ASTM E545-14

(Test Method)Standard Test Method for Determining Image Quality in Direct Thermal Neutron Radiographic Examination

Standard Test Method for Determining Image Quality in Direct Thermal Neutron Radiographic Examination

SIGNIFICANCE AND USE

5.1 The BPI is designed to yield quantitative information concerning neutron beam and image system parameters that contribute to film exposure and thereby affect overall image quality. In addition, the BPI can be used to verify the day-to-day consistency of the neutron radiographic quality. Gadolinium conversion screens and single-emulsion silver-halide films, exposed together in the neutron imaging beam, were used in the development and testing of the BPI. Use of alternative detection systems may produce densitometric readings that are not valid for the equations used in Section 9.

5.2 The only truly valid sensitivity indicator is a reference standard part. A reference standard part is a material or component that is the same as the object being neutron radiographed except with a known standard discontinuity, inclusion, omission, or flaw. The sensitivity indicators were designed to substitute for the reference standard and provide qualitative information on hole and gap sensitivity.

5.3 The number of areas or objects to be radiographed and the film acceptance standard used should be specified in the contract, purchase order, specification, or drawings.

SCOPE

1.1 This test method covers the use of an Image Quality Indicator (IQI) system to determine the relative2 quality of radiographic images produced by direct, thermal neutron radiographic examination. The requirements expressed in this test method are not intended to control the quality level of materials and components.

1.2 This standard does not purport to address the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.3 The values stated in SI units are regarded to be standard.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E545 −14

Standard Test Method for

Determining Image Quality in Direct Thermal Neutron

1

Radiographic Examination

This standard is issued under the fixed designation E545; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* 3. Terminology

3.1 Definitions—For definitions of terms used in this test

1.1 This test method covers the use of an Image Quality

2

method, see Terminology E1316, Section H.

Indicator (IQI) system to determine the relative quality of

radiographic images produced by direct, thermal neutron

radiographic examination. The requirements expressed in this 4. Summary of Test Method

