ASTM D7833-12

(Test Method)Standard Test Method for Determination of Hydrocarbons and Non-Hydrocarbon Gases in Gaseous Mixtures by Gas Chromatography

Standard Test Method for Determination of Hydrocarbons and Non-Hydrocarbon Gases in Gaseous Mixtures by Gas Chromatography

SIGNIFICANCE AND USE

5.1 The hydrocarbon component distribution of gaseous mixtures is often required for end-use sale of this material. Applications such as chemical feedstock or fuel require precise compositional data to ensure uniform quality. Trace amounts of some hydrocarbon impurities in these materials can have adverse effects on their use and processing. Certain regulations may require use of such method.

5.2 The component distribution data of gaseous mixtures can be used to calculate physical properties such as relative density, vapor pressure, and heating value calculations found in Practice D3588. Precision and accuracy of compositional data is extremely important when this data is used to calculate various properties of petroleum products.

SCOPE

1.1 This test method is intended to quantitatively determine the non-condensed hydrocarbon gases with carbon numbers from C1 to C5+ and non-hydrocarbon gases, such as H2, CO2, O2, N2, and CO, in gaseous samples. This test method is a companion standard test method to Test Method D1945 and Practice D1946 differing in that it incorporates use of capillary columns instead of packed columns and allows other technological differences.

1.2 Hydrogen sulfide can be detected but may not be accurately determined by this procedure due to loss in sample containers or sample lines and possible reactions unless special precautions are taken.

1.3 Non-hydrocarbon gases have a lower detection limit in the concentration range of 0.03 to 100 mole percent using a thermal conductivity detector (TCD) and C1 to C6 hydrocarbons have a lower detection limit in the range of 0.005 to 100 mole percent using a flame ionization detector (FID); using a TCD may increase the lower detection limit to approximately 0.03 mole percent.

1.3.1 Hydrocarbon detection limits can be reduced with the use of pre-concentration techniques and/or cryogenic trapping.

1.4 This test method does not fully determine individual hydrocarbons heavier than benzene, which are grouped together as C7+ When detailed analysis is not required the compounds with carbon number greater than C5 may be grouped as either C6+, or C7+. Accurate analysis of C5+ components depends on proper vaporization of these compounds during sampling at process unit sources as well as in the sample introduction into the analyzer in the laboratory.

1.5 Water vapor may interfere with the C6+ analysis if a TCD detector is used.

1.6 Helium and argon may interfere with the determination of hydrogen and oxygen respectively. Depending on the analyzer used, pentenes, if present, may either be separated or grouped with the C6+ components.

1.7 The values stated in SI units are to be regarded as standard.

1.8 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7833 − 12

StandardTest Method for

Determination of Hydrocarbons and Non-Hydrocarbon

Gases in Gaseous Mixtures by Gas Chromatography

This standard is issued under the fixed designation D7833; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope analyzer used, pentenes, if present, may either be separated or

grouped with the C + components.

1.1 This test method is intended to quantitatively determine

the non-condensed hydrocarbon gases with carbon numbers 1.7 The values stated in SI units are to be regarded as

from C to C + and non-hydrocarbon gases, such as H,CO , standard.

1 5 2 2

O,N , and CO, in gaseous samples. This test method is a

2 2 1.8 This standard does not purport to address all of the

companion standard test method to Test Method D1945 and

safety concerns, if any, associated with its use. It is the

Practice D1946 differing in that it incorporates use of capillary

responsibility of the user of this standard to establish appro-

columns instead of packed columns and allows other techno-

priate safety and health practices and determine the applica-

logical differences.

bility of regulatory limitations prior to use.

1.2 Hydrogen sulfide can be detected but may not be

2. Referenced Documents

accurately determined by this procedure due to loss in sample

containersorsamplelinesandpossiblereactionsunlessspecial

2.1 ASTM Standards:

precautions are taken.

D1945Test Method for Analysis of Natural Gas by Gas

Chromatography

1.3 Non-hydrocarbon gases have a lower detection limit in

D1946Practice for Analysis of Reformed Gas by Gas

the concentration range of 0.03 to 100 mole percent using a

Chromatography

thermal conductivity detector (TCD) and C to C hydrocar-

1 6

D3588Practice for Calculating Heat Value, Compressibility

bons have a lower detection limit in the range of 0.005 to 100

Factor, and Relative Density of Gaseous Fuels

mole percent using a flame ionization detector (FID); using a

E355PracticeforGasChromatographyTermsandRelation-

TCD may increase the lower detection limit to approximately

ships

0.03 mole percent.

