ASTM E2649-09

(Test Method)Standard Test Method for Determining Argon Concentration in Sealed Insulating Glass Units Using Spark Emission Spectroscopy

Standard Test Method for Determining Argon Concentration in Sealed Insulating Glass Units Using Spark Emission Spectroscopy

SIGNIFICANCE AND USE

This test method is intended to provide a means for determining the concentration of argon in sealed insulating glass units under controlled conditions in compliance with the apparatus manufacturer's instructions.

This is a non-destructive test method in that the edge seal of the test specimen is not breached in order to determine the argon gas concentration. However, damage to some glass coatings on the inner surfaces of the glass can occur.

This test method has been developed based on data collected in a controlled laboratory environment.

The device shall be used to determine the argon gas concentration in insulating glass units in a controlled laboratory environment. Refer to 12.3.

This test method may be used to determine the argon gas concentration before, during, or after the insulating glass unit is subjected to durability tests.

The accuracy of the test method is dependent upon the concentration of argon gas. As the argon gas level decreases the accuracy also decreases. When the concentration of argon is below 70 % this test method is not applicable.

SCOPE

1.1 This test method covers procedures for using a spark emission spectroscope to determine the concentration of argon gas in the space between the lites of a sealed insulating glass unit.

1.2 This is a non-destructive test method.

1.3 This test method shall be used only in a controlled laboratory environment.

1.4 This test method is applicable for insulating glass units with argon concentrations of 70 % or more, where the balance of the gas is atmospheric air.

1.5 This test method is applicable for clear, double-glazed insulating glass units.

1.6 This test method is applicable for double-glazed insulating glass units with one lite having a metallic coating or tinted glass, or both, and with clear glass as the other lite.

1.7 This test method is applicable for triple-glazed insulating glass units only when the center lite of glass has a metallic coating (either low emissivity (low E) or reflective) and both of the other lites are clear glass.

1.8 This test method also includes a procedure for verifying the accuracy of the readings of the test apparatus.

1.9 The values stated in SI units are to be regarded as the standard. The values given in parentheses are mathematical conversions to inch-pound units that are provided for information only and are not considered standard.

1.10 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific warning statements, refer to 7.1.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E2649–09

Standard Test Method for

Determining Argon Concentration in Sealed Insulating Glass

Units Using Spark Emission Spectroscopy

This standard is issued under the fixed designation E2649; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

1.1 This test method covers procedures for using a spark 2.1 ASTM Standards:

emission spectroscope to determine the concentration of argon C162 Terminology of Glass and Glass Products

gas in the space between the lites of a sealed insulating glass C717 Terminology of Building Seals and Sealants

unit. E631 Terminology of Building Constructions

1.2 This is a non-destructive test method.

3. Terminology

1.3 This test method shall be used only in a controlled

laboratory environment. 3.1 For definitions of terms found in this test method, refer

to Terminologies C162, C717, and E631.

1.4 This test method is applicable for insulating glass units

with argon concentrations of 70 % or more, where the balance 3.2 Definitions of Terms Specific to This Standard:

3.2.1 sealed insulating glass unit—an assembled unit, com-

of the gas is atmospheric air.

1.5 This test method is applicable for clear, double-glazed prising sealed lites of glass separated by dehydrated space(s),

normally intended for clear vision areas of buildings.

insulating glass units.

1.6 This test method is applicable for double-glazed insu-

4. Summary of Test Method

lating glass units with one lite having a metallic coating or

4.1 The spark emission spectroscope is placed against the

tinted glass, or both, and with clear glass as the other lite.

glass surface of a sealed insulating glass unit in a prescribed

1.7 This test method is applicable for triple-glazed insulat-

manner. A high voltage, at low current, is applied to the glass

ing glass units only when the center lite of glass has a metallic

surface. This voltage creates a spark which induces a plasma

coating(eitherlowemissivity(lowE)orreflective)andbothof

from the gas molecules inside the test specimen. This causes

the other lites are clear glass.

light emissions (photons) of characteristic wavelengths. The

1.8 This test method also includes a procedure for verifying

instrument then collects the photons and analyzes them by

the accuracy of the readings of the test apparatus.

spark emission spectroscopy. The resulting spectrum is com-

1.9 The values stated in SI units are to be regarded as the

pared to calibration data internal to the instrument to determine

standard. The values given in parentheses are mathematical

the concentration of argon inside the unit.

conversions to inch-pound units that are provided for informa-

tion only and are not considered standard.