test method are not intended to control the quality level of

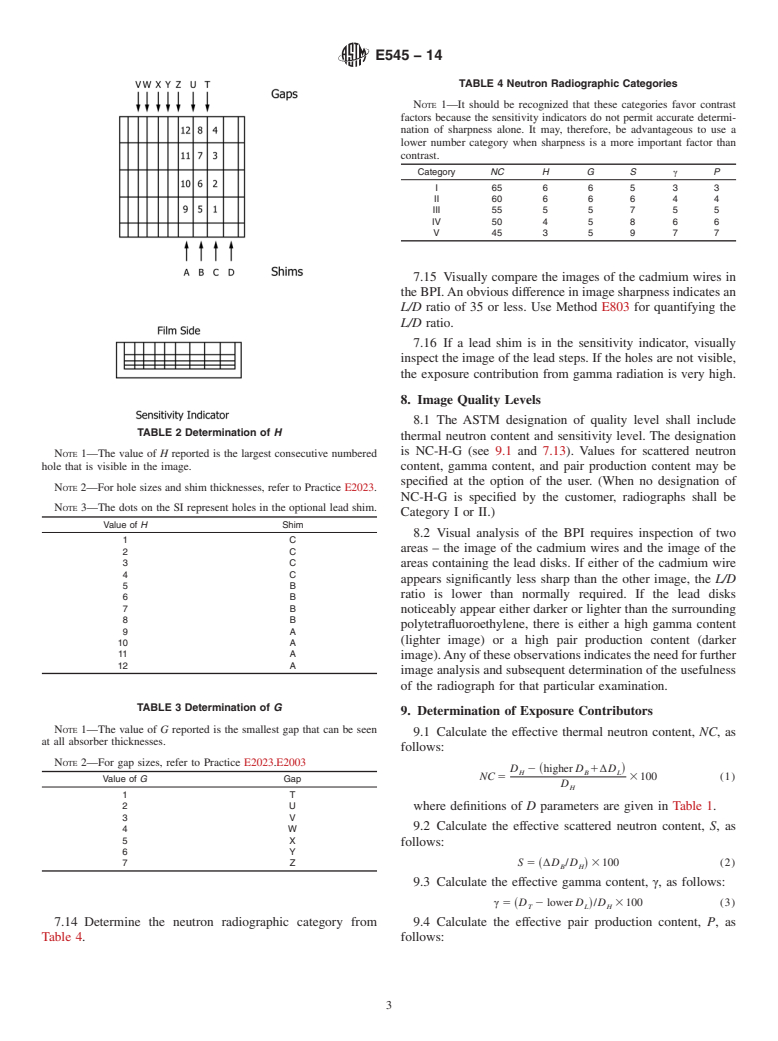

4.1 The judgment of the quality of a neutron radiograph is

materials and components.

based upon the evaluation of images obtained from indicators

that are exposed along with the test object. In cases of limited

1.2 This standard does not purport to address the safety

filmsizeorextendedobjectsize,theindicatorsmaybeexposed

concerns, if any, associated with its use. It is the responsibility

on another film immediately prior to or following exposure of

of the user of this standard to establish appropriate safety and

the test object under exactly the same conditions (refer to

health practices and determine the applicability of regulatory

ProcessControlRadiographs,Section10).TheIQIvaluesmust

limitations prior to use.

be determined from films with an optical density between 2.0

1.3 ThevaluesstatedinSIunitsareregardedtobestandard.

to 3.0. Two types of IQIs are used.

