was adopted as a joint ASTM/IP standard in 1986. DOI:

10.1520/D4625-14.

Test results have been shown to predict storage stability more

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

reliablythanothermoreacceleratedtests.SeeAppendixX1for

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

information on the correlation of test results with actual field

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. storage.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D4625 − 14

FIG. 1 Schematic of Filtration System

5.2 Because the storage periods are long (4 weeks to vacuum of up to 100 kPa be

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D4625 − 04 (Reapproved 2009) D4625 − 14

Designation: 378/87

Standard Test Method for

Middle Distillate Fuel Storage Stability at 43°C (110°F)43 °C

1

(110 °F)

This standard is issued under the fixed designation D4625; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope Scope*

1.1 This test method covers a method for evaluating the inherent storage stability of distillate fuels having flash points above

38°C (100°F),38 °C (100 °F), by Test Methods D93, and 90 % distilled points below 340°C (644°F),340 °C (644 °F), by Test

Method D86.

NOTE 1—ASTM specification fuels falling within the scope of this test method are Specification D396, Grade Nos. 1 and 2; Specification D975, Grades

1-D and 2-D; and Specification D2880, Grades 1-GT and 2-GT.

1.2 This test method is not suitable for quality control testing but, rather it is intended for research use to shorten storage time

relative to that required at ambient storage temperatures.

1.3 Appendix X1 presents additional information about storage stability and the correlation of Test Method D4625 results with

sediment formation in actual field storage.

1.4 The values given in SI units are to be regarded as the standard. The values in parentheses are for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D86 Test Method for Distillation of Petroleum Products at Atmospheric Pressure

D93 Test Methods for Flash Point by Pensky-Martens Closed Cup Tester

D381 Test Method for Gum Content in Fuels by Jet Evaporation

D396 Specification for Fuel Oils

D975 Specification for Diesel Fuel Oils

D1193 Specification for Reagent Water

D2880 Specification for Gas Turbine Fuel Oils

D4057 Practice for Manual Sampling of Petroleum and Petroleum Products

D4177 Practice for Automatic Sampling of Petroleum and Petroleum Products

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 adherent insolubles, n—gums formed during storage that remain tightly attached to the walls of the vessel.vessel after fuel

has been flushed from the container.

1

This test method is under the jurisdiction of ASTM Committee D02 on Petroleum Products Products, Liquid Fuels, and Lubricantsand is the direct responsibility of

Subcommittee D02.14 on Stability and Cleanliness of Liquid Fuels.

Current edition approved June 1, 2009Dec. 1, 2014. Published August 2009March 2015. Originally approved in 1986. Last previous edition approved in 20042009 as

D4625D4625 – 04 (2009).–04.

This test method was adopted as a joint ASTM/IP standard in 1986. DOI: 10.1520/D4625-04R09.10.1520/D4625-14.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D4625 − 14

FIG. 1 Schematic of Filtration System

3.1.2 filterable insolubles, n—solids formed during storage that can be removed from the fuel by filtration.

3.1.3 inherent storage stability, n—of middle distillate fuel—the resistance of the fuel to change induring storage in contact with

air, but in the absence of other environmental factors such as water, or reactive metallic surfaces metals and dirt.

3.1.4 total insolubles, n—the arithmetic sum of the filterable insolubles plus the adherent insolubles.

4. Summary of Test Method

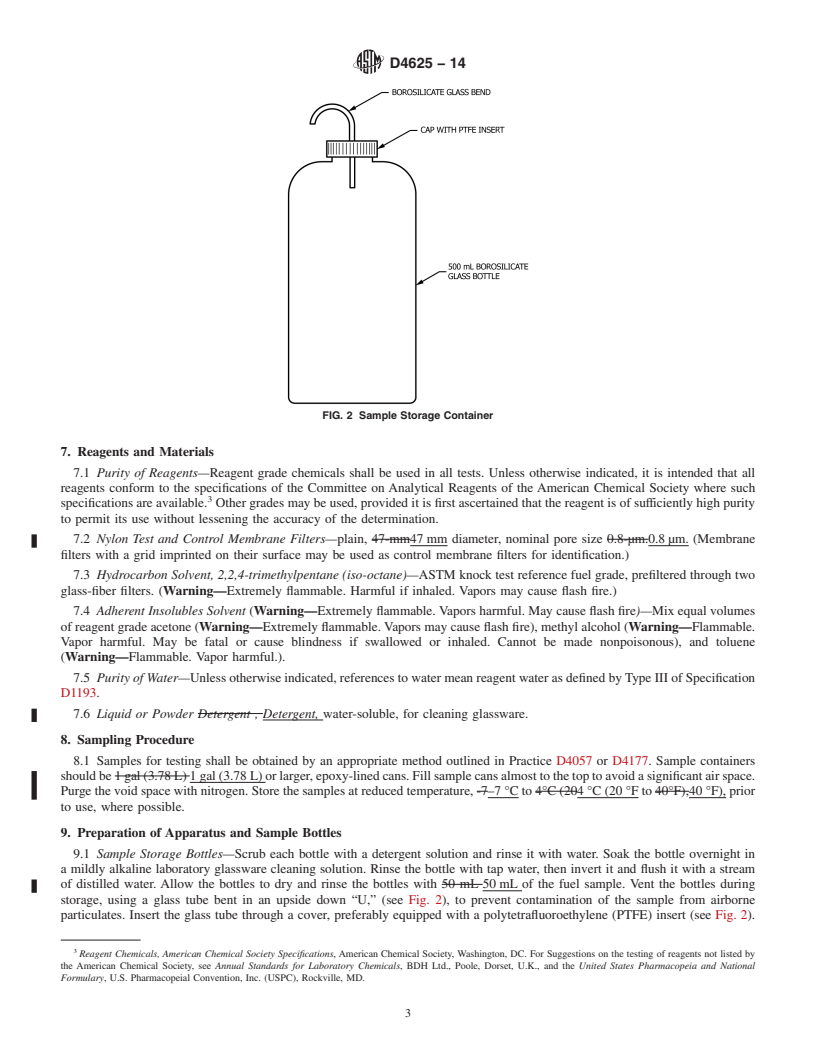

4.1 Four-hundred millilitre volumes of filtered fuel are aged by storage in borosilicate glass containers at 43°C (110°F)43 °C

(110 °F) for periods of 0,(0, 4, 8, 12, 18, and 24 24) weeks. After aging for a selected time period, a sample is removed from

storage, cooled to room temperature, and analyzed for filterable insolubles and for adherent insolubles.

5.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.