ASTM D6966-03

(Practice)Standard Practice for Collection of Settled Dust Samples Using Wipe Sampling Methods for Subsequent Determination of Metals

Standard Practice for Collection of Settled Dust Samples Using Wipe Sampling Methods for Subsequent Determination of Metals

SIGNIFICANCE AND USE

This practice is intended for the collection of settled dust samples for the subsequent measurement of target metals. The practice is meant for use in the collection of settled dust samples that are of interest in clearance, hazard evaluation, risk assessment, and other purposes.

This practice is recommended for the collection of settled dust samples from hard, relatively smooth nonporous surfaces. This practice is less effective for collecting settled dust samples from surfaces with substantial texture such as rough concrete, brickwork, textured ceilings, and soft fibrous surfaces such as upholstery and carpeting. Collection efficiency for metals such as lead from smooth, hard surfaces has been found to exceed 75 % (E 1792).

SCOPE

1.1 This practice covers the collection of settled dust on surfaces using the wipe sampling method. These samples are collected in a manner that will permit subsequent extraction and determination of target metals in the wipes using laboratory analysis techniques such as atomic spectrometry.

1.2 This practice does not address the sampling design criteria (that is, sampling plan which includes the number and location of samples) that are used for clearance, hazard evaluation, risk assessment, and other purposes. To provide for valid conclusions, sufficient numbers of samples should be obtained as directed by a sampling plan.

1.3 This practice contains notes that are explanatory and are not part of the mandatory requirements of this practice.

1.4 The values stated in SI units are to be regarded as the standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D6966–03

Standard Practice for

Collection of Settled Dust Samples Using Wipe Sampling

Methods for Subsequent Determination of Metals

This standard is issued under the fixed designation D 6966; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.2 Definitions:

3.2.1 batch, n—a group of field or quality control (QC)

1.1 This practice covers the collection of settled dust on

samples that are collected or processed together at the same

surfaces using the wipe sampling method. These samples are

time using the same reagents and equipment.

collected in a manner that will permit subsequent extraction

3.2.2 sampling location, n—a specific area within a sam-

and determination of target metals in the wipes using labora-

pling site that is subjected to sample collection.

tory analysis techniques such as atomic spectrometry.

3.2.2.1 Discussion—Multiple sampling locations are com-

1.2 This practice does not address the sampling design

monly designated for a single sampling site (see 3.2.3).

criteria (that is, sampling plan which includes the number and

3.2.3 sampling site, n—alocalgeographicareathatcontains

location of samples) that are used for clearance, hazard

the sampling locations (see 3.2.2).

evaluation, risk assessment, and other purposes.To provide for

3.2.3.1 Discussion—A sampling site is generally limited to

valid conclusions, sufficient numbers of samples should be

an area that is easily covered by walking.

obtained as directed by a sampling plan.

3.2.4 wipe, n—a disposable towellette that is moistened

1.3 This practice contains notes that are explanatory and are

with a wetting agent. (E 1792)

not part of the mandatory requirements of this practice.

3.2.4.1 Discussion—These towellettes are used to collect

1.4 The values stated in SI units are to be regarded as the

samples of settled dust on surfaces for subsequent determina-

standard.

tion of metals content in the collected dust.

1.5 This standard does not purport to address all of the

3.3 Definitions of Terms Specific to This Standard:

safety concerns, if any, associated with its use. It is the

3.3.1 field blank, n—awipe(see3.2.4)thatisexposedtothe

responsibility of the user of this standard to establish appro-

same handling as field samples except that no sample is

priate safety and health practices and determine the applica-

collected (no surface is actually wiped).

bility of regulatory limitations prior to use.

3.3.1.1 Discussion—Analysis results from field blanks pro-

2. Referenced Documents vide information on the analyte background level in the wipe,

combined with the potential contamination experienced by

2.1 ASTM Standards:

samples collected within the batch (see 3.2.1) resulting from

D 1356 Terminology Relating to Sampling and Analysis of

handling.