5. Significance and Use

1.10 This standard does not purport to address all of the

5.1 This test method is intended to provide a means for

safety concerns, if any, associated with its use. It is the

determining the concentration of argon in sealed insulating

responsibility of the user of this standard to establish appro-

glass units under controlled conditions in compliance with the

priate safety and health practices and determine the applica-

apparatus manufacturer’s instructions.

bility of regulatory limitations prior to use. For specific

5.2 This is a non-destructive test method in that the edge

warning statements, refer to 7.1.

seal of the test specimen is not breached in order to determine

the argon gas concentration. However, damage to some glass

coatings on the inner surfaces of the glass can occur.

5.3 This test method has been developed based on data

collected in a controlled laboratory environment.

This test method is under the jurisdiction of ASTM Committee E06 on

Performance of Buildings and is the direct responsibility of Subcommittee E06.22 For referenced ASTM standards, visit the ASTM website, www.astm.org,or

on Durability Performance of Building Constructions. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Current edition approved April 1, 2009. Published May 2009. DOI: 10.1520/ Standards volume information, refer to the standard’s Document Summary page on

E2649-09. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E2649–09

5.4 The device shall be used to determine the argon gas

concentration in insulating glass units in a controlled labora-

tory environment. Refer to 12.3.

5.5 Thistestmethodmaybeusedtodeterminetheargongas

concentrationbefore,during,oraftertheinsulatingglassunitis

subjected to durability tests.

5.6 The accuracy of the test method is dependent upon the

concentrationofargongas.Astheargongasleveldecreasesthe

accuracy also decreases. When the concentration of argon is

below 70 % this test method is not applicable.

6. Apparatus

6.1 Spark Emission Spectroscope:

6.1.1 The apparatus employs a high voltage, at low current,

source and employs spark emission spectroscopy.

6.1.2 The head of the spark emission spectroscope contains

an electrode which is used to apply the voltage to the glass

surface of the test specimen. It also contains a light collector

which transmits light emissions to a spectrometer for process-

ing.