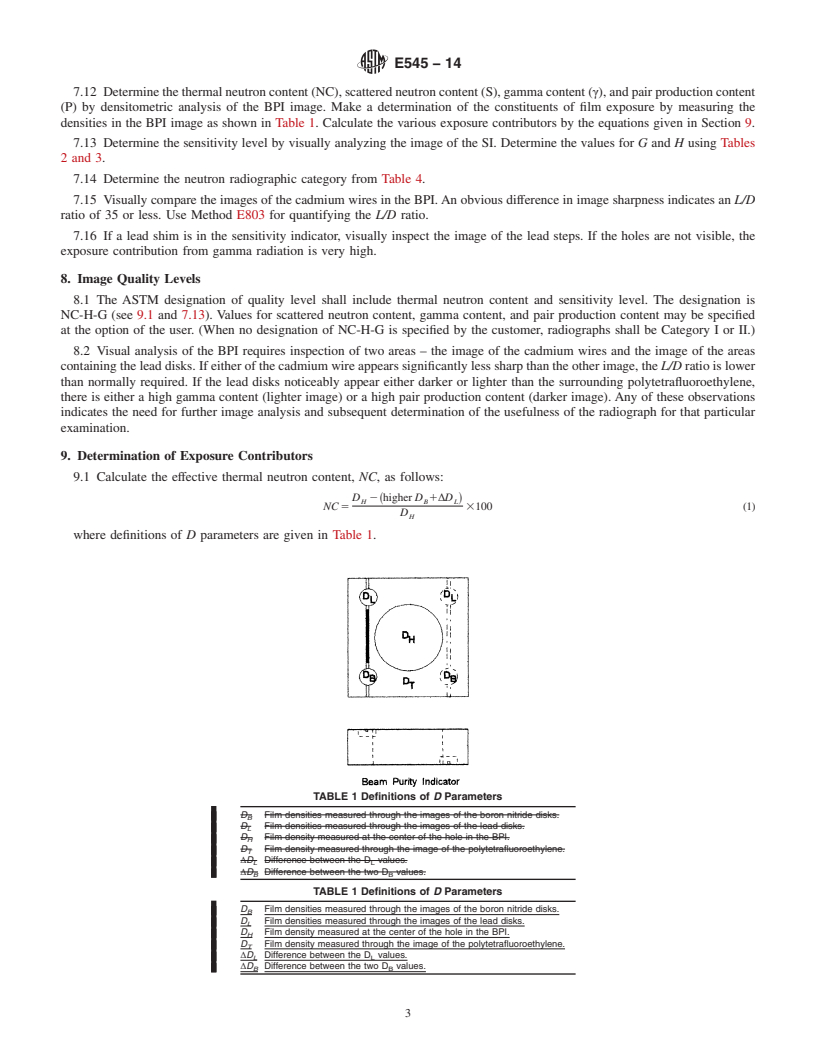

4.1.1 Beam Purity Indicator (BPI)—The BPI is a device

2. Referenced Documents

usedforquantitativedeterminationofradiographicquality.Itis

3

2.1 ASTM Standards:

a polytetrafluoroethylene block containing two boron nitride

E543 Specification forAgencies Performing Nondestructive

disks, two lead disks, and two cadmium wires.Akey feature of

Testing

the BPI is the ability to make a visual analysis of its image for

E748 Practices for Thermal Neutron Radiography of Mate-

subjective information, such as image unsharpness and film

rials

and processing quality. Densitometric measurements of the

E803 TestMethodforDeterminingthe L/DRatioofNeutron

image of the device permit quantitative determination of the

Radiography Beams

effectivevalueforthethermalneutroncontent,gammacontent,

E1316 Terminology for Nondestructive Examinations

pairproductioncontent,andscatteredneutroncontent.TheBPI

E2003 Practice for Fabrication of the Neutron Radiographic

shall be constructed in accordance with Practice E2003.

Beam Purity Indicators

Optionally, any BPI fabricated prior to publication of Practice

E2023 Practice for Fabrication of Neutron Radiographic

E2003 which conforms to Test Method E545 - 81 through 91

Sensitivity Indicators

may be used.

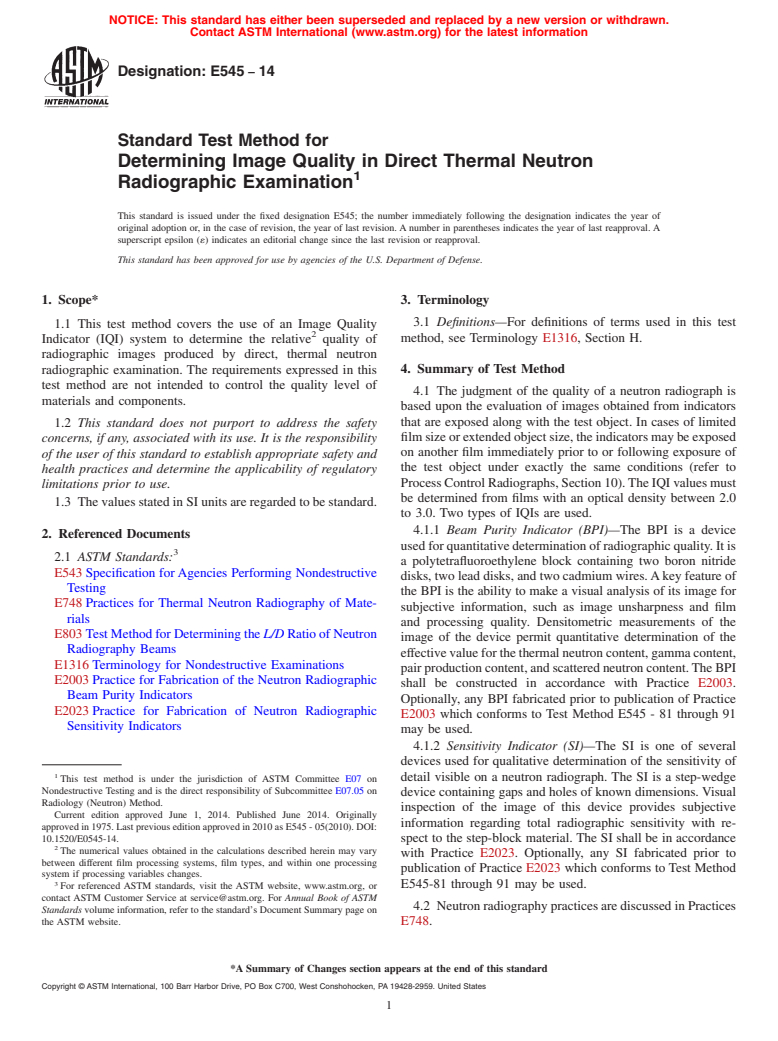

4.1.2 Sensitivity Indicator (SI)—The SI is one of several

devices used for qualitative determination of the sensitivity of

1

This test method is under the jurisdiction of ASTM Committee E07 on detail visible on a neutron radiograph. The SI is a step-wedge

