ASTM D1142-95(2000)

(Test Method)Standard Test Method for Water Vapor Content of Gaseous Fuels by Measurement of Dew-Point Temperature

Standard Test Method for Water Vapor Content of Gaseous Fuels by Measurement of Dew-Point Temperature

SCOPE

1.1 This test method covers the determination of the water vapor content of gaseous fuels by measurement of the dew-point temperature and the calculation therefrom of the water vapor content.

Note 1--Some gaseous fuels contain vapors of hydrocarbons or other components that easily condense into liquid and sometimes interfere with or mask the water dew point. When this occurs, it is sometimes very helpful to supplement the apparatus in with an optical attachment that uniformly illuminates the dew-point mirror and also magnifies the condensate on the mirror. With this attachment it is possible, in some cases, to observe separate condensation points of water vapor, hydrocarbons, and glycolamines as well as ice points. However, if the dew point of the condensable hydrocarbons is higher than the water vapor dew point, when such hydrocarbons are present in large amounts, they may flood the mirror and obscure or wash off the water dew point. Best results in distinguishing multiple component dew points are obtained when they are not too closely spaced.

Note 2--Condensation of water vapor on the dew-point mirror may appear as liquid water at temperatures as low as 0 to -10oF (-18 to -23oC). At lower temperatures an ice point rather than a water dew point likely will be observed. The minimum dew point of any vapor that can be observed is limited by the mechanical parts of the equipment. Mirror temperatures as low as -150oF (-100oC) have been measured, using liquid nitrogen as the coolant with a thermocouple attached to the mirror, instead of a thermometer well.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 1142 – 95 (Reapproved 2000)

Standard Test Method for

Water Vapor Content of Gaseous Fuels by

1

Measurement of Dew-Point Temperature

This standard is issued under the fixed designation D1142; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 2.1.1 saturated water vapor or equilibrium water–vapor

content—thewatervaporconcentrationinagasmixturethatis

1.1 This test method covers the determination of the water

in equilibrium with a liquid phase of pure water that is

vapor content of gaseous fuels by measurement of the dew-

saturated with the gas mixture. When a gas containing water

point temperature and the calculation therefrom of the water

vapor is at the water dew-point temperature, it is said to be

vapor content.

saturated at the existing pressure.

NOTE 1—Some gaseous fuels contain vapors of hydrocarbons or other

2.1.2 specific volume—of a gaseous fuel, the volume of the

components that easily condense into liquid and sometimes interfere with

gas in cubic feet per pound.

or mask the water dew point. When this occurs, it is sometimes very

2 2.1.3 water dew-point temperature—of a gaseous fuel, the

helpful to supplement the apparatus in Fig. 1 with an optical attachment

temperature at which the gas is saturated with water vapor at

that uniformly illuminates the dew–point mirror and also magnifies the

condensate on the mirror. With this attachment it is possible, in some the existing pressure.

