ASTM D2162-99(2004)

(Test Method)Standard Test Method for Basic Calibration of Master Viscometers and Viscosity Oil Standards

Standard Test Method for Basic Calibration of Master Viscometers and Viscosity Oil Standards

SCOPE

1.1 This test method covers the calibration of master viscometers and viscosity oil standards, both of which may be used to calibrate routine viscometers as described in Test Method D 445 and Specifications D 446 over the temperature range from 15 to 100°C.

1.2 The calibration constants in mm2/s 2 are to be regarded as the standard. The kinematic viscosities in mm2/s are to be regarded as the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific warning statements, see Section 7.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation:D2162–99 (Reapproved 2004)

Standard Test Method for

Basic Calibration of Master Viscometers and Viscosity Oil

1

Standards

This standard is issued under the fixed designation D2162; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

4

1. Scope 2.2 ISO Standard:

ISO 3666 Viscosity of Water

1.1 This test method covers the calibration of master vis-

cometers and viscosity oil standards, both of which may be

3. Terminology

used to calibrate routine viscometers as described in Test

3.1 Definitions of Terms Specific to This Standard:

Method D445 and Specifications D446 over the temperature

3.1.1 basic calibration, n—calibrationbasedontheprimary

range from 15 to 100°C.

2 2 standard, water.

1.2 The calibration constants in mm /s are to be regarded

2

3.1.1.1 Discussion—Purewaterhasakinematicviscosityof

as the standard. The kinematic viscosities in mm /s are to be

2

1.0034 mm /s (cSt) at 20°C. See ISO 3666.

regarded as the standard.

3.1.2 master viscometer, n—glasscapillaryviscometerwith

1.3 This standard does not purport to address all of the

a liquid driving head of at least 400mm.

safety concerns, if any, associated with its use. It is the

3.1.2.1 Discussion—It is specially designed to minimize

responsibility of the user of this standard to establish appro-

errors due to surface tension, kinetic energy, and capillary end

priate safety and health practices and determine the applica-

effects.

bility of regulatory limitations prior to use. For specific

3.1.3 viscosity oil standard, n—stableNewtonianliquid,the

warning statements, see Section 7.

kinematic viscosity of which has been related to the kinematic

2. Referenced Documents viscosity of water through the step-up procedure described in

2

this test method.

2.1 ASTM Standards:

D445 Test Method for Kinematic Viscosity of Transparent

4. Summary of Test Method

and Opaque Liquids (and the Calculation of Dynamic

4.1 Two or more master viscometers, having calibration

Viscosity)

2 2

constants in the 0.001 to 0.003-mm /s (cSt/s) range, are

D446 Specifications and Operating Instructions for Glass

calibratedwithwaterat20°C.Thekinematicviscositiesoftwo

Capillary Kinematic Viscometers

ormoreoilstandardsaremeasuredat40°Cinthesetwomaster

D1193 Specification for Reagent Water

viscometers. Corrections are made for buoyancy and, where

D1250 Guide for Use of the Petroleum Measurement

necessary, for temperature and surface tension.

Tables

4.2 Athirdmasterviscometer,withacalibrationconstantof

D1480 Test Method for Density and Relative Density

2 2

0.003 to 0.009 mm /s (cSt/s), is then calibrated at 40°C with

(Specific Gravity) of Viscous Materials by Bingham Pyc-

the two standard oils and its calibration factor calculated at

nometer

standard conditions for water at 20°C. In like manner addi-

D1590 Test Methods for Surface Tension of Water and

3 tionalviscosityoilstandardsandadditionalmasterviscometers

Waste Water

are calibrated at 40°C using the average results from at least

E1 Specification forASTM Liquid-in-GlassThermometers

two master viscometers or two oil standards. Steps between

successive calibration constants or viscosities increase by a

factor of three or less until the desired viscosity range is

1

This test method is under the jurisdiction of ASTM Committee D02 on

covered.

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

D02.07 on Flow Properties.

4.3 Oils are calibrated at other temperatures using the

Current edition approved May 1, 2004. Published June 2004. Originally

average result from at least two master viscometers.

e1

approved in 1963. Last previous edition approved in 1999 as D2162–99 .

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

4

the ASTM website. Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

3

Withdrawn. 4th Floor, New York, NY 10036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D2162–99 (2004)