E1510Practice for Installing Fused Silica Open Tubular

1.3.1 Hydrocarbon detection limits can be reduced with the

Capillary Columns in Gas Chromatographs

use of pre-concentration techniques and/or cryogenic trapping.

F307Practice for Sampling Pressurized Gas for GasAnaly-

1.4 This test method does not fully determine individual

sis

hydrocarbons heavier than benzene, which are grouped to-

2.2 ASTM Publication:

gether as C + When detailed analysis is not required the

ASTMDS4B,1991PhysicalConstantsofHydrocarbonand

compounds with carbon number greater than C may be

Non-Hydrocarbon Compounds

grouped as either C +, or C +. Accurate analysis of C +

6 7 5

components depends on proper vaporization of these com-

3. Terminology

pounds during sampling at process unit sources as well as in

the sample introduction into the analyzer in the laboratory.

3.1 Terminology related to the practice of gas chromatog-

raphy can be found in Practice E355.

1.5 Water vapor may interfere with the C + analysis if a

TCD detector is used.

3.2 Definitions:

3.2.1 sample set—a collection of samples taken from the

1.6 Helium and argon may interfere with the determination

same source or at similar component composition and concen-

of hydrogen and oxygen respectively. Depending on the

trations.

ThistestmethodisunderthejurisdictionofASTMCommitteeD03onGaseous

Fuels and is the direct responsibility of Subcommittee D03.07 on Analysis of For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Chemical Composition of Gaseous Fuels. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Current edition approved Nov. 1, 2012. Published December 2012. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/D7833-12. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7833 − 12

TABLE 1 List of Components Typically Analyzed (Hydrocarbons)

4. Summary of Test Method

Component FID TCD

4.1 Components in a representative sample are physically

C olefin / C + composite X X

5 6

separated by gas chromatography (GC) and compared to

oxygen/argon composite X

calibration data obtained under identical operating conditions

hydrogen X

carbon dioxide X

from a reference standard mixture of known composition. The

hydrogen sulfide X

numerous heavy-end components of a sample can be grouped

nitrogen X

intoirregularpeaksbyreversingthedirectionofthecarriergas

carbon monoxide X

methane X X

through the column at such time as to group the heavy ends

ethane X X

either as C and heavier, C and heavier, or C and heavier or

5 6 7

ethylene X X

alternatively elute them in the non-backflushed mode and

propane X X

propylene X X

summed accordingly. The composition of the sample is calcu-

acetylene X X

lated by comparing the peak areas with the corresponding

isobutane X X

values obtained with the reference standard. propadiene X X

n-butane X X

trans-2-butene X X

5. Significance and Use

1-butene X X

isobutylene X X

5.1 The hydrocarbon component distribution of gaseous

cis-2-butene X X

mixtures is often required for end-use sale of this material.

neopentane X X

cyclopentane X X

Applicationssuchaschemicalfeedstockorfuelrequireprecise

isopentane X X

compositionaldatatoensureuniformquality.Traceamountsof

methyl acetylene X X

some hydrocarbon impurities in these materials can have

n-pentane X X

1,3-butadiene X X

adverseeffectsontheiruseandprocessing.Certainregulations

may require use of such method.

5.2 The component distribution data of gaseous mixtures

can be used to calculate physical properties such as relative

6.1.3 Other detectors or combination of detectors may be

density,vaporpressure,andheatingvaluecalculationsfoundin

used provided that they have sufficient response, linearity, and

Practice D3588. Precision and accuracy of compositional data

sensitivity to measure the components of interest at the

is extremely important when this data is used to calculate

concentration levels required for this application and meeting

various properties of petroleum products.

all of the quality controls specified in this method. Some

analyzers, such as micro-analyzers, may contain up to

6. Apparatus

4-channels and separation systems to accomplish the analysis

6.1 Gas Chromatograph (GC)—This method allows the use

described in this method.