cases, to observe separate condensation points of water vapor, hydrocar-

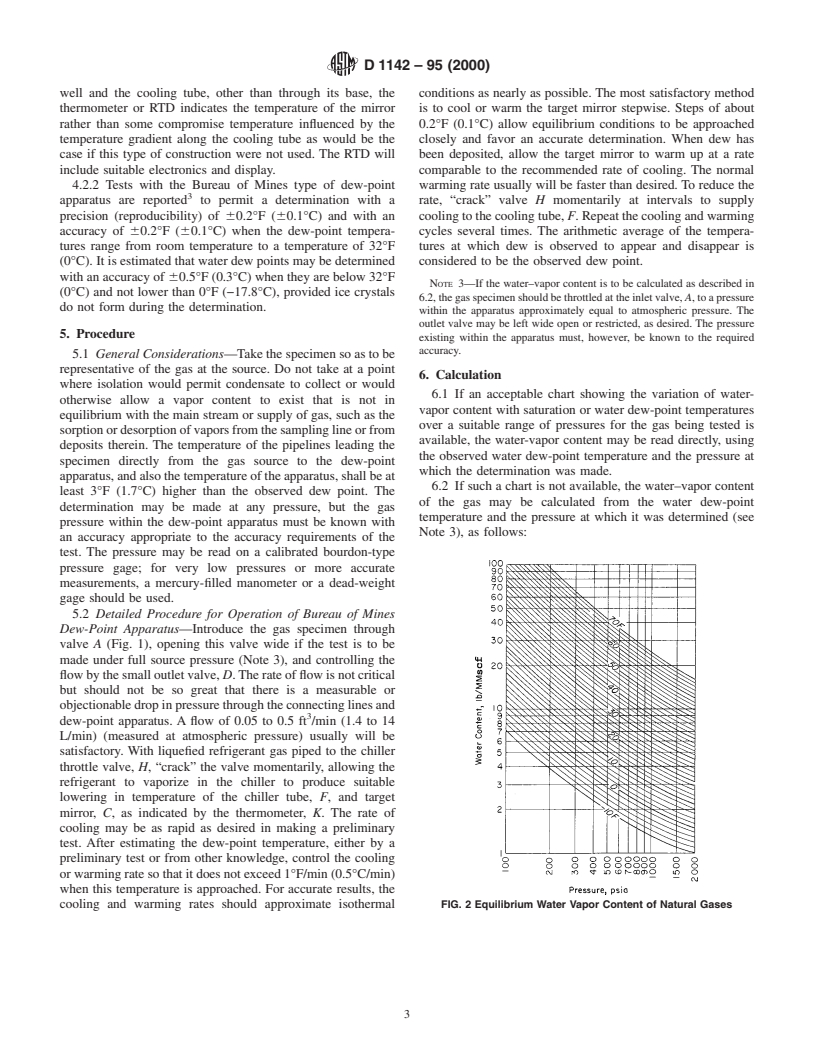

3. Significance and Use

bons,andglycolaminesaswellasicepoints.However,ifthedewpointof

the condensable hydrocarbons is higher than the water vapor dew point,

3.1 Generally,contractsgoverningthepipelinetransmission

when such hydrocarbons are present in large amounts, they may flood the

of natural gas contain specifications limiting the maximum

mirror and obscure or wash off the water dew point. Best results in

concentration of water vapor allowed. Excess water vapor can

distinguishing multiple component dew points are obtained when they are

causecorrosiveconditions,degradingpipelinesandequipment.

not too closely spaced.

NOTE 2—Condensation of water vapor on the dew-point mirror may It can also condense and freeze or form methane hydrates

appear as liquid water at temperatures as low as 0 to−10°F (−18

causing blockages. Water–vapor content also affects the heat-

to−23°C). At lower temperatures an ice point rather than a water dew

ingvalueofnaturalgas,thusinfluencingthequalityofthegas.

point likely will be observed. The minimum dew point of any vapor that

This test method permits the determination of water content of

can be observed is limited by the mechanical parts of the equipment.

natural gas.

Mirror temperatures as low as−150°F (−100°C) have been measured,

using liquid nitrogen as the coolant with a thermocouple attached to the

4. Apparatus

mirror, instead of a thermometer well.

4.1 Any properly constructed dew-point apparatus may be

1.2 This standard does not purport to address all of the

used that satisfies the basic requirements that means must be

safety concerns, if any, associated with its use. It is the

provided:

responsibility of the user of this standard to establish appro-

4.1.1 To permit a controlled flow of gas to enter and leave

priate safety and health practices and determine the applica-

the apparatus while the apparatus is at a temperature at least

bility of regulatory limitations prior to use.

3°F above the dew point of the gas.

4.1.2 To cool and control the cooling rate of a portion

2. Terminology

(preferably a small portion) of the apparatus, with which the

2.1 Definitions of Terms Specific to This Standard:

flowing gas comes in contact, to a temperature low enough to

cause vapor to condense from the gas.

1

4.1.3 To observe the deposition of dew on the cold portion

ThistestmethodisunderthejurisdictionofASTMCommitteeD03onGaseous

Fuels and is the direct responsibility of Subcommittee D03.05 on Determination of

of the apparatus.

Special Constituents of Gaseous Fuels.

4.1.4 To measure the temperature of the cold portion on the

Current edition approved Feb. 15, 1995. Published April 1995. Originally

apparatus on which the dew is deposited, and

published as D1142–50. Last previous edition D1142–90.

2

Several pieces of apparatus for this purpose are commercially available.

Information concerning this apparatus is available from ASTM Headquarters.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.