6.1.3 Different models of the spark emission spectroscope

shall be acceptable provided that new models demonstrate

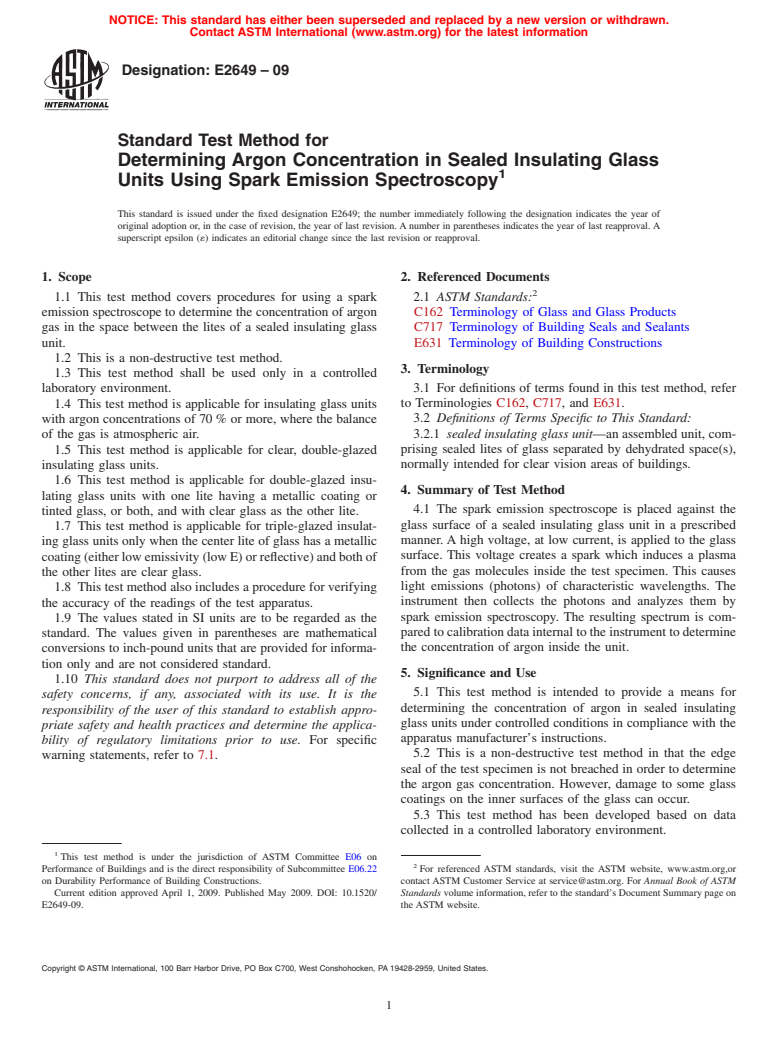

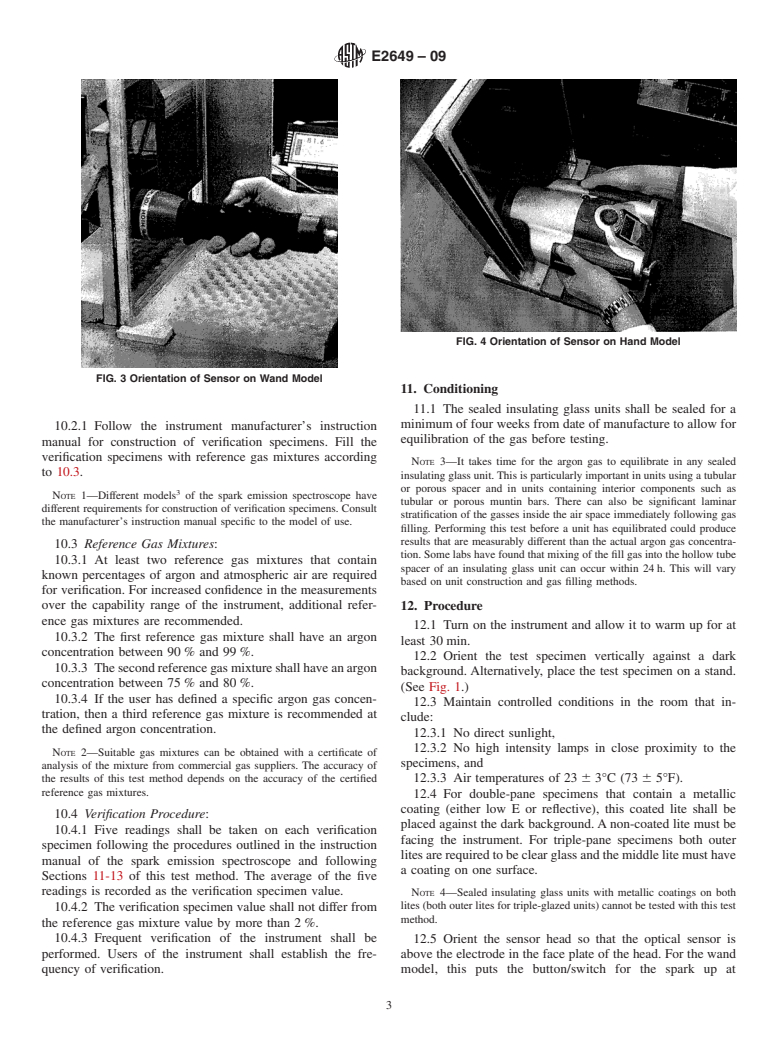

FIG. 1 Example of Test Stand

accuracy limits that are equal or greater to those of the original

model.

6.2 Specimen Stand:

6.2.1 The test specimen shall be supported in a vertical

position or up to 30° off vertical position.

6.2.2 If necessary, a stand is used to support the test

specimens. For example test stands, see Fig. 1 and Fig. 2.

6.3 Background:

6.3.1 Anon-reflective black background shall be positioned

behind the test specimen. Examples of background materials

include photographic black fabric and black closed-cell foam.

7. Hazards

7.1 Warning—The high voltage of the spark emission

spectroscope used in this test method can be harmful. Appro-

priate protective measures shall be observed. Refer to the

instrument manufacturer’s instruction manual.

8. Test Specimens

8.1 Any sealed insulating glass unit that allows the spark

emission spectroscope to excite the gas present in the airspace

can be tested using this test method.

8.2 Typically, test specimens are 355 mm 3 505 mm (14 in.

3 20 in.) sealed insulating glass units constructed using one

5 1

liteof4 mm( ⁄32 in.)clearuncoatedglass,a12 mm( ⁄2 in.)air

FIG. 2 Another Example of Test Stand

space, and one lite of 4 mm ( ⁄32 in.) coated low E glass.

Variations in the specimen construction may require a correc-

9. Calibration

tion. See the instrument manufacturer’s instruction manual for

9.1 Adjustment of the instrument is recommended to be

further information.

performed only by the manufacturer of the instrument or an

authorized service representative. The user shall verify the

This method was based on use of the Gasglass 1002 device (the wand model).

accuracy of the instrument readings using Section 10.

As of this writing, there are other models of the device which include V1 and V2

(handheld models). The sole source of supply of these apparatuses known to the

10. Verification

committee at this time is Sparklike, Ltd., Särkiniementie 5 C6, 00210 Helsinki,

Finland, http://www.sparklike.com. If you are aware of alternative suppliers, please

10.1 Verification of the accuracy of the instrument readings

provide this information toASTM International Headquarters. Your comments will

1 shall be per

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.