Nondestructive Testing and is the direct responsibility of Subcommittee E07.05 on

device containing gaps and holes of known dimensions. Visual

Radiology (Neutron) Method.

inspection of the image of this device provides subjective

Current edition approved June 1, 2014. Published June 2014. Originally

information regarding total radiographic sensitivity with re-

approved in 1975. Last previous edition approved in 2010 as E545 - 05(2010). DOI:

10.1520/E0545-14.

spect to the step-block material. The SI shall be in accordance

2

The numerical values obtained in the calculations described herein may vary

with Practice E2023. Optionally, any SI fabricated prior to

between different film processing systems, film types, and within one processing

publication of Practice E2023 which conforms to Test Method

system if processing variables changes.

3

E545-81 through 91 may be used.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

4.2 NeutronradiographypracticesarediscussedinPractices

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. E748.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E545−14

5. Significance and Use 7.6 The B

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: E545 − 05 (Reapproved 2010) E545 − 14

Standard Test Method for

Determining Image Quality in Direct Thermal Neutron

1

Radiographic Examination

This standard is issued under the fixed designation E545; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope Scope*

2

1.1 This test method covers the use of an Image Quality Indicator (IQI) system to determine the relative quality of radiographic

images produced by direct, thermal neutron radiographic examination. The requirements expressed in this test method are not

intended to control the quality level of materials and components.

1.2 This standard does not purport to address the safety concerns, if any, associated with its use. It is the responsibility of the

user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations

prior to use.

1.3 The values stated in SI units are regarded to be standard.

2. Referenced Documents

3

2.1 ASTM Standards:

E543 Specification for Agencies Performing Nondestructive Testing

E748 Practices for Thermal Neutron Radiography of Materials

E803 Test Method for Determining the L/D Ratio of Neutron Radiography Beams

E1316 Terminology for Nondestructive Examinations

E2003 Practice for Fabrication of the Neutron Radiographic Beam Purity Indicators

E2023 Practice for Fabrication of Neutron Radiographic Sensitivity Indicators

3. Terminology

3.1 Definitions—For definitions of terms used in this test method, see Terminology E1316, Section H.

4. Summary of Test Method

4.1 The judgment of the quality of a neutron radiograph is based upon the evaluation of images obtained from indicators that

are exposed along with the test object. In cases of limited film size or extended object size, the indicators may be exposed on

another film immediately prior to or following exposure of the test object under exactly the same conditions (refer to Process

Control Radiographs, Section 10). The IQI values must be determined from films with an optical density between 2.0 to 3.0. Two

types of IQIs are used.

4.1.1 Beam Purity Indicator (BPI)—The BPI is a device used for quantitative determination of radiographic quality. It is a

polytetrafluoroethylene block containing two boron nitride disks, two lead disks, and two cadmium wires. A key feature of the BPI

is the ability to make a visual analysis of its image for subjective information, such as image unsharpness and film and processing

quality. Densitometric measurements of the image of the device permit quantitative determination of the effective value for the

thermal neutron content, gamma content, pair production content, and scattered neutron content. The BPI shall be constructed in

accordance with Practice E2003. Optionally, any BPI fabricated prior to publication of Practice E2003 which conforms to Test

Method E545 - 81 through 91 may be used.

1

This test method is under the jurisdiction of ASTM Committee E07 on Nondestructive Testing and is the direct responsibility of Subcommittee E07.05 on Radiology

(Neutron) Method.

Current edition approved June 1, 2010June 1, 2014. Published November 2010June 2014. Originally approved in 1975. Last previous edition approved in 20052010 as

E545 - 05.E545 - 05(2010). DOI: 10.1520/E0545-05R10.10.1520/E0545-14.

2

The numerical values obtained in the calculations described herein may vary between different film processing systems, film types, and within one processing system

if processing variables changes.

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E545 − 14

4.1.2 Sensitivity Indicator (SI)—The SI is one of several devices used for qualitative determination of the sensitivity of detail

visible on a neutron radiograph. The SI is a step-wedge device containing gaps and holes of known dimensions. V

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.