of most gas chromatographic analyzers designed for gas

6.2 Data Acquisition—Any commercial computerized data

analysis. Generally, any gas chromatographic instrument with

acquisition system may be used for display of the chromato-

a linear temperature programmable column oven or adequate

graphicdetectorsignalandpeakareaintegrationfromallofthe

temperature control to provide the required separation of

detectors used in the analysis.The device should be capable of

gaseous compounds being analyzed may be used. The tem-

generating and storing a calibration and reporting the final

perature control must be capable of obtaining retention time

corrected response factor results.

repeatability within 5% of the retention time for each compo-

nent throughout the scope of this analysis for hydrocarbon and

6.3 Sample Introduction and System Configurations—

non-hydrocarbon gas analyses.

Sample introduction is typically performed with automated

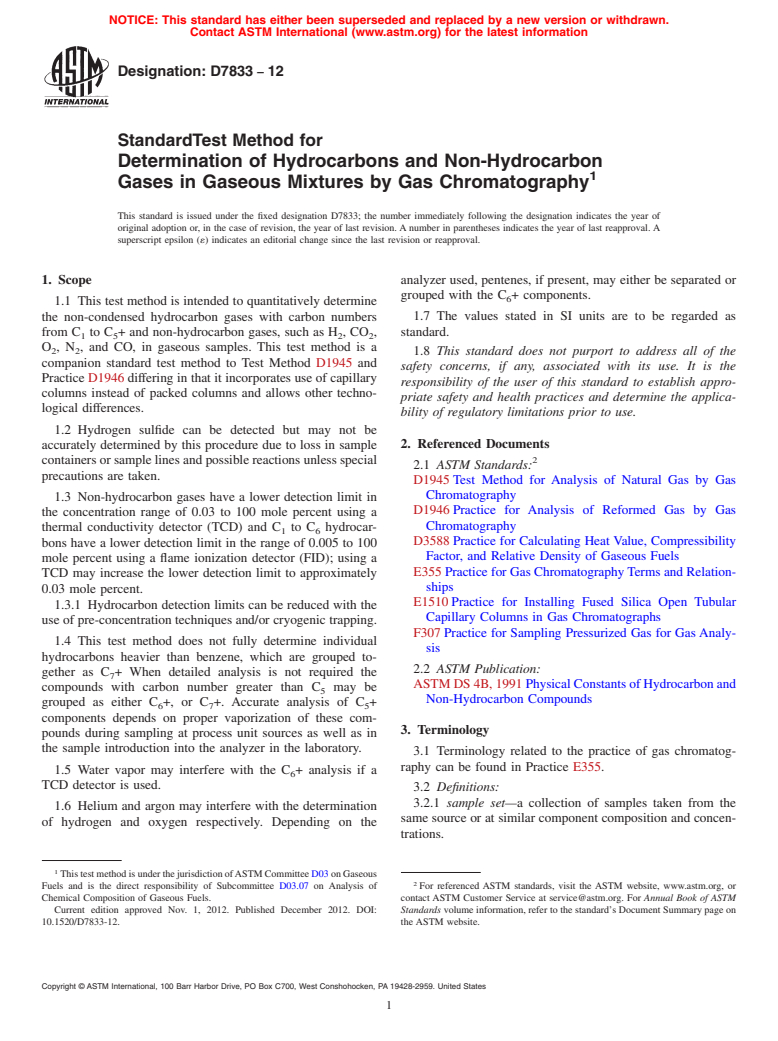

6.1.1 Detector—The type and number of detectors em- valves containing sampling ‘loops’of appropriate sizes. Fig. 1

ployed is dependent on gas analyzer model and vendor used.

gives a suggested configuration, although systems may vary

Detectors that can be used include, but are not limited to FID, slightly among gas analyzers. The combination of valve

TCD,AED (Atomic Emission Detector), HID (Helium Ioniza-

injection size and/or splitting inlet ratio must be selected such

tionDetector),andMS(MassSpectrometer).Manysystemsuse that the required sensitivity for the application is achieved and

a 3 detector system:

also that no component concentration in a sample is greater

(1)One FID (Flame Ionization Detector) for the determi- than the detector upper linearity limit.The sample inlet system

nation of the hydrocarbon gases for the compounds listed in

shall be constructed of materials that are inert and non-

Table 1, adsorptive with respect to the components in the sample. The

(2)One TCD (Thermal Conductivity Detector) dedicated

preferred material of construction is stainless steel. Copper,

to the determination of hydrogen utilizing nitrogen or argon as

brass, and other copper-bearing alloys are unacceptable. The

a carrier gas, and

sample size limitation of 0.5 mLor smaller is selected relative

(3)One TCD for the determination of all other required

to the linearity of the detector response, and efficiency of

non-hydrocarbon gases using helium as the carrier gas.