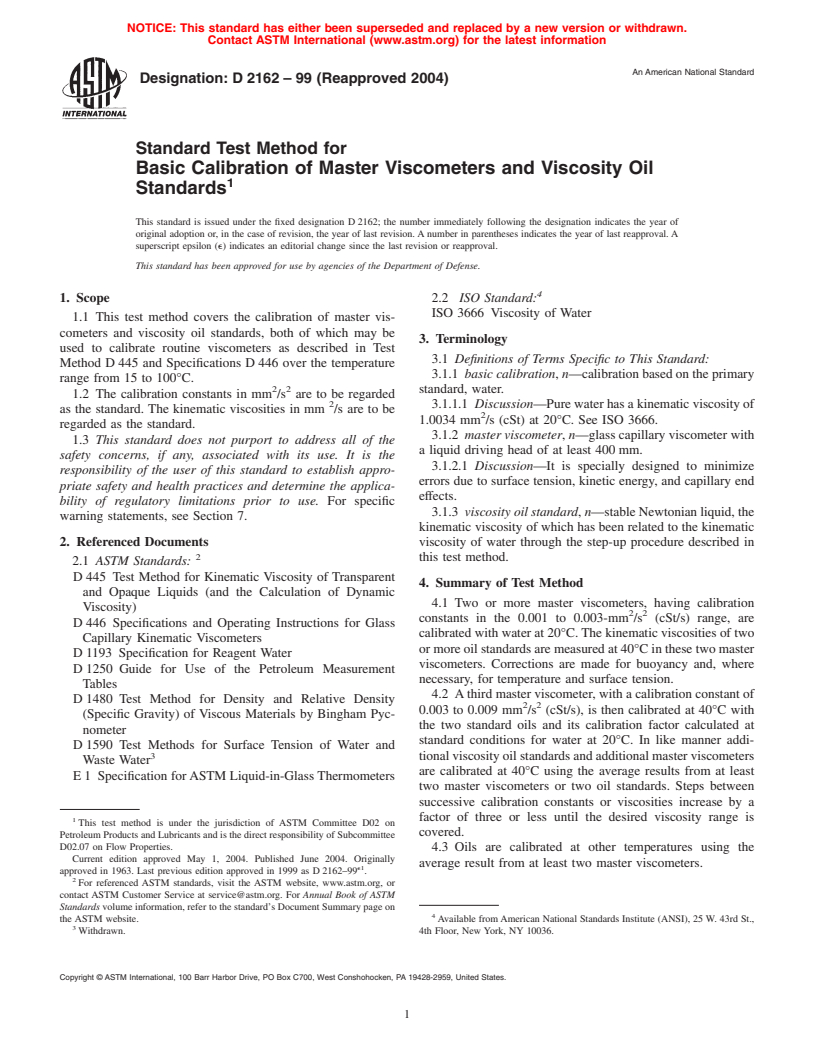

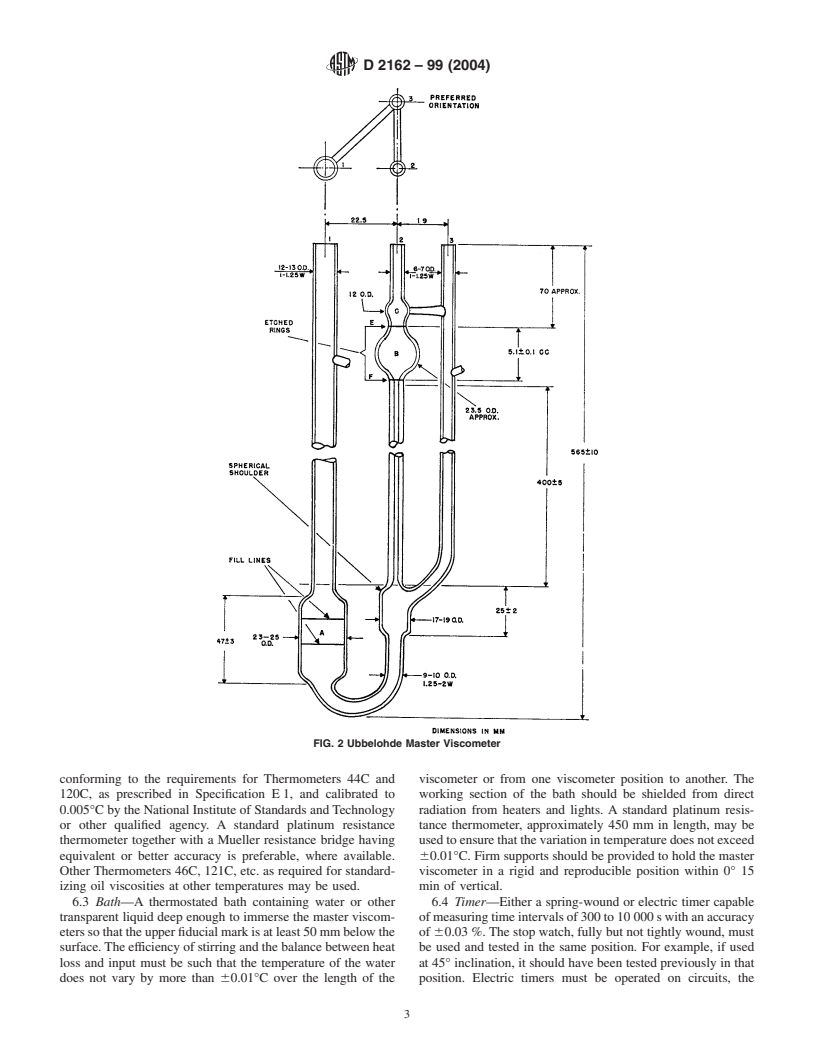

FIG. 1 Cannon Master Viscometer

5. Significance and Use 6. Apparatus

5 6

5.1 Because there are surface tension or kinematic viscosity 6.1 Master Viscometers: Cannon or Ubbelohde Type—

differences, or both, between the primary standard (7.4) and Acceptable viscometers are shown in Fig. 1

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.