Atmospheres

D 4840 Guide for Sample Chain-of-Custody Procedures

4. Summary of Practice

E 1792 Specification for Wipe Sampling Materials for Lead

4.1 Wipe samples of settled dust are collected on surfaces

in Surface Dust

from areas of known dimensions with wipes satisfying certain

3. Terminology

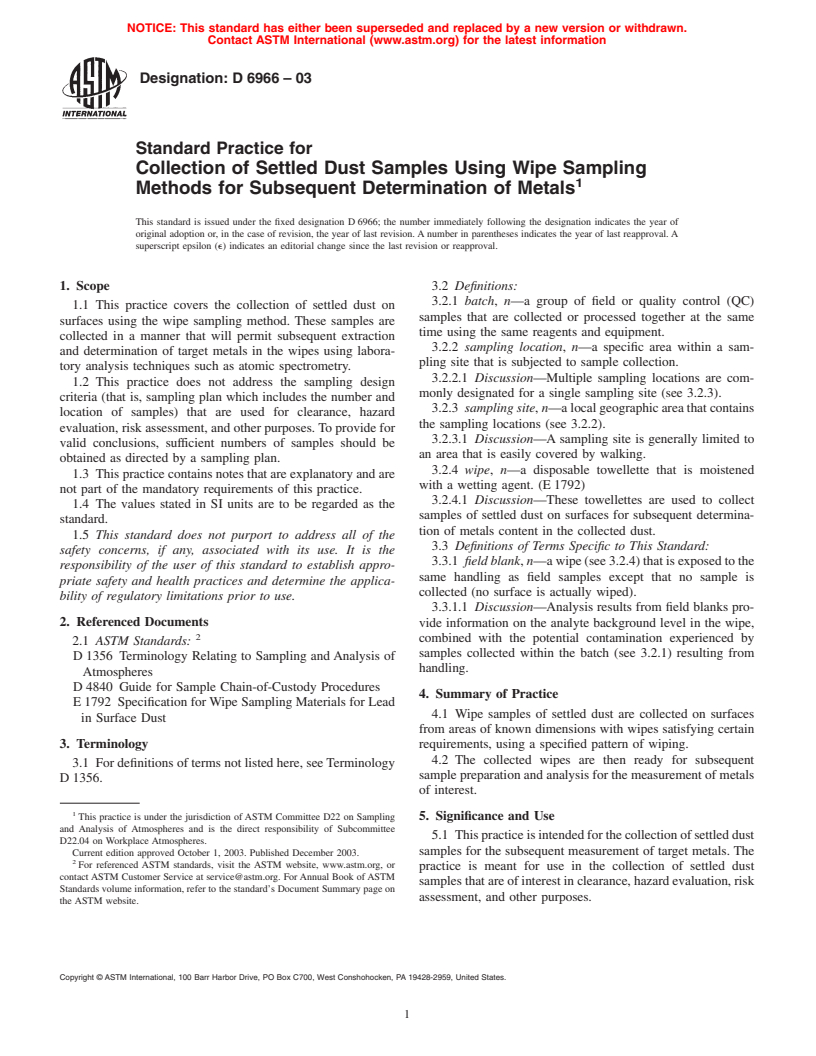

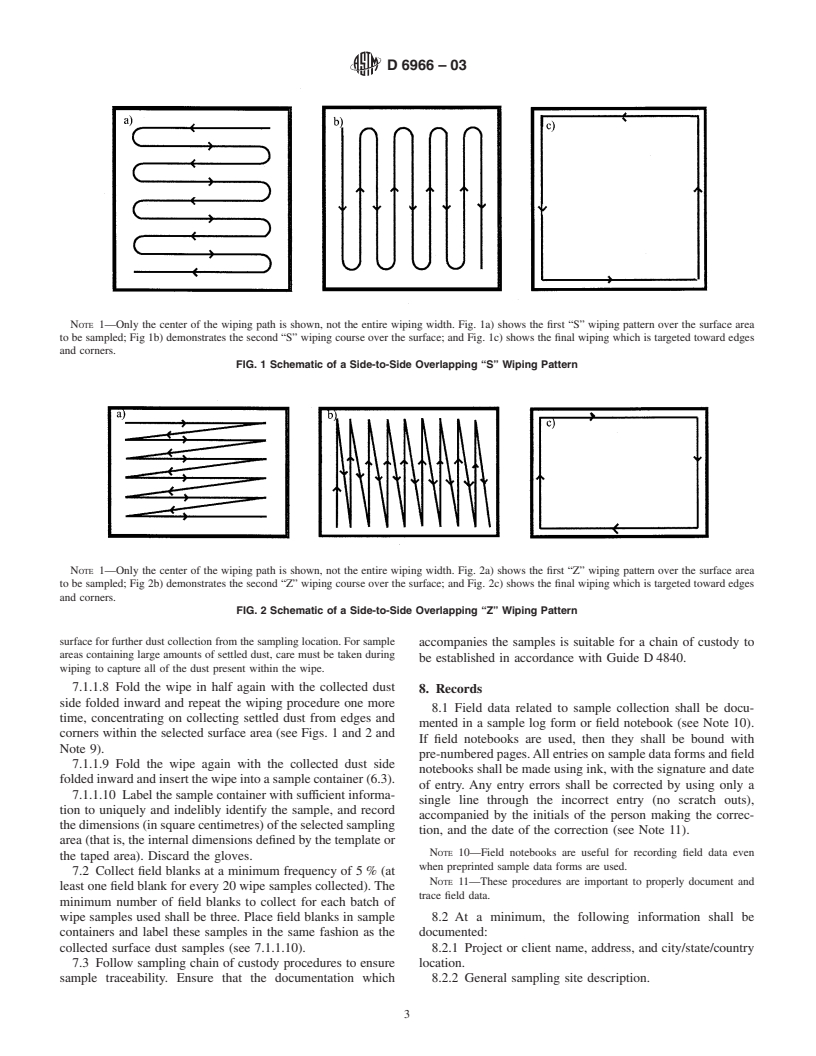

requirements, using a specified pattern of wiping.