column separation. Larger samples may be used to determine

6.1.2 A TCD may also be used for the analysis of the low-quantity components to increase measurement accuracy.

hydrocarbongases(replacingtheFID)whenhighsensitivity(< Sample sizes may be determined by experimentation or as

0.03 mole percent) for trace analysis is not required. recommended by analyzer vendors.

D7833 − 12

FIG. 1 Example of a Three Detector System for Analysis of Hydrocarbons and Non-Hydrocarbon Gases

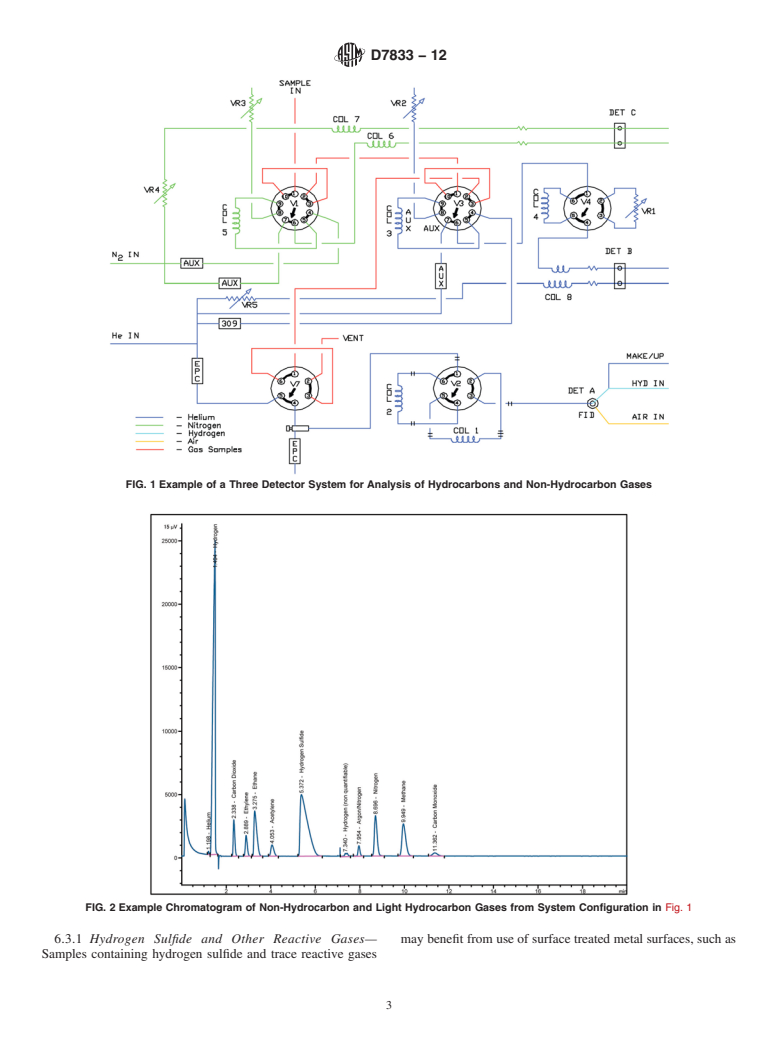

FIG. 2 Example Chromatogram of Non-Hydrocarbon and Light Hydrocarbon Gases from System Configuration in Fig. 1

6.3.1 Hydrogen Sulfide and Other Reactive Gases— may benefit from use of surface treated metal surfaces, such as

Samples containing hydrogen sulfide and trace reactive gases

D7833 − 12

NOTE 1—For the hydrocarbon analysis, the Al O PLOT was used.