4.2 The collected wipes are then ready for subsequent

3.1 For definitions of terms not listed here, seeTerminology

sample preparation and analysis for the measurement of metals

D 1356.

of interest.

This practice is under the jurisdiction of ASTM Committee D22 on Sampling 5. Significance and Use

and Analysis of Atmospheres and is the direct responsibility of Subcommittee

5.1 Thispracticeisintendedforthecollectionofsettleddust

D22.04 on Workplace Atmospheres.

samples for the subsequent measurement of target metals. The

Current edition approved October 1, 2003. Published December 2003.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

practice is meant for use in the collection of settled dust

contactASTM Customer Service at service@astm.org. ForAnnual Book ofASTM

samplesthatareofinterestinclearance,hazardevaluation,risk

Standards volume information, refer to the standard’s Document Summary page on

assessment, and other purposes.

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D6966–03

5.2 This practice is recommended for the collection of 7. Procedure

settled dust samples from hard, relatively smooth nonporous

7.1 Use one of the following two procedures for collecting

surfaces. This practice is less effective for collecting settled

settled dust samples from each sampling location. For wide,

dust samples from surfaces with substantial texture such as

flat locations, it is recommended to use the template-assisted

rough concrete, brickwork, textured ceilings, and soft fibrous

sampling procedure (see 7.1.1.2(a)). For small locations (for

surfacessuchasupholsteryandcarpeting.Collectionefficiency

example, window sill, section of a piece of equipment, or

for metals such as lead from smooth, hard surfaces has been

portion of a vehicle interior), it will ordinarily be necessary to

found to exceed 75 % (E 1792).

use the confined-area sampling procedure (see 7.1.1.2(b)).

NOTE 7—Metal contamination problems during field sampling can be

6. Apparatus and Materials

severe and may affect subsequent wipe sample analysis results. Contami-

6.1 Sampling Templates—One or more of the following: 10

nation can be minimized through frequent changing of gloves, use of shoe

cm by 10 cm (minimum dimensions) reusable or disposable covers (see 6.8), and regular cleaning of sampling equipment with

cleaning cloths (see 6.6). Use of disposable shoe covers between different

aluminum or plastic template(s), or disposable cardboard

locations, and removal of them prior to leaving the sampling site or

templates, (full-square, rectangular, square “U-shaped,” rect-

entering vehicles, can be helpful in minimizing inadvertent transfer of

angular “U-shaped,” or “L-shaped,” or both); or templates of

contaminated dust from one location to another.

alternative areas having accurately known dimensions (see

7.1.1 Sampling Procedure:

Note 1). Templates shall be capable of lying flat on a surface.

7.1.1.1 Don a pair of clean, powderless, plastic gloves (see

NOTE 1—For most surfaces, it is recommended to collect settled dust

6.5 and Note 7).

from a minimum surface area of 100 cm to provide sufficient material for

7.1.1.2 Use either a template-assisted sampling procedure

subsequentlaboratoryanalysis.However,largerareas(forexample,30cm

(a) or tape-defined sampling procedure (b):

by 30 cm) may be appropriate for surfaces having little or no visible

(a.) Carefully place a clean template on the surface to be

settled dust, while a smaller sampling area (for example, 10 cm by 10 cm)

may be appropriate for surfaces with high levels of visible settled dust. It sampled in a manner that minimizes disturbance of settled dust

is recommended to have a suite of templates with various sampling

at the sampling location. Tape the outside edge of the template

dimensions.

to prevent the template from moving during sample collection.

6.2 Wipes, for collection of settled dust samples from (b.) Alternatively, mark the defined area to be sampled with

surfaces.Wipesshallbeindividuallywrappedandfullywetted. adhesive tape (6.7) being careful not to disturb the settled dust,

Thebackgroundmetal(s)contentofthewipesshouldbeaslow and measure the area to be sampled using the measuring tool

as possible. At a maximum, the background level of target (6.4).

metal(s) shall be no more than one-tenth the target concentra- 7.1.1.3 Obtain a wipe (6.2) and, if there is a possibility for

tion the metal(s) to be measured. the package containing the wipe to be contaminated with dust,

clean the outside of the package with a cleaning cloth (6.6).

NOTE 2—Wipes meeting the requirements of Specification E 1792 may

7.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.