2 3

FIG. 3 Example Chromatogram of Hydrocarbons from System Configuration in Fig. 1

3 4

Silcosteel or Sulfinert processes. Such specially treated carrier gas is used to ensure that the hydrogen ‘peak’remains

surfaces are also recommended for sample containers that may positive over the concentration range of interest. Any column

contain such reactive species.

or multiple columns may be used, as long as helium and

6.3.2 With Capillary Columns—The gas chromatograph hydrogen are separated and also separated from the other

must include a heated splitting type inlet that is operated

components. Typically, a dedicated TCD is used for this

isothermally, or if appropriate, direct connection to the valve analysis. The gas-sampling valve shall provide a repeatability

may be possible as long as sample sizes are adjusted

ofatleast 62%relativetothesamplevolumeintroductionfor

accordingly, the calibrations are linear in the range of interest, major compounds present at >5 vol%.

and the required resolution of the compounds of interest is

NOTE 1—When helium is not expected to be present in samples the

maintained. When using a split injection, split ratios in the resolution of hydrogen from helium is not critical.

range of 5:1 to 200:1, with a typical value of 100:1, have been

6.5 Non-Hydrocarbon and Light Hydrocarbon GasAnalysis

usedsuccessfullydependinguponthesampleinjectionvolume

(Except Hydrogen) (Thermal Conductivity Detector)—A 10-

and sensitivity required.

portgassamplingvalveincombinationwitha6-portswitching

6.3.3 With Pre-concentrator and/or Cryogenic Trapping—

valve or equivalent is used with helium or hydrogen carrier to

Pre-concentratorand/orcryogenictrappingcanbeusedpriorto

analyze for CO,O,N , CH4, C H , and CO and in some

2 2 2 2 6

sample introduction into the gas chromatograph. These items

cases H S. Any column or multiple columns may be used as

may enable lower detection limits on the components detailed

longasthedesiredcomponentsarewellseparated.ATCDmay

by the manufacturer to be concentrated.

also be used for the analysis of the hydrocarbon gases

6.4 Hydrogen Gas Analysis (Thermal Conductivity

(replacingtheFID)whenhighsensitivity(<300ppm)fortrace

Detector)—A10-portgas-samplingvalveorequivalentmaybe

analysis is not required. The gas-sampling valve shall provide

used with nitrogen or argon carrier gas. Nitrogen or argon

a repeatability of at least 6 2% relative to the sample volume

introduction for major compounds present at >5 vol%.

Silcosteel is a trademarked of SilcoTek, 112 Benner Circle, Bellefonte, PA

6.6 Hydrocarbon Gas Analysis (Flame Ionization

16823.

Detector)—A6-port gas-sampling valve in combination with a

SulfinertisatrademarkedofRestekCorporation110BennerCircleBellefonte,

PA 16823. 6-port pre-column switching valve (backflush) for the C+or

D7833 − 12

C + hydrocarbons is typically used. These valves shall be pre-column that provides separation between the components

contained in a heated enclosure and operated at a sufficiently ofinterestandthecompositeheaviercomponentsmaybeused.

high temperature, and within the limits of the valve operating Choices may include lengths of column such as a 10 to 30 m

temperature as specified by manufacturer, to prevent conden- section of 0.53 mm (I.D.) 3-µm film thickness dimethyl

sation of the C + components in the sample. The use of a frit polysiloxane ora9to15cm section of the same column

or packed-screen type filter ahead of the sample introduction material as the analytical column or any pre-column that

port is recommended with use of PLOT columns. The gas- provides the desired retention of pentenes, hexanes, and

sampling valve shall provide a repeatability of at least 6 2% heavier components. This pre-column acts to keep the heavier

relative to the sample volume introduction for major com- components away from the analytical alumina PLOT column

pounds present at >5 vol%. and to backflush the heavier components as a composite peak

to the detector for quantification. If analysis of individual

6.7 Column Series/Reversal Switching Valve—If desired, a

C -C componentsisrequired,extendthebackflushvalvetime

6 7

multi-port valve may be used to provide the C olefin/C+or

5 6

until the desired components have eluted and prior to back-

C + determination for this analysis. Other switching valve

flushing the remaining heavier compounds.

configurations may be used to allow the elution of the gaseous

compounds. Consult instrument manufacturer for optimum 6.12 Analytical Columns for Hydrogen Analysis—Generally

configuration.

hydrogen analysis consists of a pre-column to remove most of

NOTE 2—If a dimethylsilicone capillary column or

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.